Subcontract manufacturing: Everything you need to know

Grow your business with subcontract manufacturing and simplify the inventory management overheads with the right contract manufacturing software. Read more about it here.

Tejas Shah

Your manufacturing business is doing well, and there is a growing demand for your products.

You decide that it is a great time to increase production. However, your facilities are already working at full manufacturing capacity, and you have your hands full with other aspects of your business. This is when you can reap the benefits of using subcontract manufacturing or outsourcing some of your production.

Subcontracting manufacturing while staying in control

Software that gives you the tools to create outsourced purchase orders and track raw material levels at contractors’ locations — stay in the loop with Katana ERP.

What is subcontracting manufacturing?

Subcontracting, otherwise known as contract manufacturing or private manufacturing, is the process of outsourcing either a part or all of your manufacturing to an external company.

This external company is then called your subcontractor. Now, why would you ever give up control of your production process and move your manufacturing to a third party, you ask? Well, as it turns out, there are plenty of reasons, such as:

- Increasing production

- Allocating capital more efficiently

- Responding to sudden demand spikes

- Reducing labor costs

For instance, let’s say that you are looking to increase production, but you have maxed out your in-house production capacity.

You are aware that setting up new manufacturing facilities is extremely capital-intensive, and taking on more debt can prove too risky for your business — this is when subcontracting comes to the rescue.

Employing external manufacturing through subcontracting can increase your output without the added risk of a large debt. If you prefer, you could think of subcontracting as a stepping stone in the process of accumulating the capital required to build more in-house production capacity.

Of course, it’s not all that easy.

There are plenty of factors that you need to consider when it comes to subcontracting. Let’s look into how the process works and the things to watch out for when adopting subcontracting into your workflow.

The subcontracting process

Let’s assume that you already went shopping for subcontractors and found a company that offers contract manufacturing.

First, quality standards will need to be established and agreed upon. The next step is to iron out important logistical details, such as coordinating the production schedules for instance. As they say, the devil is in the details, and this is where things start to get complicated.

You will need a way to track inventory levels and follow the manufacturing operations across multiple locations, including your manufacturing partner’s warehouse — these can prove challenging without the right tools.

You will then need to set up quality control checks for the finished products from the subcontractor.

Last but not least, you also need to manage invoicing and accounting for the movement of goods across these multiple locations.

These are the bare essentials that you need to take care of when setting up the subcontracting process. However, that list is by no means an exhaustive one. So, we’ve put together the ultimate guide on how to outsource manufacturing in order to give you a complete picture of contract manufacturing and outsourcing your manufacturing operations.

With so many overheads, it is natural to wonder if the juice is worth the squeeze.

Advantages of subcontracting

Here are some of the benefits of subcontract manufacturing:

- No overhead in setting up new manufacturing facilities

- Often cheaper since the subcontractors can produce the goods at a lower cost

- Easier to scale up or scale down production in response to demand

- Frees up resources to focus on core competencies

Disadvantages of subcontracting

Here’s the flip side of subcontracting:

- Lesser control over the process of manufacturing

- Higher coordination and quality control overheads

- Other softer overheads such as invoicing and accounting

Contract manufacturing vs toll manufacturing

Toll manufacturing is a model of manufacturing that is fairly similar to contract manufacturing.

The difference boils down to who takes care of the sourcing of raw materials.

In contract manufacturing, the subcontractor is responsible for the entire product cycle, including sourcing raw materials. So, as the parent company, you simply need to place an order with the subcontractor, and they do the rest. This places a lot of responsibility on the subcontractor. A lot of food manufacturing facilities work on the contract manufacturing model.

So often food products from competing brands are actually manufactured at the same facility using the same raw materials.

With toll manufacturing, the parent company handles the delivery of the raw materials to the subcontractor’s manufacturing facilities. While the subcontractor only takes care of the manufacturing process itself.

This model of manufacturing is highly prevalent in the consumer electronics industry, with Apple and Foxconn being textbook examples of toll manufacturing. Apple delivers the raw materials required to build its products, and Foxconn does the rest. Of course, the magic of Apple products is not in the manufacturing but in the design, high-quality standards, and the software ecosystem that it provides. So, outsourcing the manufacturing to Foxconn allows Apple to focus more on its competencies.

Katana manufacturing ERP software

Join thousands of companies all across the manufacturing industry using Katana to manage their entire business, from purchases to production and beyond.

Leveraging software to subcontract efficiently

As discussed earlier, subcontracting comes with inventory control overheads and logistical challenges.

Without the right tools, it can be quite overwhelming to get the process working. Thankfully manufacturing ERP software can take care of many of these challenges.

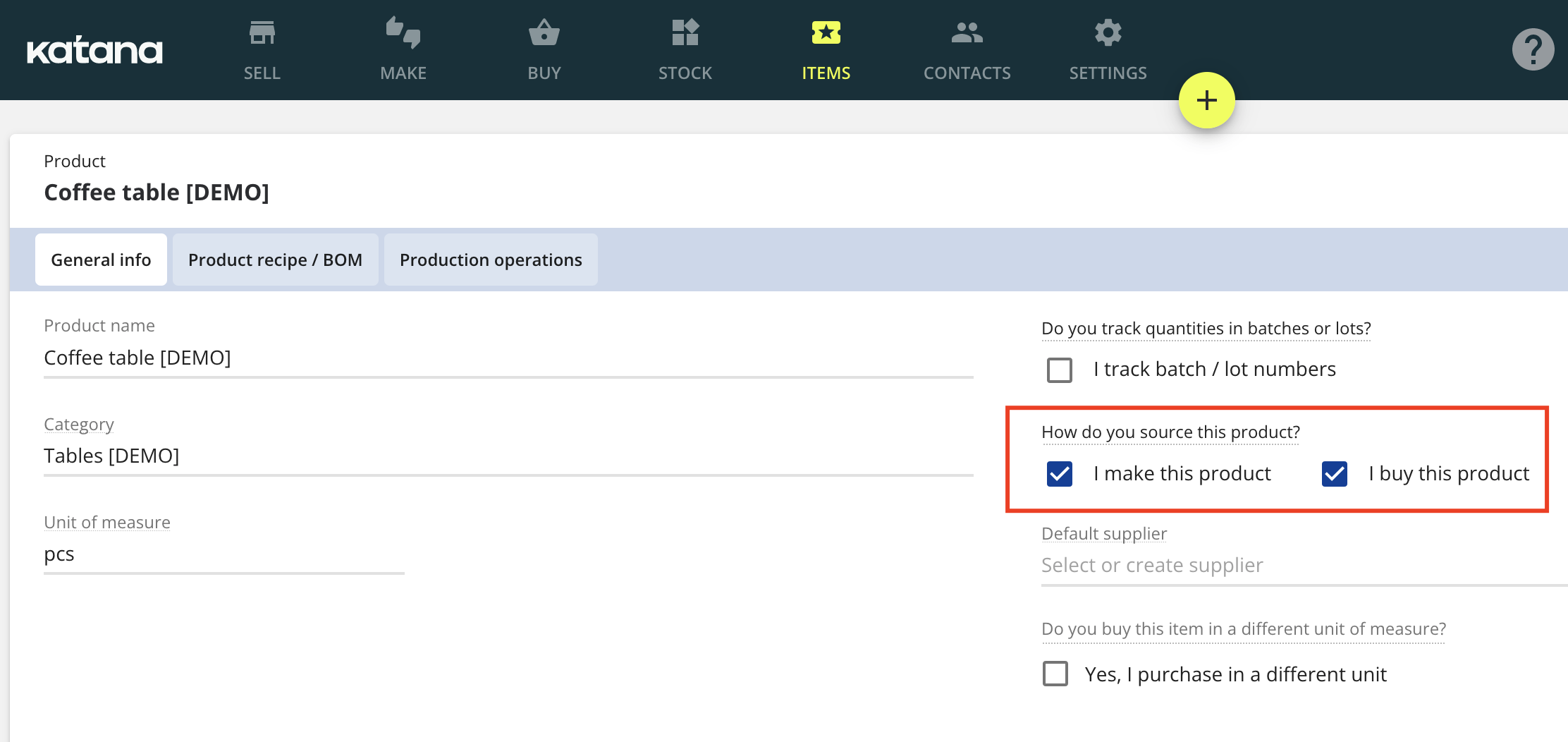

For example, with Katana’s contract manufacturing and live inventory management features, you can track materials and inventory at your partner’s locations in real-time. ERP software often comes with features that allow you to create well-defined workflows and bill of materials (BOMs), allowing you to track your subcontractor’s services fees easily.

Be it increasing your production to meet the growing demand, allocating capital more efficiently, or reducing costs. Contract manufacturing has proven to be a great way to meet various objectives.

With the right tools like Katana, you can leverage the power of contract manufacturing and grow your business. Thousands of manufacturers have used Katana to strengthen their businesses. Get a demo and see how you can simplify your subcontracting workflows.

Tejas Shah

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control