Stock keeping units (SKUs) to boost your inventory organization

The more inventory you have, the harder it becomes to keep track of everything.

To ensure all your items are well organized, there are helpful inventory management systems and different tools available. One way to keep your inventory well-organized is through the use of stock keeping units (SKUs).

So, this article will explore what is SKU, the importance of having good SKU management, SKU meaning in production, and how you can use SKUs to better organize your stock.

What does SKU stand for, and why is it important?

SKU stands for stock keeping unit, and it’s used to identify every inventory item in your stockroom.

Using SKU codes is an essential element of inventory management that helps you easily track your inventory items and their variants (e.g., color, size) in:

- Lists

- Invoices

- Manufacturing

- Purchase orders

Having SKUs is important because if your warehouse is filled with hundreds of products, having a clear understanding of stock levels without SKUs is impossible.

Now that the SKU meaning is clear let’s see what is a SKU number.

What is a SKU number?

SKU number is a unique alphanumeric code used to identify every inventory item in the stockroom. SKUs need to be set up in a way so that anyone in your manufacturing business can understand them.

Take a look at this example SKU in manufacturing:

TBL-M-WH

Do you know what it means?

How about this:

COA-14-BK

No?

Well, there is nothing to worry about because there’s no way you can know what this jumble of numbers and letters means. Yet. This seemingly random assortment of characters is an example of SKU codes that can be read by machines or workers.

SKU codes should help you identify the exact product variant you are looking for. Therefore, you should incorporate information such as color, type, size, and other similar attributes into the SKU.

This saves you time decoding the SKU during everyday operations. For example, if your product list includes a pink sleeveless shirt for women, then the following would be a good SKU example code:

This is a relatively simplistic code, but you can make your SKUs more complex. For example, if you have products that move between locations, then maybe having area codes of the original location is necessary.

Reading these codes might seem like a lot of effort at the beginning. But the reality is that they will be used daily, so eventually, reading them will become second nature.

When setting up your SKUs, remember that this is ultimately to make communication easier and help grow your business, taking into account what is important for your business so that you can tailor the SKUs to what you want.

What are SKUs used for?

SKUs are an important tool, not just for manufacturers but for retailers too. But, for manufacturers, it’s more important to have them set up since you’ll need to track the following:

So, what exactly are SKUs used for?

1. Inventory management

SKUs help you categorize, organize, and track your inventory levels, regardless of whether you manage your inventory in Excel or with manufacturing ERP software.

Without SKUs, all of your inventory management efforts will be guesswork.

Once you have your SKUs set up in your business, you can determine the best levels of stock to keep for all your items from gathering information such as sales history, which will save you time and money down the line.

2. Product recommendations

Using and defining SKUs will help your e-commerce store page make better suggestions for customers when they’re shopping because it’ll be able to determine the similarity between products.

So, let’s say you have a customer on your website looking at your apparel inventory, more specifically, clothes made with 100% cotton. The unique SKUs on products and variants mean your store can make suggestions to customers by matching similarities within the SKU.

3. Analysis

We briefly touched on this, but SKUs on your products are going to help you collect invaluable data for sales and manufacturing analytics, allowing you to analyze:

- Its popularity

- Seasonal demand

- Cyclic sale trends for different customer segments

This information enables you to eliminate dead stock, prioritize products, and better plan production cycles.

Ultimately, how you use SKUs depends on your business’ specific needs. However, you’ll need to use them, as they’re necessary for inventory management and analysis in your warehouse, manufacturing, and storefronts. SKUs will help you establish a common language for you and your staff, so there can be no confusion over your item’s variants.

Material prices increased by 80.28% in 2022

Covid-19 led to inflation surging to 8%, resulting in supply increasing raw materials. Download the report and see how rising costs have affected different industries.

SKU vs. UPC

Now that you clearly understand SKUs let’s compare them to UPCs. UPCs (universal product codes) are barcodes used for identifying goods and products.

A UPC aims to help retailers as they can quickly scan the code in store when making sales or restocking inventory. UPCs also provide customers with quick access to product information such as price and availability.

Unlike SKUs, UPCs are universal and can be used to identify products across different retailers. This makes them essential for tracking sales, inventory, and product information.

Pro tip: Looking for a way to generate and manage SKUs in inventory management? Try this free SKU generator from Katana.

SKU inventory tracking

Let’s take a closer look at how you can optimize your inventory and maximize profits by tracking your SKUs.

The best way to make use of SKUs is to set reorder points for each product variant. Having reorder points means you only order stock when needed to avoid stockouts and save money and resources. This helps keep your inventory levels optimal while still having materials to manufacture without delay.

You will need to spend a bit of time setting this up. But once you do, the amount of time you save in the long run is not even comparable. And once it’s spotless, you can see everything happening with complete visibility.

In the same way, you can use visibility with your SKUs to prioritize the product variants you can see are doing well. With an SKU inventory, each variant can be tracked and compared to others. So, upon inspection, you might see those blue T-shirts seem to be the most ordered across the board. That gives the incentive and understanding to drive sales however you see fit.

Maybe you want to market your other products more. Or you decide to take advantage of this sudden love of the color and do some blue-based promotions.

The potential benefits are clear once you have set up your SKUs, and they won’t all be apparent until then.

SKU e-commerce usage

If you have an online store where you sell your products, using the same SKU system on the store and your inventory management can be beneficial. This way, the software ensures your inventory is always up to date on both systems, and you can deliver to your customers without delay.

The most popular e-commerce platform to use is Shopify which caters to all kinds of businesses.

Implementing a Shopify SKU system means that you can optimize your Shopify inventory by using the same SKUs as you do with your inventory management software.

So, you can compare all your reports on either system without any hassle.

If the sales for TSD-S-BL are skyrocketing on your Shopify store, you can seamlessly switch to your inventory management software, see the matching SKU, and life suddenly makes sense. Now you can set the inventory levels at what you need them to be to match the sudden rise of demand, meaning no more customers desperately waiting by the door for their delivery.

That’s just one example, but integrating your Shopify store with your inventory will give you more control. One of those lucky few situations in life where there’s nothing to lose.

Pro tip: For info regarding other e-commerce platforms and how to integrate these with inventory management software, you can check out:

Alongside solving your Shopify inventory tracking, you can also involve customers with your system to make their lives easier. It might seem counterproductive to list your SKUs on your store, but there is a reason that Shopify has that feature.

Having the Shopify SKU code at hand, you can quickly determine the options for the customer.

That’s the beautiful thing about having these codes. They just work as shorthand for anyone that has anything to do with your business.

Everyone can get an understanding of all the options and variants that are available to them efficiently. It’s time saved for you and great customer service for them. If you’re wondering how to make an SKU for your Shopify store, then look no further. You can check out our Shopify SKU generator to help you get the ball rolling.

You can use inefficient Excel spreadsheets to handle your inventory and SKUs, but

this will inevitably lead to issues as spreadsheets are prone to errors.

That’s why it’s important to set up your SKUs on cloud inventory software, which will allow you to:

- Get real-time insights on inventory to avoid stockouts

- Setup reorder points to highlight inventory running low

- Get automated updates on inventory increasing and decreasing based on manufacturing orders and sales orders

And that’s it. Everything you need to know about SKU implementation and management. We hope that you found this article useful, and until next time, happy manufacturing.

Inventory management software to take control of stock

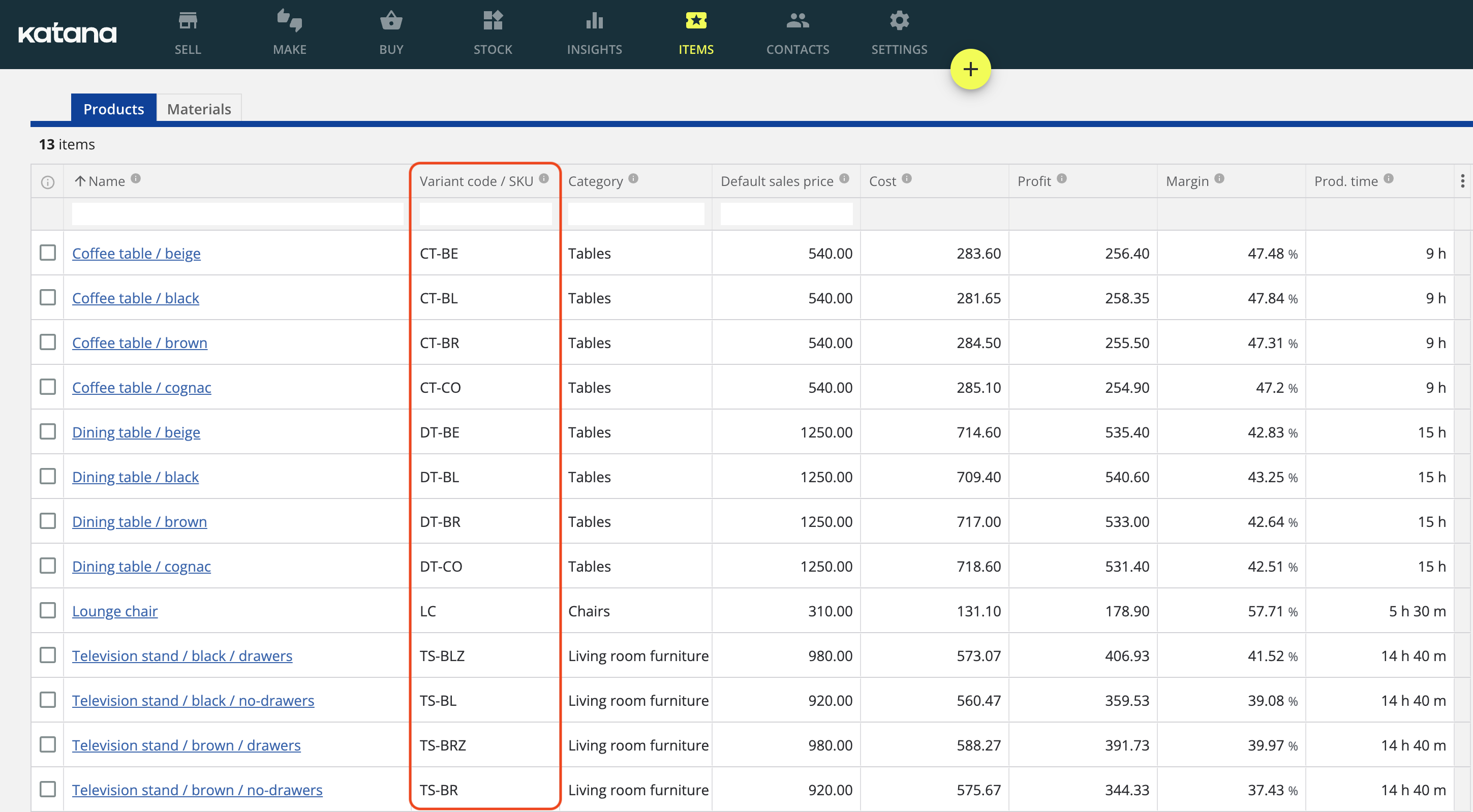

The best way to implement and track your SKUs is by adopting Katana’s cloud inventory software. Katana gives you the reins to control your inventory, manufacturing operations, and the entire business.

Katana has all the necessary features to revamp your inventory management and organize your product lineup. Katana lets you:

- Get real-time insights on inventory to avoid stockouts

- Setup reorder points to highlight inventory running low

- Monitor all four types of inventory in real time

- Integrate your existing business tools into one intuitive platform

- Manage multiple warehouses

- And much more

Request a demo to see why thousands of manufacturers use Katana to take their operations to the next level.

Table of contents

Inventory management guide

More on inventory management

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control