Minimum order quantity to ensure every sale turns a profit

When it comes to minimum order quantity, it’s not something end consumers generally have to worry about often. While you can’t go to a supermarket and buy a cup of milk or three eggs, you most likely weren’t planning to do that anyway.

So, while there are certain products you have to buy at least the minimum number of, it’s probably not something that has dramatically inconvenienced your way of living.

But when it comes to business-to-business (B2B) trade, minimum order quantity gets thought about a lot.

In this article, we’ll explore the benefits and challenges associated with minimum order quantity and see how it can help streamline your sales orders.

What does MOQ mean?

MQO stands for minimum order quantity, and it’s the smallest quantity of a product that a supplier is willing to produce or sell. Suppliers set MOQs to ensure that they are not losing money when selling a small number of items.

What does MOQ mean in manufacturing and what does MOQ mean in wholesale are really not that different:

- In manufacturing — It’s the smallest amount of products that a factory can produce in one production run

- In wholesale — It’s the minimum number of products that a wholesaler is willing to sell

When customers want to purchase a product from a supplier, they must order at least the MOQ. They can buy more than the MOQ but can’t order less.

Suppose a customer wants to purchase a product but does not want to order the MOQ. In that case, they can try to rely on their negotiation skills or find another supplier willing to produce the product with a smaller minimum order quantity. However, it’s worth keeping in mind that the product price may be higher for suppliers with a lower MOQ.

Now you know what is MOQ, what exactly is EOQ?

What is the difference between MOQ and EOQ?

The MOQ meaning is clear, but you may have also heard the term economic order quantity (EOQ). Let’s quickly go over what that means.

While MOQ is the lowest number of products a supplier is willing to produce, the EOQ is the number of products that will minimize the cost of ordering and holding inventory. The two concepts are different, but they are often used together to help businesses decide how many products to order.

MOQ — The smallest number of products you can buy from a supplier

EOQ — The number of products that will minimize the cost of ordering and holding inventory

Why should businesses care about MOQ?

We now understand what MOQ stands for, and that’s all well and great, but why should businesses care about it?

Since most suppliers have a minimum order quantity, businesses need to purchase at least that amount in order to get the product from the supplier. If a company wants to make a purchase but does not want to order the minimum number of products, it may need to look for another supplier.

Another reason is that MOQ is also related to the product price. Generally speaking, the higher the order quantity, the lower the price per unit.

Finally, businesses may want to consider MOQ when deciding on inventory levels. If a company orders more products than it needs, it may end up with excess inventory. On the other hand, if a business orders too few products, it may run out of inventory and be unable to meet customer demand

Types of MOQ

There are two main types of MOQs.

Simple MOQ

This is the most common type of MOQ. A simple MOQ is a set number of products or a set value that a customer must order. For example, a customer may have to order at least 100 widgets or $7500 worth from a supplier.

Complex MOQ

As the name suggests, complex MOQ is a bit more complicated.

With a complex MOQ, the supplier may have multiple specifications that must be filled. In addition to ordering a minimum number of products, a complex MOQ may also require the customer to order a certain amount of each product in a specific color or size.

For example, a customer may have to order at least 100 widgets from a supplier, from which at least 50 are red and 50 in medium size.

Benefits of MOQ

Minimum order quantity clearly affects both — the supplier and the buyer, so let’s see if this system also benefits both sides.

Supplier

As a seller, it may seem counterintuitive to decline sales because the customer is looking to purchase a slightly smaller quantity, but let’s dig a bit deeper to see what the benefits are.

Avoid selling at a loss

The main goal of setting MOQ is to avoid running into a loss. Let’s take a look at an example to understand this concept better.

Suppose a company is selling a product at $5 per item. Setting up the machinery and starting the production process costs $100. So, for the company to not run into a loss, it would need to sell at least 20 items, which would bring the total revenue to:

20 x $5 = $100

As you can see from this example, if the customer is only willing to purchase ten items ($50), then the company would be running into a loss of $50. By setting MOQ, the company is trying to avoid such situations.

Reduce carrying costs

Another benefit of setting MOQ is that it can help sellers reduce their carrying costs. Carrying costs include the costs of holding inventory, such as storage costs, insurance, and taxes.

Reduce production costs

Suppliers often set MOQs so that they can produce enough products to fill an entire order. This helps to reduce the costs associated with making small batches of products. Additionally, it helps to ensure that the products are shipped together, which can further reduce costs.

Buyer

The suppliers are generally the ones setting the minimum order quantity, but that doesn’t mean buyers can’t find any benefits in this system.

The main benefit of minimum order quantity for buyers is that it allows them to take advantage of economies of scale.

Economies of scale is the idea that the more units of a product you produce, the lower the per-unit cost will be. This is because fixed costs, such as the costs of setting up machinery, are spread out over a larger number of units.

Therefore, when ordering a larger quantity of a product, the per-unit cost will be lower than if you were to order a smaller quantity, and this can greatly benefit the bottom line.

Challenges with MOQ

While MOQ can be beneficial for both buyers and sellers, there are also some challenges that come with this system.

Supplier

For suppliers, the main challenge with MOQ is that it can limit customer choice and flexibility. This is because customers may need to purchase more products than they actually need to meet the minimum order quantity.

If the customer doesn’t want or need that many products, they may be forced to look for another supplier with a lower MOQ.

Even if the customer’s order quantities increase in the future, they are much more likely to stick with the supplier that was able to fill their initial order without additional hassle. Taking this into account, sometimes it may be beneficial for sellers to make accommodations for small orders to secure a customer’s business in the long term.

Buyer

When it comes to buyers, they will have fewer benefits but, unfortunately, also more challenges.

Increased carrying costs

One of the main challenges you may face with MOQ is increased carrying costs. This is because you may need to purchase more products than you need in order to meet the minimum order quantity. This can lead to increased costs associated with storing your inventory.

Tied up capital

If you can sell the excess inventory quickly, buying more than you initially wanted may not be an issue. However, if you’re stuck with inventory that you can’t sell, it can tie up your capital and prevent you from using it in other areas of your business.

Want to see Katana in action?

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Things to consider when deciding on MOQ

When setting MOQ, there are a few things that you need to take into account to ensure the benefits will outweigh the costs.

Production costs

One of the first things to consider when setting MOQ is your production costs. You need to make sure that you’re setting an MOQ that will cover your costs and allow you to make a profit.

Carrying costs

Another thing to take into account is your carrying costs. As mentioned before, these include the costs of holding inventory, such as storage costs, insurance, and taxes. You need to ensure that you’re not setting an MOQ that will be too high and lead to increased carrying costs.

Customer needs and wants

You also need to take into account your customer’s needs and wants. You need to make sure that you’re setting an MOQ that your customers are comfortable with. If your MOQ is too high, they may go to another supplier.

The market

When deciding on MOQ, you can’t forget the market. If your competitors have a lower MOQ, you may need to lower yours in order to stay competitive. If you’re unable to lower your MOQ, to make it up, you can offer a lower per-unit price or perhaps free shipping.

Your business goals

And last but not least, you have to keep your business goals in mind. You need to make sure that you’re not setting an MOQ that will be too high and prevent you from achieving your goals.

For example, if you want to increase sales, you may want to set a lower MOQ so that more customers can purchase your product. Alternatively, if your main goal is to cut back on costs associated with sales orders, you may want to set a higher MOQ.

By keeping your business goals in mind, you can set an MOQ that will help you achieve them.

MOQ formula

Unfortunately, there isn’t a one size fits all MOQ formula. The MOQ you set will depend on various factors, such as your production costs, carrying costs, customer needs, and the industry you’re in.

That being said, there are certain steps you can follow to arrive at an MOQ that will work for your business.

Calculate your production costs

The main goal of setting an MOQ is to ensure you won’t sell at a loss. So, the first thing to do is calculate your production costs. This includes the cost of raw materials, labor, and overhead.

Once you’ve calculated your production costs, you need to add a profit margin. This will ensure that you’re covering your costs but also making a profit.

For example, let’s say that it costs you $100 to produce a product. In order to make a profit, you decide to add a 20% margin. This means that your MOQ would be $120.

Determine demand

The next step is to determine the demand for your product. This will help you set an MOQ that meets customer demand while also ensuring you’re not tieing up too much capital in inventory.

There are a few ways to forecast demand, such as conducting market research or surveys. You can also look at historical sales data to get an idea of customer demand.

Consider your carrying costs

Once you’ve determined your production costs and done demand planning, it’s time to look at your carrying costs.

You need to ensure that you’re not setting your MOQ too high, which would result in you tying up too much capital in inventory.

A good rule of thumb is to calculate the number of days it would take you to sell your inventory at the forecasted demand. This will help you arrive at an MOQ that balances meeting customer demand and keeping your carrying costs low.

Set your MOQ

Now that you’ve considered all the factors, you can go ahead and set your minimum order quantity for each product.

It’s important to keep in mind that your MOQ may change over time as your business grows and evolves. So, be sure to revisit your MOQ on a regular basis to see if it still makes sense.

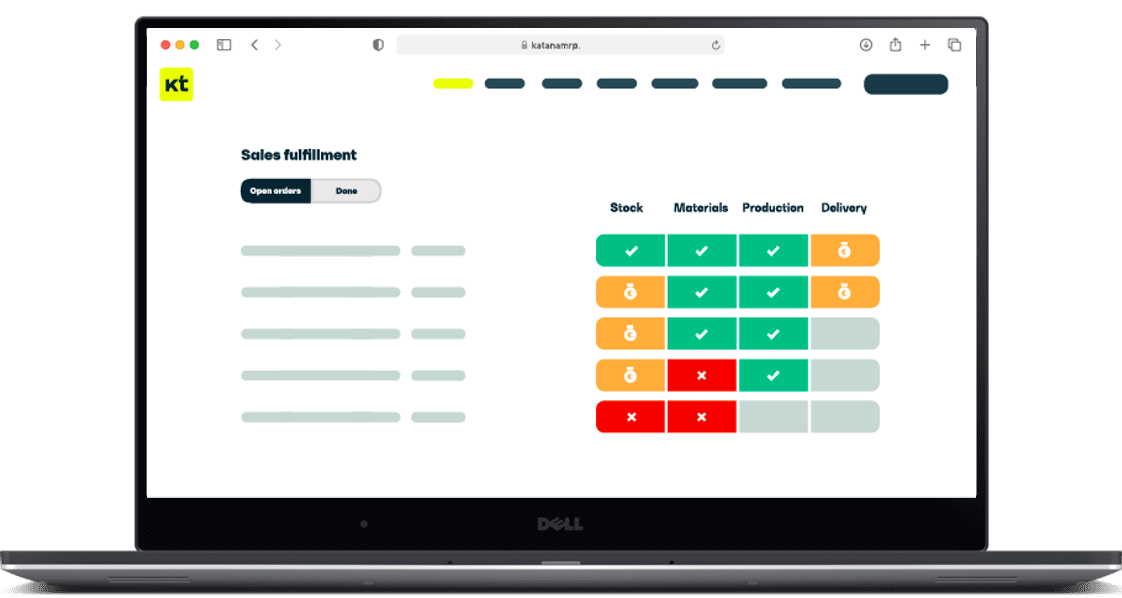

Managing your MOQs

Your minimum order quantities are set, now you need to ensure you can deliver on them. This means having a good handle on your inventory and manufacturing operations.

One way to streamline your processes is by implementing enterprise manufacturing software.

Katana’s cloud inventory software provides businesses with a central source of truth for their inventory data and manufacturing processes. This gives companies the visibility and control they need to manage their MOQs and ensure they can meet customer demand.

Besides the built-in features, you can extend your control to other critical areas by connecting with various business tools. Katana’s seamless integrations make it easy to link up all your favorite platforms, while Katana ensures your data is synched and up-to-date across all of them.

Katana makes managing your MOQs easy so you can focus on growing your business. Request a demo and see how it can benefit your business.

Table of contents

Inventory management guide

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control