The importance of an accurate engineering bill of materials

An engineering bill of materials (EBOM) is an essential part of any design, engineering, and manufacturing project. Learn all about it in this article.

Henry Kivimaa

Say you’re looking to create a delightful meal to surprise your spouse. Since you want everything to be perfect, you first look up the recipe. This is to ensure you have all the required ingredients ready and can plan all the steps ahead.

The same principle applies to manufacturing.

To make sure everybody involved knows the exact ingredients and steps, they need a detailed product recipe. This product recipe is called a bill of materials (BOM). There are many different kinds of BOMs, but this article will take a closer look at an engineering bill of materials (EBOM).

What is an engineering bill of materials?

An EBOM is a critical document that serves as a comprehensive list of all the parts, components, and materials needed to build a product. An engineering BOM typically includes detailed information about each item, such as its part number, description, quantity, and any relevant notes or specifications.

An engineering BOM serves as the foundation for the entire product development process, providing critical information to everyone involved in the design, engineering, and manufacturing stages. By creating a single, standardized source of information about the product, the bill of materials for engineering helps to ensure accuracy and consistency throughout the process, from design to delivery.

Download a free bill of materials template

Download this free bill of materials (BOM) template to better plan and budget your production. A BOM template also helps you to better manage your inventory and improves your quality control.

In addition to providing a detailed list of parts and components, the engineering BOM can also include important information about the product, such as test procedures and quality standards. This helps to ensure that the final product meets all required specifications and performs as intended.

In the following sections, we’ll explore some of the best practices for creating an effective EBOM, as well as the benefits of having an accurate and well-maintained engineering BOM throughout the product development process.

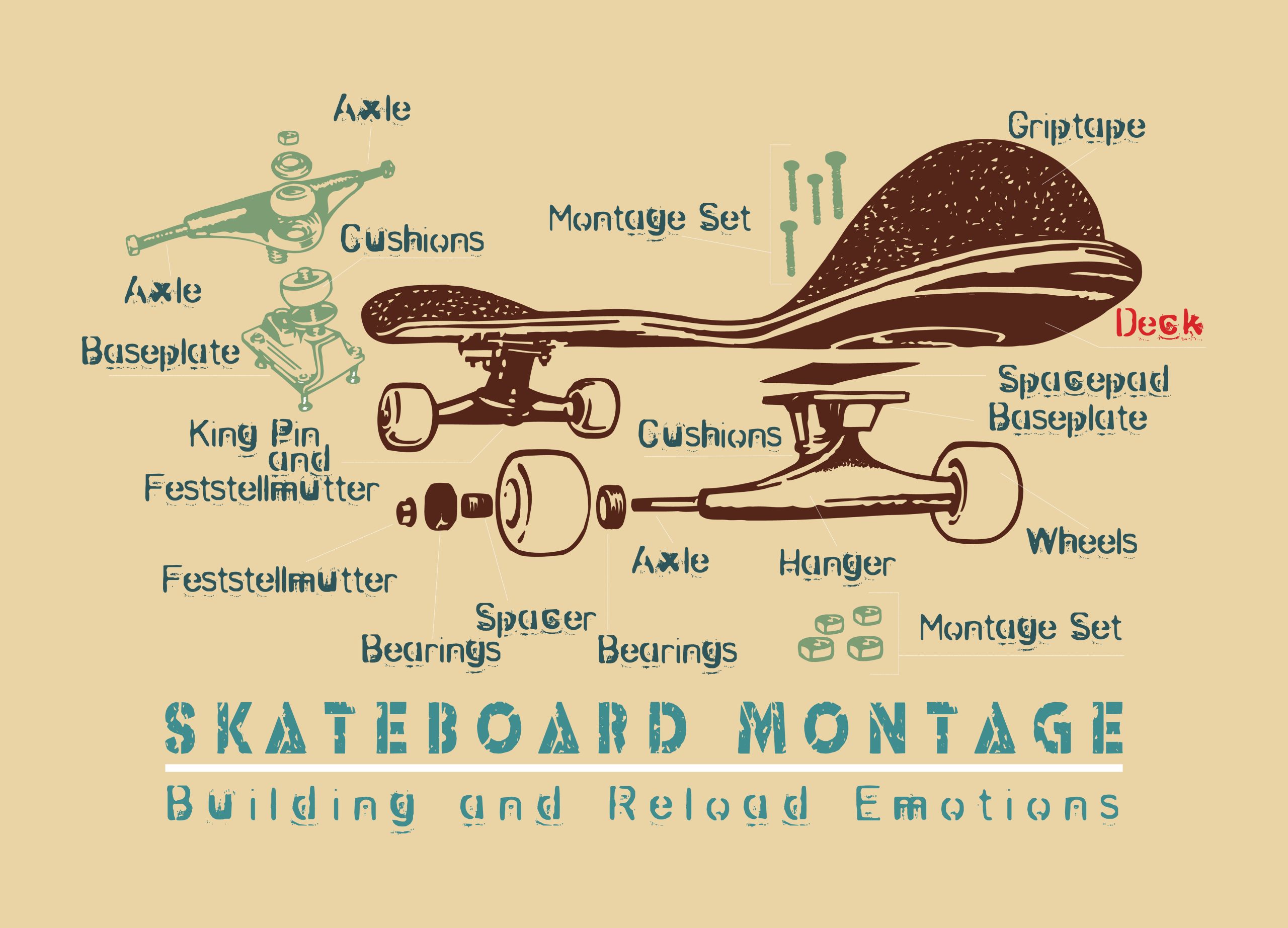

Engineering bill of materials example

Let’s look at a simplified engineering BOM example for a skateboard.

-

Deck

- Deck blank (maple)

- Grip tape

- Trucks (aluminum)

- Wheels (urethane)

- Bearings (steel)

-

Trucks

- Baseplate (aluminum)

- Hanger (aluminum)

- Kingpin (steel)

- Bushings (urethane)

- Washers (steel)

- Nuts (steel)

-

Wheels

- Wheel cores (urethane)

- Wheel covers (urethane)

-

Bearings

- Bearing shields (steel)

- Bearing balls (steel)

- Bearing races (steel)

- Bearing retainers (nylon)

Creating an effective engineering bill of materials

While the EBOM is a critical document in product development, creating and maintaining an accurate and effective EBOM can be complex and challenging. Here are five best practices to consider when creating an EBOM:

- Organize data — It’s important to establish a consistent and organized system for managing data related to the EBOM. This includes using a standardized format for part numbers and descriptions and ensuring that all data is up-to-date and accurate.

- Incorporate feedback — As the product development progresses, it’s crucial to incorporate input from all stakeholders to ensure that the EBOM accurately reflects the needs of everyone involved.

- Maintain version control — As changes are made to the product design, it’s essential to maintain a system for version control that ensures that all stakeholders are working with the most up-to-date version of the EBOM.

- Standardize components — Whenever possible, it’s best to standardize components across multiple products to reduce complexity and streamline the manufacturing process.

- Consider supply chain issues — When creating an EBOM, it’s important to consider potential supply chain issues, such as lead times, availability, and cost, to ensure that the final product can be manufactured efficiently and cost-effectively.

By following these best practices, engineers can create an effective EBOM that provides a solid foundation for the product development process. In the next section, we’ll explore some benefits of having an accurate and well-maintained EBOM.

Importance of an accurate engineering bill of materials

An accurate and well-maintained engineering BOM is crucial to the success of any product development project. Here are some of the key reasons why an accurate EBOM is so important:

- Provides a clear picture of the product — An EBOM serves as a comprehensive list of all the components and materials needed to build a product, providing a clear and standardized picture of what the final product will look like.

- Reduces errors — By providing a single source of accurate information about the product, an EBOM can help reduce errors and misunderstandings throughout the product development process, ultimately leading to a higher-quality end product.

- Facilitates customization — An accurate EBOM can make it easier to customize products to meet the needs of specific customers or markets, as all components and materials are clearly defined and organized.

- Enables cost savings — By accurately tracking all components and materials needed for a product, an EBOM can help identify opportunities for cost savings, such as using standardized components or negotiating better prices with suppliers.

Overall, an accurate EBOM plays a crucial role in the product development process by providing a single source of accurate information about the product. It reduces errors, facilitates customization, and saves costs, making it an essential tool for engineering projects.

Next, let’s explore some of the challenges associated with managing EBOMs.

Challenges of managing an EBOM

As with everything, creating an accurate EBOM comes with its challenges. Let’s go over 5 most common ones that engineers and project managers face when working with EBOMs:

- Keeping the EBOM up-to-date — As product designs change and evolve, it can be difficult to ensure that the EBOM stays up-to-date and accurate. Any discrepancies or errors in the EBOM can lead to costly errors or delays.

- Managing changes — When changes are made to the product design, it’s important to ensure that the EBOM is updated accordingly. This can be time-consuming and challenging, particularly when dealing with complex products involving many different components.

- Ensuring consistency — With multiple engineers and teams working on a product, it can be challenging to ensure everyone uses the same terminology and formatting when creating and updating the EBOM.

- Handling supplier data — The EBOM often includes data related to suppliers, such as part numbers and lead times. It can be difficult to manage this data, especially when dealing with many suppliers or when supplier information changes frequently.

- Integrating with other systems — The EBOM needs to be integrated with other systems, such as manufacturing resource planning (MRP) and enterprise resource planning (ERP). This can be a complex and challenging task, particularly when dealing with legacy systems or custom-built software.

Despite these challenges, an accurate and well-maintained EBOM is critical to the success of any product development project. By developing a clear understanding of the challenges involved in managing an EBOM, engineers and project managers can take steps to minimize these challenges and ensure that the EBOM remains accurate and up-to-date throughout the product development process.

Download the ultimate e-book for manufacturers

Learn how to organize and scale your manufacturing.

EBOM vs. MBOM: what’s the difference?

While the EBOM is a comprehensive list of all the components and materials needed to build a product from an engineering perspective, the manufacturing bill of materials (MBOM) lists all the components and materials required to build a product from a manufacturing perspective. Here are some of the key differences between the two.

While the EBOM and MBOM serve different purposes, they are closely related and must be kept in sync to ensure the final product is built correctly. By understanding the differences between the two and ensuring they are appropriately integrated, engineering and manufacturing teams can work together more effectively to produce high-quality products.

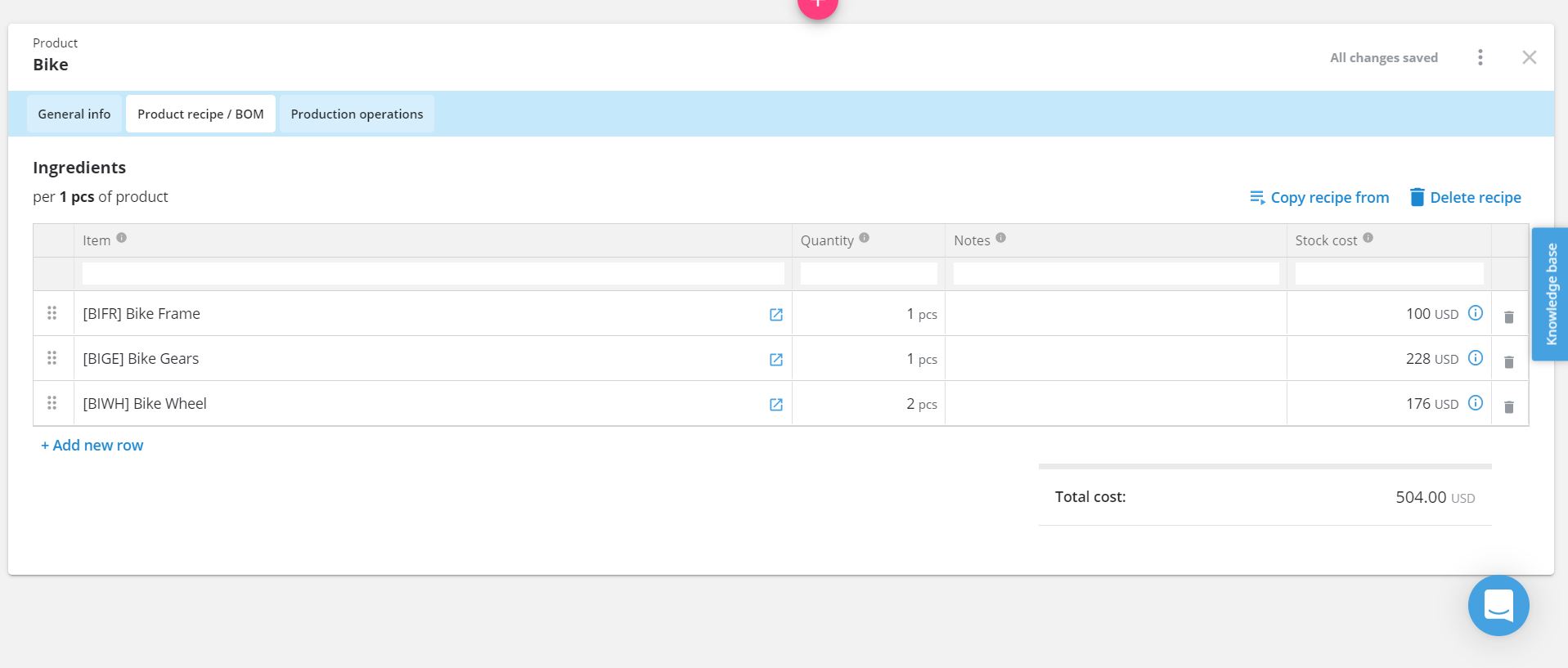

Software to manage your BOMs

BOMs are an integral part of any manufacturing business, so it’s essential that your software solution supports that feature.

One such solution is Katana.

Katana is a cloud manufacturing platform that helps small and medium-sized manufacturers manage their production processes, including their BOMs. With Katana, manufacturers can:

- Manage inventory — Katana provides real-time visibility into inventory levels so manufacturers can avoid stockouts and overstocking.

- Create and manage BOMs — Katana allows manufacturers to create and manage their BOMs in one central location, with the ability to add and remove components as needed.

- Track production processes — Katana provides real-time updates on production processes, allowing manufacturers to identify bottlenecks and optimize their workflows.

- Integrate with other systems — Katana integrates with other software systems, such as QuickBooks Online and Shopify, to provide a unified experience and a complete view of your business.

By using a software solution like Katana, manufacturers can streamline their BOM management processes, reduce errors, and improve overall efficiency.

Request a demo and take your manufacturing business to the next level.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control