How to manufacture a product: 5 simple steps

Ever get to the end of the aisle and think, “I wish there were a way to ______.” For most people, those ideas come and go without another thought.

But for some, those bit by the entrepreneurial bug become an obsession. They see a problem, think of the solution, and can’t sleep without making it a reality.

Are you one of those people?

If you have brilliant business ideas, are interested in building a better mousetrap, or have already started doing the market research required to bring your product to life — congratulations! You are about to embark on an amazing journey.

But where do you start your business? How do you take that first step from idea to mass production? How do you get a product manufactured?

We’re here to help.

In this article, we’ll walk through a step-by-step guide for how to start manufacturing a product and the best small business manufacturing software to help you out once you start to scale.

Get everything off the ground with manufacturing software

Getting started with product manufacturing is one thing. The next step is to keep going and growing. Small business manufacturing software will help you manage your entire business without breaking the bank.

How do you start manufacturing a product?

Manufacturing a product can be a complex process that involves many different steps. Here are some general steps to consider when starting the manufacturing process:

- Develop your idea

- Research the market

- Create a business plan

- Find a manufacturing partner

- Launch your product

- Boost your business with ERP software

Step 1: develop your idea

You may think you already have this figured out, but there’s more to it than just saying, “I want to make something cool.”

You’ll need to focus on three things to increase your chances of success when learning how to manufacture a product.

What problem does it solve?

Even boutique high-end clothing manufacturers will have an answer to this question. For them, it might be:

“We provide an escape from the mundane.”

Your product doesn’t have to be life-altering, but it should make someone’s life better somehow, even if it’s just making them smile. Define the problems your product solves and be as specific as possible. Consider it from every angle, and you might even find some ways it can be marketed to unexpected potential customers.

Take the Slinky, for instance. Before it was the most popular toy of all time, the metal coil was designed to help stabilize naval equipment on the high seas. Only later did its utility as a children’s toy become evident. Make sure that you don’t pigeonhole yourself at this point. You should be open to any applications for your product.

Features and benefits

Start thinking about your product’s features and how those features will benefit your customer. Do some competitive analysis to see what similar products are on the market and consider what you can do to make yours stand out — whether that’s a lower price point, differentiating design, or additional functionality.

It’s also important to think about how this product will be used. If it’s a piece of technology, is it easy to use? If it requires installation, is that something the customer can do themselves, or will they need to hire someone?

Design

Your design when manufacturing a new product is what will make it unique and set it apart from the competition. This includes its physical appearance — think about shape, color, and size — and how it functions.

For example, if you’re designing a new type of screwdriver, you’ll need to decide on the size and shape of the handle, what kind of tip to use, and how many different types of screws it can accommodate. These are all important factors that will affect your manufacturing cost.

You don’t need to have everything figured out at this point, but it’s important to have a clear vision for your product. Once you have a general idea of the design, you can start thinking about how it will be made.

How much does it cost to manufacture a product?

The cost of manufacturing a product can vary greatly depending on various factors, such as:

- The type of product

- The materials and components required to make it

- The labor involved

- The production process

- The location of the manufacturing facility

Manufacturing cost accounting involves identifying and allocating all costs of producing the product.

Step 2: research the market

While you may already have a surface-level understanding of what is available, it’s at this point that you will need to fully understand the market that you are going to target.

This means research.

You need to understand who would want your product, what’s already available, what features and benefits are important to customers, how much they are willing to pay, and anything else that might impact your ability to sell your product.

This is also the time to start thinking about your target audience and how you will reach them. Are you going to start selling direct-to-consumer or through retailers? Will you need an e-commerce website or a brick-and-mortar store? Are there patents and trademarks protecting intellectual property filed that might block you from continuing?

You should also be thinking about your competition. How will you differentiate your quality product? What is your competitive advantage? Start developing your USP (unique selling proposition).

Before you move on to the next step, you should be able to answer the following questions:

- Who is your target customer?

- What needs does your product address?

- What are the demographics of your target market?

- Where do they spend their time (online and offline)?

- How will you reach them and market your business?

- Who are your main competitors?

- What is your competitive advantage?

If you have all of this information, you’re ready to start thinking about the specifics of how to get a product manufactured and how you will make money.

Step 3: create a business plan

Business owners and product developers can get stuck depending on the products in question. They will spend hours, days, weeks, or even months trying to perfect their idea without ever taking the time to develop a business plan. They have a brilliant invention and no way to get it into consumers’ hands.

Business plans are critical for a few reasons:

- They will help you communicate your vision to potential investors or partners

- They will force you to think through all aspects of your business, from startup costs to quality manufacturing to effective marketing

- They will give you a roadmap to follow as you bring custom products to market

You will have to dig into the dollars and cents of production, shipping cost, and marketing to make your business plan a reality. Questions like:

- What are the benefits of using a domestic vs overseas manufacturer?

- How do I optimize profit margins?

- What are the selling tools I will use?

- What is the most cost-effective way to ship my product?

- Will I be an e-commerce business or sell wholesale to retailers?

- How do I plan to market my product, and what budget will I need?

All of these factors will be critical in developing your business plan, and they can make or break your bottom line. One mistake that entrepreneurs often make at this point is not considering scale. Can you fill it if your product takes off and you receive a purchase order for 10,000 units?

You need to have a plan for scaling up your production process to meet demands, or you risk losing out on revenue and damaging your reputation. This is also where you’ll start to develop partnerships with manufacturers and suppliers overseas and other key players in bringing your product to market.

Pro tip: At this stage, you’re pretty committed. Alongside learning how to manufacture your product, you’ll have to learn how to start a manufacturing business too.

Step 4: find a manufacturing partner

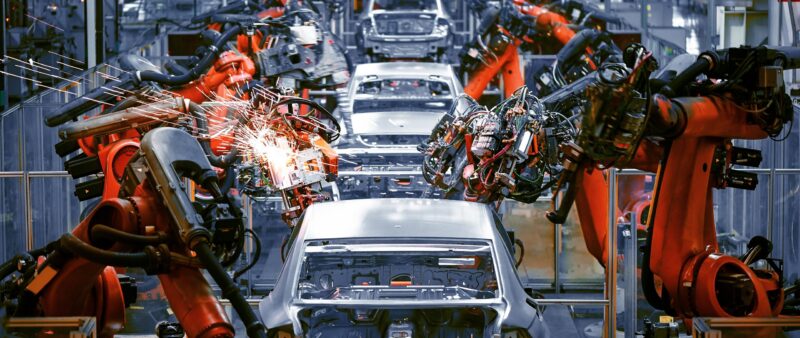

Manufacturing your own products could be as simple as individually sewing dresses in your bedroom, but you’ll need to find a reputable partner in most cases.

How do you find one? Start by asking around — reach out to your network and see if anyone has any recommendations. If you’re beginning from scratch, start looking for contract manufacturers that know how to manufacture a product similar to yours. Once you have a few names, do your research!

Check out their website, read online reviews, and even visit their facility if possible. This is a critical step in the process, and you want to be sure that you’re doing your due diligence.

Here’s a quick checklist of questions to answer about potential partners:

- Do they have experience manufacturing new products in my category?

- Are they local manufacturers or in a different region?

- Are they able to produce a minimum order quantity that’s realistic for my needs?

- What is their manufacturing lead and turnaround time?

- What is their reputation like?

Remember, don’t be afraid to reach out to other businesses and ask about their experience with a potential manufacturer. The last thing you want is to be sucked in by optimistic language on a website, or worse, tricked by a fake review.

Make sure you get a quote from multiple manufacturers — don’t go with the first store on the block.

Manufacturing new products in-house is always better.

If you want something done right, you gotta do it yourself. However, that might not always be possible. So, here are some advantages and disadvantages of outsourcing this process.

Advantages

Cost savings — CMs frequently have economies of scale, which allows them to make goods at a lower price than a new business could internally.

Access to specialized expertise — CMs often have specialized expertise in a particular area, such as product design, engineering, or manufacturing. A company can leverage this expertise to develop high-quality products by partnering with a contract manufacturer.

Flexibility — CMs allows companies to ramp up or scale down production as needed quickly. This can be especially important for startups or companies with fluctuating demand.

Faster time to market — CMs can help speed up product development by handling prototyping, testing, and regulatory compliance. This can help companies get their products to market faster and gain a competitive edge.

Reduced risk — CMs assume some of the risks associated with manufacturing, such as equipment maintenance, quality control, and supply chain management. This can help reduce the risk for the company and allow them to focus on other areas of the business.

Disadvantages

Communication challenges — communication can be challenging when working with a contract manufacturer, especially if there are language or cultural barriers. This can lead to misunderstandings, delays, and other issues.

Intellectual property risks — there is a risk that a contract manufacturer could use the company’s intellectual property (IP) to produce similar products for other customers or even compete with the company directly. This risk can be mitigated by carefully selecting a trusted contract manufacturer and establishing clear IP protection agreements.

Dependency on a third party — when a company relies on a contract manufacturer, it depends on its capabilities and capacity. If the contract manufacturer experiences production issues, quality problems, or other challenges, it can affect the company’s ability to deliver products to customers.

Higher upfront costs — while contract manufacturing can result in cost savings over time, higher upfront costs may be associated with outsourcing production. These costs can include tooling, prototyping, and other expenses related to setting up the manufacturing process.

Step 5: launch your product

After all that work, it’s finally time to produce your product and launch your business.

This is an exciting but also nerve-wracking time — you’ve put so much effort into learning how to manufacture a new product, and now it’s out there for the world to see.

Here are a few pointers to help make sure your final product has the best chance of being one of the many manufacturing success stories:

- Make sure you have a great website that’s easy to navigate and sell online (hire a graphic design firm for this, you won’t regret it)

- Get involved in social media marketing and online communities related to your product

- Make sure you have a solid marketing plan in place to generate awareness and excitement

- Have a plan for how you’ll handle customer service inquiries

- Be prepared for feedback — both positive and negative

Does it sound complicated? It doesn’t have to be! While there will be a lot of hard work involved, starting your own business and bringing a product to market can be an incredibly rewarding experience.

Get everything off the ground with manufacturing software

Getting started with product manufacturing is one thing. The next step is to keep going and growing. Small business manufacturing software will help you manage your entire business without breaking the bank.

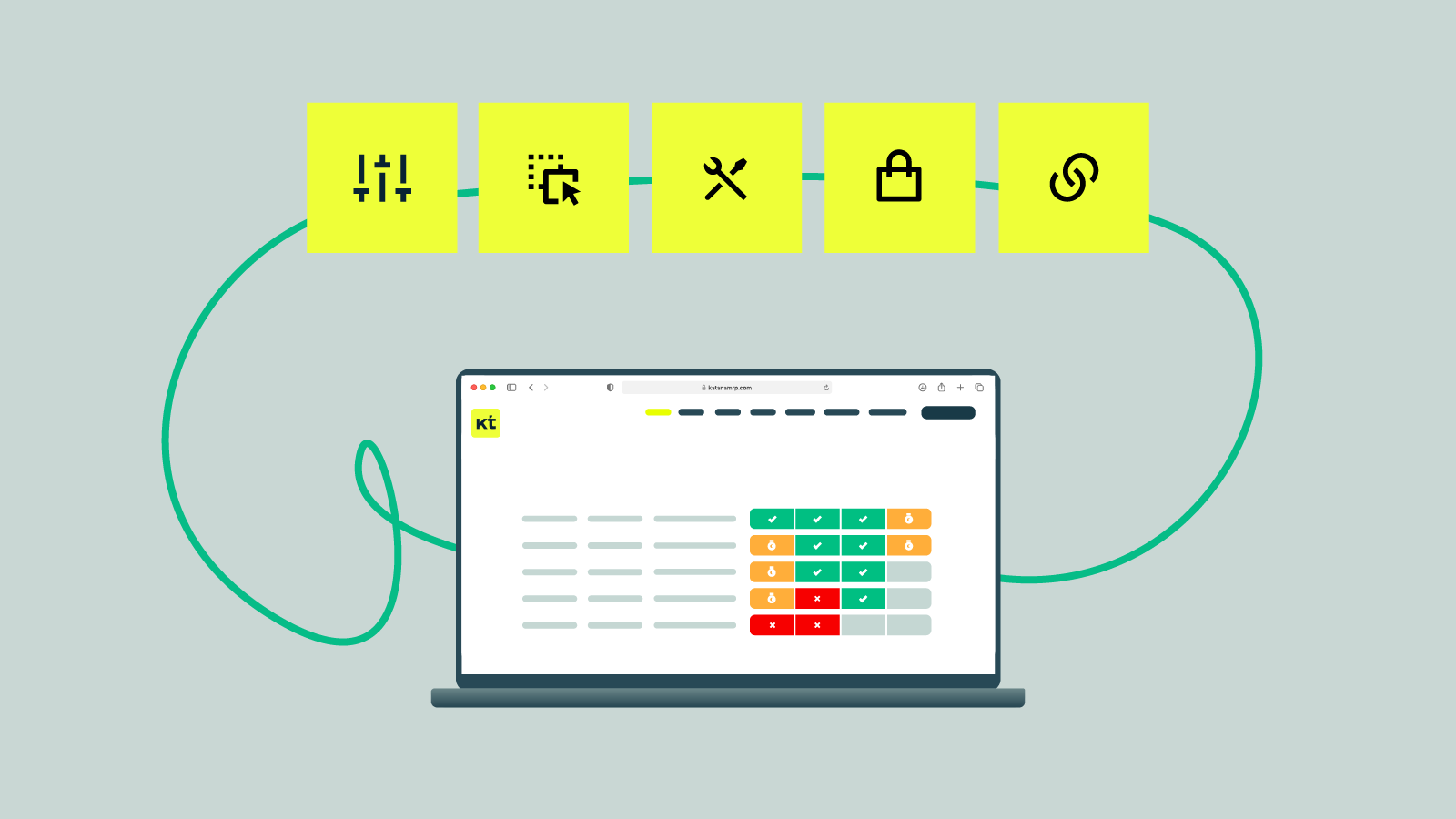

Bonus step: boost your business with ERP software

There’s one thing they don’t tell you about how to manufacture a new product — plenty of services are out there to help.

Enterprise resource planning (ERP) software is designed to be a comprehensive guide for businesses to streamline and automate their manufacturing processes.

From inventory planning to tracking production costs and quality control — Katana’s ERP platform can help take your business to the next level. Plus, an extensive knowledge base will make sure you’re ahead of the game from day one in the manufacturing industry.

Table of contents

Manufacturing guide

More guides and atricles from Katana

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control