Automation in manufacturing: embracing the future

Automation in manufacturing is quickly becoming a standardized tool across all businesses. In this article, we explore process automation and all it has to offer.

James Humphreys

There are a lot of assumptions people formulate when they think about automation along a production line.

They envision conveyor belts, mass layoffs, and soulless robotic arms picking and packing away products. Yes, this is the case in some areas of the manufacturing industry that uses a repetitive manufacturing process. But, since the industrial robotics boom of the 1980s, the application of automation in manufacturing has changed, from robotic arms for large-scale manufacturers to inventory management tools for crafters.

Automation is no longer a threat to employees but an important tool for any manufacturing business.

Automation in production is here to stay and will only continue to improve daily as the technology becomes more accessible.

As mentioned, an automated manufacturing system isn’t limited to production lines. It can be a tool that can automate your inventory, orders, purchasing, or even marketing. Pretty much anything can be automated to improve your manufacturing business process.

In this article, we look into how a manufacturer can implement these tools into their business and the different functions these tools perform.

So, without further ado, let’s delve straight into it.

What is automation in manufacturing?

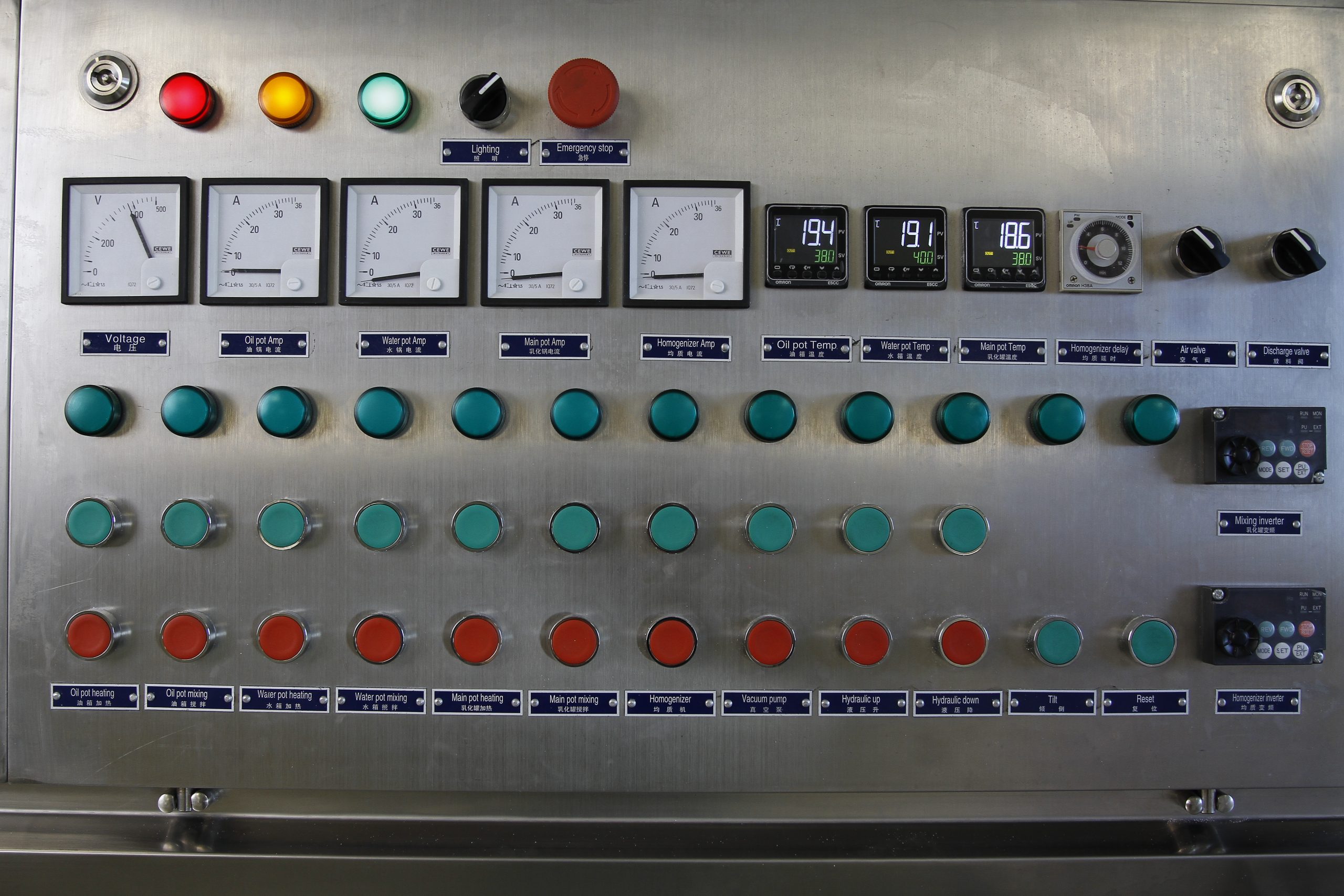

Automation in manufacturing is the process of using production management software or robotic tools to operate a factory when making a physical product.

These tools are built to perform operations to help businesses with tasks such as:

- Processing

- Assembly

- Inspection

- Inventory management

- Production planning

In the past, a tool would perform a specialized task, but with technological advancements, the number of operations that a tool can perform has increased.

In a nutshell, this is what is meant by process automation.

It’s quickly become essential to consider the automation of the manufacturing process, as 76% of manufacturers use automation to improve their factory floor’s productivity as a key strategy for increasing growth.

Manufacturers have shifted their focus to improving this area because it’ll help them.

Reduce costs and production waste

To properly adopt lean inventory techniques into your business, you’re going to need to adopt a tool that can help you track inventory movements, WIP manufacturing costs, and operation progress.

Automated manufacturing will allow you to handle multiple projects at once, in turn generating more revenue.

Improve product quality

Having real-time data about your products and following your production quality control checklist, you can refine your production with process automation manufacturing. This will allow you to discover the inferior components in your products and make the necessary replacements.

Improve response time

With real-time data, you can better understand your stock levels to immediately know if you can start production or need to order more material, drastically increasing your business’s fulfillment rate.

Of course, this is mainly focused on manufacturing process software, but when it comes to using robotics, there are two main reasons:

- It’s cheap to use

- It helps compensate for skilled labor shortages

However, since robotics are mostly used in the automotive industry, we’ll focus on manufacturing process software for this article instead.

And you might be surprised to know that there is software built to perform a wide range of different manufacturing tasks on the market.

The different types of process automation systems

So, what manufacturing automation solutions are out there, waiting to be utilized by small and large manufacturers?

Procurement

From supplier portals to Vendor Management Systems (VMS), the purpose of procurement automation is to free employees from time-consuming, repetitive tasks, so they can instead focus on the more important requirements of the business.

Order processing

Sales and manufacturing orders can quickly become difficult to fulfill when business picks up, especially if you’re a bespoke manufacturer.

By automating this manufacturing process, you’ll be able to:

- Monitor orders in real time

- Track customized orders

- Handle pricing calculations

- Store customer information

- Adapt to any order changes

Supply chain

Automating your supply chain will help you decrease the delivery times of your products to customers. Also, you’ll be able to improve your routing manufacturing, which is especially important if you have products stored at multiple locations.

Customer service

From upselling/cross-selling to automatic responses to queries during out-of-office hours, anything that can improve the customer’s shopping experience is only going to help increase customer satisfaction rates.

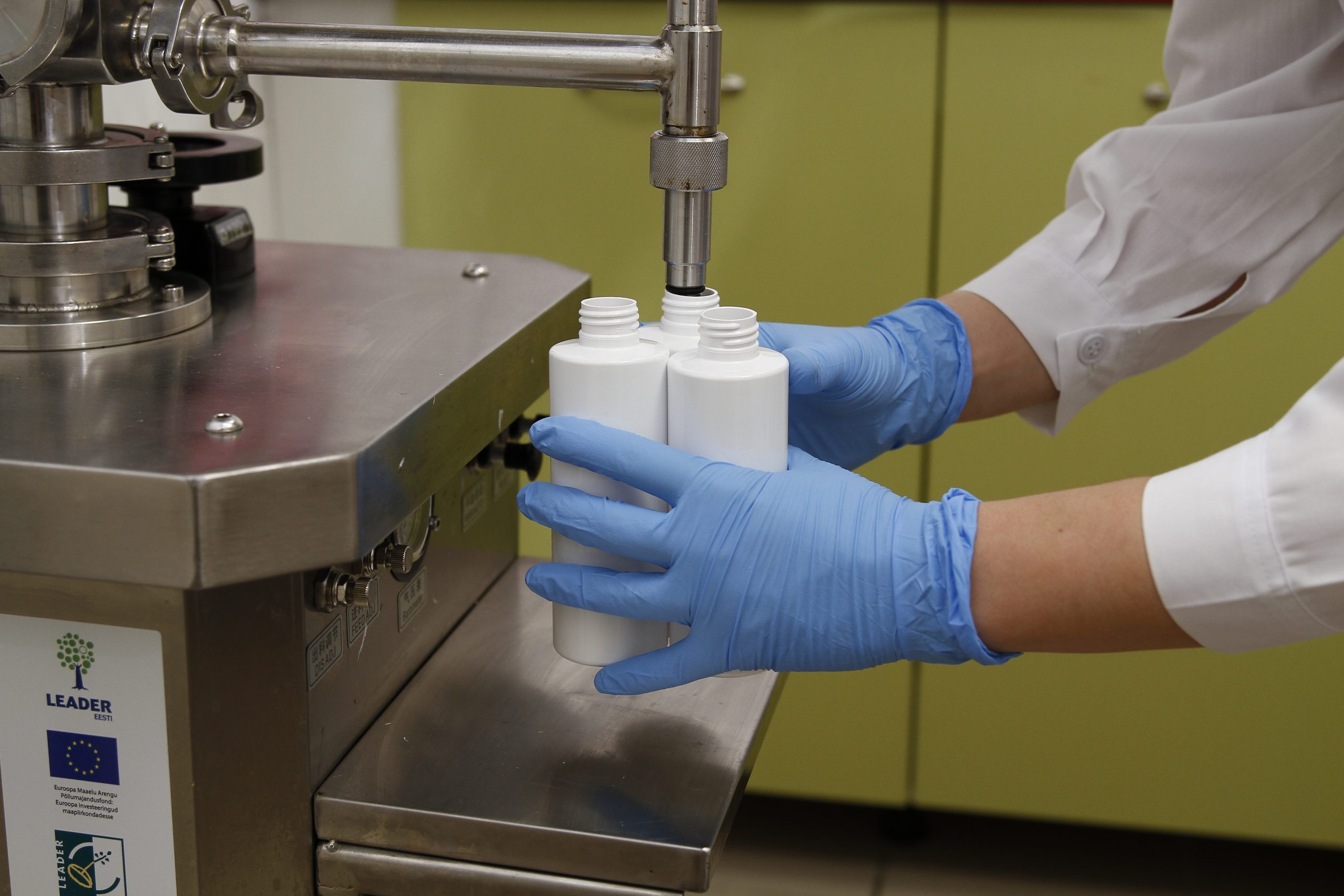

Production

Using automation in manufacturing is extremely important for manufacturers.

Using software will allow businesses to improve bottleneck management, store bill of materials, and even make use of AI-assisted decisions. And if you outsource your production (or part of it), contract manufacturing software can be of huge help when it comes to managing inventory and processes at your suppliers’ locations and at your own.

Operations

Manufacturing process automation of your operations will allow you to improve your workflow, reduce your manufacturing lead time, and ultimately boost your bottom line.

So, these are the manufacturing automation solutions manufacturers need to consider using. However, be sure to read on as we look into cloud manufacturing software, an all-in-one solution that can perform all of the above tasks and functions.

The benefits of using automation in manufacturing

We briefly touched on the benefits of manufacturing automation in the first chapter.

However, the actual list of benefits extends way beyond those three points. The sooner you implement manufacturing process software into your business, you’ll experience:

- An increase in labor productivity

- A reduction in labor costs

- A way of mitigating the effects of a labor shortage

- A reduction or elimination of errors from abandoning spreadsheets or other documentation

- An improvement to product quality

- A reduced manufacturing lead time

- Increased savings by avoiding the high cost of not automating your production

If you’re a small-scale manufacturer with sale orders here and there, it probably won’t be necessary to get set up with process automation systems.

But, once your business starts to expand and you’re handling more orders, it will quickly become a no-brainer when deciding if it’s time to upgrade your processes.

Even more so for D2C manufacturers because the assistance of automation will help them truck along, as they’ve decided to go solo and cut out the middleman.

Why manufacturing automation is crucial for D2C manufacturers

The manufacturing process and automation go hand in hand for D2C manufacturers since they’re taking back control of their business, but ultimately increasing their responsibilities.

For this reason, D2C manufacturers can’t afford to waste time updating inefficient spreadsheets or trying to fix a bottleneck, as they also need to divert resources to customer services, marketing campaigns, and building their direct to consumer brands.

An automated manufacturing system allows D2C manufacturers to develop a master production schedule, monitor their floor-level production, and manage their inventory levels automatically, so the D2C manufacturer can stay focused on manufacturing their goods and growing their business.

However, as D2C manufacturers are also handling their sales, they’ll likely be using an e-commerce platform to sell their products.

That’s why it’s essential to find manufacturing process software with Shopify inventory integration (or integration with whichever preferred sales channel) to have your entire business centralized onto one platform.

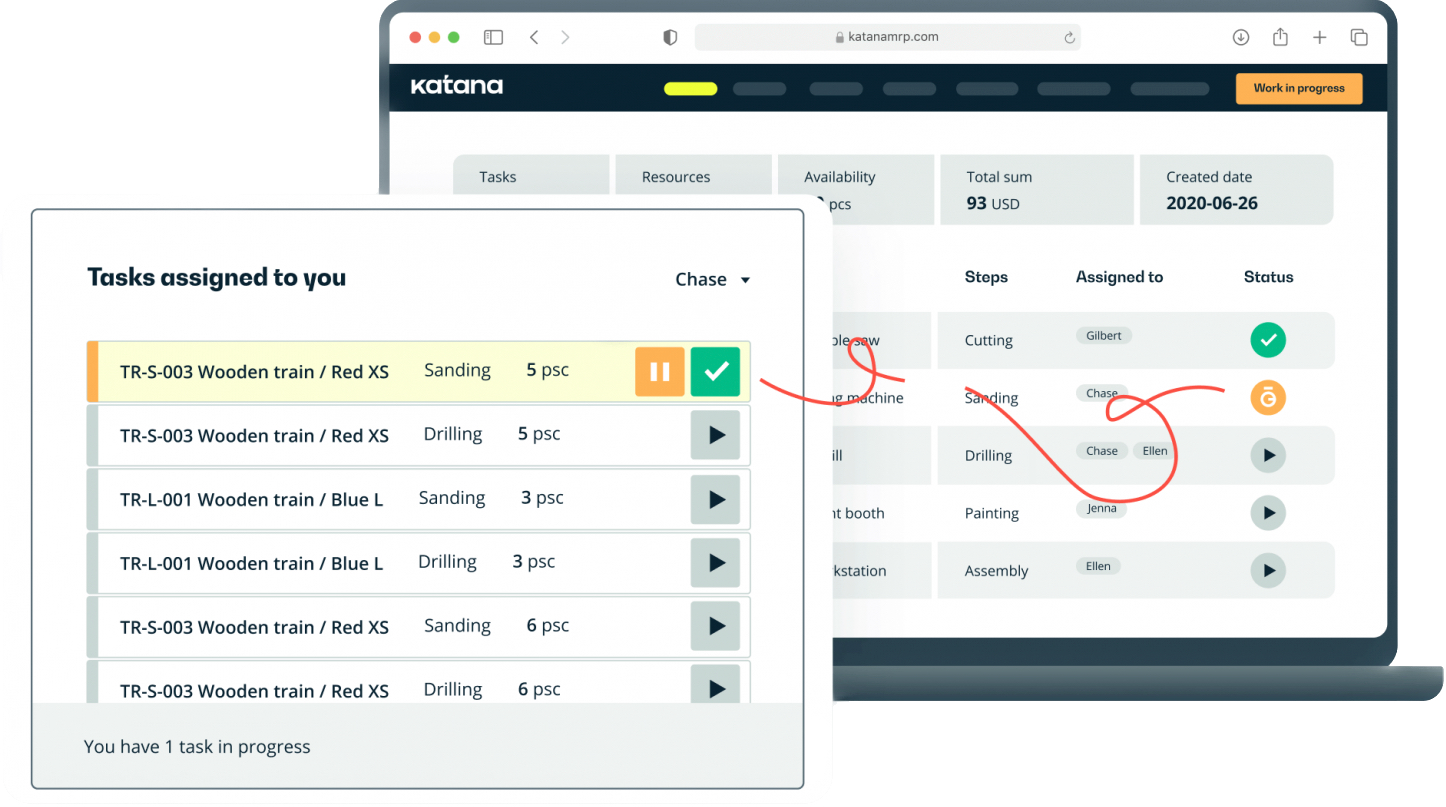

Thankfully, tools like Katana’s cloud manufacturing software has been built specifically for D2C manufacturers looking for manufacturing process software that can bring their sales channels, manufacturing, and orders to once place.

Automated manufacturing with cloud manufacturing software

Automation in manufacturing industry is made easy and possible with tools such as Katana’s cloud manufacturing software, which has been built by manufacturers, for scaling manufacturers.

Katana is an all-in-one solution that, will not only streamline your business, but can integrate with your favorite business tools, and help you with:

- Procurement

- Order fulfillment

- Your supply chain

- Customer service

- Production

- Operations

- Process automation

The other terms you’ll recognize from earlier in the article, but what is process automation?

The process automation definition is a term used to describe software that can automatically monitor and handle your inventory movement.

For example, Katana can give you the full power of automated manufacturing with its unique real-time master planner, designed to take available finished goods and raw materials, and allocate them to any sale, or manufacturing orders, you have open.

But not only will you have access to this feature, but Katana also offers:

- On-demand access to your manufacturing costs

- Synchronization with your accounting software like QuickBooks

- Finished goods and raw material inventory management

- Inventory tracking of items on consignment or across multiple warehouses

- Outsource manufacturing management

- Manufacturing scheduling software

- Efficient material purchasing plans

- An easy to understand, visual platform, which can centralize your entire business

If you consider yourself more of a visual learner, be sure to check out the video below to get a better understanding of how Katana works:

Want to see Katana in action?

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

What to do with all this newfound information?

Businesses using automation in production management are going to become the norm soon. It’s not just going to be our factory floors, as you can already see automation pouring into our homes and streets.

Don’t believe us? Tesla, Starship Technologies, and Google Assistant are all examples of automation for personal use.

And as technology improves and becomes more accessible, it’s only going to become more crucial that you use manufacturing process automation, even if it’s only for one process in your business.

Otherwise, you won’t be able to keep up with the competition, and you’ll quickly become submerged as your business grows.

So, why not be ahead of the curve like many other scaling manufacturers? Cloud software can show manufacturing process automation’s power in your business.

Book a demo with Katana, and take your manufacturing business to the next level.

That’s all we have for today. We hope that you found this article useful, and if you have any questions, please do not hesitate to get in touch by leaving a comment below or hitting us up on our social media pages.

And until next time, happy manufacturing.

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control