Purchase order process: The complete guide for manufacturers

The purchase order process helps you easily manage the transaction of goods and services from a supplier. Learn how to Implement the perfect PO process for your business here.

James Humphreys

Starting a manufacturing business is a complex and complicated puzzle. One of the most important steps is understanding how to create and manage the purchase order process.

PO processing is vital communication between buyer and seller that outlines the details of purchased products or services. These documents represent an agreement on price, payment terms, delivery date, quality standards, quantity requirements, and more.

Knowing how to utilize purchase orders properly can help any business function smoothly by providing an organized system for tracking product purchases.

Below, we’ll examine the details of a purchase order, clarify how it differs from an invoice, look at a few different types, and offer a template on how to build your own.

Purchase order management software

Thousands of manufacturers are already using Katana manufacturing software to automate their purchase order management processes.

What is a purchase order?

A purchase order (PO) is a formal document created by the buyer that authorizes a seller to provide goods or services at an agreed-upon price.

This document is an official offer from one company to another, which includes all pertinent information, including item descriptions, delivery dates, and payment terms.

Purchasing orders provide buyers with leverage when negotiating prices and other details with suppliers since they are legally binding agreements. Therefore, suppliers will often adhere to these documents to ensure that their invoices get paid in full and on time.

Purchase order vs invoice

While these two documents often end up looking similar, they are quite different. A PO is an offer from the buyer to the seller, while an invoice is a request for payment from the seller to the buyer.

The PO will outline all of the details and expectations of a product or service that’s being ordered, whereas an invoice simply summarizes what was purchased and how much is owed.

Think of it like this:

- A PO is a contractual agreement for the transfer of goods or services

- An invoice is a bill for goods or services rendered

The purchase order process, then, is the series of steps a company follows to create, approve, and submit an order to acquire materials or other items that are needed for operation.

Types of POs

Not all purchase order procedures are created equal. Depending on the size and scope of a company, different types may be used to facilitate the PO process.

Blanket

A blanket PO is an agreement between a buyer and seller that allows for multiple orders to be placed within a certain timeframe without having to submit a new PO over and over.

This type of PO is most often used when there is a need for frequent purchases of the same items and is beneficial for both parties as it simplifies the ordering process.

Some of the benefits of using blanket orders include:

- Agreed-upon pricing and payment terms

- Frequent orders with no need to resubmit or process POs each time

- Reduced paperwork for both parties

- Lower carrying costs

- Easier tracking and record keeping

It can also be helpful to create a blanket PO when working with multiple vendors, as it allows for all orders to be placed under the same agreement.

Recurring

Recurring is a sub-type of a blanket PO that is placed repeatedly but with periodic changes in the order details. This type of PO is often used when a company needs to acquire an item regularly but with slight modifications each time.

For example, if your business orders office supplies every month, you could create a recurring PO that will automatically submit an updated request based on inventory levels.

Standard

The one-time, standard PO is the most basic type and is used when a company needs to place an order for goods or services from a supplier. This type of PO contains all of the necessary details, including item descriptions, quantities, prices, payment terms, and delivery dates.

Sometimes, even if a company knows it will need multiple orders from the same supplier, it may still opt for a standard PO. This is because each order can be tracked and accounted for separately, allowing for better visibility over purchase activity.

Planned

A planned PO is used when a company needs to place an order for goods or services but does not yet have all of the necessary information. This type of PO serves as a placeholder in the system until more details become available, such as delivery dates and payment terms.

This can be helpful if there are long lead times on items that need to be ordered in advance or if multiple vendors will need time to provide quotes.

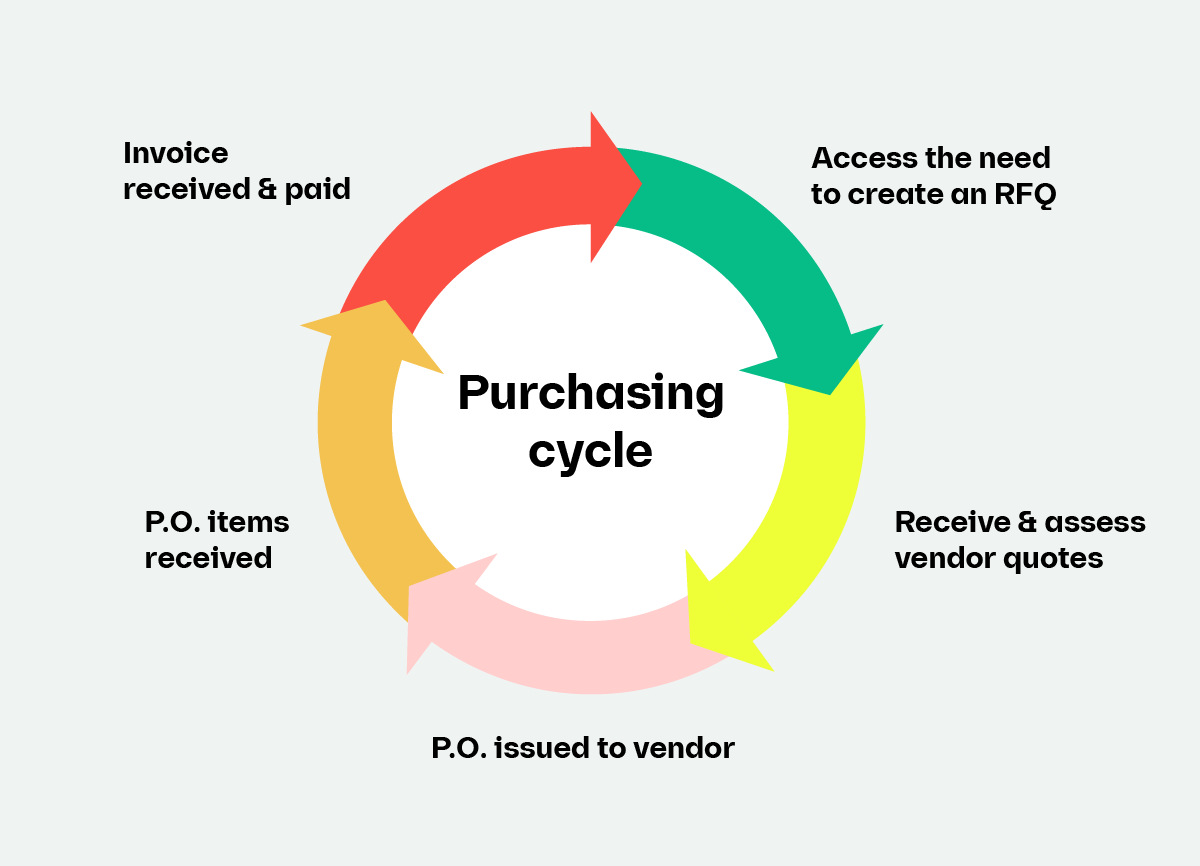

Steps of the purchase order process

The purchase order process begins when the buyer identifies a need for goods or services and makes an agreement with the supplier. The following steps outline the PO process from start to finish:

- Creation: The buyer creates and submits a PO to the seller with all necessary details included, such as item description, quantity, price, and payment terms

- Review: The seller reviews the PO and confirms that they can provide the requested goods or services

- Approval: The seller then sends an acknowledgment of receipt of the PO to confirm their acceptance of the order request

- Certification: Once both parties agree on all details in the PO document, it is signed by both parties and becomes a legally binding contract between them

- Delivery: The supplier then ships out the product or provides services according to agreed-upon delivery dates and timelines outlined in the PO

- Inspection: The buyer receives and inspects goods to ensure they meet all quality standards outlined in the PO document

- Invoicing: Once approved, an invoice is issued by the supplier, and payment is made according to terms specified in the PO

- Completion: Upon receipt of payment, a receipt acknowledgment is sent from the seller to the buyer indicating that the transaction has been completed satisfactorily

Each of these steps is an important part of the overall purchase order process and must be followed accurately to ensure smooth transactions between buyers and sellers without conflict.

Three-way match

One of the most important steps of purchase order processing is the three-way match. This process involves a comparison between the PO, supplier invoice, and receiving documents to ensure that all goods or services delivered have been properly documented and paid for.

The three-way match ensures that each item listed on the PO has been received by the buyer, invoiced by the supplier, and paid in full according to the terms outlined in both documents.

If any discrepancies are found during this process, it is up to buyers and suppliers to resolve any issues before payment can be made.

This process can be time-consuming and tedious for companies still manually creating and managing purchase orders. Automated PO software helps streamline the process by providing a centralized database for all documents associated with a PO, as well as other features such as automated three-way matching capabilities.

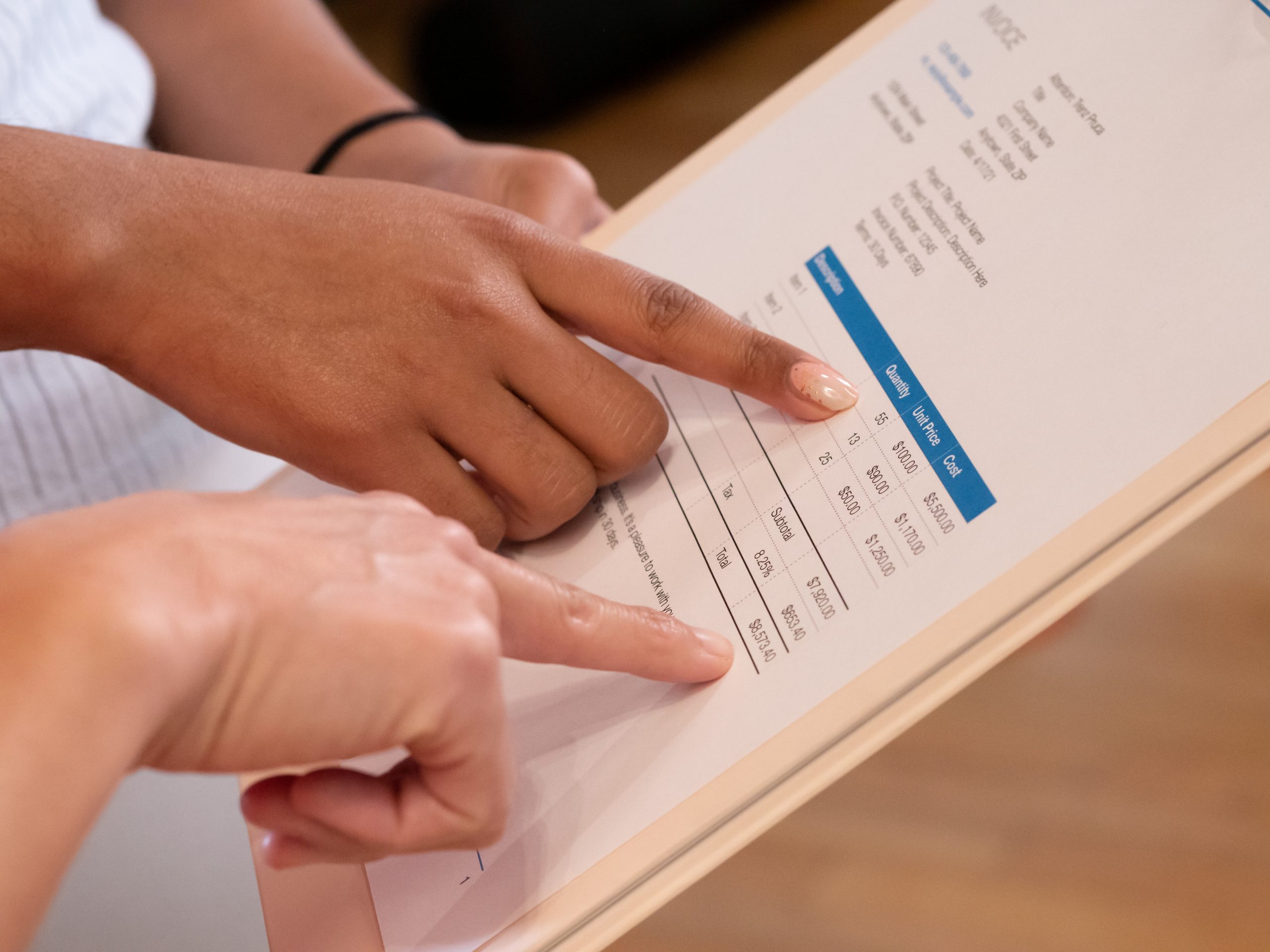

PO template

A PO can be unique to each business, but some standard elements should be included in every document. Below is a template to help you create your POs:

- Company name & address

- PO number

- Order date

- Bill-to and ship-to information (if different)

- Vendor name & address

- Description of goods or services ordered (including SKU numbers, quantity, and unit price)

- Payment terms/conditions/discounts offered

- Delivery date(s)

- Shipping instructions (if applicable)

Make sure to include as many details as possible without overcomplicating the document. This will help ensure that all parties understand the terms of the agreement and prevent any future confusion or disputes.

Ways to improve your purchase order process

Once you have a solid purchase order process in place, you can still take some steps to ensure it is as efficient and effective as possible.

- Automate wherever possible — By automating the PO process, you can reduce errors and help streamline communication between buyers and sellers

- Create standardized templates — This will make it easier to generate documents quickly for orders that happen frequently

- Negotiate better deals — Take advantage of discounts and other offers from vendors by negotiating with them for better prices, payment terms, or delivery dates

- Utilize analytics — Analyzing your purchasing data will help identify potential savings opportunities when dealing with suppliers

- Maintain transparency — Ensure that all stakeholders have access to the latest PO information by utilizing a cloud-based system that is available to everyone

- Invest in technology — A quality tracking system that allows you to monitor orders in real time will help you stay on top of the PO process

By following these best practices, businesses can ensure that their purchase order process is as efficient and effective as possible.

Purchase order management software

Centralize your entire purchase, sales, and manufacturing order processes to one place to easily track an item’s movement throughout your entire supply chain.

Support your purchase order process with ERP

The purchase order process is an essential part of any business and can be difficult to conquer alone. Enterprise resource planning (ERP) software like Katana can help businesses streamline their PO process, allowing them to focus on what’s important.

With Katana, you can manage and centralize all your order management systems, from procurement to sales and manufacturing. More specifically, using Katana, you can handle your purchase order process effortlessly by:

- Generating new POs

- Tracking the delivery status of orders

- Fully or partially receiving deliveries

- Creating outsourced purchase orders for your subcontracted manufacturing

To get started, get a demo and change your PO nightmare into a breeze!

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control