Inventory control: Laying paths for a bright business future

Inventory control, aka stock control, aka “oh no, not again.”

If the phrase inventory control conjures up feelings of dread and despair, you’re not alone. In fact, it may be an issue that some business owners avoid altogether. They don’t employ any effective inventory control techniques and just hope for the best.

Perhaps you, too, feel that inventory control systems are overrated.

Most of the time, things get to where they’re supposed to, and that’s good enough. But if you don’t have adequate control over your stockroom, it will eventually lead to stock emergencies as you ignore this important aspect of business management.

In short, it pays to get this right sooner rather than later.

So, let’s get to it.

Get to know the ins and outs of controlling your inventory, including how to implement some killer techniques in your business, and feel the daily pressure of stock management being lifted away.

What is inventory control?

Inventory control is the process of managing a business’s inventory levels, allowing companies to optimize inventory management and assess account balances and financial reports.

The terms inventory control and inventory management are often used interchangeably. In fact, they are separate entities — think of the former as a part of the broader discipline of inventory management. The primary objectives of control over inventory are to know where everything is and to make sure it always gets to the right place.

Inventory management deals with inventory costing, buying policies, and selling prices.

A good analogy of stock control is the human heart.

At its essence, the heart’s job is to pump blood. Not only does it pump blood to every organ in the body, but it also dynamically maintains the correct volumes. If you exert your body more than usual, the heart must compensate and begin pumping blood faster — everything runs in balance.

The more you use it, the stronger it gets, and disasters occur if things aren’t regulated properly.

Inventory control is similar and focuses on:

- Keeping track of stock — What you already have, how much you have, and where you have it

- Stock logistics — Organizing the stock in your warehouse or storeroom so transport time is optimized, which in turn reduces lead time

- Correct storage of goods — Some products require specific conditions for storage. For example, if wood is not stored at the correct temperature or if the humidity is off, then this leads to it becoming obsolete faster than you can use it. This is also a concern of health and safety — is everything stored and transported according to industry regulations and standards

In contrast, inventory management is concerned with:

- Optimal stock — Stocking the right amount of inventory to minimize holding costs and associated waste

- Making sure you get the best deals for materials — For example, managing economic order quantity (EOQ). This is reflected in your overall cost of goods sold (COGS)

- Inventory valuation — Choosing the right costing method like LIFO, FIFO, or MAC (also part of COGS). Inventory management techniques can change the costs you report on your financial statement, like how much you spend on raw materials (part of manufacturing cost)

In addition, there is one more term that should not be confused with either of the above:

This is the catch-all term for ultimate business efficiency. Sounds intimidating, but your inventory control and management both funnel into your operations management.

In short, operations management involves:

- Inventory management

- Quality control

- Production scheduling and planning

Think of operations management as a big circle that encapsulates all your processes — the day-to-day of your business.

Within that is a smaller circle lies inventory management. And within that circle, there’s another smaller circle called inventory control. This specialized area is central to your operations and has repercussions across your whole business — so stay sharp.

So that’s the very complex definition of inventory control. Now, why exactly is inventory control important?

Why is inventory control important?

Inventory control management is an important part of any business, helping track:

- Materials

- Products

- Supplies

It ensures that businesses have the right items in stock to meet customer demand and operate efficiently.

By using effective inventory control procedures, businesses can reduce costs associated with wasted materials, overstocking and understocking issues, as well as access timely information about their stock levels.

Additionally, inventory control can help identify slow-moving or dead stock and evaluate supplier performance. Properly managing inventory allows for smoother production processes and more accurate forecasting of future demand, thus leading to improved financial results for the business overall. A company can improve its performance significantly by carefully planning and implementing an effective inventory management system.

Inventory control also helps ensure that a business can meet customer service and delivery expectations. By keeping an accurate count of stock levels, companies can avoid over or under-selling products and provide customers with the right items when they need them.

Tracking inventory levels in real time allows for more timely restocking decisions, allowing companies to stay on top of customer demand. Additionally, having accurate records of incoming and outgoing stock makes it easier to locate specific items quickly and efficiently.

Inventory control is essential for any business that stocks goods, materials, or supplies. It helps businesses manage their stock levels more effectively and means that your customers get what they need when they need it.

Properly managing inventory enables smoother production processes, more accurate forecasting of future demand, and improved financial results for the business overall.

Inventory control techniques

These are the best inventory control techniques that every business should implement.

Think of it as a basic checklist. It’s all about the fundamentals. This is the bread and butter of what you need to be doing.

These are always worth going over as these are your best money and time-savers.

1. Organize all your products logically

The best way to do this is to generate an SKU for each of your product variations. This lets you categorize your stock so you know where to put everything without thinking.

Another way is to create and attach barcodes to all your inventory items, be it finished goods or components. Barcode scanning allows you to streamline day-to-day tasks, such as:

- Identifying incoming goods

- Change the status of orders

- Receive and send shipments

- Track products within a warehouse

- Facilitate returns

Barcode automation speeds up tasks that you’d never again want to do manually. It also minimizes the risk of errors, shows you accurate data in real time, and enforces better business decisions.

2. Set your safety stock

This is the extra stock you keep around in case there’s a temporary supply chain breakdown or bottleneck. Keep your processes running smoothly while waiting on a delayed shipment.

Keep in mind that the amount of safety stock you need may not be as much as you think. Apply a safety stock formula to find the optimal level.

3. Set reorder points

These numerical thresholds tell you when you need to order more of something.

The different stock items you keep will need different reorder points because you go through them at different rates. Lower reorder points lower your stock investment but increase the risk of an out-of-stock situation.

So, incorrectly setting a reorder point may interrupt your workflow. You have the reverse problem if it is set too high. Finding the right cloud inventory software can help you stay on track.

4. Cut your dead stock

We’ve all done it — held onto something for too long because you never know when you might need it.

But there are some things that all the proverbial rainy days in the world will never shift. And guess what? All those grand pianos sitting in the back of your warehouse aren’t exactly “harmless.” Ever heard of carrying costs? This useless stock is like an unwanted guest that won’t leave. It’s time you evicted it and freed yourself of the stock that’s weighing you down.

5. Scale up and go omnichannel

So, what to do now everything’s working like a well-oiled machine? Have a break? Well, you’ve certainly earned it, but remember, you can’t put your feet up forever. And who would want to? This is just the beginning. Your business can get even more awesome. The beauty of an effective inventory control system is that when done correctly, it scales up without you having to change your inventory plan again.

So, when you’ve caught the business bug and want to keep riding the wave of your additional success, you can increase your sales by opening up new sales channels.

This is where things get fun.

The types of inventory control systems

There are two types of systems of inventory control when looking into how to approach this momentous task.

Periodic inventory systems

A periodic inventory system is a method of inventory control that utilizes periodic physical counts to determine the quantity and value of items in stock.

The periodic inventory system requires regular counting of all or some of the items in inventory, allowing for deviations between actual stock levels and book values to be determined. This discrepancy can then be used to adjust the inventory records so that they accurately reflect what is on hand.

A periodic inventory system also provides valuable information about sales trends and product performance, which can help businesses make more informed decisions regarding their purchasing strategies.

Perpetual inventory systems

A perpetual inventory system is a stock-controlling method used to track the stock balance of items in real time.

This system is designed to provide a more accurate and up-to-date reflection of the current stock level of each item within the inventory. The perpetual inventory system automatically updates its records every time there is an addition or removal from the inventory, allowing for more efficient management and tracking of stock levels.

This type of system can help businesses accurately monitor their stock supply and manage their orders in a timely manner, minimizing potential out-of-stock scenarios or overstocking problems.

How to control your inventory

Here are nine rockstar-level inventory control techniques:

- Track supply and demand in real time — Use a perpetual inventory tracking system and track your inventory at all times. This lets you fulfill one of the main goals of inventory control, which is knowing where your stock is 24/7

- Establish stock control policies — This includes maximum and minimum inventory levels, reorder points, backorder allowance, and so on

- Have an emergency plan — Make sure you know it backward, forward, and sideways. Also, train your staff to effectively cope with all eventualities

- Prepare an inventory budget — This should include carrying costs and the expected inventory turnover ratio. Stick to it by adapting make-to-order to not exceed your budget

- Split your inventory up — Don’t think of your stock as a single entity. Figure out what your fast-moving stock is. It could be that 20% of your SKUs contribute to 80% of your revenue. For the rest, does its infrequent revenue justify the increased carrying costs? Inventory control models assume that demand for an item is not dependent on demand for other items in your stock. Concentrate on your high-turnover stock and reduce your low-turnover stock

- Resist temptation — Things like supplier discounts can cost you more money in the long run because you need to find a place to store the extra stuff. All the extra minutes it takes your staff to locate materials adds up to hours each week. Of course, you are paying for these hours of zero-return

- Barcoding — This is fairly easy and cost-effective to set up. It integrates with your point of sale system (POS) to instantly track what’s going in and out of your factory

- Account for non-sale stock adjustments — Adjustments could be returns that will happen at some point. They could be gifts, like charitable donations. You need to adjust your stock by putting in a zero-value sale in your inventory control system. This will update it to the correct level

- Implement cloud-based inventory management software — Keep control of inventory levels from anywhere with an internet connection and cooperate with teams across the map

Inventory control challenges

As the old saying goes: “Nothing worth having comes easy.”

The same goes for effortless inventory control. It takes time for you to find out what works best for your business. Your policies depend on many factors. These include your industry, the cost of your raw materials, the amount of MRO you require, and the frequency and the average size of your sales orders.

That means you can spend your whole life reading and researching inventory control, but the only way to master it is to get your hands dirty.

You must put effort into fine-tuning your stock control.

Here are the core areas in which to exercise inventory control at all points in your business.

1. Raw materials availability

There must be enough available to ensure that new orders can be processed to keep your order fulfillment cycle at a good pace. Once your raw materials come in, it is your job to allocate them to get the maximum value from every cent spent on materials. This means prioritizing orders and completing the highest in your queue before you move on.

2. Work-in-progress

It’s best to keep the amount of inventory being worked on to a minimum to further reduce your investment in inventory.

Split up production into cells that work on different sub-assemblies to reduce lead times between each operation (cleaning, machining, and so on). This can be done by:

- Reducing machine setup time to decrease downtime

- Minimizing inventory travel time within the facility to speed up operations

- Streamlining the movement of employees between workstations to enhance productivity

- Optimizing the process of starting new orders to ensure a quicker turnaround

3. Finished goods availability

If these are readily available, then super-fast order fulfillment awaits.

Companies that do this can justify higher prices. Customers won’t mind paying to get stuff quicker. Of course, it is difficult to find a happy compromise. It’s a challenge to balance the number of allowable backorders with the amount of on-hand products.

5. Bottlenecks

There is almost always a bottleneck lurking somewhere in a warehouse, even if it is not obvious at first.

Inventory control can be used to alleviate these. Some stock control methods put an inventory buffer directly before a bottleneck. This allows an area to keep running while other parts of your process struggle, so there are fewer delays when everything gets up to speed again.

6. Backorders

This is an inventory technique that gives you a second chance in the event of an out-of-stock situation.

But be careful. If you use this as a crutch, your customers will start to look elsewhere. Good inventory control is making sure the number of backorders you make a year stays under a reasonable threshold.

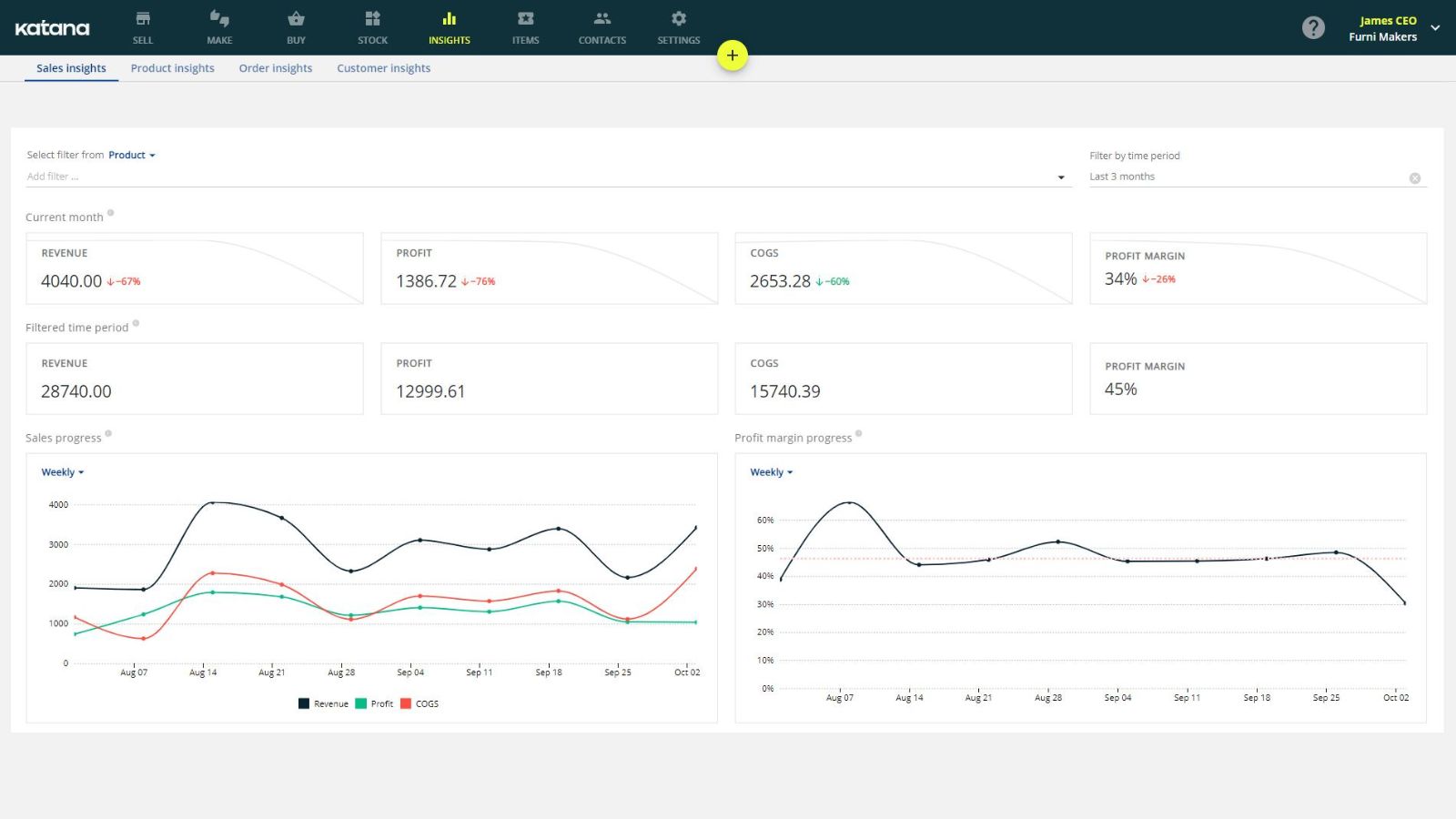

Get total inventory control and visibility with Katana

Katana Cloud Inventory is the ultimate platform for businesses looking to implement inventory control strategies into their everyday operations.

Katana is a perpetual inventory management system that gives businesses the essential tools to:

- Tracks raw materials, WIP, and finished goods inventory in real-time

- Create a flexible production schedule with the real-time master planner

- Collect data on sales item’s performance for analysis

- And so much more

Contact our sales team and request a demo to see it for yourself.

Table of contents

Inventory management guide

More guides from Katana

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control