How to implement a barcode system in manufacturing

Barcodes are like signatures on your products that help clarify certain information about the item to speed up manufacturing processes. Keep reading to learn how barcodes can help you raise the bar for your business.

Henry Kivimaa

If you happen to be running a manufacturing business, chances are that you have a warehouse to keep in order. Wouldn’t it be nice if, instead of manually entering all your products into some inventory management system, you could just wave a wand and have all these items magically documented?

Well, look no further because a magic wand like this does exist — it’s called a barcode scanner.

In the beginning, business owners want to do everything manually, crunch the numbers twice just to be sure, and go over all the documents. But, as orders grew and the business scaled, it became too time-consuming to continue this analytic tradition. This is the moment successful companies turned to technology for help.

Sure, AI and robots might not be at that level for world domination, but they can certainly help you as you aim to take over the world with your fantastic products.

The best way to streamline your workflow is to digitize tasks and automate as many processes as possible. One of the ways to do that is to label your products with barcodes and start scanning them. You’ve undoubtedly seen the little stripy pictures on packages, everyone seems to be using them — and for a good reason.

Here’s all you need to know to start implementing a manufacturing barcode tracking system in your business.

What are barcodes? How do they work?

Barcodes are little visual elements consisting of numbers and lines that can entail various types of data. They can be used to identify products in retail or to label documents for accounting purposes.

Barcodes can be scanned using a barcode reader, which translates the visual element into data. The codes are divided into standards based on build: 1D and 2D. Both of these need different types of scanners.

What is WMS barcode?

Sometimes barcode systems are referred to as WMS (warehouse management system) barcodes, which do precisely what the name says — help manage your warehouse.

How are barcodes used in manufacturing?

There are a few areas of business where you can really benefit from barcode scanning:

- Inventory management

- Batch tracking

- Accounting

- Cooperation across teams

- Quality assurance

But how exactly can a tiny little element affect your business that much?

Inventory management

Accept supply deliveries and allow tracking of finished products by just scanning them. It will significantly speed up your inventory tasks like receiving materials from partners, identifying existing items, and shipping out deliveries.

No more manually adjusting spreadsheets or picklists, simply scan the barcode on a product and automatically update its quantity to the correct value.

Batch tracking

If you ever need to trace a product to its original batch or even find the particular components that were used, all you need to do is scan the item, and you will instantly get a clear overview of which parts were used.

This practice can also prove helpful in case you’ll ever have to issue a recall for a particular product, as you can trace all the items — from supplier parts to manufacturing and resellers.

Accounting

Your bookkeeping will significantly benefit from adding barcodes to the documents, from invoices to contracts. Instead of going through the paperwork to get an overview, your legal team will simply scan the barcodes to find all the necessary information.

Seeing as scanning also updates your inventory records, your accountants will be able to carry out their tasks more efficiently.

Pro tip: Take a look at how to generate barcodes using accounting tools such as QuickBooks Online and Xero.

Cooperation across teams

Socializing is fun, but streamlining processes and optimizing workflows is even more fun! You’ll no longer have to chase people down between departments and micromanage everything.

All the data is shared between departments that just have to scan a barcode to access the information they need to keep a steady workflow.

Quality assurance

To err is human, and little hiccups can sneak in from time to time. Try to automate and digitalize as many processes as possible to reduce mistakes. Whether we’re ready to accept it or not, computers work more efficiently, so we might as well use them to our advantage.

Barcode scanning also gives a good overview of which quality control steps have been taken, which are still in progress, or which have been skipped altogether. This speeds up the quality assurance process and provides even more security regarding product standards.

How do I set up a barcode system for manufacturing?

By now, you’ve obviously realized that barcodes are magical little things, and you must be wondering how to implement barcode systems in manufacturing. It’s nothing complicated, and once you start using barcodes, you’ll be amazed at how you could have ever lived without them.

There are a few things to take into consideration when implementing a manufacturing barcode tracking system.

Select a barcoding software that meets your business needs

There is no one-size-fits-all solution when it comes to creating a barcode system. Make sure to outline your requirements before settling for software.

There are a lot of platforms out there that offer barcode scanning for manufacturing as one of many features. Instead of having separate software for every task, try to look for one that ticks as many boxes as possible.

Figure out which data you want the barcodes to contain

As impressive as they may be, one barcode can only fit a certain amount of information. To pick a suitable barcode standard, you’ll first have to outline all the data you need the codes to contain.

Be specific about the details you include and add as much information as possible. Remember, the more you can automate, the more efficient your manufacturing becomes.

Generate visual manufacturing barcodes

You’ve gathered the data and chosen a barcode standard. Now it’s time to create the codes themselves. Many platforms are able to generate their own barcodes. You simply have to select the product and the software will craft a code for that specific item.

However, if your chosen software doesn’t have this feature, or you want to be fancy and make especially pretty barcodes, there are also online generators to use.

Pro tip: There are many online barcode generators or software options. But if you want to keep it simple, there’s another solution. Check out this article on how to use Excel spreadsheets to generate barcodes.

Keep in mind that to work correctly, your software and scanners will have to support that type of code. All that’s left, is to print out the labels, stick them on your products and start scanning them bad boys.

If you’re fortunate and your inventory is already labeled, then all you have to do is scan the codes and sync them with your system.

Make the most of your new manufacturing barcode tracking system

Now that you have finished your stripy masterpieces, it’s time to put them to good use. Once all your employees have been trained to use scanners, they will become a part of everybody’s daily work. Depending on what type of data you store on your barcode, manufacturing can be significantly optimized and sped up.

For example, if you have correctly set up an inventory system and barcodes to support it, your stock management processes will be much smoother. You can also add critical dates to track important schedules per product.

With the proper setup and a scanner, the world is your oyster!

An efficient and low-risk workflow benefits not only you but also your business partners and customers. Your processes will run smoother, product standards and quality will rise, and customers will be satisfied with their purchases. Don’t forget — a happy customer is a returning customer.

Pro tip: We’ve also put together a thorough guide on how to implement a barcode inventory system.

How to get started with Katana?

Katana is all-in-one manufacturing software that ties all your operations together on one platform. From production to sales, accounting to quality control — access all areas of your business at once and have separate departments automatically synced. All in an effort to help your business reach its full potential fast and in a simple way.

Katana also offers barcodes as a feature so that businesses can optimize their costs and reduce errors. Update your inventory count, move products in and out of stock, and reduce losses throughout your manufacturing process.

How to start using barcodes in Katana?

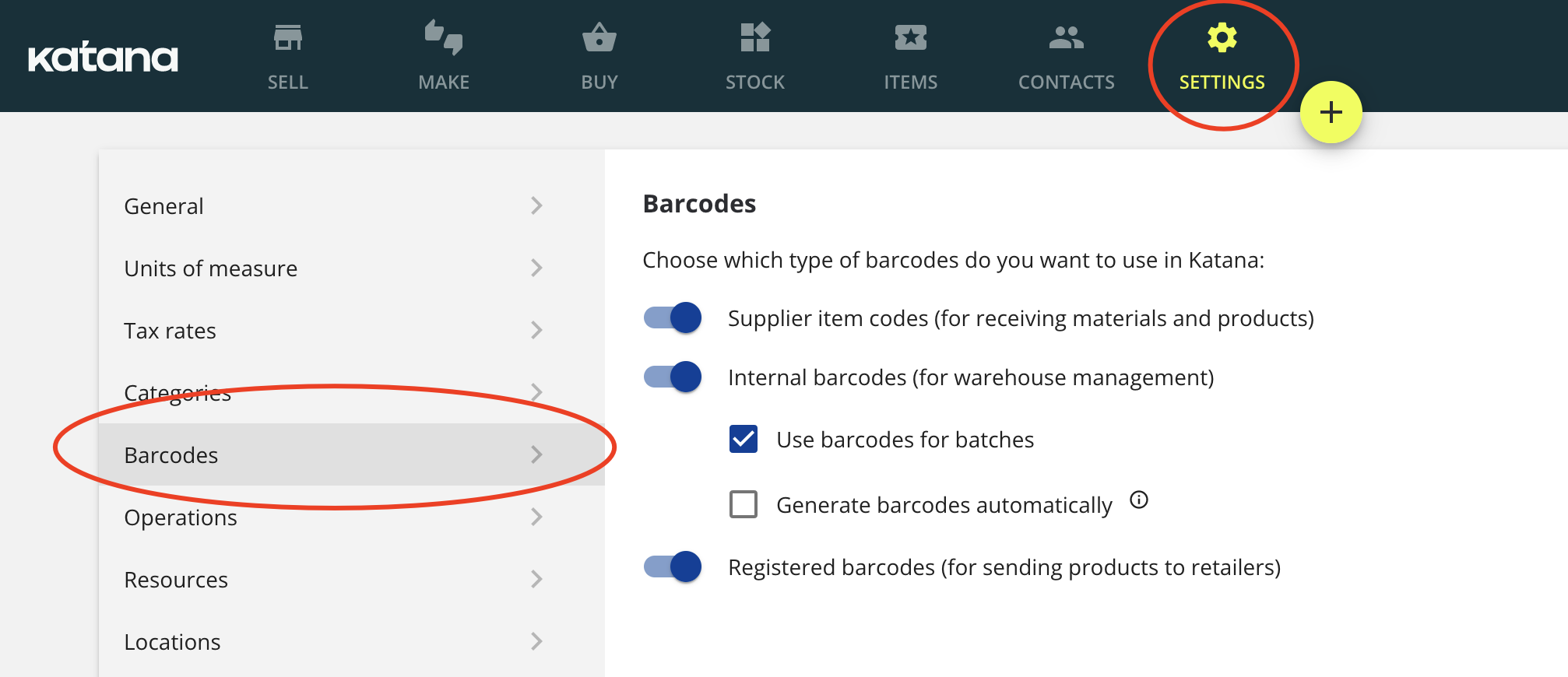

Barcode configurations can be accessed in Settings -> Barcodes.

In this view, you can select the type of barcodes you want to use, whether you want the codes to be generated automatically, and if you want to label separate batches as well.

Pro tip: If you decide to disable barcodes at one point, just toggle the switch off. That will stop new codes from being generated but will not delete existing ones.

Automatically generating barcodes is an excellent way to start using them for the first time. However, if you’ve already used barcodes and have existing labels, you can keep using them once you import them to Katana.

Once you’ve set up (or imported) your barcodes and all your items have been properly labeled, all you need is a supported scanner and the fun can begin!

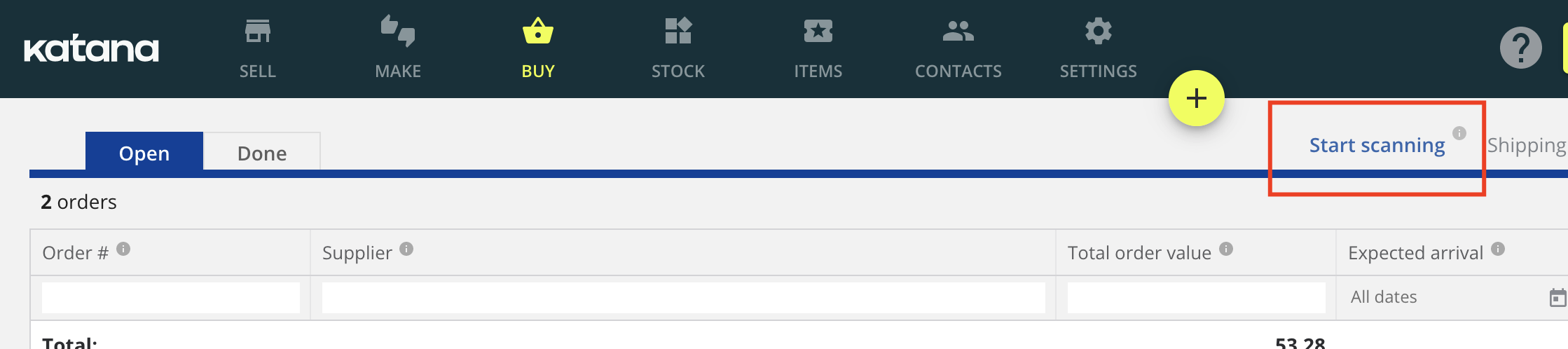

To start with scanning, you’ll need to activate Scanning Mode by either clicking on “Start scanning” or using a keyboard shortcut (CTRL+B for PC or CMD+B for Mac).

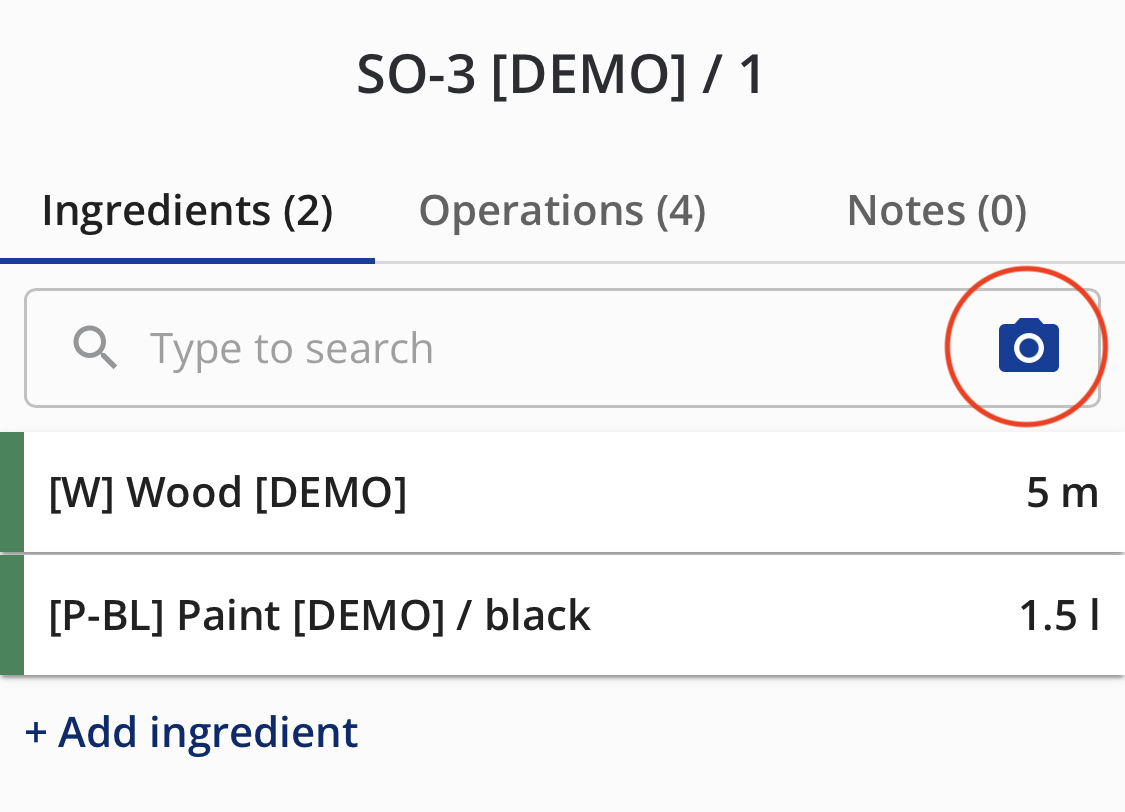

When working in the Shop Floor App, you can use a smart device as a scanner. Open a task and tap on the camera icon. That will open the camera and you can scan the code as you would with a regular scanner.

If you’re more of a practical learner, then we have a special treat for you. We’ve put together an informative video on how to start using visual manufacturing barcodes using Katana manufacturing ERP.

It will guide you through the entire setup process and explain everything step by step.

Now that you know everything about barcodes, why not see it all in action? Request a demo to see firsthand how much time and money you’ll save by automating your operations.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control