Omnichannel inventory management guide

James Humphreys

You’ve heard it before, and we’ll say it again — don’t put all your eggs in one basket.

So, let’s say you have eight eggs, and you lay each of them carefully in their own basket. Now, you have eight baskets, and if something should happen to one, you still have seven more. However, you’re faced with a new challenge — how exactly will you carry eight baskets at once?

Unless you’re an octopus, this will be a difficult challenge to overcome.

That’s why we’re going to look into omnichannel inventory management.

Traditionally in sales, a business would have multiple sales channels. But, someone would be in charge of managing a specific channel. With an omnichannel approach, you can leverage several sales channels and create an interconnected system to manage all channels from one place.

As opposed to juggling eight eggs and eight baskets.

What is omnichannel inventory management?

Omnichannel inventory management is the process of managing inventory across multiple sales channels from one point of truth.

This can include:

- Online

- Brick-and-mortar

- Mobile channels

As the business grows and the number of sales channels grows, it becomes more difficult to keep track of inventory levels and ensure that products are available. This is especially true for businesses with limited resources. Omnichannel inventory management can help businesses save time and money by streamlining inventory across multiple channels.

It can also help businesses improve customer satisfaction by ensuring companies have goods ready for clients.

What are the benefits of omnichannel inventory management?

There are many benefits of omnichannel order management. Below, you’ll find the most impactful ones.

Improved customer satisfaction

Omnichannel inventory management lets customers choose their favorite way of shopping and ensures they have access to the same products regardless of the preferred method.

Reduced costs

Businesses can save time and money by streamlining the inventory management process across multiple channels.

Increased sales

By making it easier for customers to find and purchase products, businesses can increase sales.

Improved efficiency

By reducing the need to track inventory levels across multiple channels manually, businesses can improve their overall efficiency and greatly reduce human errors.

Download the ultimate guide to inventory management

A comprehensive ebook with everything you need to know about inventory management.

What are the challenges of omnichannel inventory management?

As businesses grow and expand their sales channels, inventory management becomes increasingly complex and difficult to do properly.

An omnichannel management strategy can help to keep track of stock levels across all channels and ensure that orders are fulfilled promptly and efficiently. However, several obstacles can make implementing such a strategy difficult. While there are many benefits to omnichannel inventory management, there are also some challenges that businesses should be aware of. Below we’ll take a look at those.

Complexity

Omnichannel inventory management can be complex, especially for businesses with multiple online and offline sales channels.

Keeping track of stock levels for each channel and predicting future demand can be a daunting task. In addition, different channels may have different requirements in terms of manufacturing lead time, minimum order quantity, etc., which further complicates matters.

Inventory data entry errors

With so much data to keep track of, businesses are at risk of making data entry errors that can impact inventory levels.

Trying to avoid these errors increases the need for real-time visibility into inventory levels. With so many moving parts, it can be difficult to get a clear picture of what inventory is available at any given moment. This can lead to stockouts and other disruptions in the fulfillment process.

Inaccurate inventory data

Inaccurate data leads to problems with inventory management, like overstocking or understocking products.

Coordinating inventory across multiple channels can be a logistical nightmare. Ensuring that orders are fulfilled from the correct location, and that inventory is replenished correctly can be a complex and time-consuming process.

Despite these challenges, an omnichannel management strategy is essential for businesses that want to stay competitive in today’s marketplace.

By carefully planning and implementing such a strategy, businesses can overcome these obstacles and reap the many benefits of omnichannel selling.

How can businesses overcome omnichannel inventory challenges?

There are a few ways that businesses can overcome the challenges of omnichannel inventory management. Let’s take a closer look at the available options.

Using inventory management systems

Inventory management systems can help businesses keep track of their inventory levels and ensure that their warehouses and storefronts are stocked with the optimum items, and at optimal levels.

Working with a third-party logistics provider

Third-party logistics providers can help businesses manage their inventory levels and ensure that products are always available when and where customers want them.

Outsourcing inventory management

Some businesses choose to outsource their inventory management to a company that specializes in this area. This can be a good option for businesses that don’t have the time or resources to manage their inventory levels themselves.

Omnichannel inventory management made easy

Katana’s makes tackling the challenges a walk in the park. Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Omnichannel inventory management: 4 crucial steps to get started

If you’re not sure where to start implementing an omnichannel inventory management approach, don’t worry — we’ve got you covered. Below are four steps to get you started.

1. Define your business goals and objectives

It’s important to understand your business goals and objectives when implementing an omnichannel management system.

This will ensure your inventory system is aligned with your business goals and that you can track and manage inventory across all channels effectively. Without clear goals or objectives, it would be difficult to measure the success of your inventory management strategy. There are a few key reasons why having well-defined business goals and objectives is so important in omnichannel inventory management:

-

Ensures everyone is working in unison

When everyone in your organization understands the company’s goals and objectives, they can work together more effectively to support them. Having clearly defined goals also helps to avoid confusion and miscommunication. -

Facilitates decision-making

Having a clear understanding of your goals and objectives will help you to make better business decisions about inventory management, including what products to stock and how to allocate inventory across multiple channels. -

Enables you to track progress

With well-defined goals, you can track your progress and adjust your strategy as needed to ensure that you’re meeting your objectives. This is especially important in omnichannel inventory management, where there are many moving parts, and it can be difficult to keep track of everything. -

Helps you focus on what’s important

When you know what your goals are, you can focus your attention on the things that are most important to achieving them. This is especially important in inventory management, where there are many details to keep track of. -

Improves communication

Having well-defined goals and objectives helps to improve communication between different departments and team members. This is essential for coordinating inventory across multiple channels and supply chains.

Defining your business goals and objectives is a critical first step in implementing an effective omnichannel inventory management strategy.

Without a clear understanding of what you’re trying to achieve, it would be difficult to make informed decisions about inventory and track your progress. If you’re not sure where to start, consider talking to a professional inventory management consultant who can help you develop a customized plan that meets your specific needs.

2. Identify your existing inventory management processes and procedures

Inventory management is critical for any business, but it becomes even more important when managing an omnichannel operation.

Each channel has its own unique set of challenges. By identifying your existing inventory management processes and procedures, you can develop a plan to address the specific challenges of each channel. This will help ensure that your inventory is accurately managed across all channels, ultimately improving your bottom line.

There are a number of factors to consider when developing your omnichannel inventory management plan. Here are just a few of the most important things to keep in mind:

-

Channel-specific requirements

Each channel has its own unique set of inventory management challenges and requirements. It’s important to understand these before you can develop an effective plan. -

Technology

Technology is vital in omnichannel inventory optimization. You need to make sure you have the tools in place to track and manage inventory across all channels accurately. -

Processes and procedures

Having well-defined processes and procedures is critical for any business, but it’s even more important in an omnichannel operation. That’s because you need to be able to quickly and efficiently adapt your processes and procedures as needed to accommodate the unique challenges of each channel. -

Inventory data

Accurate real-time data is essential for effective inventory management. You need to collect and track data across all channels in order to make informed decisions about your inventory. -

Flexibility

In an omnichannel environment, things can change quickly. You need to be prepared to rapidly adjust your omnichannel inventory management plan as needed to keep up with the demands of each channel.

You can develop an effective inventory management plan for your omnichannel operation by keeping these factors in mind. This will help ensure that your inventory is accurately managed across all channels, ultimately improving your bottom line.

3. Evaluate your current inventory levels and stock management practices

Inventory management is a key component of any omnichannel strategy.

By evaluating your current inventory levels and stock management practices, you can ensure that your inventory is appropriately aligned with your overall business goals. This can help you avoid out-of-stock situations, maximize customer satisfaction, and improve your bottom line.

4. Develop a plan for implementing an omnichannel approach to inventory management

There are a few key reasons it is important to develop a plan for implementing an omnichannel approach to inventory management:

- First, with an omnichannel management system, companies can provide their customers with a consistent shopping experience regardless of how they choose to shop — whether in-store, online, or through a mobile app.

- Second, an omnichannel inventory management system can help businesses manage their inventory and stock levels across all channels. All inventory information is centralized in one system, making it easier to track and manage.

- Third, an omnichannel approach can help reduce excess inventory and stockout costs. By having visibility into inventory levels across all channels, businesses can make more informed decisions about their inventory levels, which can help minimize excess inventory and stockouts.

- Fourth, an omnichannel inventory management system can improve customer satisfaction by reducing lead times and ensuring that products are available.

- Finally, an omnichannel approach can give businesses a competitive edge by providing them with the ability to meet customer needs more efficiently and effectively.

Developing a plan for implementing an omnichannel approach to inventory management is important. By taking the time to develop a plan, companies can ensure that they can implement an omnichannel approach that is best suited for their business and their customers.

If you follow these steps, you’ll be well on your way to reaping the many benefits of an omnichannel inventory management system.

5 tips to improve omnichannel inventory management

If you’re a manager, already precariously spinning several plates, and want to get better, here are five tips to improve your omnichannel inventory management.

1. Cross-channel integration

One key area to focus on is cross-channel integration.

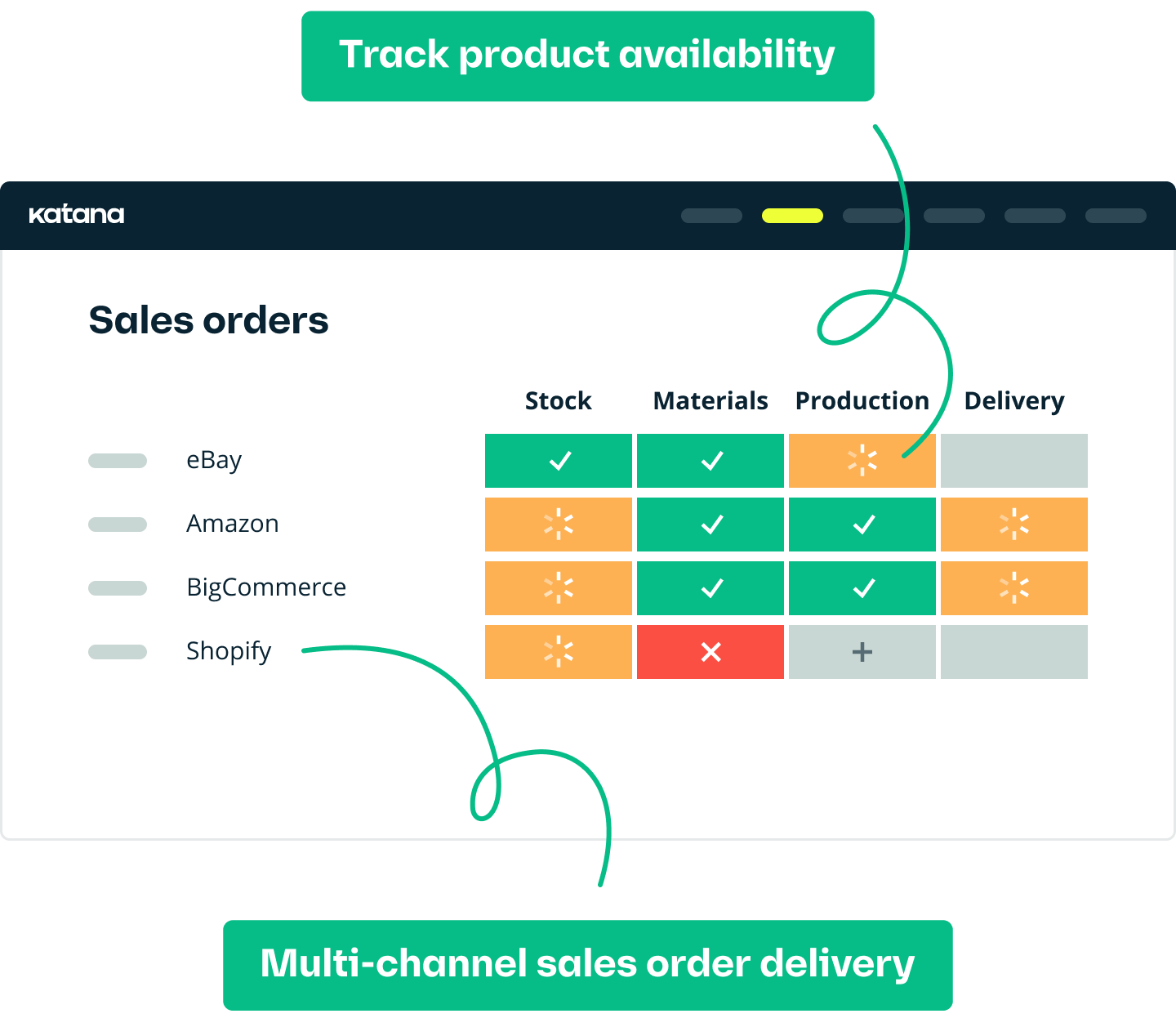

This means making sure your inventory management system can connect with all your sales channels, including online stores, brick-and-mortar locations, and marketplaces like Amazon and eBay. Integrating your inventory data across all channels gives you a more accurate picture of your stock levels and sales patterns. This can help you better decide inventory levels, pricing, and promotions.

Also, don’t forget to include social media in your omnichannel selling approach. Besides being able to share cat pictures, most social media platforms allow users to sell products. This has led to a rise in omnichannel social selling and shouldn’t be overlooked.

2. Data visibility

Real-time data visibility is another important aspect of omnichannel inventory management.

Having visibility into your data will allow you to see which products are selling well across all channels and which ones may be overstocked in certain channels. This information can help you adjust your inventory levels and stocking strategy.

3. Improved forecasting

Improved forecasting is another benefit of omnichannel inventory management.

By integrating your data and using forecasting tools, you can better estimate future demand for your products — helping you avoid stockouts and overstocks, which can negatively impact customer satisfaction.

4. Automation

Automated inventory management is another way to improve handling your omnichannel stock.

Automating tasks like ordering and reordering can help save you time and improve accuracy. Additionally, automated systems can help you keep track of stock levels across all channels and send alerts when inventory levels get low.

5. Enhancing the customer experience

Finally, enhancing the customer experience should be a top priority for any business using an omnichannel management strategy.

Inventory management plays a big role in the customer experience, as customers need to trust that their orders will be fulfilled promptly and accurately. By ensuring that your inventory management system is up to par, you can help create a positive customer experience that will keep them coming back for more.

These are just a few tips to help you improve your omnichannel inventory management. By focusing on cross-channel integration, data visibility, and improved forecasting, you can take your omnichannel inventory management system to the next level.

What is the future of omnichannel inventory management?

As a business grows, companies will need to rely on omnichannel inventory management to keep track of their inventory levels and ensure they can maintain a good order fulfillment rate with customers.

Cloud inventory software like Katana will continue to play a vital role in helping businesses manage their inventory levels and make sure they can keep delivering products to customers. Third-party logistics providers will also continue to be an important part of the omnichannel inventory management process, as they can help businesses save time and money by managing their inventory levels for them.

Omnichannel inventory management will likely become more complex as the number of orders and sales channels grows.

Still, businesses that embrace this challenge will be well-positioned to succeed in the future.

Katana’s omnichannel inventory management software

Katana is the perfect platform for omnichannel inventory optimization. It gives you a real-time view of all your sales channels, both online and offline, and integrates seamlessly with the best e-commerce platforms. This makes it easy to set up and sync your inventory across all channels.

In addition, Katana offers unified order management, inventory insights, great support, and much more. Katana really delivers on the omnichannel experience, making sure you can manage your entire business from one platform.

Request a demo today to see how everything works, so you can get your omnichannel sales up and running in no time.

Omnichannel inventory management FAQs

What is omnichannel inventory management?

Omnichannel inventory management is a method that synchronizes inventory across all sales channels, including physical and online stores, to ensure accurate stock levels and efficient order fulfillment. This approach provides a real-time view of inventory, helps avoid stockouts, and minimizes excess inventory. For businesses aiming to improve their inventory management, software with strong integration capabilities and real-time tracking, such as Katana, can be beneficial.

What is the meaning of omnichannel management?

Omnichannel management involves integrating and coordinating various customer interaction channels — physical stores, online, mobile apps, and social media — to deliver a seamless, consistent, and personalized experience. It encompasses marketing, sales, customer service, and inventory management, aiming to provide smooth transitions across channels for customers. The goal is to ensure customer centricity and consistency at every touchpoint.

What is omnichannel in the supply chain?

Omnichannel in the supply chain refers to the integration of logistics, inventory, and distribution processes to support sales across multiple channels seamlessly. It focuses on flexibility, customer satisfaction, and integrated operations to meet demands for various fulfillment options like ship-from-store and buy online pick up in-store (BOPIS). Advanced management tools that offer real-time visibility and data analytics, similar to what Katana provides, are crucial for optimizing omnichannel supply chain efficiency.

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control