Production tracking software to get your business organized

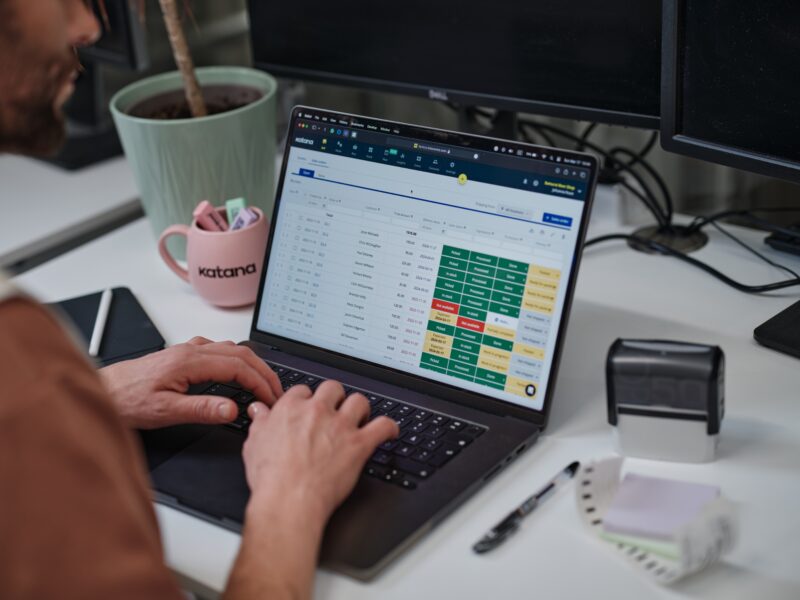

Implement Katana’s production tracking software and gain complete visibility of your manufacturing operations. Katana gives you all the necessary tools to efficiently manage everything on-the-fly.

Production tracking software to ensure you stay on course

Running your operations without properly tracking everything is a quick way to run your business off-track. To ensure each task is performed in the most efficient manner, you need to be able to track every part of your business. Katana’s manufacturing tracking software allows you to do just that, leading to a reduction of waste and an improved bottom line.

Track materials, finished products, and operations

Customers are very particular about their orders arriving on time. To make sure every customer gets their items in a timely manner, you need to have a clear overview of every aspect of your business. You need to know whether you have the materials, equipment, and human resources available to start manufacturing.

Katana’s production tracker software keeps you updated in real time, so you always know if you have everything to fulfill the order. With Katana, you can easily track:

- Different inventories

- Purchases and sales

- Production operations

Manufacturing tracking software that gets your orders out on time

Katana’s production tracker software comes with a real-time master planner. This intuitive system lets you to track your order priorities and automatically reallocates resources to get the highest-priority ones done in time.

Katana ensures you never have to worry about running out of stock or missing a deadline by offering features like:

- Live inventory updates

- Reorder points and safety stock

- Real-time master planner

A single source of truth for all your business needs

Shuffling between multiple tools while trying to ensure data accuracy across platforms can quickly become a hassle. With Katana’s prduction tracker, you dont’ have to worry about that.

Katana’s production tracking software comes with simple plug-and-play integrations, so you can connect your favorite business tools without any coding knowledge.

Katana also integrates with the tools you use to centralize your data. Connect Katana with:

- Accounting software

- CRM platforms

- Analytics and reporting tools

- Ecommerce platforms

Katana allows us to have a complete, real-time overview of our manufacturing processes and keeps our operations under control.”

Pablo Baque

Walk With Me CEO

We chose Katana because it seemed to be the most user-friendly software we tried – it is very easy to use and the customer service is great!”

Candice Murno

Founder and Designer at Buttercream Clothing

Having the shop floor know what they can or can’t make on a given day is amazing, and replaces our previous “system” of spreadsheets.”

Sara Varela

Founder and Designer at Sara Gabriel

Katana provides us with all the features for manufacturing order management and can track inventory usage and incorporate our sales order tracking into Katana.”

Mikhail Moore

Chief Executive Office (CEO) at Vitacore Industries

Integrate with the best ecommerce, accounting, reporting, and CRM apps out there

All your business tools — connected

Optimize your workflow with native and third-party integrations, automating data transfer between systems and reducing errors. Or build your own custom integrations using the open API for seamless data flow with other applications. Check out the API documentation for more details.

Production tracking software FAQs

A production tracking system is a software that helps you to track and manage your production processes, schedule production, and control quality.

Katana’s manufacturing tracking software is designed to help you streamline your production processes and improve your bottom line. With Katana’s production tracker you get access to real-time data on your manufacturing operations, allowing you to make informed decisions about your methods.

When it comes to production tracking, the most important thing is to have a clear and accurate understanding of what you’re trying to track and why. Collecting data without a clear goal does no good. Once you have the goals clearly defined, the best way to do it is through the use of production tracking software.

With Katana’s production tracking system, you have a central source of truth that keeps track of your entire business. Katana gives you a clear understanding of your inventory levels, orders, production lines, and more.

With its seamless integrations, Katana gets all your business tools talking to each other, ensuring that information is synchronized and up to date on every platform.

To track production output, you will need to have a clear understanding of your manufacturing process. You should know what inputs are required in order to produce your product, as well as the desired outputs. Once you have this information, you can begin tracking.

A great way to track production output is by using production management software. This system can help you to keep track of your production progress by recording the inputs and outputs for each production order. This information can then be used to monitor your manufacturing process and make improvements as necessary.

A few of the most common benefits of production tracking apps include:

- Improved efficiency — A production tracking system can help you to identify bottlenecks in your production process. By eliminating bottlenecks, you can improve your overall production efficiency.

- Improved quality control — Tracking production allows you to monitor the outputs of your manufacturing process. This information can then be used to improve the quality of your products.

- Reduced costs — Streamlining your production process helps to reduce waste and save money on labor, materials, and other resources.

- Improved customer satisfaction — Production tracking software can help you improve your products’ quality, leading to increased customer satisfaction and repeat business.

- Improved communication — A manufacturing tracker like Katana can help you to improve communication between different departments within your organization. By sharing information, you can improve the flow of information and make sure that everyone is on the same page.

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control