Make-to-order (MTO) vs. make-to-stock (MTS)

By the end of this article, you’ll know what is the main difference between make-to-order and make-to-stock systems and which is the best for you.

Henry Kivimaa

The big question your business needs to answer if you want to improve your inventory control?

Which is better: Make-to-order vs. make-to-stock?

You might be pondering, “How can a change in workflow help me?” Well, if you have products stuck in inventory, maybe it’s time to consider a switch from make-to-stock over to make-to-order instead, as the latter will (theoretically) leave you with no inventory. Make-to-order (MTO) and make-to-stock (MTS) are both implemented by different companies, so please sit back and get ready for the main event — make-to-order vs. make-to -tock, which is best for scaling manufacturers?

You may discover that your business is more of a hybrid, and depending on circumstances, can switch processes whenever your company needs to evolve to cope with the demand.

By the end of this article, you’ll know the advantages and disadvantages of employing one of these lean manufacturing tactics in your business.

What is make-to-order (MTO)?

The make-to-order definition is the manufacturing strategy of making products only when a customer’s order is confirmed. Having items make-to-order allows products to be customized to customers’ specifications.

A make-to-order business also applies to companies that sell products that are built to order, such as a bespoke manufacturing company. If your business follows a make-to-order, the customers will have to wait for the products.

As the business will hold production until receiving the order, this will affect leading times, meaning the customer’s waiting time will be longer.

Though, there are ways of combating this by calculating your lead times. The make-to-order method belongs to a pull system of manufacturing as it relies on customer orders before starting production. Other methods that fall under this type are built-to-order (which is another term for make-to-order), assemble-to-order, and engineer-to-order.

A PC manufacturer will only increase production by 40% if a retailer increases orders by 40%.

A make-to-order example

How about this for a make-to-order example?

You want to be the coolest kid on the block, so you decide to become a video gamer. However, you don’t want to buy some generic PC sold by some big faceless companies. But you really don’t trust yourself in building the computer and handling the hardware.

If you go to a company that builds customized PCs you will have tons of options and variations to build a desktop or laptop that meets your specific needs.

Once you’ve populated a form or talked through your dream PC’s specifications with an employee, you’ll immediately place and pay for your order. That’s the customers’ side of the journey finished — well, almost finished. Now they wait for the delivery of their product.

Over at the company, they receive the customer’s order, and now the manufacturing of that PC will begin on receipt of a manufacturing order.

A well-organized business will have the materials and components on-site ready — or at another location depending on how they store inventory and operate — so that the manufacturing can begin and avoid delays from low inventory levels.

As mentioned before, the products in these make-to-order examples exist under a pull system:

The pull system = Products being pulled to manufacturing from a customer’s purchase.

What are the advantages of make-to-order?

The three reasons why a business will choose MTO when it comes to make-to-order vs. make-to-stock:

1. Minimize waste

Minimizing waste doesn’t just apply to your business attempting to reduce expenses on material disposal or that is unnecessary to production. Minimizing waste means that resources are only spent on your product if it benefits your customers. If a process, action, or addition to a product does not add value to the customer, it is considered waste.

2. Reduce the risk of inefficiency

All manufacturing takes place upon receiving the customer’s order, directing the company’s operations to just focusing on manufacturing products as efficiently as possible. However, you’ll need to decide when to start production by choosing either forward scheduling or backward scheduling.

3. Customizable products

Customers will come to you when they want a more personalized shopping experience, making your products unique compared to other make-to-stock companies. Unfortunately, there also come some downsides to being a business that is make-to-order.

What are the disadvantages of make-to-order?

Let’s look at three disadvantages that you can face if you decide to take this approach to manufacturing:

1. Irregular sale demands

Businesses usually experience peaks or spikes in sales. Adding more make-to-stock examples to the article, seasonal periods increase in sales since it’s Christmas. This means that your business might notice lulls in sales, or even a massive boom in demand, both of which can put a major strain on your business.

2. Material stock falling behind

The nature of a make-to-order business means that your business must always be ready for the next customer order to begin manufacturing as soon as possible. Although, incorrect stock level readings of materials or a ton of orders can result in your business running out of material at a crucial moment, putting you behind on your orders.

3. Customer wait times

It’s not their fault, and if we’re honest with ourselves, we’re all a little impatient. Customers want their products, and they want them now.

Once again, make-to-order, given the nature of the method, customers have to wait a while before receiving their products. And if they must wait longer than they originally realized, this will manifest in their dissatisfaction toward you.

That was a brief overview of the make-to-order definition method and how it could potentially benefit your business.

But, now let’s look at its counterpart, which is again another avenue of a manufacturing technique that you could explore.

PRO TIP: Regardless of which workflow you decide to run your business with, you’re still going to find issues if you’re managing your inventory with inefficient spreadsheets. That’s why a lot of businesses improve their inventory management system with cloud inventory software.

What is make-to-stock (MTS)?

Make-to-stock is a production workflow technique of planning and scheduling production based on demand planning — final products are produced to fulfill expected orders in the next production period.

This traditional production strategy aims to match your business’s production and inventory with customer demand forecasts. However, this can be tricky and even risky as the slightest miscalculation can mean dead stock, a shortage, or excess inventory. If you’re a company that practices make-to-stock, you should be able to spread production at certain periods to avoid an expected influx in sales.

The make-to-stock method is a push system of manufacturing products for forecasted demand.

The push system = Products being pushed to production from expected sales.

A make-to-stock example

What is the main difference between make-to-order and make-to-stock systems?

Unlike make-to-order, make-to-stock products wait for the customers to come and purchase them.

To keep the examples in a similar field as earlier, you want to buy a PC for the family. You’re not looking for something fancy. You just want a PC that can get the job done.

You head to an electronics store that sells all sorts of electronic goods, and they stock several PCs.

You look at the different models on display, you pick out one that you like, and someone from the store runs behind the scenes and emerges with your product. The customer’s journey is finished, but the journey toward creating the final product started long before, in anticipation of the customer’s arrival. The business would have analyzed their previous sales and made assumptions on different trends — in the current economy and its own sales history.

It will make a forecast based on its capacity and demand.

Perhaps, just for an example, the PC was purchased leading up to Christmas, and the company can see a spike in PC sales from the Christmas before and were able to surmise that they will need more stock for the expected rush.

This means the PC you bought for your family in December may have been manufactured several months before, so the business could increase stock levels to cope with the Christmas rush.

A PC manufacturer will only increase production to 40% based on past performances and demand.

What are the advantages of make-to-stock?

As already stated before, this might be a viable method for you, depending on your type of business.

But we’ll still look at the advantages and disadvantages to understand if make-to-stock is a strategy you should incorporate. Three advantages are:

1. Spread resources and production

As you’ll be manufacturing your products ready for the customer’s demand, you can properly and carefully organize your resources and production that will be carried out to maximize your efficiency.

2. Make-to-stock scheduling

Using this method means that you’ll be able to design a master production schedule to make sure your workflow is as smooth as it can possibly be. It allows you and your employees to know where they need to be and what is left to do.

3. Minimize customer wait times

Finally, your products will be waiting for your customers — obviously, if everything is completed on time. As soon as your customers have placed their order, their product can be shipped out to them, reducing the customers waiting time by a huge amount.

Using a make-to-stock method seems like a dream come true for someone who values organization and has complete control of their business’s workflow.

The best defense is a strong offense, so to speak.

What are the disadvantages of make-to-stock?

However, this tactic can also come with some disadvantages as, for the most obvious reason, this type of manufacturing process relies heavily on the assumption of the industry.

Let’s take a look at three disadvantages that could affect you and your business:

1. Unpredictable nature of consumer trends

You forecast by analyzing historical sales and seasonal spikes, but even though you’ve made it as completely accurate as you can and with correct assumptions, your products, unfortunately, aren’t selling as well as you originally predicted.

Or the other extreme, a sudden boom that you weren’t prepared for. It’s just the nature of the beast.

2. Inventory levels

You can technically be in a perpetual state of either having too much or not enough stock.

3. The difficulty of making accurate sales forecasts

The industry can be complex and affected by a ton of variables, so that already makes it difficult to forecast your sales. However, one little mistake or miscalculation means you could end up with too little or an excess of stock, which will cost your business.

There are pros and cons to following either workflow — make-to-stock vs make-to-order.

However, you should know that if you decide to organize production following one of these tactics, that doesn’t have to be your final choice. You can experiment and switch between the two, or it might even be beneficial for your business to switch completely over to a different workflow. It all depends on your business’s needs.

But, either way, you probably realize that there is a lot of work needing to be done, regardless of choice.

And when it comes down to brass tacks, successful implementation is what’s key here.

But, how?

Organize your workflow with cloud inventory software

Using a cloud-based inventory management software such as Katana can help you with inventory management and production scheduling from one easy-to-use platform so you can stay focused on crafting your products.

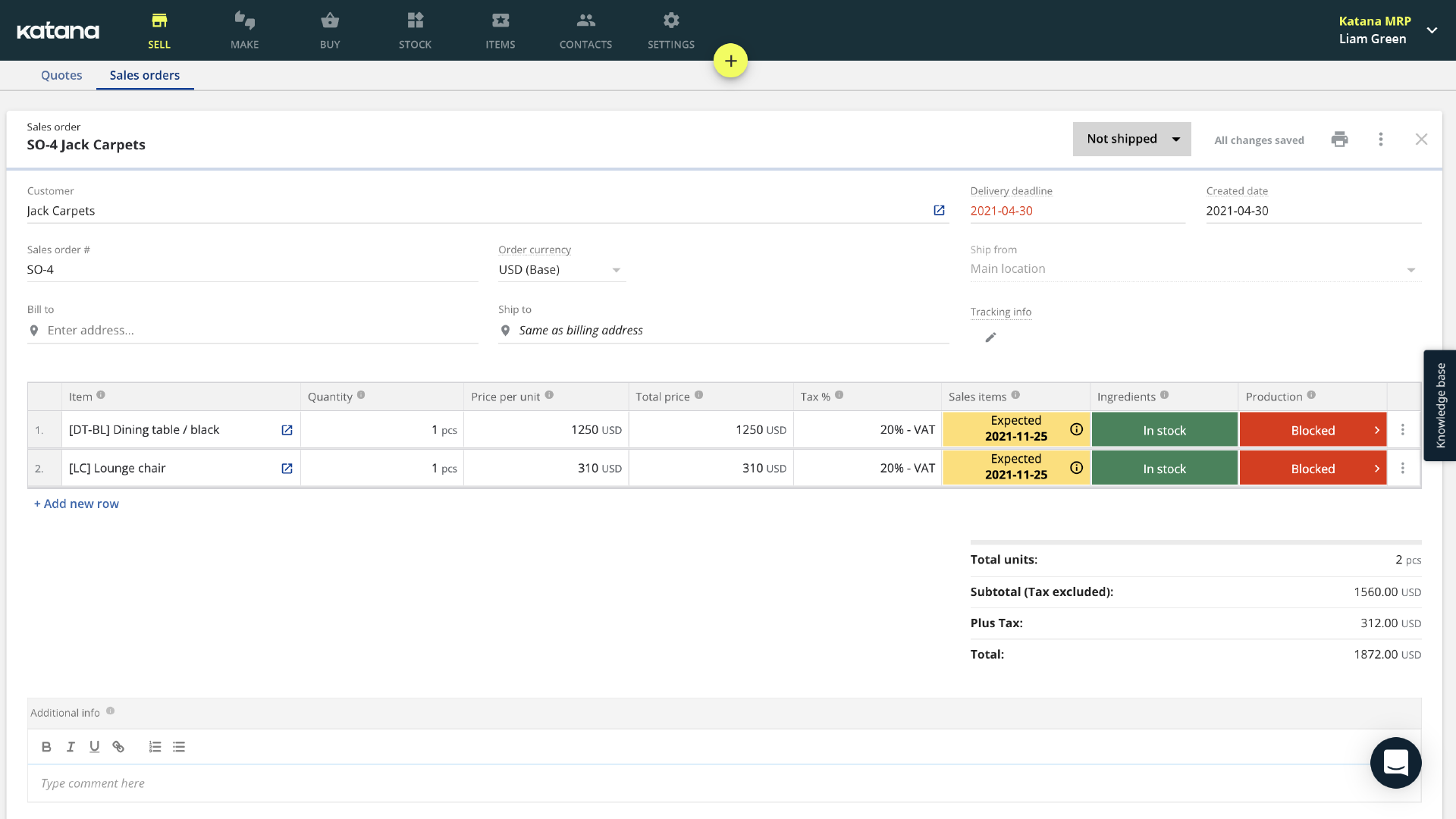

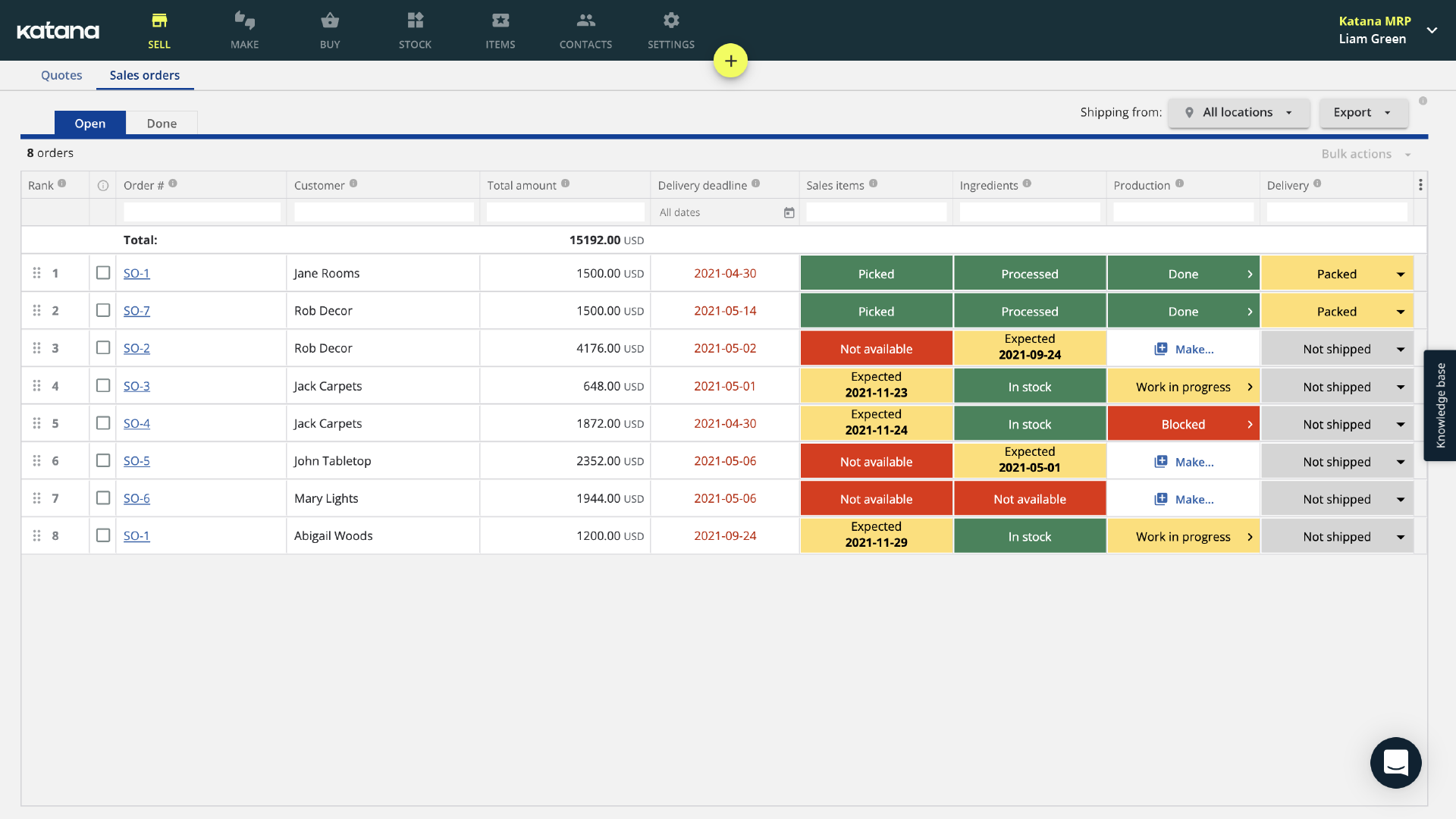

If you decide to use a make-to-order vs. make-to-stock workflow, Katana can assist you. Sales orders can be added either automatically via integration of your e-commerce accounts like Shopify or applied manually. If you’re a make-to-order business, a make-to-order option can be selected, which will generate a manufacturing order for your business.

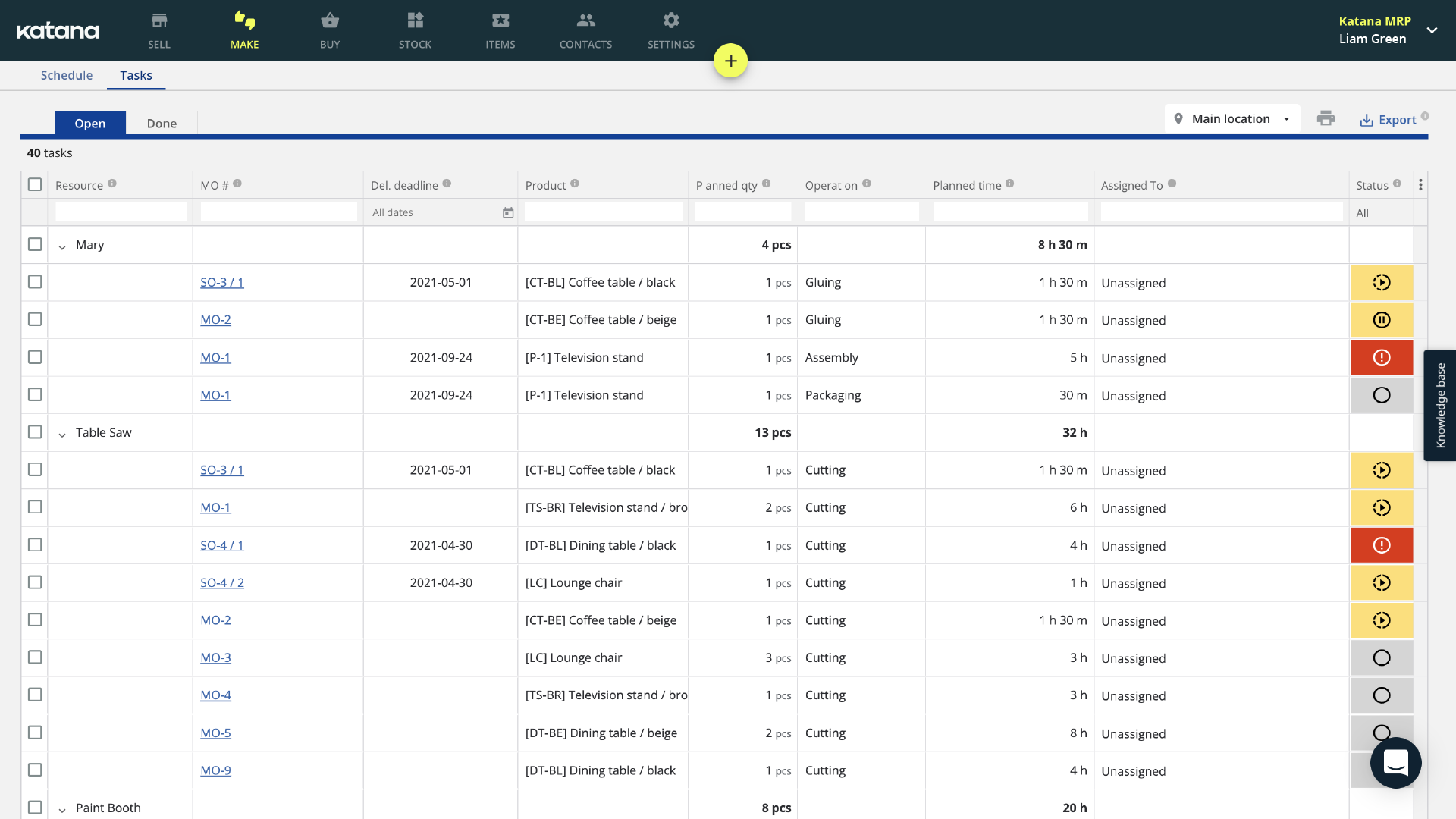

Production schedules update automatically, and you can adjust accordingly if you wish to prioritize a certain production. Make-to-stock workflows are used by businesses that manufacture in bulk and carry product inventory. You can access and view items in inventory on the Stock screen.

Here it displays materials in stock, your expected stock, and material already committed to production — all of these update automatically to represent your business’s most recent activity.

You can also set a reorder point on this page to ensure that you always have some safety stock in your inventory. Finally, you can also see your missing or excess stock levels. If a number is highlighted red, it means that stock is running low, and it’s time to get more.

By selecting the Make option, you can schedule production for the missing stock.

Download the Ultimate Guide to Inventory Management

A comprehensive ebook with everything you need to know about inventory management for manufacturing.

Still unsure which workflow to use?

If you’re still unsure which workflow is best for you, it can be simplified further down to this:

Make-to-order is a viable strategy when the products you’re manufacturing are complex, with many customizable features for your customers.

Make-to-stock is a viable strategy when there isn’t much variation between the products you manufacture and little customization on orders.

Both workflows come with their own risks, but a good rule of thumb to follow in deciding your method is the complexity of your product and the demand for your product. It’s not unusual for a make-to-order business to have some safety stock in inventory.

Regardless of your choice, integrating quality cloud inventory software will relieve a ton of stress and help you not get overwhelmed with the manual micro-management of your inventory’s movements.

Reach out to our sales team today and request a demo.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control