The 7 best manufacturing software in 2024

With a market jammed-packed with different types of software, finding the right tool for your business is overwhelming.

This article will focus on ERP to help you find the best manufacturing software solutions. But why ERP? It provides a comprehensive solution that addresses the unique challenges of the manufacturing industry while incorporating almost all the features of other manufacturing tools.

With that all being said, now onto the important question:

Which one is the best manufacturing software for your business?

If you’re looking for software or want to switch, this article will help you start with the 7 best manufacturing ERP software on the market.

What is manufacturing software?

Manufacturing software is a type of software specifically designed to assist manufacturers in planning, executing, managing, and optimizing their production processes. It encompasses a wide range of functionalities and systems that aim to improve various aspects of the manufacturing process, including:

- Engineering design

- Production planning

- Inventory tracking

- Forecasting

- Purchasing

It also facilitates communication between different departments within a company to ensure that the manufacturing process runs smoothly and efficiently. Manufacturing software can be used to track inventory levels and raw materials needed for production and easily identify where additional supplies are needed. This allows businesses to plan ahead when it comes to fulfilling customer orders quickly and accurately.

Manufacturers can use this type of software for quality control purposes, helping them ensure that products meet safety standards before they’re shipped out.

Manufacturing software can be used to help analyze manufacturing data and control the factory floor. This includes identifying areas of waste or inefficiency and making changes that will reduce overhead costs while improving overall efficiency. By streamlining their production processes with the right software, businesses can keep up with customer demand while ensuring top-notch quality control.

What are the manufacturing software benefits?

Manufacturing ERP software offers a variety of benefits to help your business achieve efficiency and accuracy. Here are the seven key advantages just to get you started:

1. Automated workflow — ERP systems use automation to move processed information from one part of the system to the next, eliminating manual data entry. Thus:

- Reducing errors

- Saving time

- Increasing productivity for your team

2. Increased visibility — You’ll have better visibility into every step of the production process with an ERP system, including:

- Inventory management

- Demand forecasting

- Scheduling optimization

With this information at hand, you can make better decisions that improve workflow efficiency and reduce costs.

3. Improved traceability — Manufacturing ERPs provide detailed records on each component involved in the manufacturing process. This traceability helps you quickly identify and address issues with:

- Product quality

- Non-conforming materials

- Incorrect orders

4. Faster delivery — Manufacturing ERP software allows you to plan production runs more efficiently, leading to increased:

- Throughput

- Faster delivery times for customers

- Customer satisfaction

5. Enhanced compliance — With full traceability of production processes, manufacturers can ensure that they comply with:

- Safety and environmental standards

- Regulations

- Legal and ethical requirements

6. Increased accuracy — Automation reduces errors while ensuring data accuracy across multiple systems. This leads to:

- Greater customer satisfaction

- Identifying and addressing inefficiencies

- Fewer recalls due to inaccurate shipments or products not meeting quality standards

7. Cost savings — By improving automation throughout the production cycle, you can reduce labor costs and operational expenses while increasing throughput. This helps to:

- Increase your profit margins

- Improve the overall bottom line

- Deliver the most value to your customers

Overall, ERP software is vital for any manufacturing business looking to maximize efficiency, accuracy, and profits. You can gain a competitive edge in today’s marketplace by leveraging this software’s many benefits.

Key features of ERP for manufacturing

Before we deep dive into some of the best manufacturing software systems on the market, it’s necessary to understand what you need from your system and what most systems come equipped with. You can use the following list as a guide as you test and trial the different ERP systems.

When looking for the best manufacturing software, make sure it includes the following key features:

- Material and inventory management — Allows enterprises to track and manage their raw materials, finished goods, and inventory levels in real time

- Production scheduling and forecasting — Helps companies plan and schedule their production processes and forecast future product demand

- Quality control and traceability — Enables companies to monitor and control the quality of their products and track the movement of materials and products throughout the manufacturing process

- Financial management — Provides companies with real-time financial information and analytics, including cost accounting, budgeting, and financial reporting

- Supply chain management — Allows businesses to manage and optimize their supply chain, including tracking suppliers, managing purchase orders and deliveries, and monitoring logistics and transportation

- Maintenance management — Lets companies schedule and track maintenance of production equipment and facilities to minimize downtime and maintain optimal production efficiency

- Human resources management — Enables businesses to manage employee data, payroll, and benefits and track employee attendance, performance, and training

- Reporting and analytics — Allows companies to access real-time data and analytics to monitor production, inventory, sales, and other key business metrics and generate reports that are important in helping manufacturers make informed decisions

Now you know what to keep your eyes open for when looking for software. The next step is to dive in and get testing. So, Without further ado, here are the top ERP systems for manufacturing your business can implement.

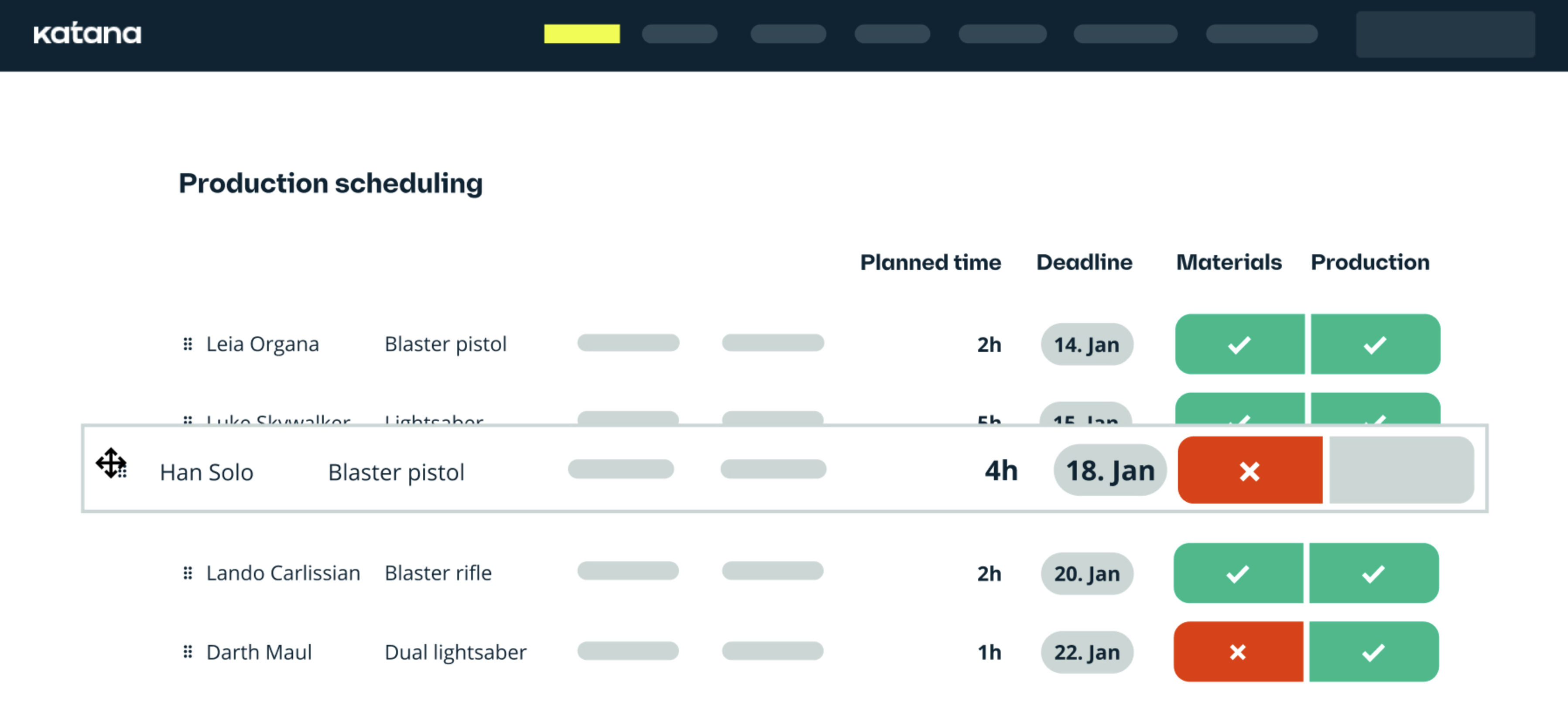

1. Katana Cloud Inventory Platform

Price: Starts at $359 per month

Demo/trial: Request a demo

Katana is a purpose-built platform for inventory, production, and sales management.

Thousands of SME manufacturers use Katana for a real-time overview of their entire business and processes with features to help them:

- Automate production planning

- Inventory planning and forecasting

- Manage in-house and outsourced manufacturing operations

- Create a smooth workflow by integrating with their other favorite tools

Katana gives users the essential and advanced tools for managing manufacturing and production, such as:

Bill of materials (BOMs)

Katana BOMs automatically allocate materials to production and calculate the manufacturing costs of making that product.

Inventory forecasting and planning

Remove the guesswork from your inventory planning — Katana uses real-time sales data for forecasts, so you can plan accordingly for customer demand.

Master production schedule (MPS)

Anything can happen that’ll throw a wrench into the works — be that metaphorically or literally. Katana’s MPS gives you a real-time overview and the ability to make changes on the fly.

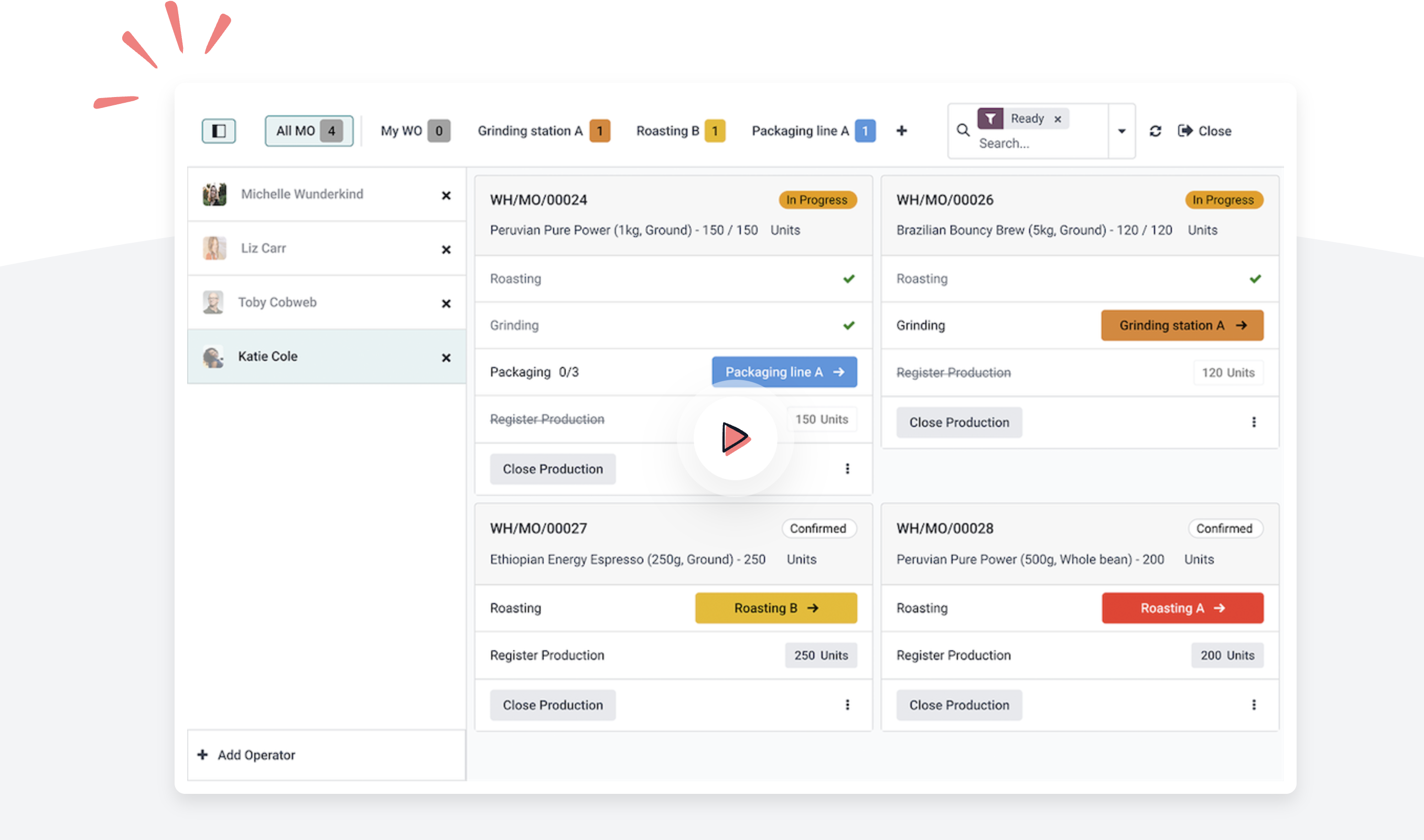

Shop floor control (SFC)

Katana’s Shop Floor App allows managers to oversee the entire production run and monitor the status of employees’ tasks with a clear communication channel.

Barcode scanning

Katana comes with barcode scanning capabilities, allowing users to assign barcode numbers to inventory items, view barcode numbers in Katana, and identify inventory items using barcodes.

Batch tracking

Batch tracking in your manufacturing management is invaluable and often required by regulations for full traceability and returns management.

Integrations with other tools

Katana comes pre-equipped with the functionality to integrate your favorite accounting tools, CRM platforms, e-commerce platforms, reporting tools, and more.

Hassle-free native integrations with your essential business tools, including:

API access

If there isn’t already a solution for you, then Katana gives you the tools to create your own integrations. If you are a coding Wizkid, you can become an Integration Partner and help other manufacturers too.

Have questions?

Request a demo and see exactly how Katana can help you optimize your business processes.

2. Fishbowl

Price: Starts at $329 per month

Demo/trial: Demo

The next one on the list of best manufacturing software is Fishbowl Inventory.

Fishbowl manufacturing ERP inventory is a hybrid solution that helps manufacturers manage their warehouse and production operations. It has typical ERP inventory management features, as well as more advanced ones like predicting inventory requirements based on historical data. This can be used for setting reorder points, allowing the user to be flexible with their inventory management. Unlike most manufacturing management software, it can either be installed at an operation location or accessed via the cloud.

Fishbowl is worth checking out if you’re looking for:

- Bill of materials management

- Job shop management

- Cycle management

- E-commerce and accounting integrations

3. Unleashed Software

Price: Starts at $279 per month

Demo/trial: 14-day trial

The next manufacturing software solution is Unleashed — a cloud-based app that supports manufacturers who make, manage, and transport products.

Unleashed ERP gives users powerful inventory management features to get an overview of their suppliers, production, warehouses, and sales. All this helps them easily and accurately track stock movements in real time. Unleashed manufacturing software allows manufacturers to gather data by creating graphs and reports to understand their inventory movements better.

Unleashed is good manufacturing management software if you’re looking for inventory management with:

- E-commerce features

- Integrations with other tools

- API access

- Manufacturing warehouse management

4. Odoo

Price: Starts at $11.90 per month per user

Demo/trial: Free trial for Standard and Custom plans

The next one in our best manufacturing software round-up went through a big change in 2022 with how it prices itself. The first app is free with Odoo, but if you wish to add more apps, you need to pay.

Odoo is a suite of open source business apps that starts off free but offers different packages depending on your needs. An open-source ERP allows you to build your own integrations and features upon their core ERP offerings. This means Odoo ERP can be set up on a desktop at a location or accessible via the cloud.

The open-source ERP manufacturing software is impressive, but if you go for the paid versions, you can get features such as:

- Customer relationship management

- Accounting tools

- Manufacturing management tools

- Product lifecycle management

5. Megaventory

Price: Starts at $135 per month

Demo/trial: 15-day trial

Another web-based one in this best ERP system for manufacturing listicle is Megaventory.

Megaventory is an order and inventory management solution for medium-sized manufacturers.

Megaventory manufacturing ERP software with inventory management helps users manage different inventory types at multiple locations to get a complete overview of stock levels in real time, allowing them to check supplier availability and easily manage returns. The manufacturing ERP software allows business owners to define users’ permission to keep information confidential and avoid other employees making mistakes.

Megaventory manufacturing ERP comes with order fulfillment features to help users easily manage sales orders and purchase orders.

Manufacturing ERP like Megaventory is great for business owners looking for:

- Handling multiple currencies

- Manufacturing reports

- Integrations with other tools

- API access

6. Netsuite ERP

Price: Varies but is expensive

Demo/trial: Demo

Oracle NetSuite ERP is a well-known cloud-based software that helps manufacturers control their key back-office operations and finances. Due to its high cost and complex system, it’s better suited for large enterprises.

The biggest selling point of NetSuite manufacturing ERP is its powerful financial management capabilities — including revenue management, billing solutions, and inventory costs. This manufacturing software solution has built-in business intelligence, giving users real-time reporting and analytics to give them the tools for faster and better decision-making. Like the other software, it also comes with essential ERP features like inventory management, e-commerce hosting, and customer relationship management.

You should check out Netsuite manufacturing ERP software if you’re a manufacturer looking for:

- Business management

- Order management

- Supply chain management

- Warehouse management

7. ERPAG

Price: Starts at $25 per month

Demo/trial: 15-day trial

Last but not least, ERPAG is a cloud-based manufacturing ERP solution built for small and midsize businesses from industries such as automobile manufacturers and retail.

Manufacturing software like ERPAG gives users access to barcode scanning, which supports EAN, EAN-13, and UPC to help you manage and track stock. The features also help support different manufacturing processes, including simple production by managing work orders and a bill of materials or complex production with time and materials tracking. ERPAG software for manufacturing companies offers different pricing packages to customize their software to be compatible with their manufacturing.

You should check out ERPAG if you’re on the hunt for:

- Reordering

- Order fulfillment

- Integrated invoicing and purchasing module

- Multi-language interface

What is the best software for manufacturing?

The best software for manufacturing depends on the specific needs and requirements of the manufacturing company.

ERP is the best all-around software for manufacturers, but that doesn’t necessarily mean it’s the best for your business. As mentioned at the beginning of the article, there are a ton more software options for manufacturers who need something other than an ERP solution.

Some popular options include:

- Computer-aided design (CAD) software — Used to design and create 3D models of products, allowing for virtual prototyping and testing

- Computer-aided manufacturing (CAM) software — Used to translate the designs created in CAD software into instructions for CNC machines and other manufacturing equipment

- Manufacturing execution systems (MES) — MES software is used to track and control manufacturing processes, typically in real time

- Product lifecycle management (PLM) software — Used to manage a product’s entire lifecycle, from design and development to retirement, including managing and tracking changes to the product design and its associated data.

It’s important to note that many software providers offer integrated solutions that combine multiple of the above functionalities. It’s also important to thoroughly evaluate the different options and determine which best fits the manufacturing company’s specific needs.

But, back to the topic at hand.

ERP software is great for manufacturing because it integrates and automates various business processes, such as supply chain management, financials, and human resources.

This can help manufacturers streamline their operations, improve efficiency, and better use data to inform decision-making. An ERP system can provide real-time visibility into the entire manufacturing process, from raw materials to finished goods, enabling manufacturers to identify and address any issues that may arise quickly. Overall, an ERP system can help manufacturers to increase productivity, reduce costs, and improve customer satisfaction.

Best of all, as you have already seen from the list, many offer demos and free trials, so you can find the best manufacturing software system without having to drop a single penny.

Best ERP for the manufacturing industry

If you want to see the best manufacturing software in action, book your demo and get ready to take your business to the next level.

Best manufacturing software FAQs

What is ERP used for in manufacturing?

ERP (enterprise resource planning) is a type of software used in manufacturing to manage and automate various business processes, such as production planning, inventory management, financials, and supply chain management. It can help manufacturers to improve efficiency, reduce costs, and make better business decisions. It also allows for real-time data tracking and analysis, which can be used to monitor the performance of the manufacturing process and identify areas for improvement.

What are the 3 common types of ERP?

The three common types of ERP systems are:

- Manufacturing ERP — Designed for manufacturers and includes modules for production planning, inventory management, and quality control

- Financial ERP — Focuses on financial management and includes modules for accounting, budgeting, and financial reporting

- Supply Chain ERP — Helps optimize and manage the flow of goods and services and includes modules for procurement, logistics, and warehouse management

What is CRM vs ERP?

ERP and CRM (customer relationship management) are separate business management systems used to handle various areas of an organization. CRM is used to manage and analyze customer interactions and data throughout the customer lifecycle to improve customer relationships and drive sales growth. On the other hand, ERP is used to manage and automate a company’s internal processes, including accounting, human resources, procurement, and supply chain management. While both CRM and ERP are important tools for businesses, they serve different purposes and are typically used by different teams within a company.

What are manufacturing software solutions important?

Manufacturing software solutions are important for a variety of reasons. They can help increase efficiency and productivity by automating repetitive tasks, reducing errors, and streamlining workflows. They can also help with inventory management, supply chain coordination, and quality control. Many industrial software solutions can connect with other systems, such as ERP and CRM systems, to provide a more thorough perspective of the production process and improve decision-making. Overall, using manufacturing software solutions can lead to cost savings, improved quality, and increased competitiveness for a manufacturing business.

Table of contents

Manufacturing guide

More content from Katana

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control