What’s cooking: Everything you need to know about food manufacturing

When you begin your manufacturing endeavor, you need to ask yourself one important question. Will your product satisfy a need or a want?

Convincing someone that they want your product is great, but the best thing is to have something that consumers need, something that is essential to living. Anything that ticks our physiological needs is certainly a product that will perform well.

Theoretically speaking, that is. There’s still competition you’ll need to overcome and a lot of room for error when making something as seemingly simple as food.

This article explores the history of food manufacturing, the processes businesses implement, the steps you can take to become a successful food manufacturer, and the perfect tool to help you along the way.

What is food manufacturing?

Food manufacturing is the process of turning raw agricultural materials into food products that people can consume. It involves various steps such as cleaning, processing, packaging, and distributing food items. Food manufacturing aims to create safe, healthy, and nutritious food products that meet the needs and preferences of consumers.

Food manufacturing is a complex and highly regulated industry that requires strict adherence to food safety and quality standards. Manufacturers must follow strict guidelines and regulations set by local and international authorities to ensure that the food they produce is safe for human consumption.

This includes measures to prevent contamination, ensure proper labeling, and maintain proper hygiene and sanitation practices throughout the production process.

Food manufacturing industry statistics

- Global food manufacturing generates about $4.15 trillion

- Consumers spent $2.12 trillion on food in the US alone, which accounts for about 11% of the country’s GDP

- 1.7 million people are working in food and beverage manufacturing

- Approximately 133 billion pounds of food is wasted in the US yearly, which is about 35% of the food produced

The history of food manufacturing

Food manufacturing spans back to ancient times when communities took steps to preserve their harvests to help them survive the harsh winters. In addition to the saved vegetables and meats, our ancestors practiced lean inventory techniques by taking the skins from hunts and converting them into apparel.

As soon as these communities had a surplus of food, they could grow and build a hierarchy around the food based on management, tracking, and the distribution of their inventory.

Food manufacturing probably started on an industrial level with sugar, which was taken from New Guinea, grown in plantations, and manufactured into different products across the globe.

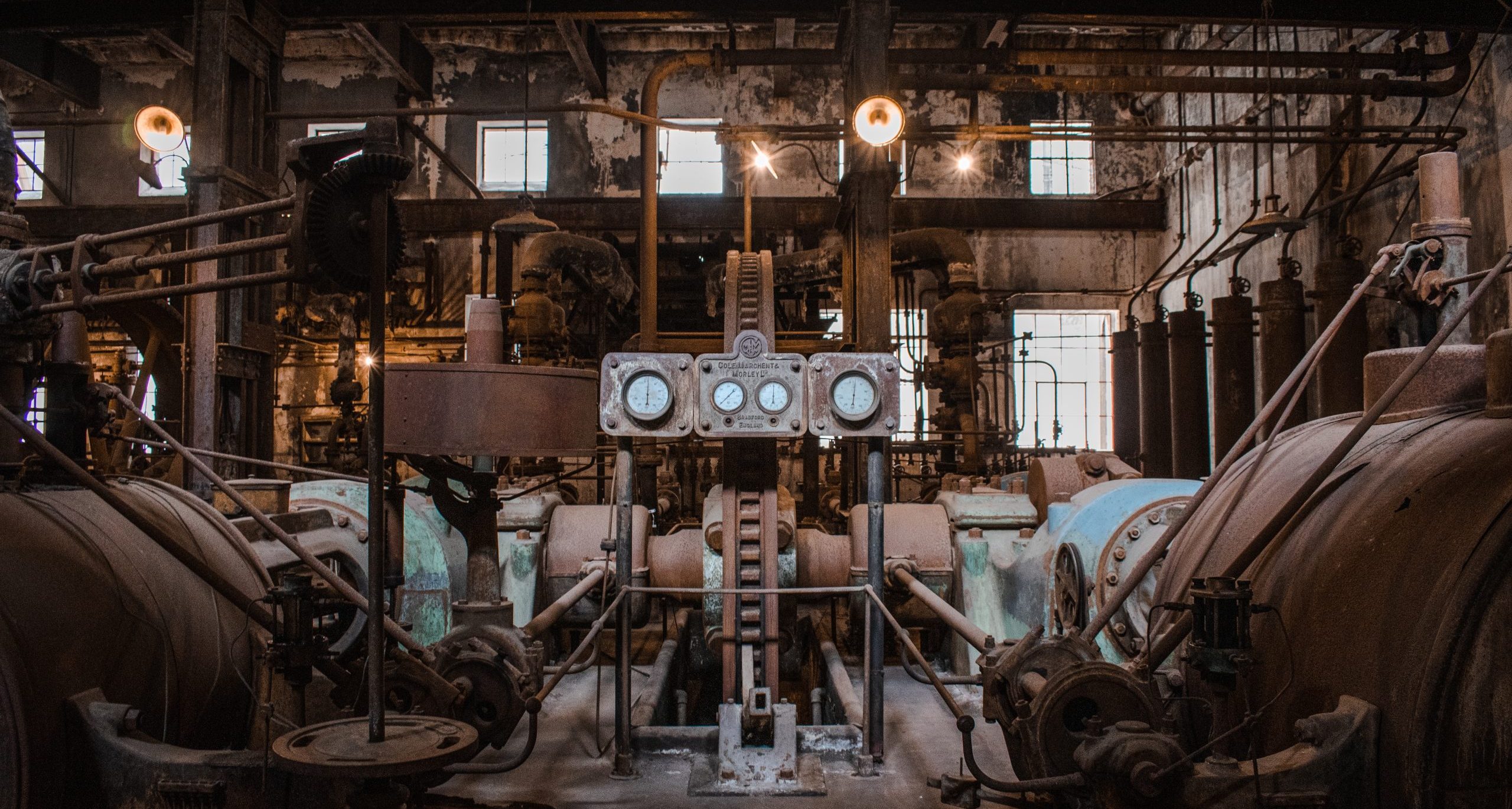

With the Industrial Revolution and expanding urban populations, food production changed drastically. The new focus was put on producing foodstuffs with a longer shelf life since an increasing amount of people lacked access to fresh food. Large production facilities started popping up, like the early meatpacking factory, Frigorífico Anglo, pictured above.

In the modern era of food production, manufacturers create a range of products, from frozen foods to supplement pills for essential nutrients. Synthesized products now often bear no resemblance to the raw materials they’re originally made from.

So, what exactly are the food manufacturing processes?

Food production process

The exact processes of food production depend on the type of product being made. Generally, however, most businesses stick to the following 6 steps when it comes to creating products:

- Raw material sourcing — The first step in food production is to source the raw materials needed to make the product. This can include sourcing ingredients from suppliers or growing crops on a farm.

- Pre-processing — During this step, the materials are cleaned, sorted, and prepared for processing. This may involve washing, peeling, slicing, or other forms of preparation.

- Processing — The raw materials are processed to create the final food product. This may involve cooking, baking, fermenting, or other methods depending on the type of food.

- Packaging — Once the food is processed, it is packaged into containers or packaging that will protect it from contamination and extend its shelf life.

- Quality control — During the production process, quality control measures are put in place to ensure that the food product meets certain standards for taste, texture, and nutritional content.

- Distribution — The final step in the food production process is distributing the food product to retailers, wholesalers, or consumers.

Maintaining proper hygiene and sanitation practices throughout the food production process is crucial to prevent contamination and ensure food safety. This involves regular cleaning of equipment, proper storage of raw materials and finished products, and following strict food safety regulations and guidelines.

Food manufacturing industries

The food manufacturing industry encompasses a wide range of sectors that produce food and beverage products for consumption. Some of the major food manufacturing industries include:

- Meat processing

- Dairy products

- Baked goods

- Snack foods

- Beverages

- Confectionery

- Frozen foods

- Canned and preserved foods

Each of these sectors has unique production processes, equipment, and regulations specific to the types of food products they produce.

5 food manufacturing tips and tricks

To ensure your business succeeds, you need to be prepared for the future, so make sure to follow manufacturing trends and avoid the mistakes others have made in the food production industry.

But in addition, let’s go over 5 tips you should keep in mind to ensure long-term success in the food manufacturing industry.

1. Prepare for risks

Every manufacturer should have a Plan B. For example, you need to be able to quickly identify and fix bottlenecks in production. However, when handling food with a short expiry date, you can’t afford to have any stalls in production. Think ahead by performing some strategic planning.

2. Reduce waste

Did you know a food manufacturing company spends 60% of its energy bills on refrigeration? If you simply work on your routing manufacturing, you could put less stress on your chillers by storing them away from heat sources. This will save you money and reduce your carbon footprint.

Another resource that often gets wasted is water. The food production industry uses more water than any other sector in the manufacturing industry.

Cutting back on your water consumption will make your production more eco-friendly and, in addition, will save your company a lot of money. Chicken-nugget manufacturer, The Equity Group reduced water usage by 30% and saved $100,000 annually.

3. Use predictive maintenance

Predictive maintenance is the technique of determining the condition of equipment to estimate when maintenance should be performed on said equipment. This allows you to perform maintenance before a machine breaks down and stops production. New Belgium, a beer brewer, was able to cut downtime by 50% with predictive maintenance.

4. Reduce the risk of contamination

This is extremely important, as there are tons of regulations you’ll need to follow, and a recall due to contamination can be expensive (or have more serious repercussions). To avoid contaminations, be sure to only use equipment intended for food and drink manufacturing. Also, perform inspections on raw materials to avoid contaminations, such as the wrong meat being used in your products. That’s also where your production quality control checklist comes in handy.

5. Embrace automation

Finally, the quickest and easiest way to enhance your food manufacturing business is to adopt automation into your production lines. That doesn’t mean firing all your employees and using electronic arms. But rather, make use of automated systems that help you optimize your processes in terms of safety and efficiency while also freeing up time for your employees to focus on other tasks.

For example, Raw Coffee Company improved their on-time order fulfillment by 60% by simply using food traceability software.

Food manufacturing GMPs

GMPs (good manufacturing practices) are a set of guidelines used to ensure the safety, quality, and consistency of food products during the manufacturing process. These guidelines cover various aspects of food manufacturing, including equipment and facilities, personnel training, and production processes. Here are some examples of the food industry’s good manufacturing practices:

- Equipment and facilities — Equipment and facilities should be designed, constructed, and maintained in a way that prevents contamination and ensures the safety of the product.

- Personnel training — Personnel should be trained on the proper handling of food products, hygiene practices, and safety procedures.

- Production processes — Production processes should be well-defined, documented, and controlled to ensure consistency and quality.

- Raw materials — Raw materials should be sourced from approved suppliers and inspected and tested for quality and safety before production.

- Cleaning and sanitation — Equipment and facilities should be cleaned and sanitized regularly to prevent contamination.

- Quality control — Quality control measures should be implemented to ensure the final product meets certain taste, texture, and nutritional content standards.

- Recordkeeping — Accurate and complete records must be maintained to track the production process and ensure the traceability of the product.

GMPs in the food industry are essential to ensure the safety and quality of the products produced. Local and international regulatory agencies enforce them to ensure compliance with food safety standards.

Food manufacturing software

Food manufacturing software or food ERP software is a type of software designed specifically for the food manufacturing industry to help manage various aspects of the production process. This software is often used to streamline operations, improve efficiency, and ensure compliance with food safety regulations. So what should you look for in food manufacturing software?

Production planning and scheduling

Production planning is necessary for manufacturers to plan and schedule production runs, taking into account factors such as equipment availability, labor availability, and raw material availability.

Katana automatically schedules your production in the order that manufacturing orders are generated. However, if you have a manufacturing order that needs to be completed as soon as possible or if you have an order come in from a VIP customer, Katana’s nifty drag-and-drop system allows you to easily reprioritize your production workflow, and the system automatically redistributes your available inventory to fit the new schedule.

Product recipes/bill of materials

If you’re producing chocolate bars or making pastries that all use different ingredients, Katana’s got you covered. You can easily save your bill of materials (BOM), including your product materials and operations.

Once you’ve saved your BOMs, Katana will automatically calculate your manufacturing costs and check your raw materials availability for any open manufacturing orders.

Inventory management

Running a manufacturing business always involves managing inventory. Whether raw materials, finished products, work-in-process, MRO, or all four. This means you need to have a platform with robust inventory management features.

Good inventory management practices are even more crucial when managing food inventory, as the likelihood of handling perishable goods is high.

Katana lets you manage all four types of inventory across multiple locations while providing you with a real-time view of your stock levels.

In addition, Katana’s real-time master planner automatically allocates your raw materials to manufacturing orders and your finished goods to sale orders. This will let you know right away if you have the inventory to fulfill open orders or if you’ll need to purchase more supplies or make new products.

Traceability

Product traceability is not only essential in food manufacturing but also a legal requirement. Katana offers expiry date tracking, batch tracking, and barcode scanning, giving you end-to-end traceability for all your inventory.

Integrations

Constantly switching between platforms to check order statuses, inventory levels, and invoices can quickly become tedious. What’s more, copy-pasting information from one system to another is error-prone and can lead to all sorts of issues.

Katana integrates seamlessly with the most popular business tools out there, including:

This can save you hours previously spent on mindless admin tasks and eliminate human errors.

Want to see Katana in action? Reach out to our sales team today and request a demo.

Table of contents

Manufacturing guide

More on manufacturing

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control