CT LAB Improves Daily Operations Efficiency by 30% with Katana

CT LAB is a South-Africa-based company specializing in power quality solutions. Being a quite complex electronic device manufacturer means keeping track of all the transistors, circuits, diodes, and other components.

60%

Improved inventory control

50%

Optimized production planning and scheduling

About CT LAB

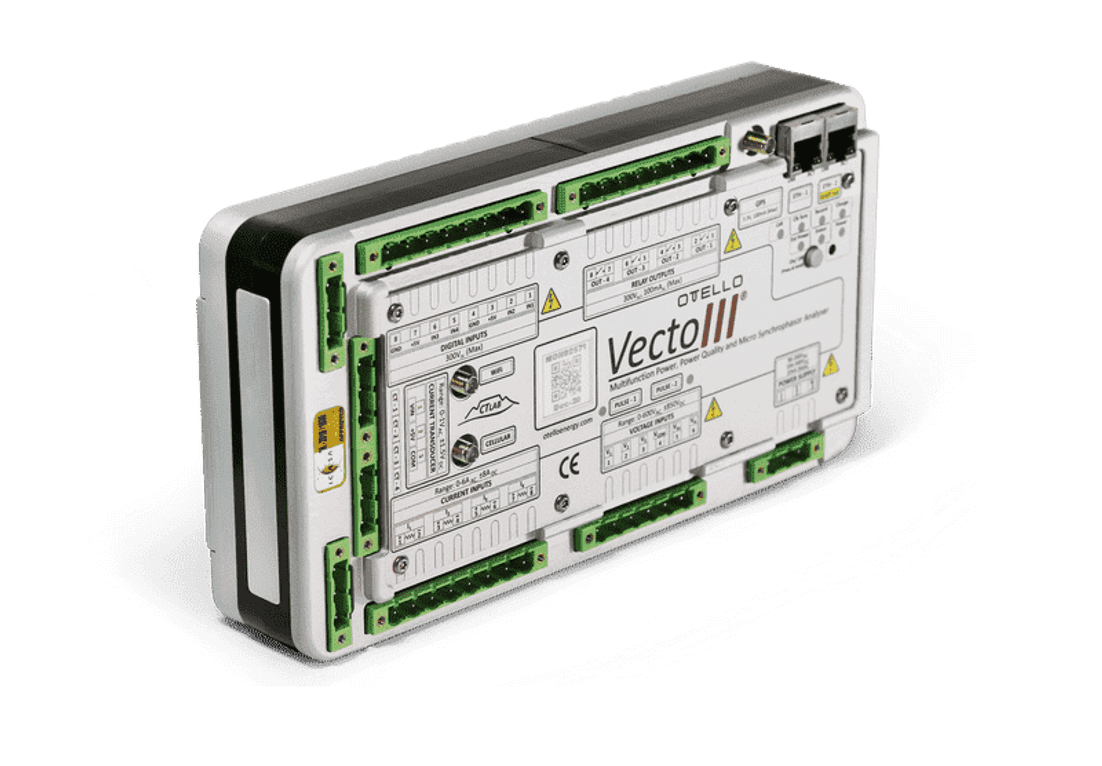

CT LAB is a South-Africa-based company specializing in power quality solutions. CT LAB designs, develops and manufactures multi-functional device Vecto III. It has created the OTELLO platform, using its own software Osprey Pro, that collects Vecto III data to provide real-time insights into power grid performance. CT LAB currently manages and hosts one of the world’s largest grid performance data-stores, encompassing over 1,200 devices from more than 90 customers.

Vecto III® is an intelligent electronic monitoring and controlling device that synchronizes with every other device installed across the network. It is capable of rating and analyze over 9,000 electrical parameters in near real-time and deliver online access to the data that engineers and other decision-makers need.

Challenges

With Katana, we can now know what we have in store and where to look for it. It has also helped us a lot with our manufacturing and purchase processes.

Danielle Louw, Production Manager at CT LAB

Being a quite complex electronic device manufacturer means keeping track of all the transistors, circuits, diodes, and other components. Inability to have sufficient inventory control can lead to chaos not only in the warehouse and shop floor but also impact the company’s bottom line.

Before Katana, CT LAB used business management software combined with spreadsheets. However, the solution was not perfect and prompted them to look for another solution to:

- Keep track of components and ready item stock; and

- Gain control over the resource and production planning.

Why Katana

More than a year ago, CT LAB set out to look for a new solution, and after finding out that Katana integrates with their new accounting platform (Xero), they decided to go for it.

Recently, we switched over to Xero, so we decided to work with Katana since it integrates well. Our previous system did not provide the necessary support, but Katana now offers a quick response.

How Katana Helped

How does it look in numbers? CT LAB has managed to achieve the following:

- Improved inventory control by 60% by being able to track components in each location;

- Optimized production planning and scheduling by 50%;

- And have managed to increase the efficiency of their day-to-day operations by 30% due to system integrations.

Katana has given them the power to control their manufacturing operations, get a complete overview of the manufacturing operations to easily manage their resources, set tasks for team members, and monitor projects’ progress.

Everything is integrated, making for effective company-wide resource planning and control.

More case studies

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control