How to master wholesale order management with the right software

A well-integrated wholesale order management software is vital for the success of your business. Learn more about wholesale orders, the challenges of bulk selling as a manufacturer, and how to overcome them.

Tejas Shah

Managing wholesale orders without software can be difficult. With multiple sales channels and complex supply chains, relying on manual tools like spreadsheets increases the risk of human error. As you scale, wholesale order management solutions can help streamline the process and solve your inventory management problems.

In this article, we explain what wholesale order management is, the different software products that streamline operations like wholesale inventory management software, and how you can leverage them to take your business to the next level.

What is a wholesale order management solution?

A wholesale order management software allows you to:

- Manage and track bulk orders

- Bring orders from all your sales channels together

- Synchronize the orders with your wholesale inventory in real time

- Leverage the power of the tools you already use to manage your business

Each aspect listed above adds a layer of complexity to already complex manufacturing workflows. In addition to order management the software you pick should also be able to handle:

Before we dive into more details about wholesale orders, let us make a brief detour to understand the different steps related to order management.

The order management process simplified

Every order that is created needs to go through the following steps to be completed:

Order placement

The lifecycle of an order starts when your customer decides to place an order using your preferred sales channel. This can be directly from consumers via a webshop hosted on an e-commerce platform, or if you’re doing B2B e-commerce, entered through a CRM tool via email or a call.

Fulfillment

Then depending on the order, the product information is forwarded to the right warehouse for packing and shipping. If you’re a manufacturer, this step also involves the production of the goods sold.

Accounting

Once the order is fulfilled, the transaction as well as associated costs need to be accounted for.

Shipping

In this final step of an order’s lifecycle, the products are shipped and delivered to the customer.

Wholesale vs. retail order management

Depending on your business model you might start catering to larger orders. These bulk orders are fundamentally different from those you would complete as a retailer or direct-to-consumer manufacturer. The major difference is the type of customer making the order.

Retail orders are usually completed by private consumers, meaning that they are small and tend to include a range of different products. On the other hand, wholesale orders come from wholesale businesses looking to purchase manufactured goods at scale, then sell them to retailers or consumers themselves. Manufacturers today use a combination of B2B and D2C sales channels, allowing them to cater to both retail and wholesale customers. However, wholesale order management comes with a unique set of challenges.

Things to consider when selling to wholesale customers

Let us take a look at the challenges you might face when you shift towards wholesale supply and order management, and how the right software can help you overcome them.

Out of sync inventory

With orders coming in from multiple channels, it is important that all your sales channels have a unified view of your inventory and stock levels. Without a proper inventory management system, there is a high chance that you will commit to a large order only to find out that you are out of stock. There is no better way to ruin customer trust than to backtrack on an order commitment — especially a large one.

Compared to direct-to-consumer sales, the cost of making a mistake when dealing with B2B commerce skyrockets. This is where inventory management software automatically updates and syncs your inventory across warehouses based on all your sales channels can help.

Lack of inventory control

With retail and small order volumes, you can manage your stock with just an intuitive understanding of customer demand and some basic inventory management techniques like spreadsheets or a whiteboard.

At some point this no longer works — specifically, when order sizes and volumes go up, making it difficult to keep track of all the moving parts. So, it is a great idea to pair your intuition with the power of automated tools. Some inventory systems come with forecasting tools that predict your required inventory counts ahead of time based on historical sales data. Additionally, it can also allow you to set reorder points for your products so you never run out of stock.

Not able to prioritize orders

All orders are not created equal. Depending on the needs of your business and customers and the stock at hand, you might have to reprioritize large orders. Changing priorities means that the changes need to cascade into all the affected orders — meaning a domino effect of changes.

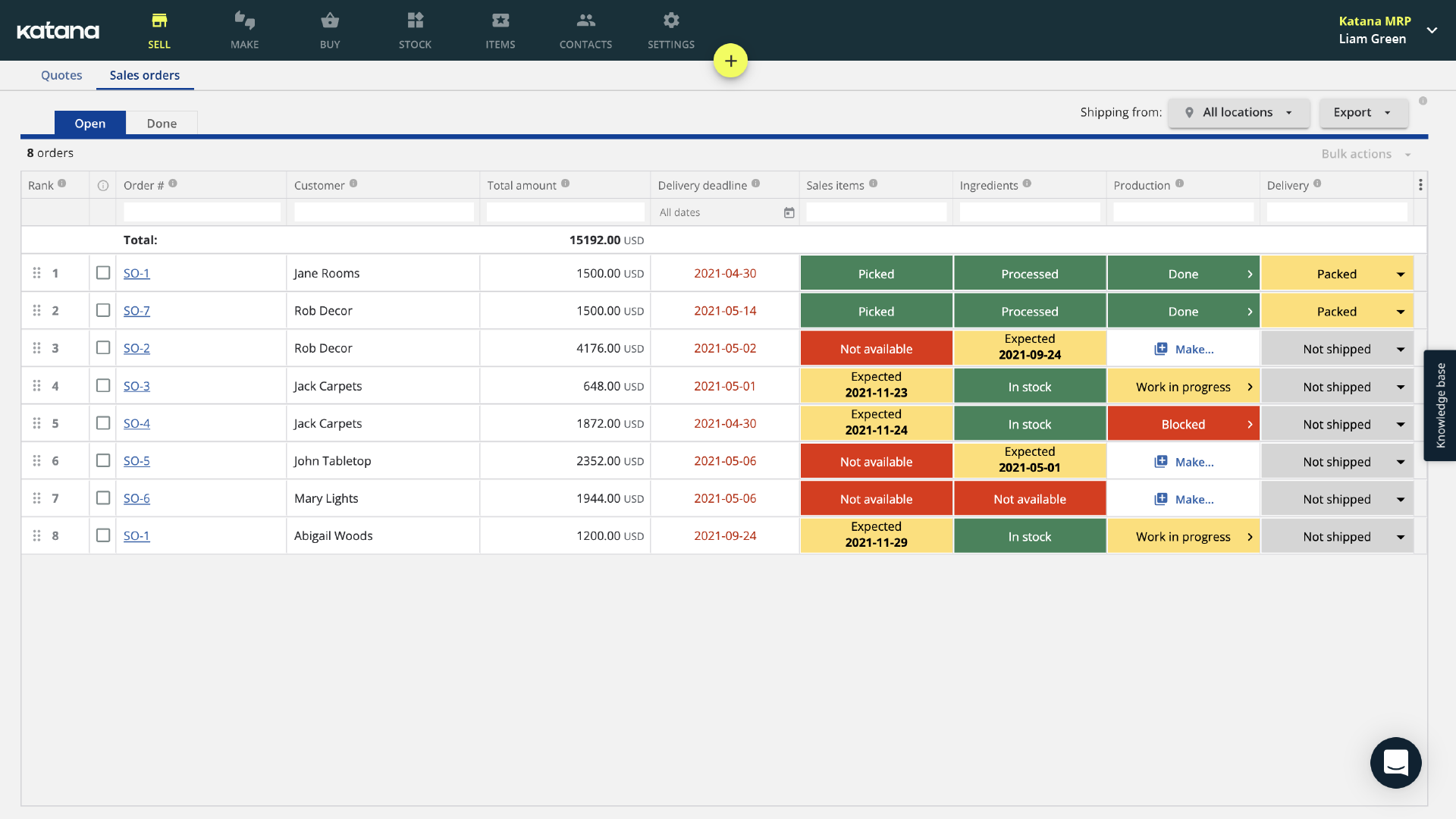

Real-time master planning, a feature included in order management software solutions and manufacturing ERPs, automates the reprioritizing of orders based on inventory and sales data. Having a central tool for both order fulfillment and manufacturing centralizes both sales order information and maps them according to what materials and products you have available. This ensures that orders are completed as quickly as possible with minimal delay.

Setting wholesale prices

Prices of retail orders compared to wholesales orders of the same goods tend to be higher, as they take into account higher overhead costs of advertising, shipping, and storage. When it comes down to it, wholesale customers expect a lower price given the large volume of business that they bring you — economies of scale and all that.

There are plenty of pricing strategies that you can consider when figuring out price lists for wholesale orders. To do this, you would need to have a system that ensures accurate costing so you avoid short selling your products and incurring losses when dealing with wholesalers.

The benefits of ERP software for wholesale manufacturers

When shifting towards wholesale customers, and especially when adding them to an existing retail sales channel, not having wholesale inventory software that accommodates both in tandem can result in many costly mistakes.

With live inventory management, omnichannel order management, native integrations with e-commerce platforms, and an open API for custom workflows, Katana’s cloud inventory software helps you handle bulk orders with ease. Thousands of manufacturers use Katana to optimize business operations and keep track of costs, inventory, sales, and order fulfillment — request a demo today.

Tejas Shah

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control