Wholesale inventory management: take charge of your stock

Manually managing wholesale inventory for your business is no easy feat. Read about the ins and outs of the wholesale inventory management process and learn about the tools that can make your inventory control woes a thing of the past.

Tejas Shah

With great orders come great inventory management responsibilities — even more so with a wholesale selling strategy.

A sudden surge in sales can completely clear out your stock if you are underprepared. Thankfully, there are powerful software products available that will help you carry out these responsibilities with ease.

What is wholesale inventory management?

Wholesale inventory management refers to the stock management techniques that you use to optimize your manufacturing workflows to better suit large product volumes.

A business ready to supply bulk orders can grow at a remarkable speed. However, it involves thinking volume-first and optimizing your supply chain, production, sales, storage, and distribution logistics to handle larger quantities of products and materials.

Wholesale inventory management covers a wide range of activities, such as:

- Bulk purchases of inventory

- Tracking your inventory levels across multiple warehouses

- Synchronizing on-hand inventory for multiple sales channels

- Optimizing warehouse management and storage

- Calculating and setting up reorder points to replenish critical inventory

- Accounting and invoicing for both inbound and outbound products

With so many variables at play in this process, it can be quite hard to keep track of it by hand. Of course, it can be done with some smart inventory management techniques and excel spreadsheets. That, unfortunately, doesn’t scale. It also leaves room for a lot of mistakes as spreadsheets are time-consuming to maintain, prone to errors and file corruption, and are usually managed by one admin. When it comes to wholesale businesses in particular, those mistakes can end up being extremely expensive.

Clearly, an excel spreadsheets solution and other manual techniques simply fall short in helping you unlock the true value of your wholesale distribution. So, in order to grow your wholesale business, you should consider setting up a wholesale inventory management system.

Why is wholesale inventory management important?

Let’s say that you do not have a wholesale inventory management system and that your workflows rely on a system of inventory tracking spreadsheets. This works well when your team is small and communication about on-hand inventory is quick and easy. However, once your volumes grow and your team starts to expand, challenges start to multiply as well.

For instance, once you have a couple of warehouses to store your inventory, you need a way to track your inventory across those warehouses. With orders being fulfilled and inventory being returned, damaged, or lost, you need an effective way to know where your raw materials and finished products are in the lifecycle of an order.

Additionally, all your sales channels need to have a singular view of the inventory counts of your products. If they don’t, you could end up overselling products and committing to orders which will inevitably get delayed. Needless to say, this damages customer trust and is bad for your brand reputation.

These are just some of the challenges you may face with multiple warehouses and sales channels. In order to increase profitability, it is important to keep the inventory moving and your stock at optimal levels. It is essential to understand your customers’ needs and have an effective way to forecast demand for different time periods.

Forecasting is a tough problem to solve without reliable inventory management solutions. Good wholesale inventory management tools often come bundled with historical data tracking and allow you to avoid overstocking and stock shortages with this information.

Scaling your business and handling the challenges presented as volumes grow can be tough, especially when it comes to bulk orders. An inventory management software for wholesale makes it possible to handle a lot of these complexities while streamlining your business operations.

Benefits of wholesale inventory management software

Optimizing your wholesale inventory comes with a lot of benefits beyond profitability. Let us take a look at the top three advantages of adopting a wholesale inventory software solution.

1. Greater inventory control

An inventory management solution gives you an overview of your materials and products and, as a result, greater inventory control. Having an inventory management system in place allows you to track your purchase orders, product sales, and inventory items across multiple warehouses in multiple currencies.

Some inventory systems come bundled with functionalities that enable smart inventory management techniques. For example, with historical data about your purchase orders and integrations with customer demand forecasting tools, wholesale inventory management software can help you predict required inventory counts ahead of time.

Additionally, wholesale management software can also allow you to set reorder points for your raw materials to minimize stockouts.

2. A unified overview of your business

When implementing an inventory software solution, you connect and tie in all the moving parts of your business beyond inventory.

As mentioned earlier, when your order volumes grow and when you sell your products through multiple channels, it is important that every team has access to the same stock data. This reduces the risk of overstocking raw materials and overselling your products. In the same system, you can also keep track of sales order progress as well as manufacturing progress.

3. Ability to reprioritize orders

Business needs are dynamic and are constantly changing. An inventory management tool allows you to adjust your business processes according to shifting priorities and the resources you have available.

You could have landed a large make-to-order sale and now need to redistribute resources, or a customer could have changed or canceled their order. These changes in priorities need to be accounted for, and your workflows need to adapt quickly to accommodate them. Factoring in these changes manually can be painful and result in costly mistakes.

Real-time master planning features often included in wholesale inventory control and inventory management systems help automate this reprioritizing of orders based on inventory and sales data. This minimizes lead time and ensures that your orders are completed as quickly as possible.

Download the ultimate guide to inventory management

A comprehensive ebook with everything you need to know about inventory management.

Challenges of wholesale inventory management

While wholesale inventory management has its perks, it doesn’t come easily. There are some obstacles to climb before you can conquer the peak of that mountain, but if addressed wisely, you should have no problem jumping those hurdles with ease.

Large volumes of products

Having control over large quantities of goods can be difficult, especially if those products are distributed across multiple locations and warehouses. Manually tracking those items can quickly become overwhelming, if not impossible, to do accurately.

This is where wholesale inventory management systems and software come to the rescue. Automating and streamlining your processes can help track inventory levels, orders, sales, and deliveries in real time.

Additionally, adopting strategies like just-in-time inventory can minimize holding costs and reduce waste. Efficient warehouse organization and barcode scanning can also improve data and inventory management accuracy, speeding up your processes significantly.

Accurate forecasting

Forecasting demand is a complex challenge due to factors like market trends, consumer behavior, seasons and holidays, and, of course, the economy.

Overcoming this requires extensive research, diving into historical sales data, market analysis, and utilizing trend forecasting tools.

Collaboration between sales and marketing teams to understand necessary activities and market dynamics is crucial. Regularly update your forecasts based on real-time data and market feedback to adapt to changes as quickly as possible.

Maintaining optimal stock levels

Stocking requires a delicate balance between having enough inventory to meet demand and avoiding overstocking, which can increase your holding costs and waste.

Strategies to achieve this include implementing software solutions for real-time tracking, forecasting and planning demand, and setting reorder points. Regularly review your inventory performance and adjust strategies based on actual data and market conditions to ensure that your current stock levels are sufficient and not excessive.

Changes in supply and demand

Adapting to fluctuations involves agile inventory management and responsive planning.

This includes closely monitoring market trends, customer behavior, and supply chain dynamics. Employing flexible inventory strategies, such as safety stock and demand forecasting, can help manage these fluctuations effectively.

Strengthening relationships with multiple suppliers for diversification and employing technology for real-time data analysis are also vital in adjusting quickly to changing market conditions.

Integrations

The biggest challenge in integrating technology solutions like inventory management software for wholesale with existing systems (accounting, CRM, e-commerce, etc.) is ensuring compatibility, data accuracy, and seamless operation.

It requires careful planning, data migration strategies, and, often, custom development to ensure all systems communicate effectively.

Overcoming these challenges involves thorough testing and possibly engaging with integration specialists to ensure a smooth transition and real-time data synchronization across all business operations.

Delivery time

Managing deliveries involves handling logistics, coordinating with suppliers and transportation providers, and adapting to unforeseen delays.

The main challenges include handling logistical complexities, managing inventory levels to meet demand without delays, and dealing with external factors such as transportation disruptions.

To overcome them, it’s important to establish reliable logistics partnerships, implement efficient order processing systems, and maintain clear communication channels for real-time adjustments to delivery schedules.

Logistics

Inventory logistics means coordinating the movement of goods efficiently from suppliers to warehouses, retailers, and customers. This includes optimizing routes, managing warehouse operations, and dealing with customs for international shipments.

Challenges arise from the complexity of coordinating multiple shipments, ensuring timely customs clearance, and adapting to any disruptions.

Some strategies to address these obstacles include using logistics software for route optimization, establishing solid relationships with your logistics partners, and maintaining a flexible inventory strategy to adapt to interruptions.

Best practices in wholesale inventory

The high demands of today’s market call for equally high standards in your operations.

It’s about finding the sweet spot between using the latest tracking technology and staying nimble in your strategies. Learn more about practices that can transform your operations and keep you ahead in the game.

Real-time tracking technology

Make the most of all the technology available to you and your team. Online inventory systems provide immediate updates on stock levels, order statuses, and shipment tracking.

This enables businesses to monitor their inventory across multiple locations, make informed restocking decisions, and respond quickly to customer demand. Tracking software enhances efficiency, reduces the risk of manual errors and stock level miscalculations, and improves overall customer satisfaction by ensuring accurate and timely order fulfillment.

Demand forecasting

Demand forecasting in wholesale inventory management involves using historical sales data, market trends like seasonality and holidays, and predictive analytics to estimate future customer demand. This process helps make informed decisions about stock levels, inventory costs, and sales opportunities.

Accurate demand forecasting enables businesses to optimize their inventory, reduce the risk of stockouts or excess inventory, and improve supply chain efficiency.

Optimized warehouse operations

Streamline processes for receiving, storing, picking, and shipping goods efficiently.

Key practices for this include implementing a practical warehouse layout that reduces handling times, adopting automation technologies like conveyor belts or robotic pickers, and utilizing warehouse management systems (WMS) for better inventory control.

Regularly training your staff on best practices and safety standards, along with continuous process evaluation and quality control, are essential to enhance productivity and reduce operational costs.

Strong supplier relationships

Collaboration with suppliers involves establishing clear communication, setting mutual expectations, and developing trust. It includes negotiating favorable terms for both sides, ensuring timely deliveries, and maintaining quality standards.

Solid relationships can lead to more flexible arrangements, such as better pricing, priority delivery, and access to exclusive perks and products. Regular performance reviews and feedback can help identify areas of improvement and strengthen partnerships.

Using technology to streamline order processing and communication can also enhance supplier relationships.

Efficient order processing systems

Implementing efficient order processing systems in wholesale involves automating and streamlining the steps from order receipt to fulfillment.

This includes integrating e-commerce platforms with inventory management and logistics systems to ensure accurate, effortless, and live data flow. Automation helps reduce manual errors, speed up order processing times, and enhance customer satisfaction through timely deliveries.

Data analytics

Data analysis tools and techniques help you gain insights into inventory performance, customer behavior, and market trends.

By analyzing historical sales data, businesses can accurately identify patterns, forecast demand, and make informed decisions about inventory levels, marketing plans, and pricing strategies.

Flexibility

Wholesale inventory flexibility involves multiple supply options, adaptable logistics partnerships, and scalable inventory management systems.

This allows businesses to respond quickly to any fluctuations and disruptions in order processing, whether caused by market changes, supply chain interruptions, or sudden changes in demand.

It’s about always having a plan B, such as alternative suppliers or transportation methods, and using technology that provides real-time visibility into the supply chain, allowing rapid adjustments when necessary.

Get a demo

Wholesale inventory management doesn’t have to be difficult. See what Katana can do and see why thousands of businesses made the switch.

5 tips for finding the right wholesale inventory management solution

There are hundreds of inventory management solutions out on the market, and looking for a good fit for your needs can be quite overwhelming. Here are five tips that will help you find the right inventory software depending on your unique business needs.

1. Set a clear budget

This should be the first step in your search. Setting a budget accomplishes two extremely important tasks.

First and foremost, it helps you to understand the cost benefits of purchasing wholesale inventory software. Secondly, it filters out products that don’t suit your budget and ultimately yields a shorter list of products you would need to consider.

2. Shop around for different products and compare features

Plenty of websites compare different software products and help you pick the right software for your business. For instance, you can take a look at directories like Capterra or GetApp, and browse their inventory management software categories.

You can even create custom shortlists on Capterra and compare the features that they offer. This step will help you understand how different products stack up against each other and how they differentiate themselves from competition. It also filters out solutions that don’t have features that are essential to your business.

3. Talk to businesses that are already using the product

Before you go to the next step, it can be beneficial to talk to other businesses that already use the products in your shortlist. This will give you an excellent idea about what it is like to use the product, especially if you find a business with similar workflows.

4. Request for a demo to see it in action

Most inventory management products come with a demo or a trial period. So, once you have a manageable shortlist, your next step should be to sign up for the free trials or request a demo. There is no better way to evaluate what inventory software can do.

5. Evaluate the product fit and ask questions

During the demo or trial period, it is important to keep an eye out for how well the product fits your needs and how easy or difficult it is to use it.

An additional point to keep in mind here would be to assess how well the usage of the product is documented. A well-designed product should be easy and intuitive to use and will have straightforward documentation available in the form of a Knowledge Base.

What to look for in inventory management software for wholesale

Now that you are equipped with all the tips you need to pick the perfect wholesale inventory software for your needs, let us take a look at the different features that you should keep in mind when doing so.

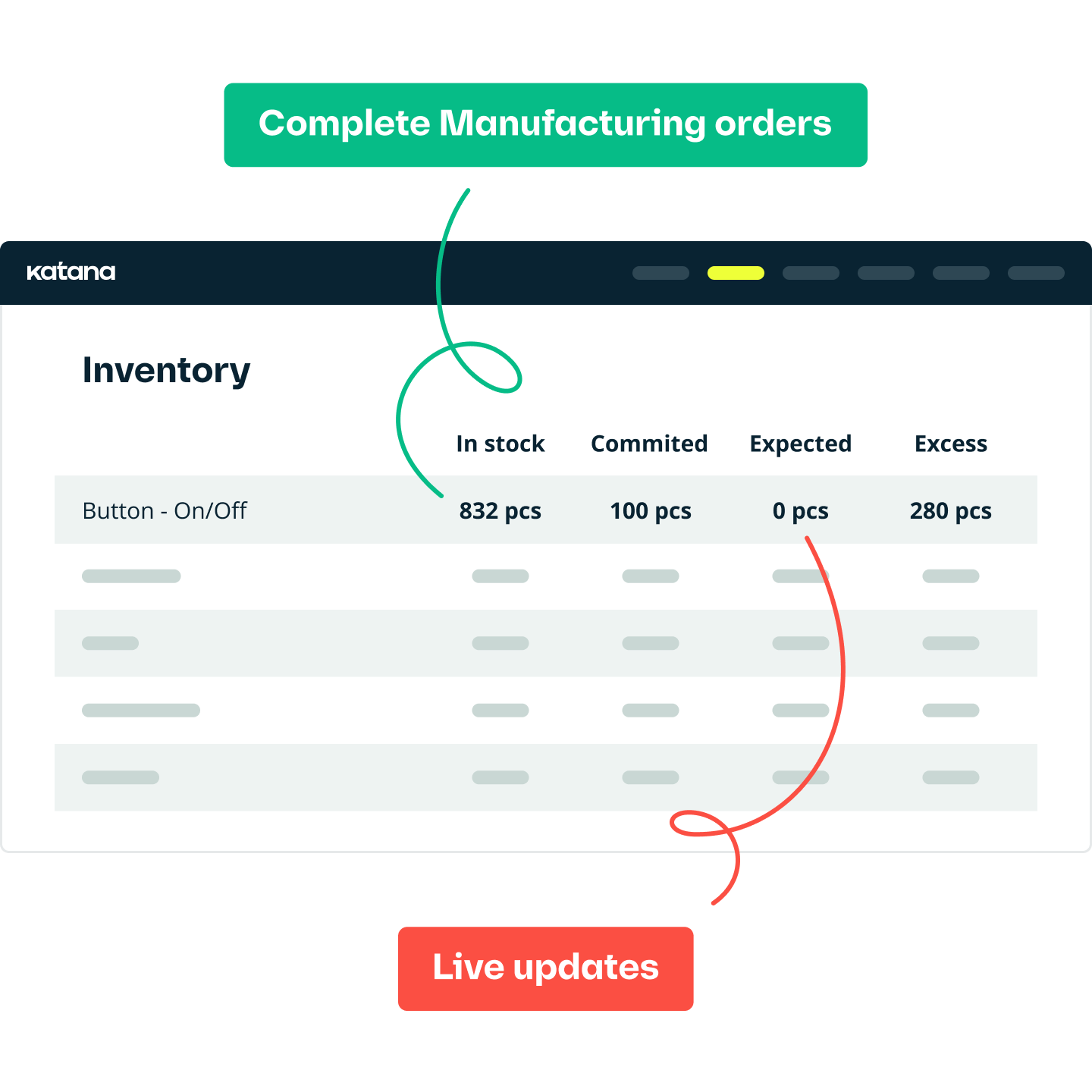

Live inventory management

Having a clear overview of all of your finished products and raw material inventory in one place eliminates a lot of hassle. An inventory management solution should notify you when your raw material stocks are running low. This can be done by setting up reorder points for various products. A real-time overview of all of your inventory should be a non-negotiable feature.

Omnichannel order management

The ability to sync sales orders from multiple channels into a single platform ensures your sales teams are all on the same page when it comes to inventory counts. This prevents overselling and also allows you to identify delivery delay risks depending on the stock you have at hand.

Purchase order management

Tracking purchase orders is another pain point that can be effectively solved with wholesale inventory management software. The software that you consider should allow you to track purchase orders for your raw materials and delays in your supply chain. This will help you keep all your teams informed about the supply chain risks. You will also be able to manage your relationships with suppliers, negotiate better deals, and partially receive orders for more flexibility.

Real-time master planning

Based on a live inventory overview, the software you decide to adopt should allow you to prioritize and plan different orders based on raw material availability, ensuring changes cascade through the affected orders automatically.

Integrations

Inventory management is only one part of your business. To take total control of your operations, it’s crucial to ensure that your wholesale inventory management software also covers other business aspects and streamlines the communication between each task. Whether e-commerce of accounting — there’s no point in managing multiple systems if you can centralize them all into one platform.

With live inventory management, omnichannel order management, and native integrations with e-commerce platforms, Katana’s cloud inventory software helps you manage all of your inventory with ease. Thousands of manufacturers use Katana to optimize business operations and keep track of costs, inventory, sales, and order fulfillment — request a demo here.

Tejas Shah

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control