What is RFID and how does RFID work?

Looking to automate your inventory management? This article looks into what is RFID, so you can figure out the best system to implement into your business.

James Humphreys

It isn’t easy running a business — but running and organizing a company that manufactures its goods, either in-house or via a contract manufacturer, presents even more challenges.

As operations and inventory movement increase, the best decision any business owner can make is to find tools for automating the day-to-day tasks. This will save time and money and reduce human errors occurring. So, what systems can manufacturers introduce to improve their business efficiency?

Today, we’re going to be answering the following question — what is RFID?

By the end of this article, you’ll know exactly what is RFID, the different systems, and if your business should implement it in your inventory management or other areas of your business.

What is RFID and how does RFID work?

RFID stands for radio frequency identification — a wireless system for transferring data using electromagnetic or electrostatic technology.

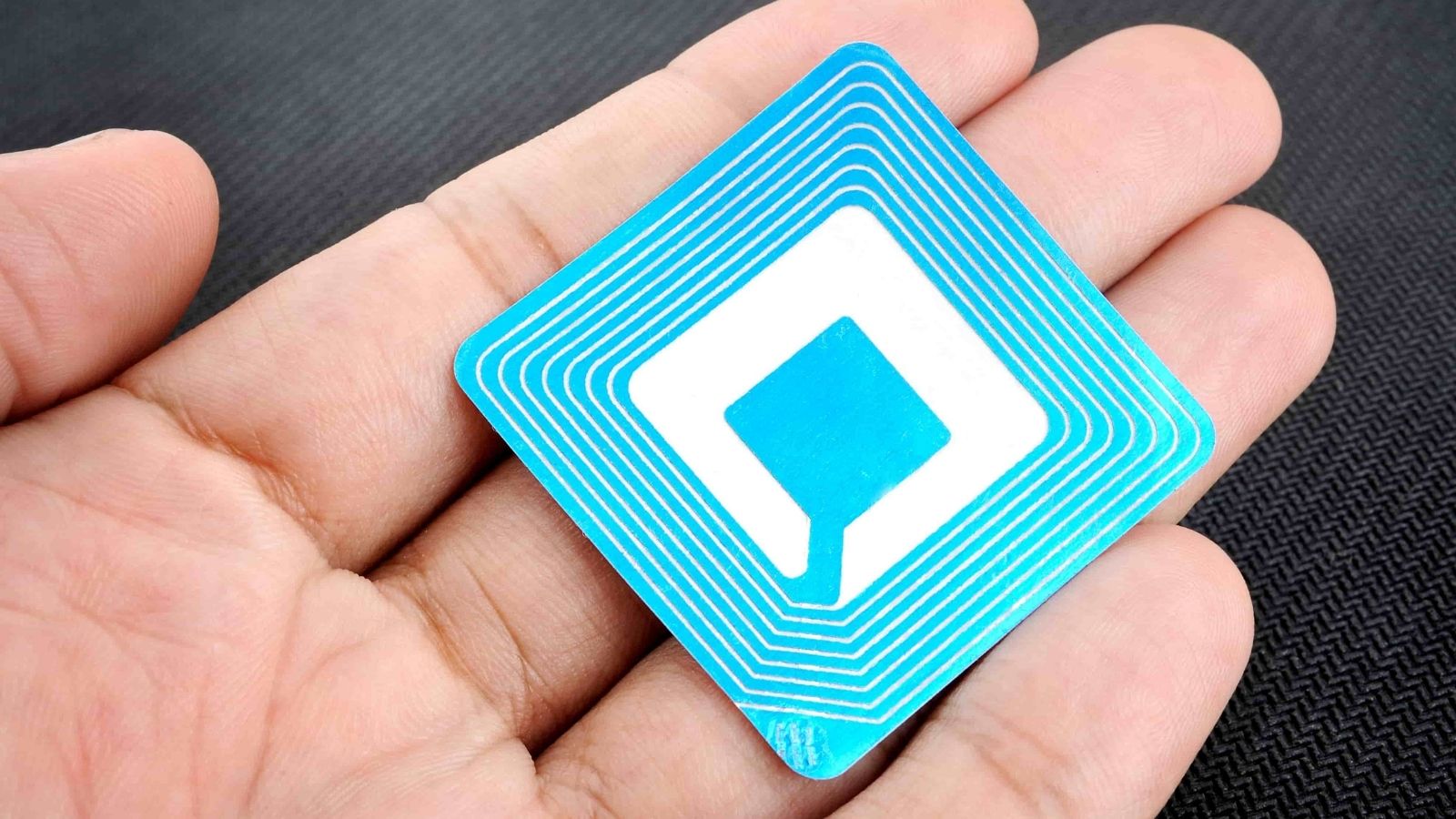

RFID tagging involves small devices that use radio frequencies for tracking and identifying objects, animals, and personnel. There are four main components to an RFID system:

- Tags

- Readers

- Antennas

- Databases

Tags are the smallest part of the system and can be as simple as a sticker or button.

They contain a microchip that stores information about the item to which it is attached. Readers are slightly larger than tags and emit radio waves that power the tag’s microchip so it can transmit its stored information. The antennas can either be integrated or standalone to send and receive signals between RFID tags and RFID readers.

Finally, databases store all the information collected by the tags and readers.

RFID systems have many potential applications.

One common use of RFID systems is live inventory management in warehouses or retail stores. RFID tags can be attached to products or packaging, and readers can be used to track the movement of these items throughout the supply chain. Placing an RFID tag on an item allows manufacturers to automatically and easily identify the item.

In RFID systems, there are two types of tags, which we will investigate later:

- Active

- Passive

RFID systems offer many benefits over traditional barcode-based tracking systems.

RFID tags can store more information than barcodes, and they can be read without a line of sight, which means they can be read even if they are hidden from view. This makes RFID ideal for tracking inventory in difficult-to-see places, such as inside containers, under clothing, or even behind walls.

How does RFID work?

Step 1:

When RFID tags for inventory pass within range of an RFID reader, the antenna on the tag captures the energy from the reader’s signal and uses it to power up the tag’s circuitry.

Step 2:

The tag then sends back its unique identifier code to the reader.

Step 3:

The reader, which is connected to a computer, then looks up the identifier in a database and can access information about the item that has been tagged. This information might include the item’s location, its history, or other data.

Did you know? RFID is an auto-identifying technology that with a strong enough power source can reach distances of over 20+ meters. In WW2, RFID technology was crucial for identifying friendly and enemy aircraft.

RFID technology is rapidly evolving, and the potential uses for this versatile technology are endless.

Our manufacturing trends and predictions are that as the cost of RFID tags and readers continues to fall, we will likely see this technology become increasingly commonplace in various applications.

When choosing an RFID system for your business, it is important to consider the specific needs of your application. Active tags are more expensive than passive tags, but they offer a longer read range and can be used to track larger items. Passive tags are less expensive and smaller, making them well suited for tracking small items or tagging large numbers of items.

Consult an RFID expert to ensure you select the best tags and readers for your application.

Now you know what is RFID and, what does RFID stand for, what exactly is it used for?

What is an RFID used for?

RFIDs are used in a variety of applications, including:

Access control

RFID tags can be used to grant or deny access to certain areas. For example, an RFID tag could be used to unlock a door or gate.

Inventory tracking

You can use RFID tags for inventory levels and movement tracking. This information can improve stocking levels and purchase order management accuracy.

Security

RFID tags can be used as a security measure. For example, an RFID tag could be required to enter a secure area.

Although RFID can be used in several other applications, including:

- Tracking tools and equipment

- Supply chain management

- Retail inventory management

- Real-time locations systems

- Healthcare

- Manufacturing

- Tap-and-go credit card payments

What are examples of RFID?

There are various ways that RFID can be used to benefit businesses and organizations.

As already mentioned, examples include:

- Inventory tracking

- Supply chain management

- Security

- Identification

RFID can be used in product traceability by tagging items with RFID tags and then using RFID readers to track the movement of those items throughout the supply chain. This allows businesses to keep track of their inventory levels and multiple locations in real-time, which can help to optimize stock levels and prevent losses due to theft or misplaced items.

In supply chain management, RFID can be used to track the movement of goods through the supply chain from shop floor to delivery.

This visibility can help businesses to identify issues and bottlenecks in their supply chain and take steps to improve efficiency.

RFID can also be used for security purposes, such as controlling access to buildings or areas within buildings. Businesses can track who or what is entering and exiting specific areas by tagging people or objects with RFID tags. This helps increase security and prevent unauthorized access.

Finally, RFID can be used for identification purposes, such as in employee badges or animal tags. This can help businesses to keep track of their employees or other assets and ensure that they are where they are supposed to be.

Overall, RFID provides a variety of benefits that can be tailored to the needs of any business or organization. The examples above are just a few of how RFID can be used to improve operations and increase efficiency.

What is an RFID system?

As mentioned earlier in the article, RFID tags can be active or passive:

- Active RFID tags have an onboard power source, such as a battery, which allows them to transmit their signal over long distances (100 m and further)

- Passive RFID tags have no onboard power source and rely on the reader’s energy to activate and transmit their signal. This limits the transmission range of passive RFID tags to just a few meters

Passive RFID tags are much less expensive than active RFID tags, making them the preferred choice for many applications.

RFID systems work on frequency waves, and there are three main types of RFID systems:

- Low frequency (LF)

- High frequency (HF)

- Ultra-high frequency (UHF)

Bonus frequency: microwave RFID is also available.

Low-frequency RFID systems

LF RFID systems can range from 30 kHz to 500 kHz, but the typical LF is around 125 kHz to 134 kHz.

The reading range of an LF system can be touch-based or reach up to six feet. The costs of LF tags are some of the lowest per tag, from $0.75 to $5. Applications of low-frequency RFID systems include:

- Animal tracking

- Security control

- Car key-fob

- Manufacturing processes that have high volumes of liquids and metals

Pros of using LF RFID systems

LF RFID systems work well near liquids and metals and meet global standards.

Cons of using LF RFID systems

LF RFID has a very short read range, small memory, low data transmission rate, and a high production cost to make.

High-frequency RFID systems

HF RFID systems can range from 3 mHz to 30 mHz, though the typical HF range is 13.56 mHz.

The reading range of an HF system is touch-based and can reach up to several feet. HF tags are more expensive than LF tags, from $0.20 to $10. Applications of high-frequency RFID systems include:

- DVD Kiosks

- Library Books

- Personal ID Cards

- Poker/Gaming Chips

- NFC Applications

Pros of using HF RFID systems

HF RFID has a higher memory capacity than low-frequency systems and satisfies NFC global protocols and global standards.

Cons of using HF RFID systems

HF RFID has a short read range and a low data transmission rate.

UHF RFID systems

UHF RFID systems can range from 300 mHz to 3000 mHz, though the typical UHF range is 433 – 960 mHz.

The reading range of a UHF system can reach over 25 feet. We mentioned earlier that RFID systems could be either active or passive. UHF systems reside in active or passive states. Here are the differences, in more detail, between active and passive RFID systems:

Active UHF RFID systems

Active UHF RFID systems can range from 433 mHz to 2.45 gHz under the extremely high-frequency range.

The reading range of an active RFID system can read from 30 to over 100 meters. The priciest of RFID tags, costing around $25 to $50 per tag. Applications of active UHF RFID systems include:

- Vehicle tracking

- Automated process manufacturing

- Mining

- Construction

- Asset tracking

Pros of using active UHF RFID systems

The longest reading range, a lower infrastructure cost compared to passive RFID, the largest memory capacity, and high data transfer rates.

Cons of using active UHF RFID systems

Very expensive per tag, come equipped with batteries which means it has shipping restrictions, the software required to use them is complex, has high interference from metal and liquids, and has few global standards.

Passive UHF RFID systems

Passive UHF RFID systems can range from 860 mHz to 960 mHz.

The reading range of a passive RFID system can be near contact with reader to 25 meters. The RFID tags are reasonably priced, from $0.09 to $20 per tag. Applications of a passive ultra-high frequency RFID system includes:

- Supply chain tracking

- Manufacturing

- Pharmaceuticals

- Electronic Tolling

- Lean inventory management

- Race timing

- Asset tracking

Pros of using passive UHF RFID systems

Long read range, low costs for RFID tags, a huge selection of tag sizes and shapes, global standards and a high data transmission rate.

Cons of using passive UHF RFID systems

Equipment is expensive, memory capacity isn’t the largest, and it also experiences high amounts of interference from metal and liquids.

Science lesson — How do liquids and metals interfere with RFID?

RFID signals are detuned and reflected by metals. Liquid, on the other hand, absorbs RFID signals. The higher the frequency, the more likely it is that higher frequencies will be distorted, leading to:

- Poor tag read ranges

- Unreliable readings

- No readings whatsoever at UHF levels

Get Katana cloud inventory platform

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Which RFID system is best for you?

The system you’d use in your business depends on what the RFID system will be applied to in your business — for example, is it for tracking personnel or inventory?

And even then, it’s not guaranteed that the RFID system will meet the required reading distances you need. When the U.S. State Department issued electronic passports with RFID chips, they expected the reader range to reach about 4 inches. However, they soon discovered that the RFID readers could skim information from further away, as far as 33 feet in some instances.

If you need your reading range to be further than 300 feet, you’ll need tags with additional power to boost their signals.

RFID systems have a wide range of potential applications, but inventory management is perhaps the most well-known application of RFID technology. By tagging items with RFID tags, businesses can keep track of their inventory in real-time without manual counting or barcode scanning. This can lead to significant efficiency gains, as well as reduced costs.

Another common application of RFID is access control.

Businesses can grant or deny access to certain areas using an RFID reader by tagging people or objects with RFID tags. This can improve security, for example, by ensuring that only authorized personnel has access to certain areas.

Asset tracking is another common application of RFID. By tagging assets with RFID tags, businesses can keep track of their location and movements. This can be used for various purposes, such as security or inventory management.

Types of RFID tags

As already briefly touched upon, the difference between active and passive RFID systems is the use of power sources:

Active tags — They need their own power source, such as a battery, that gives them the energy to transmit their stored data to greater distances.

Passive tags — Do not require a power source and rely on their data by the power emitted by an RFID reader. This means the range of a passive tag isn’t far, maybe just a few feet.

Types of RFID readers

RFID readers are network-connected devices, that can be categorized as three different types of readers:

- Fixed

- Mobile

- Vehicle-mounted

Fixed RFID readers

Readers that are stationary where the tag needs to be placed within a detection range of the reader. Fixed readers are often used in manufacturing for tracking items that move along a conveyor belt line or in warehouses at a point inventory needs to pass through, so a stock take can happen in real-time without workers having to do anything else.

Mobile readers

Battery-powered, hand-held devices that allow users to read and alter RFID tags when scanning. These devices usually come with a touchscreen or keyboard so you can make changes to the tag on the fly, which automatically updates the database software too. If you go to a retail store early enough, you might see the staff doing inventory updates with these devices.

Vehicle-mounted readers

Perfect for supply chain management. These are attached to forklifts, pallet trucks, or other heavy machinery used for moving inventory. These RFID readers will automatically read and record where cargo is transported in real-time.

Want the best RFID reader for your business?

Answering the following questions will help you decide:

- What range do you need your reader to reach?

- Are there any environmental conditions that need to be taken into consideration?

- Does the reader need to be mobile, or can it be static or attached to a vehicle?

- How many reading points do you require?

- How many tags do you need to read at once?

- How quickly will the tag be passing the reader?

What is an RFID antenna?

An RFID antenna is a type of antenna that is designed to work with radio frequency identification systems. RFID antennas are used to transmit and receive radio signals between an RFID tag and an RFID reader. For an RFID system to function properly, the antennas must be tuned to the specific frequency that is being used by the system.

A few different types of RFID antennas are available on the market, including:

- Dipole antennas

- Monopole antennas

- Patch antennas

Each type of antenna has its own set of advantages and disadvantages, so it is important to choose the right antenna for the specific application.

Dipole antennas

Dipole antennas are the most common type of RFID antenna. They are typically composed of two metal rods aligned perpendicular to each other. The length of the rods is generally one-half of the wavelength of the desired frequency. Dipole antennas are easy to construct and can be made with various materials, making them a popular choice for many RFID applications.

Monopole antennas

Monopole antennas are similar to dipole antennas but only have one rod. Monopole antennas are often used in portable RFID applications because they are smaller and lighter than dipole antennas.

Patch antennas

Patch antennas are a type of antenna composed of a flat patch of metal attached to a ground plane. Patch antennas are often used in RFID applications where space is limited, such as on a tag that will be attached to a small object.

When choosing an RFID antenna, it is important to consider the application’s specific requirements. Factors such as size, weight, shape, and frequency all need to be taken into account to ensure that the antenna will work properly with the RFID system.

RFID vs barcode scanning technology

Regarding inventory tracking, two of the most popular technologies are RFID and barcodes.

Both have their pros and cons, so it’s important to understand the differences before choosing a solution for your business.

Barcodes have been around for decades and are still widely used today. They are cheap and easy to use, making them a good choice for businesses with limited budgets. However, barcodes can be easily damaged or obscured, making them less reliable than other options.

RFID tags are newer than barcodes, but they offer several advantages over traditional barcodes. RFID tags can store more information than barcodes, and they can be read from a greater distance. Additionally, RFID tags are more resistant to damage and tampering.

RFID tags are generally more expensive than barcodes when it comes to cost.

However, the tag’s durability and increased functionality may make up for the higher price tag.

So, which technology is right for your business?

It depends on your needs and budget. If you need a cheap and easy solution, barcodes may be the way to go. However, if you need a more reliable and durable solution, RFID tags may be worth the investment.

Or, take a page from manufacturers who perform retail inventory management — they use both systems, RFID for security and barcodes for selling.

Have your eyes set on barcode scanning solutions that that integrate with your favorite e-commerce and accounting software? Be sure to check out the following articles:

What are the benefits of using RFID systems?

RFID systems offer a number of potential benefits to businesses, including:

- Improved accuracy and efficiency in inventory management

- The ability to track assets in real-time

- Reduced labor costs associated with manual tracking methods

- Greater visibility into the supply chain

- Improved customer service through faster and more accurate order fulfillment

When used in conjunction with other technologies, such as barcodes and GPS, RFID systems can provide an even higher level of asset tracking and management accuracy. The benefits of RFID are numerous and can offer a significant competitive advantage to businesses that adopt this technology.

If you’re considering implementing an RFID system in your business, be sure to partner with a reputable provider who has extensive experience in designing and deploying these types of systems. With the right partner, you can realize all the potential benefits RFID has to offer.

What are the challenges of using RFID systems?

Several challenges come along with using RFID technology for physical RFID inventory management.

One challenge is that RFID tags can be expensive, which means that initially outfitting a facility with the necessary tags can be costly. Additionally, RFID systems require special infrastructure to work properly, meaning that businesses need to invest in RFID-compatible equipment and software. Finally, RFID systems can be complex to set up and maintain, requiring training for staff members who will be using the system.

While the challenges of using RFID technology should not be ignored, the potential benefits of implementing an RFID system can be significant.

RFID systems can improve inventory accuracy, reduce stock-outs, and increase efficiency in the supply chain when properly implemented. Ultimately, whether to implement an RFID system is a decision that needs to be made on a case-by-case basis by businesses considering the specific needs of their production planning and operations.

RFID systems in manufacturing

Some ERP manufacturing software can track RFID tags within their software.

For example, Katana ERP is a tool built specifically for manufacturers looking to use barcodes, QR codes, or RFID tracking for their raw materials, WIP manufacturing, and finished goods inventory. Connect the relevant hardware and the RFID reader to the same device you have Katana ERP open to get started with this. Then, once everything is ready, you simply select the Start scanning button, and away you go.

Want to know more about automating your inventory management? Feel free to book a demo with us, and one of our manufacturing experts will explain the process.

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control