How Wabanaki Maple got out of a sticky situation — doubled sales without increasing costs

Wabanaki Maple produces barrel-aged maple syrup in Canada and distributes their products throughout North America. With the company growing rapidly, they realized that continuing to manage their business with Excel spreadsheets would limit their scalability. By switching to Katana and our integrations, Wabanaki Maple streamlined its manufacturing processes and doubled its sales volume.

2x

sales increase

Website

Integrations

Prospect CRM,

QuickBooks Online

Industry

Food and beverage

Location

Canada

About Wabanaki Maple

Wabanaki Maple is a value-added maple syrup company based in Neqotkuk, New Brunswick, Canada. We spoke with Zak, a Sales & Operations Lead who joined the company a couple of years after it was founded.

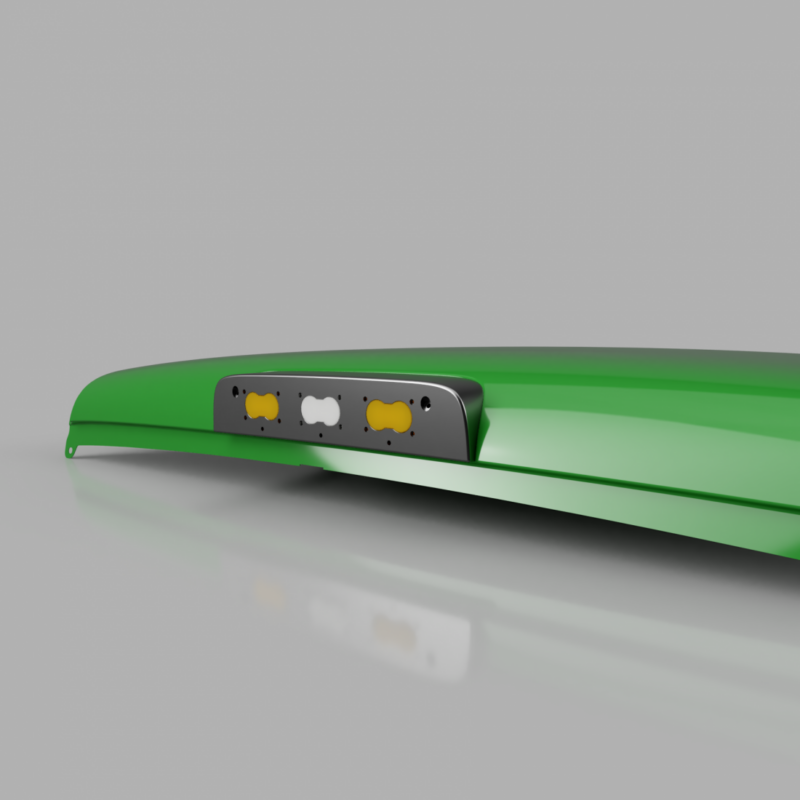

Wabanaki’s primary product is a uniquely flavored barrel-aged maple syrup. Founder and CEO Jolene Johnson is a part of the Tobique First Nation, an indigenous Wolastoqiyik community in New Brunswick, and Wabanaki maple syrup is a traditional indigenous product with a modern spin.

Using the right tech to boost efficiency at scale

The company grew rapidly from a two-person team to a small facility (500ft² building) and then grew into a more prominent company with substantial production space (4,800ft² custom facility) and a dedicated on-site staff. The previously used Excel documentation simply couldn’t keep up with processes anymore.

Moving to a more sophisticated facility added complexity, underscoring the need for advanced tools to manage operations efficiently.

We’d require a full-time person doing documentation in Excel to match what is automatically done by Katana.

Zak Genefaas, Sales & Operations Lead at Wabanaki Maple

Tackling efficiency and traceability with one inventory solution

To deal with the new scale of their business, Wabanaki Maple hired a consultant to help develop their roadmap and current business development and establish new processes. Several inventory systems were suggested during the consultation, and they decided to settle with Katana.

Before Katana, Wabanaki Maple relied on manual processes like Excel for inventory management. Katana not only introduced a way to track products but also allowed detailed batch tracking, such as including information on which barrel was used for each product and the aging process of the maple syrup.

The batch tracking system within Katana ensures regulatory compliance and facilitates smooth recall processes — a feature that is particularly important for Wabanaki when dealing with large chains that require stringent recall capabilities.

Knowing exactly what barrel goes into what product, being able to track what maple syrup is in that barrel, how long it has aged, and really quantifying all those costs through the system have been real game changers for us.

With a diverse customer base spanning Canada and the US, managing multicurrency transactions was crucial. Katana provided real-time currency conversion and separated stock and labeling requirements for different countries, simplifying international operations.

Also, by Integrating Katana, Prospect CRM, and QuickBooks Online, Wabanaki eliminated redundant data entry and ensured accurate customer information across all platforms. This integration saves significant time and effort, helping enhance overall operational efficiency.

To get up and running, Zak leveraged resources like the Katana Academy and chat support for onboarding and troubleshooting. This support system helped the team adapt quickly to the new system and maximize its capabilities.

More accuracy with an integrated tech stack

Implementing Katana and having additional integrations to cover and automate workflows allowed Wabanaki Maple to drastically improve their fulfillment process and increase sales volume without hiring new team members.

Wabanaki Maple experienced a substantial increase in sales, estimating a doubling of sales volume without hiring additional staff for sales and fulfillment. Instead, they directed their resources towards marketing and business development, leveraging the efficiency gains from the new systems. They avoided the need to hire additional staff to manage operations manually. The cost of implementing these systems was far lower than hiring new employees, resulting in substantial savings for the business.

Transitioning from Excel to an integrated system like Katana significantly improved accuracy and tracking capabilities. The automation and real-time visibility offered by Katana surpassed what could be achieved with manual methods like Excel, reducing errors and enhancing overall operational efficiency.

Katana acts as the main hub on our Shopify ecommerce side, and our Prospect CRM and QuickBooks Online on the other side. Everything goes through Katana, but everything can be seen from there as well.

By adopting Katana into their tech ecosystem, they achieved substantial sales growth, realized cost savings by avoiding new hires, reduced error rates, enhanced tracking capabilities, and facilitated business expansion without proportional increases in staffing.

More case studies

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control