What is an order management system?

Henry Kivimaa

Imagine you run a bustling online retail store, Vintage Visions, specializing in retro clothing and accessories. When you first launched, enthusiastic about the venture, you decided to manage orders using spreadsheets. It seemed straightforward enough. After all, how complicated could it get? As it turned out, quite complicated!

Initially, with only a handful of orders each day, this system worked well enough. You had a spreadsheet for orders, another for inventory, and yet another for shipping information.

However, as Vintage Visions grew in popularity, the cracks in this system began to show. The spreadsheets became a tangled mess, difficult to navigate, and even harder to keep updated. Mistakes became more frequent — an item marked as ‘in stock’ would suddenly be out of stock when you went to retrieve it, or an order would get misplaced in the digital shuffle, leading to delays and unhappy customers.

You realized you spent more time managing spreadsheets than focusing on business growth or customer needs. It became clear that the makeshift system was not only slowing you down, but also impacting customer satisfaction and, ultimately, the bottom line.

This article is all about order management systems, a way to transform the chaos of spreadsheet management into a well-oiled machine. We’ll see what order management systems are, processes, benefits, best practices, and much more.

What is an order management system?

An order management system (OMS) is a software platform designed to help businesses manage and track the entire lifecycle of their orders. The system integrates with various sales channels, such as e-commerce websites, marketplaces, point-of-sale systems, and more, to automate and streamline order processing and fulfillment.

The primary purpose of an OMS is to provide a centralized system for managing orders, inventory, and customer data. It allows businesses to monitor and track orders in real time, from the point of sale through to delivery, so they can quickly identify and resolve any issues that may arise during the process.

An OMS can be particularly useful for businesses that have opted for multichannel selling, have a high volume of orders, or operate in complex supply chains. It can help reduce errors, improve order accuracy, and provide a better customer experience by ensuring timely and efficient order processing and delivery.

While the general function of order management systems remains the same, there are some differences depending on the exact industry and business practices. Let’s take a look at two examples.

Order management system for manufacturing

In the manufacturing sector, an order management system is pivotal for streamlining the complex process of producing goods from raw materials to finished products. It integrates closely with supply chain management systems to ensure that inventory levels are accurately maintained, reducing the risk of overproduction or stockouts.

Order management system for manufacturing facilitates the scheduling of production runs, considering the availability of materials, machinery, and labor. It also enables manufacturers to track the progress of orders through various stages of production, quality checks, and final dispatch.

The system provides real-time data, which aids in forecasting demand, planning for future production needs, and optimizing resource allocation. Furthermore, it enhances communication between sales, production, and distribution teams, ensuring that customer requirements are accurately translated into production plans and that finished goods are delivered on time.

Order management system for e-commerce

For e-commerce businesses, an OMS is crucial for managing the online ordering experience, from the moment a customer places an order to the final delivery. This system handles various facets of the e-commerce operation, including inventory management across multiple warehouses or fulfillment centers, processing payments, updating order statuses, and initiating returns or exchanges.

A key feature of an e-commerce OMS is its ability to provide a seamless omnichannel shopping experience, allowing customers to purchase online, through mobile apps, or in physical stores, with consistent inventory visibility and customer service. It automates the routing of orders to the most appropriate fulfillment center based on factors such as stock availability and the delivery location, optimizing shipping costs and times.

Additionally, an e-commerce OMS integrates with customer relationship management (CRM) systems to personalize the shopping experience, offering recommendations and promotions based on past purchasing behavior. This integration improves customer satisfaction and drives repeat business and loyalty.

What is the difference between EMS and OMS?

An enterprise management system (EMS) refers to a broad suite of software applications designed to manage the core processes of a business, including finance, supply chain, operations, reporting, production, and human resource activities. It aims to improve efficiency and streamline the management of the entire organization.

On the other hand, an order management system specifically focuses on the tracking and management of orders, from inception to fulfillment, dealing with the lifecycle of an order, inventory management, customer service, and the ordering process itself. While an OMS can be a component of an EMS, an EMS encompasses a wider range of business functions beyond order management.

What does an order management system do?

An OMS typically offers features such as order processing, multilocation inventory management, shipping and logistics management, customer management, and reporting and analytics. With these features, businesses can manage inventory levels, track shipping and delivery status, manage production processes, update customer information, and generate reports to gain insights into their sales performance.

Some of the core functions of an OMS typically include the following:

- Order processing — This includes processing sales orders, creating new ones, tracking the status of existing orders, and updating order information as necessary.

- Shipping and logistics — You can use OMS to automate the shipping process by calculating shipping costs, generating shipping labels, and tracking the shipment of orders.

- Customer management — An OMS can store customer information, including order history and shipping information, and enable customer service representatives to view and update this information as necessary.

- Inventory management — Businesses can use an OMS to track their inventory levels in real time, so they can quickly identify low stock levels and avoid stockouts.

- Reporting and analytics — An OMS can generate reports on order and inventory data, providing businesses with insights into their sales performance and inventory levels.

Overall, an OMS can help businesses improve their order processing, reduce errors and delays, and provide a better customer experience.

The order management process, explained

The order management process involves various steps that a business follows to process an order, from receiving to delivering it to the customer. The process may differ slightly depending on the specific business and industry but generally includes the following 7 steps:

- Order placement — The first step in the order management process is when a customer places an order through a business’ sales channels, such as a website, marketplace, or in-store.

- Order capture — The business captures the order information, which includes the customer’s name, shipping address, product details, and payment information. This information is typically stored in an order management system.

- Order processing — The OMS processes the order, which involves verifying the customer’s information, checking the inventory for the requested products, and calculating the total order cost, including any taxes or shipping fees.

- Order fulfillment — Once it’s processed, the business proceeds to fulfill the order. This step may involve picking and packing the products, generating shipping labels, and arranging for the order shipment.

- Shipping and delivery — The order is shipped to the customer using the chosen shipping method, and the customer is provided with a tracking number to monitor the delivery status.

- Order tracking and updates — The OMS tracks the order status, updates the inventory levels, and provides updates to the customer on the order progress, such as estimated delivery time and any delays.

- Order confirmation — Once the order is delivered, the customer is notified, and the order status is updated in the OMS. The customer may be asked to confirm the delivery and provide feedback on their purchase experience.

6 benefits of using an order management system

Now that you have a good overview of order management systems, their basic functionality, and how they work. Let’s move on to the benefits of adopting an order management system.

1. Efficiency through automation

You might be the lord and master of spreadsheets, but unfortunately, you won’t be able to outperform inventory automation.

Effective order management can help you save money on manual labor, decrease the risk of human errors, and free up time so you can refocus your priorities on growing your business and improving customer satisfaction.

2. Around-the-clock access

If you suddenly wake up in a nervous sweat and want to quickly check your orders for peace of mind, without order management system, it will be a sleepless night for you. Getting set up with cloud inventory software, especially one with order management capabilities, allows you to check your orders from any place at any time.

Other than settling any paranoid thoughts about your order management being out of whack, this instant, 24/7 access allows for greater data control, improved customer services, and a more efficient order management process.

3. Growth

Your order management system automates your order processes. More importantly, it takes all your sales channels into one single platform. This smooth automated process will run in the background, so you can free up time to collect and analyze data.

Invaluable free time to gather this information allows you to intelligently identify improvement areas and plan for further growth.

4. Inventory management

Order management solutions will greatly improve your inventory management by giving you real-time information on current stock levels, and items sold, returned, exchanged, or in production. This helps you avoid over-selling inventory or ordering too much and unnecessarily increasing your carrying costs.

5. Centralize your business

As touched upon earlier, using an order management system allows businesses to not only manage their sales channels in one place but their entire business.

An order management system will break down complex information to simplify your orders into one place, protecting you from order errors, customer dissatisfaction from delays, lost revenue from low inventory, and incorrect invoicing.

6. Real-time information

Finally, and once again touched upon in the earlier points, real-time information about your business performance with an order management system is critical for growth. Having live updates on inventory and sales is going to help you react to any issues immediately with your automated order management rather than allowing problems to develop and for the customer to be left dissatisfied.

Alongside this, having all your information in real-time means the inventory, orders, and payment data are all up to date and in sync.

What are the 5 best practices of order management?

How can you start streamlining your order management operations and unleash the full potential of your business? Here are 5 best practices for effective order management to get you on the path to success:

- Streamline order processing — One of the best practices for effective order management is streamlining the order processing workflow. This can involve automating various order management tasks, such as order capture, processing, and fulfillment. By streamlining these processes, businesses can reduce the risk of errors and ensure a faster, more efficient order fulfillment process.

- Centralize order information — This can be achieved through the use of an order management system, which provides a centralized hub for order information, including order details, shipping information, and customer information. By centralizing this information, businesses can more effectively manage orders, reduce errors, and improve order fulfillment speed.

- Maintain accurate inventory — Effective order management requires maintaining accurate inventory levels. This involves regular inventory checks, cycle counting, and real-time inventory updates. By keeping accurate inventory levels, businesses can fulfill orders more quickly and accurately, improving customer satisfaction.

- Prioritize order fulfillment — Another best practice is to prioritize order fulfillment based on order volume, shipping requirements, and other factors. By prioritizing orders, businesses can ensure that orders are fulfilled promptly and efficiently, reducing the risk of order cancellations or dissatisfied customers.

- Monitor order performance — The final best practice for effective order management is regularly monitoring order performance. This includes tracking order fulfillment times, shipping times, and order accuracy. By monitoring order performance, businesses can identify areas for improvement and optimize their order management processes to improve order fulfillment speed, accuracy, and overall customer satisfaction.

When do you need an order management system?

In the early days of your business, handling orders was pretty easy. You can probably even recall your first, from the customer’s information to the product you sold, and even how you delivered it. But with each new sale, you’ll lose that magic you once felt as more and more sales roll in. And the quicker you grow your brand and reputation, the faster the number of sales your business handles increases.

In this make-or-break moment, if you’re unable to fulfill the increasing orders, you will do more harm than good.

At this stage, it’s important to find the perfect order management software. There are certain things to look for when choosing an OMS system, so let’s go over them to ensure you don’t have to start looking for a new one in the near future.

How to choose the right order management system

There are so many options available on the market right now, that it can be tricky choosing an order management system that’s just the right fit for your business.

But don’t worry, we’ve got your back. We’ve put together a checklist that you can follow to select the perfect order management software for your small business or a large one, depending on your exact needs.

Your budget

Your order management system is going to be a crucial ally in your business’ success. You might commit to a cheap system to save money, but it will cost your business much more in the long run.

The same can be said about the other extreme. Some systems can cost tens of thousands, but if you only end up using 20% of the features, it’s not a good use of your resources.

Be realistic with the amount you’re willing to spend, as most systems will charge different rates depending on what you need, so be sure to compare the market.

Compare the market

There are a lot of order management systems targeting a specific type of company or industry. There’s no one-size-fits-all tool you can just pick out at random. Be sure you know what are the strengths and weaknesses of each system and evaluate what’s the most important to you. Review sites can be a good resource if you want to hear from people who actually use the system daily.

Integrations

At the end of the day, you’re probably using certain applications and would like to keep using them. Your best bet is to choose an order management system that can integrate with your existing e-commerce, accounting, and other tools your business has decided to adopt.

After you’ve made your list of the order management systems you want to use, explore their integration features to see if they support all your sales channels. But be warned, many order management solutions can charge you extra for additional integrations.

Demos and trials

Following the points above, you should now have a list of different order management systems that:

- Are reasonably priced

- Can integrate with your other software

- Can support different types of processes

- Are the right fit for your specific type of business

Go through each piece of software and ask for a demo to see if the OMS is suitable for your business.

Some software providers offer a live step-by-step integration session, using your business as an example, so you can see firsthand how their order management solutions can benefit you.

Katana, your order management system partner

Katana is a cloud-based inventory and order management platform that helps thousands of retailers, distributors, wholesalers, manufacturers, and e-commerce firms get a live look at their business. It comes with features built specifically for businesses looking to get more control over their:

- Order management

- Inventory management

- Inventory planning

- Production management

Finding an order management system that ticks all the boxes for your business can be a challenge, because there are so many options to choose from. Luckily, Katana can be your one-stop shop, fulfilling all of your inventory and order management needs in one easy-to-use solution. These are just some of the features you get when you partner with Katana:

Multilocation inventory management

Do you have warehouses or inventory stored here, there, and everywhere? Not a problem! Maybe you even have inventory on consignment, with an outsourced manufacturer, or sat at another location, Katana allows you to track each location. This way, you have a clear overview of your entire inventory, regardless of where it’s stored.

Running low on inventory in one location but got some spare at another? Perform a stock transfer and have the issue solved with just a few clicks.

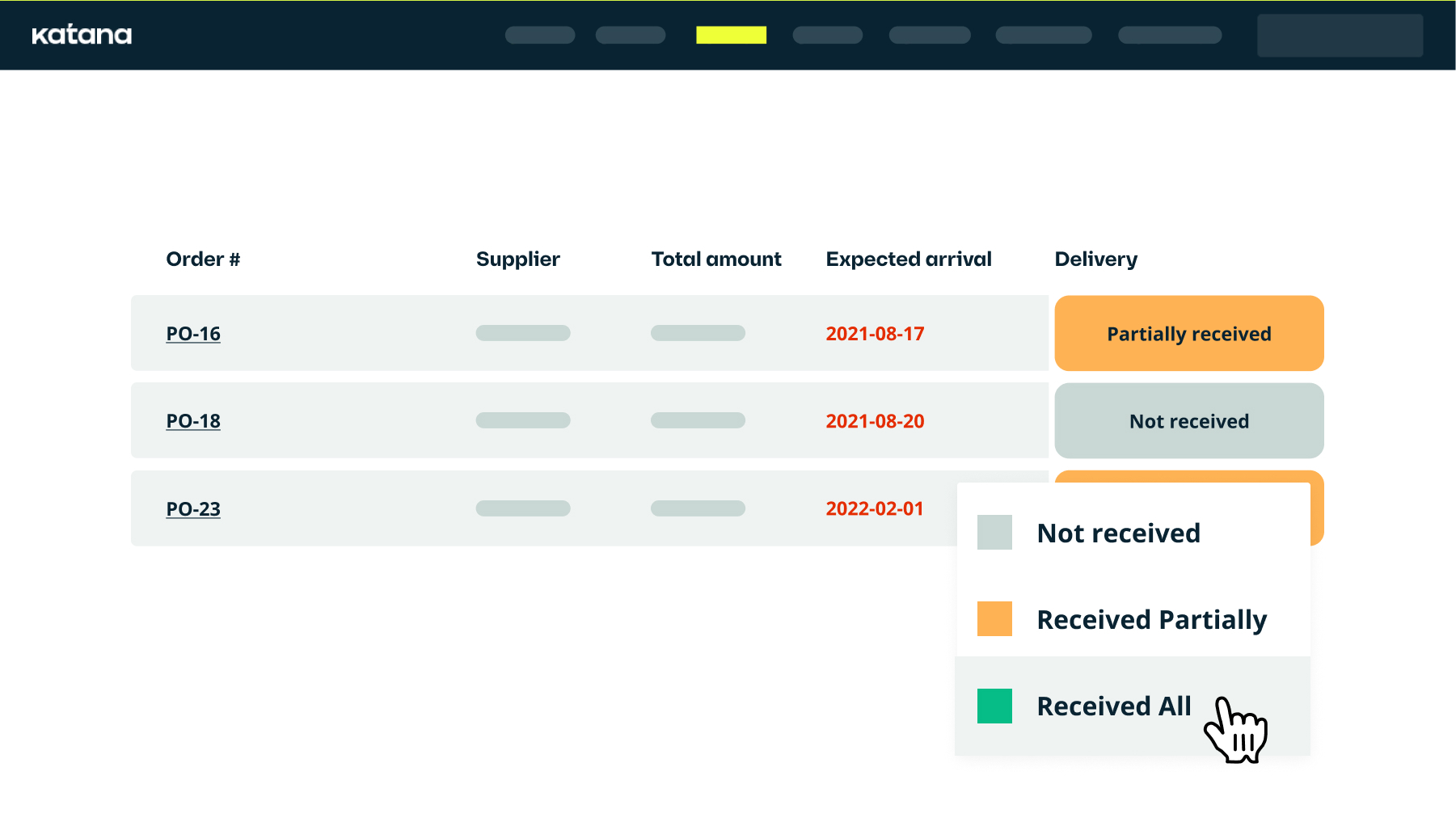

Purchase order management

Sometimes, your orders don’t arrive together, and you can quickly forget some are on the way and order items you don’t need. Katana’s order management system allows you to partially receive deliveries, so you and your team members know more is on the way.

Inventory planning

Use historical sales data to forecast demand and plan accordingly. Take complete control of your inventory with demand-based restocking suggestions, safety stock levels, and much more.

Integrations

Katana offers seamless integration with the best platforms out there, including e-commerce and accounting software such as:

Request a demo now to see Katana in action!

Order management system FAQs

No, an enterprise resource planning (ERP) system is not the same as an order management system.

An ERP system is an integrated software suite that helps businesses manage various aspects of their operations, including finance, accounting, human resources, manufacturing, and supply chain management. An ERP system provides a centralized database for managing data and automating business processes, helping businesses to improve efficiency and reduce errors.

On the other hand, an OMS is a specialized software system that manages and processes orders from multiple sales channels, including e-commerce websites, marketplaces, and brick-and-mortar stores. An OMS provides features such as order processing, inventory management, shipping and logistics management, customer management, and reporting and analytics.

While some ERP systems may include order management as one of their features, they do not provide the specialized functionality of a dedicated OMS. An OMS is designed specifically to manage the complexities of order processing and fulfillment across multiple sales channels, providing businesses with a centralized hub for managing order data, inventory levels, and shipping logistics.

While ERP and OMS systems share some similarities in terms of their focus on streamlining business operations and improving efficiency, they are different types of software systems with different functionality and purpose.

Yes, OMS can integrate with other systems, such as e-commerce platforms, marketplaces, and shipping carriers, through Application Programming Interfaces (APIs) or pre-built integrations.

OMS can integrate with different systems to ensure that data flows seamlessly between different parts of the order management process, improving efficiency and reducing errors. For example, an OMS can integrate with an e-commerce platform such as Shopify or BigCommerce to automatically import orders and update inventory levels. It can also integrate with accounting software like QuickBooks Online and Xero for invoicing and other financial tasks.

By integrating with other systems, an OMS can provide a complete and real-time view of inventory levels, order statuses, and business financials, helping companies make better decisions and improving the overall customer experience. It can also help businesses scale their operations and streamline their workflows.

An order management system and a customer relationship management system serve distinct functions within a business, focusing on different aspects of customer interactions and operational processes:

- Order management system — Primarily concerned with the efficient management and processing of orders. It tracks orders from inception to fulfillment, handling inventory management, order entry, processing, dispatch, and delivery. The goal of an OMS is to streamline and automate the order fulfillment process, ensuring that products are delivered to customers efficiently and accurately. It deals with the logistical aspects of completing sales, including the management of supply chains and integration with shipping services.

- Customer relationship management — Focuses on managing a company’s interactions with current and potential customers. It is designed to improve relationships, specifically helping businesses stay connected to customers, streamline processes, and improve profitability. A CRM system compiles data from various channels, including the company’s website, phone, email, live chat, marketing materials, and, more recently, social media. It allows businesses to analyze customer interactions and data throughout the customer lifecycle, with the goal of improving business relationships with customers, assisting in customer retention, and driving sales growth.

In summary, while an OMS manages the order flow and fulfillment processes, a CRM system is centered on managing the company’s relationships and interactions with customers and potential customers.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control