Win buyers and influence sales with consignment inventory

You’ve put blood, sweat, and tears into a product (metaphorically speaking, perhaps even literally).

You’re proud of your accomplishments and try to push your brilliance onto the world. Even though you’re only trying via one sales channel, it’s not been going as successfully as you had hoped — mostly because you compete with companies selling products that are already well-established. But you’re confident that your products will fly off the shelves once customers know about them.

Luckily for you, there exists another avenue to take — which is selling your goods via consignment inventory.

Even better news for you, this isn’t a tactic in which you hand over all your rights to some corporate giant (one who slowly excludes you as they engulf your product and life’s work). Inventory consignment allows you to retain ownership of your products while a merchant advertises and sells them on your behalf.

Sounds too good to be true, doesn’t it?

In this article, we’ll look into what is consignment stock and how you can leverage it within your business’s workflow.

What is consignment inventory?

Consignment inventory allows a business to place its products in a retail store while keeping ownership of the goods, effectively managing stock levels and reducing upfront costs. This inventory consignment management strategy benefits both the supplier (consignor) and retailer (consignee) by optimizing inventory levels and minimizing the risk of unsold stock for both parties.

Businesses use the consignment strategy when products are:

- Seasonal

- Perishable

- Previously owned

However, that doesn’t exclude products that have no market experience. Consignment inventory is great for businesses coming out with brand-new products.

A benefit for the sellers is that they don’t have to commit to selling a product with no history. If the products are not selling well, the seller can return them to the original owner.

Here’s a great video available on YouTube explaining in detail what inventory consignment is:

But what exactly is the process of using this method of inventory management?

Get a demo

Sign up for a free demo call with our experts and find out how Katana can boost your consignment agreement.

The process of consignment inventory management

Maybe you’re a new business and unsure how your product will be received in the marketplace, but you have a gut feeling that it will do well.

This is a scenario in which having stock on consignment could benefit you.

So, what do you do?

First things first, you need to establish a strong relationship with a potential consignee who’ll be willing to stock your inventory. You and your prospective partner have agreed to embark on this endeavor. You’ll then design a contract explaining both partners’ responsibilities and liabilities.

Usually, the terms and conditions will contain details such as:

- The commission fee (if any) on items sold

- The duration for how long products will be held by the consignee until being returned to the consignor

- Who pays freight costs

- Who’s liable for items damaged in transit

- Who’s liable for items damaged in inventory

- Who’s responsible for any goods lost or stolen

There’s plenty more a consignor and consignee can consider when agreeing to the T&Cs.

But, once it’s all crystal clear on who does what, the contracts can be finalized, and the products shipped over to the consignee. The next step in the process is to send an agreed-upon number of products to the consignee, who’ll have them in inventory and sell them to consumers. Unless, of course, the products are for use by the company itself, then they will sit in their MRO inventory until they use them.

But, for the sake of simplicity, we’ll stick to consignees who sell the products.

How much they have and for how long they sell the items is down to the terms and conditions agreed to prior. If the consignee takes 1000 products and sells all 1000, they’ll send an invoice to the consignor for the whole inventory. But, if they sell only 300 items within the specified time limit, the remaining 700 items will be shipped back to the consignor.

How to choose a consignee?

When venturing into consignment inventory, selecting the right consignee is essential.

This decision can significantly impact the success of your partnership, influencing sales performance, brand representation, and customer reach.

Here’s how to make a strategic choice, with insights from various industries.

1. Understand your target market

Fashion and apparel — If you’re in the fashion industry, choose a fashion ERP and consignees that cater to your target demographic. For instance, a high-end fashion brand would benefit from consigning with boutique stores located in affluent neighborhoods or luxury department stores known for carrying designer labels, ensuring alignment with your brand’s image and customer base.

Technology and electronics — For innovative tech products, partner with stores that have a tech-savvy customer base and staff knowledgeable about the latest gadgets. This could include specialty tech markets or larger electronics retailers with a dedicated section for emerging technologies.

2. Evaluate the consignee’s market presence and customer traffic

Art and handcrafted goods — Artists and crafters should look for consignees with a strong local presence and high traffic, such as popular local galleries or artisan markets. These venues can offer greater visibility and appreciation for unique, handcrafted items.

Health and wellness products — For this category, partnering with health food stores, gyms, or wellness centers that share your commitment to health and wellness can provide a captive audience interested in your products.

3. Assess compatibility with your brand values and goals

Sustainable and eco-friendly products — Brands focused on sustainability should seek consignees that prioritize eco-friendly practices and products. This could include zero-waste stores, organic markets, or eco-conscious boutiques that align with the brand’s mission and attract like-minded customers.

Specialty foods — Producers of gourmet or specialty foods will find success with consignees that focus on high-quality, artisanal, or locally sourced products, such as specialty food shops, local farmers’ markets, or upscale grocery stores.

4. Check the consignee’s reputation and reliability

Research potential consignees thoroughly to ensure they have a solid reputation for fair dealings, good customer service, and effective sales strategies. Online reviews, business ratings, and even discussions with other vendors can provide valuable insights into a consignee’s business practices.

5. Consider the terms of the consignment agreement

Different consignees may offer varying terms for consignment deals, including the split of sales revenue, duration of consignment, and policies on unsold inventory. Look for terms that are favorable yet fair to both parties. Make sure that there’s a clear understanding of responsibilities regarding inventory loss, damage, and insurance.

6. Leverage technology and tools

Utilize technology solutions like inventory management software that offer features for tracking consigned inventory in real-time, managing multiple consignment locations, and analyzing sales performance. This can help you monitor which consignees are performing well and adjust your strategy accordingly.

Choosing the right consignee involves a careful evaluation of several aspects of your business and strategies. By selecting partners that align with your goals and technology to manage and analyze consignment performance, you can maximize the success of your consignment inventory strategy across various industries.

Example — a business with inventory on consignment

Cleanliness is next to godliness.

You’ve figured out how to make the most perfect bar of soap. But you’re having difficulty getting your product out there. Also, e-commerce has been unsuccessful since consumers can only see the product (not touch or smell — which is normal, it’s soap).

This is when you decide to reach out to a cosmetics store. You find one that you think would be a suitable match for your products. After some schmoozing with the owner, you eventually preposition them.

Thankfully they agree, and you quickly draft and sign contracts.

In the agreement, they said they would like 800 bars of soap, which they will hold for 3 months. Each bar of soap is valued at $15, and the store has agreed to pay you at the end of each month:

- First month: 800 – 115 = $1,725

- Second month: 685 – 375 = $5,625

- Third month: 310 – 310 = $4,650

Keep in mind this doesn’t have to be your only source of revenue. You can continue to trade via e-commerce with your own inventory at the same time. The consignee doesn’t own exclusive rights to your products — unless specified.

As this example illustrates, successful implementation of consignment stock can yield significant benefits to both parties. Unfortunately, hiccups might occur in your partnership, which is why you should be aware of the advantages and disadvantages for both parties.

Consignment inventory best practices

Accurate records

Keeping accurate records stands as the cornerstone of effective consignment inventory management.

It’s crucial to thoroughly track details such as the receipt dates of items, quantities sent, and sales transactions. This comprehensive tracking ensures the efficient management of your inventory, preventing complications that arise from inaccurate or missing data.

Implement a robust system to log critical information, including the identity of purchasers and the prices at which items were sold. Utilizing digital inventory management software can streamline this process, offering real-time updates and minimizing the risk of errors.

Fair pricing strategies

Determining the right price for consigned items is essential to attract buyers.

Your pricing strategy should reflect the market value, ensuring that the items are appealing to customers without undervaluing them. Consider incorporating discounts or promotional offers to boost sales.

These incentives can play a significant role in attracting customers, enhancing sales volume, and clearing out inventory more efficiently.

Organized inventory system

Organizing your consignment inventory is pivotal for smooth operations. An orderly system that enables quick identification and retrieval of items can significantly enhance operational efficiency, making the process of restocking and selling seamless.

Adopt inventory management tools that facilitate easy organization and tracking. Labeling, categorizing, and using software solutions can help maintain an organized inventory, saving time and reducing the potential for errors.

Enhancing sales and satisfaction

Ensuring a consistent supply of the right products leads to higher sales and improved customer satisfaction. It’s important to regularly review and adjust your inventory management strategies based on sales data and customer feedback to keep up with market demands.

By following these best inventory management techniques for consignment, you can ensure that the right products are always available. This will lead to increased sales and greater customer satisfaction. With the right management and inventory systems in place, you can maximize your profits and achieve success in the long run.

Advantages and disadvantages of using consignment

Unfortunately, hiccups might occur in your partnership, which is why you should be aware of the advantages and disadvantages for both parties.

Advantages for consignors

- Long-term business — If you have a strong relationship with your business partner, it can be a regular source of capital

- Established supplier with a bigger customer base — Your products will be with a seller who is already recognized and trusted by consumers

- Save on inventory costs — All or most of your products will be held by your customer, meaning you avoid the costs associated with storing inventory

- Restock according to sales — This will depend on your relationship with your partner, but if you have good communication with them, you can have a smooth flow of products between the businesses

- Reduce risk for new products or sales channels — New products can be slowly released through consignment inventory to analyze market demand. This also means it won’t affect other sale channels if products are sold via another medium

Disadvantages for consignors

- Increased cost for unsold inventory — If your consignee can’t shift the product, it will eventually be returned to you

- Uncertain cash flow — You won’t know how much capital from sales you’re gaining until your customer invoices you. You could be waiting until an entire batch is sold, or it could be determined some other way. Either way, you don’t get paid until your customer makes the sale. This makes tracking progress very difficult

- Carrying costs — You might lower the costs of storing inventory, but the products that are stored with your customer belong to you. Until the items are consumed or returned, you’re responsible for financing, damage, obsolescence, and theft

- Reconciling inventory — What happens if your customer says they sold only 100 bars of soap but actually 150? Or you make a delivery, but they claim that the items were stolen during transit. Regardless of if it’s true or not, you’re just going to have to take their word and foot the bills

That’s the consignor’s side of things, but what about consignees?

Advantages for consignees

- Minimal risk — Your customer is not stuck with the inventory. If they’re unable to sell the products for whatever reason, they can just return the items to you

- Lower price — Customers will be purchasing items in advance and in bulk, so they will be given a discount for doing the consignor a favor

- Reduce lead time — Purchasing the items in bulk means they’ll be able to get the stock on their shelves quicker

Disadvantages for consignees

- Increased risk of damaging inventory — The consignor inventory is stored among the consignee’s inventory, with no ideal way of monitoring the inventory. This can lead to stock becoming damaged while being moved around

- Increased chance of stock error — As mentioned above, the inventory isn’t a part of the business’s stock, meaning it must be monitored separately. This can be tedious and lead to errors as the inventory is essentially invisible

Consignment inventory isn’t without its risks.

But, if you’re a scaling business and believe that it would be more beneficial for your business to have the physical goods in front of your customers, it can be a viable supply chain strategy.

But, to reiterate the benefits for scaling companies who want to consider this process:

- Low inventory carrying costs

- Direct-to-retailer shipping

- Gets your products in front of more customers

If you can do it correctly and with a trustworthy consignee, it can be an extremely beneficial business arrangement.

Another pro is that you’re not in a business partnership either. If the consignor or consignee wishes to stop the agreement, they can! But if you don’t want the good times to stop, you and your consignee should be proactive.

There should be constant updates between you both, and you should be doing your own marketing campaigns to increase the likelihood of customers buying your products. As in any relationship, communication is the foundation of everything.

At the end of the day, you both want this deal to succeed!

Get a demo

Keeping track of inventory can be easy. See Katana in action and see learn thousands of businesses made the switch.

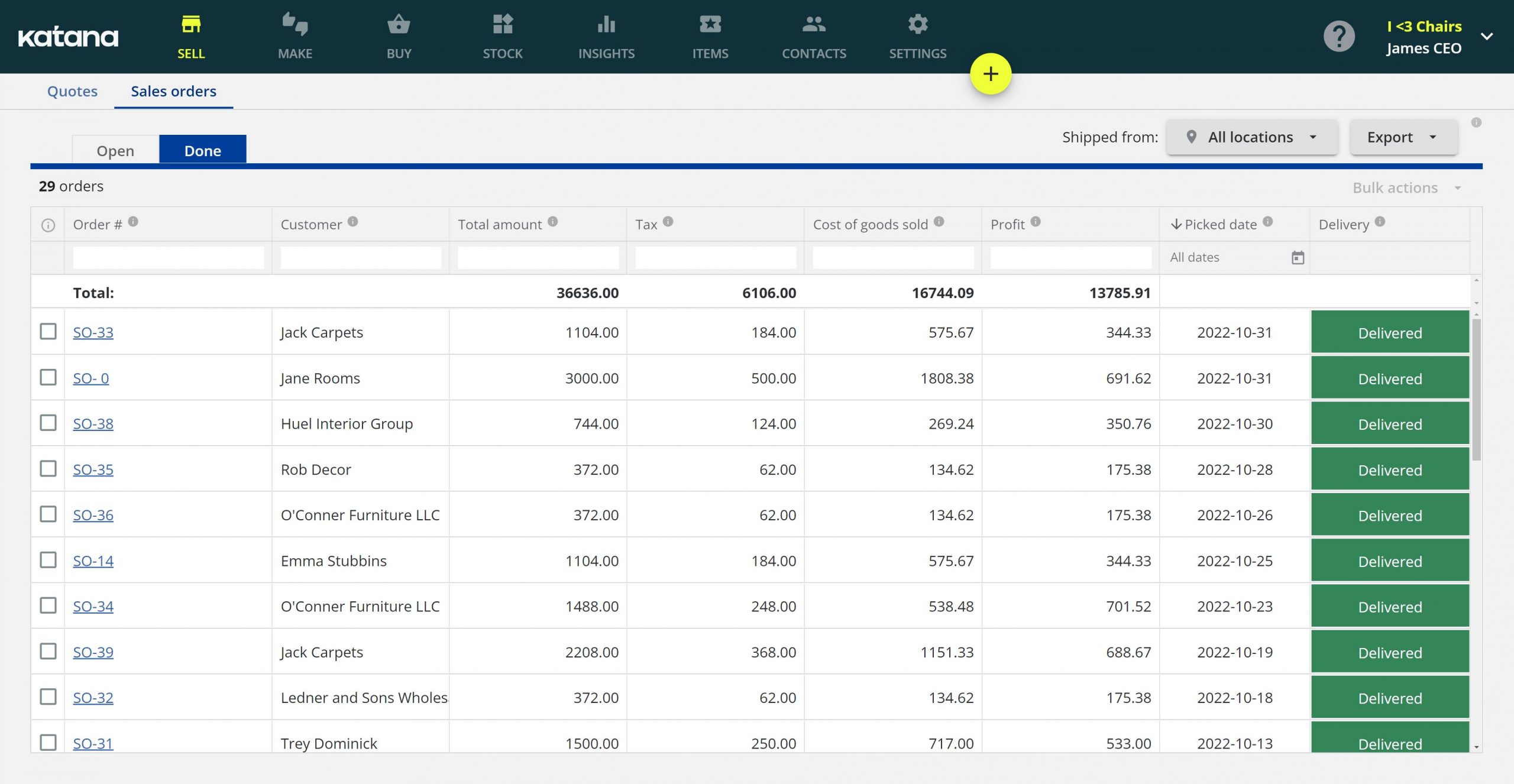

How to manage consignment inventory with Katana

Katana’s cloud inventory management software is the ultimate tool for businesses looking to centralize all their operations onto one easy-to-use platform.

Managing consignment inventory with Katana can streamline your operations, offering a blend of features tailored for consignment needs while also addressing broader business management requirements.

Here’s how:

Real-time inventory tracking

Katana provides live inventory management, allowing businesses to keep accurate track of consigned inventory levels. This feature ensures that you always know how much stock you have at consignment locations, helping to prevent stockouts or overstocking.

Multilocation management

With Katana, you can manage your consignment inventory across multiple locations seamlessly. This capability allows for efficient distribution of products to various retailers, ensuring that your consignment stock is optimally placed to meet demand.

Order management

Katana simplifies the management of sales orders, including those fulfilled through consignment inventory. This helps in quickly updating inventory levels as sales occur, providing visibility into which products are selling and where.

Production management

For businesses that manufacture and distribute their own goods, Katana offers production planning and scheduling tools that integrate with inventory management. This ensures that production is closely aligned with demand, including demand from consigned inventory, reducing waste and improving efficiency.

Centralization

Katana acts as a central hub for all your business operations, integrating inventory, sales, and production in one platform. This centralization provides a holistic view of your business, allowing for more informed decision-making and streamlined processes.

Integrations

With a wide range of integrations, Katana connects with platforms and software that allows you to manage:

- E-commerce with Shopify and WooCommerce

- Accounting with QuickBooks and Xero

- Shipping

- Other business aspects by creating your own workflows with Katana’s open API

This versatility means you can manage not just consignment stock but also direct sales, online orders, financials, and shipping logistics from a single system.

By leveraging Katana, businesses can not only manage consignment inventory more effectively but also improve overall operational efficiency. Katana’s focus on real-time data, centralization, and versatility in business operations makes it a powerful tool for businesses looking to optimize their inventory management and production processes.

But don’t just take our word for it. Book a demo with our team of experts and witness firsthand how Katana can take your business to the next level.

Table of contents

Inventory management guide

More guides from Katana

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control