Production vs manufacturing: What’s the difference?

As the global economy becomes more and more connected, gathering people from all over the world into the same markets, the need for a shared language is incredibly important.

Correct terminology can mean the difference between a smooth quarter of growth and a disastrous one, especially as multinational organizations tackle cultural barriers.

Despite the importance, some terms are still used incorrectly, assuming that the other party will understand what they mean in context. One of the most common is manufacturing and production, which are often used interchangeably, even though there is a key difference or two.

Below, we’ll work through those differences and give you a full understanding of how to use each term correctly so that you aren’t involved in any future misunderstandings.

What is manufacturing?

Manufacturing is the process of converting inputs like raw materials, components, or parts into a tangible product. The word is derived from the Latin term manu factus, which translates to “made by hand.”

In other words, manufacturing used to refer to only by-hand production and didn’t require any machines. However, over time, as technology has progressed, machines have been introduced to handle certain tasks or steps in the manufacturing process.

Today’s factories are full of all sorts of machines, from those that cut and convert raw material to those that assemble the final product.

What is production?

Production is a broader term that includes manufacturing but also encompasses other steps in the process of getting a product ready for market.

In addition to manufacturing, production means activity-based processes like farming, mining, fishing, logging (extracting raw materials from the earth), and any other steps required to get those raw materials into finished productions.

Production also includes the process of packaging and labeling a product so that it’s ready to be sold. It can also cover tangible or intangible services that satisfy human needs.

Manufacturing vs production

In the debate of production vs manufacturing, five key things differentiate them.

Scope

Manufacturing involves a much smaller scope (relatively speaking) than production. When we talk about production, we’re talking about extracting or growing raw materials on a large scale so that they can be used in manufacturing.

For example, you can’t manufacture a car without first producing the steel that will be used to make its frame. And you can’t produce steel without mining the iron ore that will be used to make it.

Function

You can think of manufacturing as turning specific raw materials into specific products, including the creation of utility. In contrast, production refers to a much wider range of activities necessary to get raw materials into a state where they can be manufactured.

For example, when we talk about the production of wheat, we’re not just talking about growing it — we’re also talking about harvesting it, threshing it (removing the kernels from the stalk), winnowing it (separating the kernels from the chaff), and milling it (grinding the kernels into flour).

The production also then includes everything after the manufacturing process, such as packaging, labeling, and shipping. It spans a greater timeline and is meant to include everything from collecting raw materials to delivering a product to the customer.

Resources

In manufacturing, the available resources for the process are procured from the environment. In production, the resources are procured from other industries or economic sectors.

For example, you need steel (procured from the mining sector) and rubber (procured from the farming sector) to manufacture a car. But you also need workers (procured from the labor market), machines (procured from the construction sector), and electricity (procured from the utility sector).

So, the production of a car covers the steelmaking, rubber farming, machine construction, and electricity generation industries, in addition to the manufacturing process itself. It can be considered in a simple factor of input into output:

- Manufacturing — Steel + rubber = car

- Production — Electricity + machine construction + steelmaking + rubber farming + workers = car

Products vs services

Perhaps the easiest difference between manufacturing and production to grasp is the eventual outputs of each process. Manufacturing refers to only physical products, whereas production results in both physical products and services.

For example, if you run a farm, the production of wheat would include the service of planting and harvesting the crop. But once the wheat is harvested, the manufacturing process would begin, which would turn it into flour (a physical product).

Different types of production can also include tangible and intangible products. If you are a consultant, the production of your service might include everything from market research to creating a presentation for your client — no physical output is necessary.

Financial analysis

The final difference between produced vs manufacturing processes is how they are considered from a financial analyst perspective.

In general, when we talk about the cost of production, we are referring to the total cost of all types of input necessary to get the product or service ready for market. This includes both direct costs (like labor and materials) and indirect costs (like overhead).

On the other hand, manufacturing costs generally only refer to the direct costs associated with converting raw materials or resources into finished products. That is called variable costing and is used more commonly, though there are also methods that include overhead in the cost analysis of the manufactured product.

For example, if you are a furniture store chain, financial management might include the cost of wood, fabric, labor, and shipping from the factory to your stores. The cost of manufacturing would just be the cost of labor and materials at the factory.

This means it can be more difficult to get a full view of production costs, as there are quite a few extra factors of production to consider.

Separate production and manufacturing with Katana

Because of those challenges, along with the common misunderstanding of each term, many businesses will need some help to keep the financial statement analysis of their manufacturing and production processes separate.

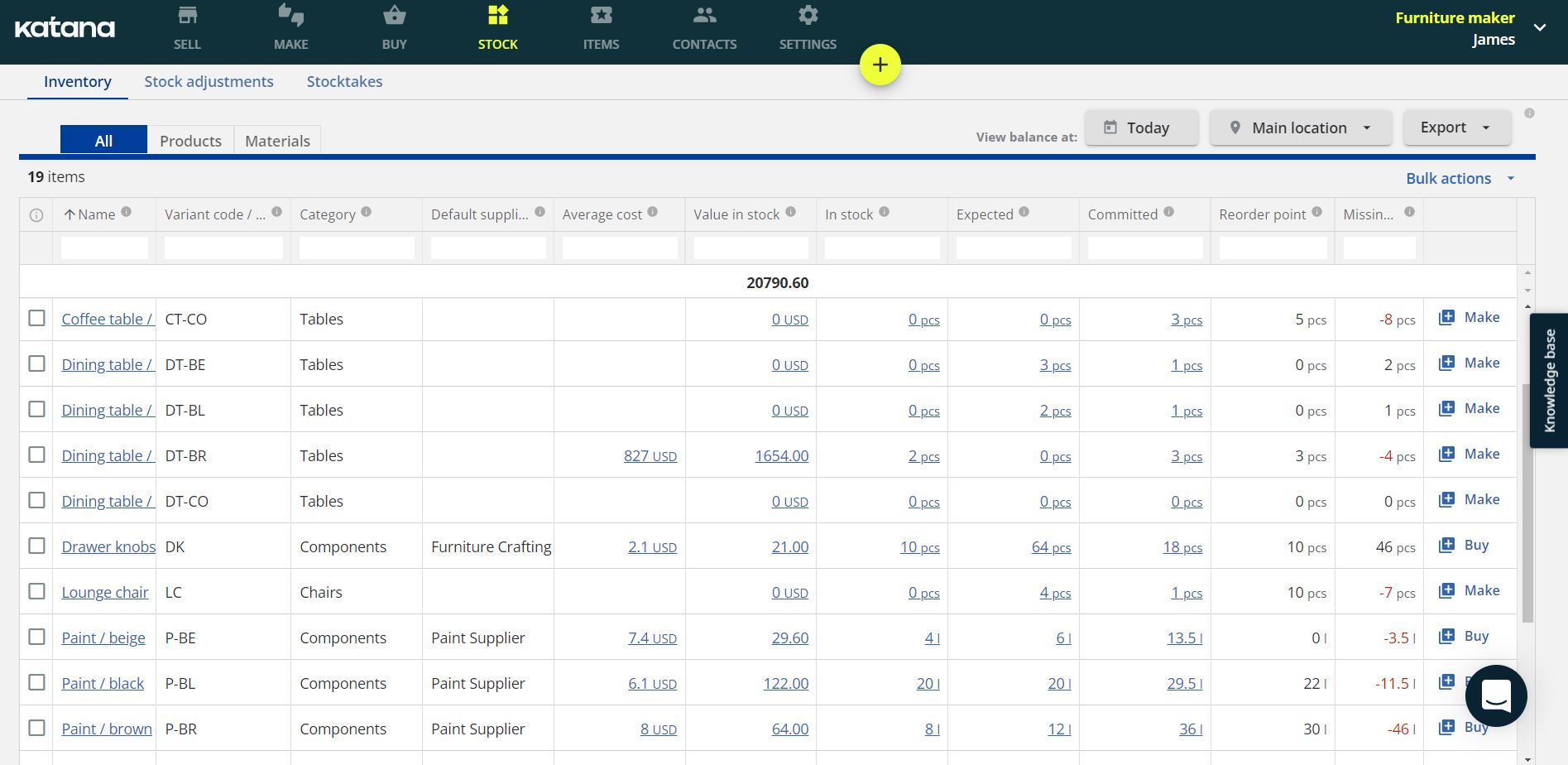

Katana Cloud Inventory software is purpose-built for small to mid-sized enterprises that need an effective way to manage all aspects of their business, from sales and inventory systems to production and shipping.

If you are interested in getting increased end-to-end visibility, request a demo today and see how Katana can help your business today.

Table of contents

Manufacturing guide

More on manufacturing

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control