How Kron Technologies streamlines sales with Katana and WooCommerce

Kron Technologies is a manufacturer of high-speed imaging cameras and uses the seamless Katana and WooCommerce integration to streamline the sales process and improve customer experience.

Shop Floor App

for streamlining shop floor operations

1-2 day shipping

with WooCommerce and Katana

About Kron Technologies

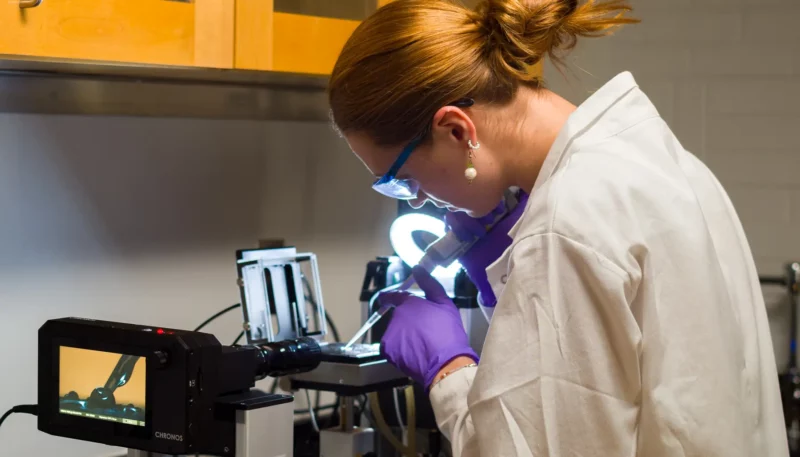

Kron Technologies is a Canadian high-speed imaging system design and manufacturing company located in the heart of the Greater Vancouver Area (British Columbia). Kron Tech aims to make high-speed imaging accessible to everyone. Their target customers cover a broad spectrum — from cinematography and sports to research and industry — anything a person might want to have slowed down beyond the human eye’s capability.

Inventory visibility gets tricky with growth

Before Katana, Kron Technologies used spreadsheets to manage their inventory and production, but it became unsustainable and required a new solution. As an electronics manufacturer, following raw materials inventory and component delivery times was crucial, especially after the pandemic put stress on supply chains.

Kron Technologies knew they needed an ERP system to keep up with their commitment to quick order fulfillment — a 1 to 2-day turnaround time from order placement to shipment for B2B and B2C clients. To maintain a rapid turnaround time as a competitive advantage, it’s crucial for Kron to ensure that inventory levels are accurately monitored and maintained to meet this tight shipping schedule without encountering stockouts or delays.

It was hard to see how many orders were open, completed, or delivered. We also had more team members coming on board and needed a system in place that would help improve transparency.

Jax Hughes, IT Manager at Kron Technologies

Another challenge they faced, a common one faced by rapidly growing businesses, is managing and maintaining control over operations as they expand. Rapid growth can lead to increased complexity in managing inventory, production, and overall business processes. Kron required better organization and management practices to support scalability. This includes implementing efficient systems to streamline operations and maintain visibility and control over the expanding business.

Saving time with the right workflows

Finding an ERP proved to be challenging as many did not fit Kron’s workflows or were clunky to use.

They needed a solution that was not only functional but also user-friendly and visually appealing. The adoption of Katana provided them with an intuitive platform that met their operational needs while being accessible and easy to use, thereby supporting their startup’s requirements effectively.

What sets Kron Technologies apart is availability. The turnaround between an order being placed and shipped is 1-2 days on average for B2B and B2C customers. Katana allows Kron to ship worldwide the next day.

Kron recognized the limitations of standard ecommerce platforms for their specific business model, which involves selling high-value items in larger quantities with specific documentation requirements. To address this, they adopted WooCommerce, a flexible ecommerce platform, and seamlessly integrated it with Katana. This integration allowed them to manage complex sales processes efficiently, ensuring they meet customers’ needs while maintaining operational clarity and accuracy.

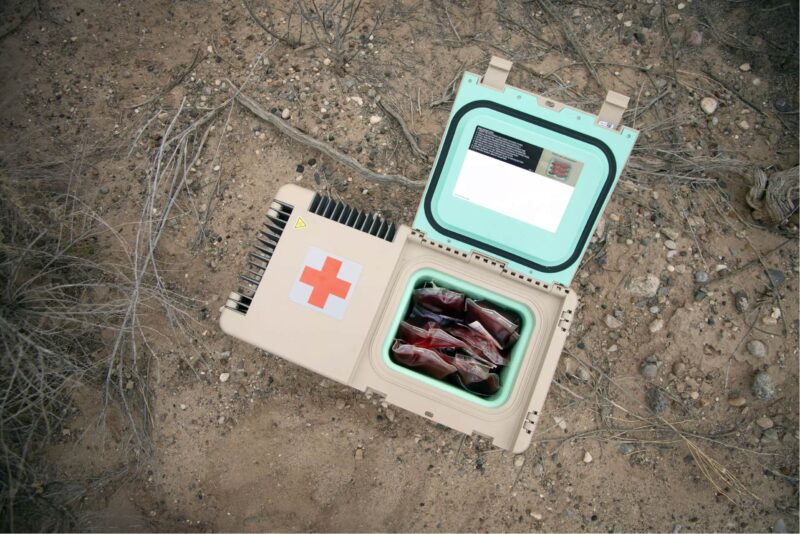

The Katana Shop Floor App helps Kron in their production, task management, and preparation for shipping. For production, they use the Shop Floor App for two different types of order processing — based on sales orders and for subassemblies.

Kron developed another workflow with the Katana Shop Floor App — a pre-shipping check for the ready orders. Once the camera assembly is done, they collect the rest of the items for shipping (for example, cables), and a new operation is added to the manufacturing order called “Check” that enables them to check whether all items, including, for example, the correct plug for the order, is selected.

Fast shipping and centralized data keeps customers and the team happy

As a high-value, lower-volume product manufacturer, it’s imperative to have a clear overview of the inventory and sales demand. Managing stock is critical, and having a solution that gives clear visibility over what is available, what is running low, and what needs to be reordered is vital to ensure next-day shipping for the client.

With the sales page in Katana, Kron has gained real-time visibility into their sales pipeline. This capability allows them to track ongoing sales activities and monitor customer interactions promptly, resulting in improved sales visibility and enhanced pipeline management.

We use Katana as a one-stop shop for operations, so we’re really utilizing all the features Katana offers. Anytime I have a question, I use the chat, and the team has been an immense help during the implementation and integration of all our products.

Kron has enhanced sales visibility and streamlined manufacturing operations by effectively leveraging Katana. The real-time insights from Katana’s sales page enable proactive sales management, while comprehensive utilization of Katana’s features optimizes manufacturing efficiency and operational coordination. Additionally, Katana’s support team has contributed to the successful implementation and ongoing operational success of Kron Technologies.

More case studies

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control