Katana blog Articles, product updates, and company news

Get inventory trends, news, and tips every month

Explore all categories

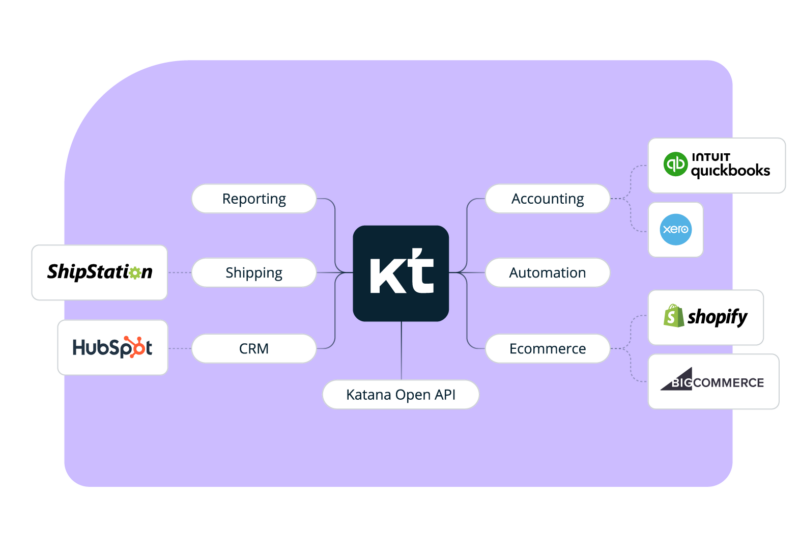

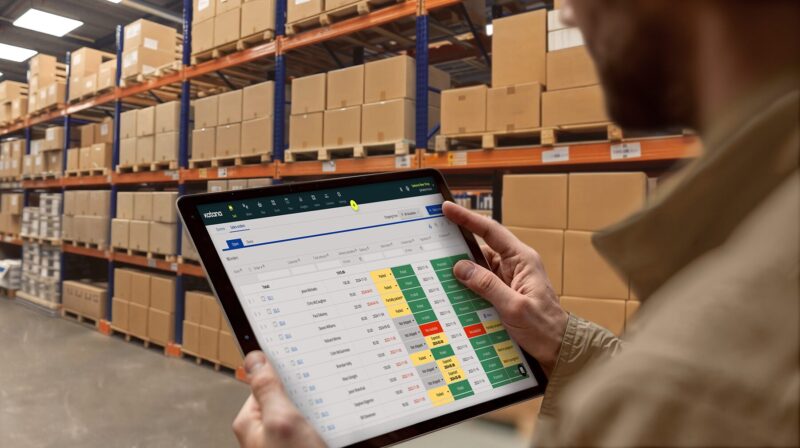

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control