Inventory management for ecommerce business 101

Sustainability, profitability, scalability can all be easily achieved just by focusing on one aspect of your business — improving inventory management for ecommerce. This guide details everything you need to know, from challenges to methods to implement pitch-perfect ecommerce inventory management.

James Humphreys

In today’s digital era, the landscape of commerce is evolving at a rapid pace. For businesses aspiring to expand and thrive, establishing an online presence has become more crucial than ever.

Ecommerce platforms offer a vast and accessible marketplace, enabling companies to reach a global audience and connect with customers beyond geographical boundaries.

As businesses embark on this digital journey to grow their reach and enhance sales, effective ecommerce inventory management can’t be overlooked.

This article dives into the significance of streamlined ecommerce inventory management, exploring key strategies and tools that empower businesses to navigate the online marketplace seamlessly.

State of Inventory Management: A Review of Rising Costs

According to Katana’s data, revenue from sales orders generated from ecommerce platforms increased by 46%. While sales from other sources decreased by 2% when comparing 2021 to 2022. Indicating that ecommerce selling is gaining more traction:

- 46% increase in ecommerce sales orders

- 2% decrease in other sales orders

What is inventory management for ecommerce?

Inventory management for ecommerce involves overseeing and controlling the order, storage, and use of products that are sold online.

There isn’t much of a differentiation between inventory management and managing ecommerce inventory, other than ecommerce focuses exclusively on the products you sell over the internet. Perfecting your ecommerce inventory management allows businesses to improve their efficiency and reduce operational costs. Given how globalized the world is nowadays, ecommerce inventory management is important because, if done properly, it will help you:

- Track items in your own warehouse

- Track items provided through a third-party logistic fulfillment center (3PL)

- Track items stored with contract manufacturers or consigned inventory with another business

- Track products sold via dropshipping

- Monitor your multichannel selling strategies

By accurately optimizing your inventory management for ecommerce, you can better understand your logistics and analytics.

You can then use this information to get complete inventory control, maintain ideal stock levels, and make more accurate predictions on inventory demand.

Good inventory management for ecommerce allows businesses to set precise reorder points to avoid:

- Overstocking

- Understocking

- Stockouts

It will also help you improve your supply chain management by understanding when you need to order products and how much. If you’re selling inventory across different sales channels, online and offline, proper ecommerce inventory management means you know exactly where your products are at any given time.

Platform-specific inventory management

If you use a specific ecommerce platform and want to learn more about ecommerce inventory management focused on that platform, be sure to check out the following articles below:

What are the benefits of good inventory management for ecommerce?

Poor ecommerce inventory management can severely disrupt your business.

First, if there’s an issue with your inventory levels, you can’t get products to customers by the time they originally expected. Or your order fulfillment rate will fall below what is needed to meet demand. Regardless of the problem, all of this will damage your business’ reputation and drive away customers and even suppliers.

With that said, here are the benefits of improving your inventory management for ecommerce.

1. Customer relations

First impressions are everything.

According to Bain and Company, a 5% increase in customer retention accounts for at least a 25% profit increase. Establishing loyal customers is critical for success — after all, customer retention is cheaper than customer acquisition. Having your inventory management for ecommerce fully optimized will help you avoid delays and long lead times, leaving customers satisfied and giving them the confidence to shop with you again.

2. Clearer oversight of your inventory

As already touched on in the article, improved inventory control helps you and your managers see when to restock items or determine which items are actually costing you money.

Improving your inventory management for ecommerce will optimize how you handle all your different inventory types, including:

- Raw material inventory

- Finished goods inventory

- WIP inventory

- Warehouse or third-party stored inventory

All of this will assist you in identifying your bestselling products and your not-so-great ones — allowing you to increase inventory levels of good stock and take measures against the bad stock, such as selling them at a discount or liquidating items altogether.

3. Improved efficiency

Inventory management stands as the pivotal element of your ecommerce operations, influencing not only your day-to-day functioning but also the long-term sustainability of your business.

Mastering the flow of items through your business and across the supply chain unlocks critical insights. These insights empower you to refine various facets of your operation, such as:

- Streamlined supply chain dynamics — Efficiently manage your relationships with suppliers, ensuring a smooth and reliable flow of goods.

- Demand forecasting — Accurately predict customer demand to maintain optimal stock levels, avoiding both overstocking and stockouts.

- Inventory optimization — Embrace lean inventory practices to reduce costs while ensuring product availability.

- Order fulfillment and logistics — Enhance the efficiency of your order processing and delivery systems, improving customer satisfaction.

- Financial planning and analysis — Make informed financial decisions based on inventory trends and data analytics.

By embracing these principles, your ecommerce business can navigate the complexities of inventory management, leading to improved operational efficiency and heightened customer satisfaction.

Download the ultimate guide to inventory management

A comprehensive ebook with everything you need to know about inventory management.

What are the challenges of inventory management for ecommerce?

Now you have some theory under your belt, it’s time to start optimizing your ecommerce inventory.

To do this, we’re going to set out some common challenges manufacturers face when looking to improve inventory management in ecommerce. These challenges will help you understand the areas of your business you need to focus on to optimize inventory handling. After that, we’ll lay out some methods you can follow to address these issues.

1. Managing inventory via an ecommerce platform

In the beginning, it was probably an advantageous opportunity to set up your ecommerce business with a platform such as Shopify, WooCommerce, or BigCommerce, for example. While these platforms have an ecommerce order management system, they lack more advanced inventory tracking features. The sooner you implement an external ecommerce inventory management system, the quicker you can reduce costs related to:

- Wasted time

- Lost inventory

- Unnecessary labor

- Tax and accounting errors

In short, these obstacles make business growth risky and difficult to manage — even more so when considering further customizing your ecommerce channels, for example, using headless ecommerce platforms to manage multiple shop fronts with a single back-end system. While headless ecommerce platforms have many advantages, these are rendered obsolete without a software system that supports managing your inventory and omnichannel orders.

2. Overstocking and overselling

Suppose you don’t understand your inventory requirements or your customers’ shopping habits. In that case, you’re in danger of heading into a scenario where you can’t meet demand, or you’ve overestimated how much stock you actually need.

It might sound like a good idea to have your shelves fully stocked and waiting to be sold. But, every second an item spends in your warehouse diminishes the profit margin for that product. Not only do you risk increasing carrying costs, but your chances of storing dead stock increase, too. According to a report by Celect and Coresight Research, a mindboggling $300 billion in revenue is lost due to markdowns.

3. Lack of transparency

Sometimes, miscommunication that could have easily been avoided between suppliers, warehouses, factory workers, or retailers can lead to big problems.

If you want your supply chain running smoothly as silk, you’ll need to figure out how to make your business transparent. This way, your sales department or retailers know whether they can make fulfillable commitments. According to a 2017 report on global supply chain resilience from the Business Continuity Institute, 69% of respondents said they do not have full visibility of their supply chains.

4. Lack of reliable data

It is a capital mistake to theorize before one has data.

— Sherlock Holmes

If you plan to grow your ecommerce business, you’re going to need to find a way to uncover and track data about your inventory movements, such as:

- What items are selling the most?

- What items are selling the least?

- How does inventory fluctuate over time?

- Do you need more items?

- Do you need fewer items?

Finding the answers to these questions alone will be a great start to boosting profits, supporting growth, and catering to your customers’ needs.

7 ecommerce inventory management methods to adopt

1. Safety stock

Keeping safety stock gives you a buffer when something unexpected happens, like an issue with your supply chain or a sudden surge of orders.

Safety stock means you can keep fulfilling orders as you top up your inventory levels. However, the amount of safety stock you should keep depends on several factors. You can use the following formula to calculate how much safety stock your business should be holding:

Safety stock = (Max daily usage x max lead time in days) – (average daily usage x average lead time in days)

2. Inventory kitting

You identify products that have been loitering for too long in your inventory — what do you do?

It might be tough to admit this, but it comes to a point where you might have to consider cutting your losses. Though, that doesn’t mean you should throw everything out the window. One technique you can implement is kitting your products.

This is where you bundle your slow-moving or dead stock with an item that is selling well so you can offload the products and recuperate some of your costs.

3. Demand planning

This is an essential process step for a spring clean and a method of optimizing your inventory handling.

The purpose of performing demand planning is to make future sales and stock level requirements a little less uncertain. To do this, look into historical sales data and identify past trends to make a prediction on what you’ll need for the coming period. You can use PEST analysis to make these estimations by looking into the following factors:

- Political

- Economical

- Sociocultural

- Technological

4. Storage and routing

In ecommerce inventory management, storage and routing involve optimizing how and where products are stored and the paths they take from storage to customer. Key strategies include:

- Optimized warehouse layout — Arrange high-demand items for easy access, streamlining the picking process

- Inventory segmentation — Categorize inventory for efficient storage and handling

- Use of technology — Implement warehouse management system and automated inventory solution for enhanced efficiency

- Cross-docking — Directly transfer goods from incoming to outbound vehicles to minimize storage time

Rethinking how your warehouse, factory, ecommerce inventory, and physical store locations are laid out will help you improve inventory management, minimize costs, and maximize value for the customer by reducing waste.

5. Reorder points

Reorder point is an essential tool for managing inventory and improving operational efficiency.

By using a reorder point system, businesses can always have the right amount of stock on hand to meet customer demand. This leads to lower costs, increased profits, and happier customers. You can calculate your ideal reorder point with the following formula:

Reorder point = (Average daily usage x average lead time in days) + safety stock

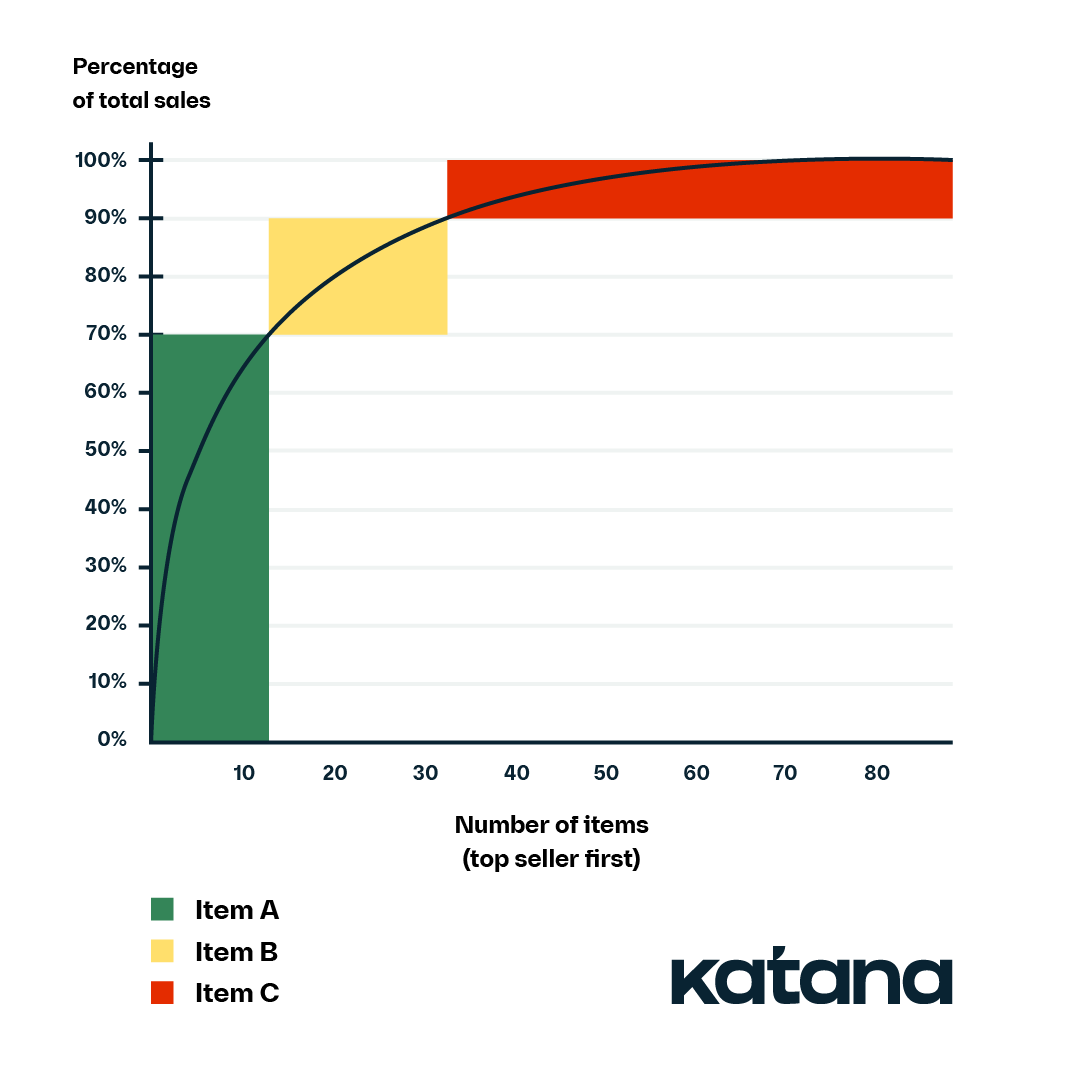

6. ABC inventory

ABC analysis is an inventory management technique that helps organizations better manage their high-value inventory.

In particular, it allows managers to use their stock management resources more efficiently. The ABC inventory system works by dividing all the items in a company’s inventory into three categories:

- A

- B

- C

Items in category A are the most important, and those in category C are the least important.

By managing the items in category A, companies can improve their availability and reduce losses and costs. The ABC inventory system is a great tool for improving inventory management. By using it, organizations can make sure that their most important items are always available when they need them.

This improves overall business efficiency and helps to reduce losses and costs.

7. Stocktakes

When you conduct a stocktake, you’ll compare your physical stock with your records to identify any discrepancies that might exist.

This will help you to identify any areas where you may need to improve your inventory management practices. You can then take steps to address these discrepancies and improve your overall inventory management. A stocktake is also a good way to identify any damaged or expired products.

This information can help you decide whether or not to continue stocking these products. Damaged or expired products can be costly and can take up valuable space in your inventory, so it is important to make decisions about these products based on the data from your stocktake.

Optimized ecommerce inventory management with cloud inventory software

Katana Cloud Inventory empowers users to optimize their inventory management for ecommerce effortlessly.

It does this by giving you real-time data on sales, production, and inventory so you can make important business decisions and scale your company. Katana has all the necessary inventory management tools you need to streamline your ecommerce stock management.

Integrating Katana and your favorite ecommerce platform not only allows you to improve your inventory management but also equips you with features for:

- Serial number and expiry date tracking

- Sales and manufacturing order management

- Barcode scanning for selling and receiving goods

- Insights to monitor your sales performance and other business metrics

Katana makes inventory management a breeze for ecommerce sellers by connecting all your business tools and acting as a central source of truth.

Glossary of inventory management terminology

There are a lot of industry-specific phrases, terms, and abbreviations that get thrown around constantly. It’s necessary to understand these to fully grasp all the concepts talked about. Here, you’ll find some of the common terms used in the industry:

- Stock keeping unit (SKU) — A unique code that identifies each distinct product and service that can be purchased.

- Economic order quantity (EOQ) — A formula used to determine the most cost-effective quantity to order to minimize costs associated with ordering, receiving, and holding inventory.

- First in, first out (FIFO) — An inventory management method where the oldest stock (first in) is sold first (first out).

- Last in, first out (LIFO) — A method where the most recently produced or purchased items are sold first.

- Just-in-time (JIT) — An inventory strategy companies employ to increase efficiency and decrease waste by receiving goods only as they are needed in the production process.

- Warehouse management system (WMS) — Software and processes that allow organizations to control and administer warehouse operations from the time goods or materials enter a warehouse until they move out.

- ABC analysis — A method of categorizing inventory into three classes, typically based on value and frequency of use, with A being the most valuable and C being the least.

- Safety stock — Extra inventory held to guard against stockouts caused by variability in supply and demand.

- Reorder point — The level of inventory that triggers an action to replenish that particular inventory stock.

- Minimum order quantity (MOQ) — The smallest amount of set stock that a supplier is willing to sell. If you cannot purchase the MOQ of a particular product, then the supplier won’t sell it to you.

- Lead time — The amount of time that passes from the start of a process until its conclusion. In inventory management, it often refers to the time taken for goods to be restocked after an order is placed.

- Turnover rate — A measure of how quickly inventory is sold or used over a certain period.

- Backorder — An order for a good or service that cannot be filled at the current time due to a lack of available supply.

- Cross-docking —A practice in logistics of unloading materials from an incoming semi-trailer truck or railroad car and loading these materials directly into outbound trucks, trailers, or rail cars, with little or no storage in between.

- Demand forecasting — The practice of predicting which and how many goods will be purchased over a specific period in the future based on historical data and other information.

Ecommerce inventory management FAQs

Inventory management in ecommerce refers to the process of overseeing and controlling the ordering, storing, and use of a company’s inventory. This includes the management of raw materials, components, and finished products, as well as warehousing and processing of such items.

It’s a crucial part of e-commerce as it helps in maintaining the right balance of stock, avoiding both surplus and stockouts and ensuring that orders are fulfilled efficiently.

Managing stock inventory in ecommerce typically involves several key steps:

- Real-time monitoring — Utilize software to monitor stock levels in real-time

- Demand forecasting — Analyze sales data to predict future demand

- Automated reordering — Set up automatic reordering of items when they fall below a certain threshold

- Supplier management — Maintain good relationships with suppliers for timely restocking

- Regular auditing — Periodically check inventory to ensure records match actual stock levels

Tracking inventory for e-commerce can be done through:

- Ecommerce inventory management systems — Software that tracks inventory levels, orders, sales, and deliveries.

- Barcode scanning — Using barcode scanners to update inventory levels automatically as products are sold or restocked.

- Integration with sales platforms — Linking inventory systems with ecommerce platforms for real-time inventory updates.

- Cloud-based solutions — Using cloud-based platforms to access inventory data from anywhere, facilitating remote management.

The inventory-based model of e-commerce is a business model where the e-commerce company owns and manages the inventory of the products they sell.

In this model, the company purchases goods in bulk from manufacturers or suppliers, stores them in a warehouse, and then sells them directly to customers. This model offers greater control over inventory, quality of products, and supply chain management but also involves higher risk and investment in terms of stock management and warehousing costs.

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control