Manufacturing planning and scheduling software

Ditch the spreadsheets for an intuitive production scheduling software that automatically prioritizes your manufacturing and allocates materials to open orders. Get a production plan up and running without lifting a finger.

Empower your manufacturing business with cutting-edge production planning software

Seamlessly manage resource allocation and production schedules, mitigating potential pitfalls that could disrupt your operations. Experience streamlined efficiency and optimized supply chain coordination, all thanks to the power of manufacturing scheduling software. Stay ahead of competitors and achieve your business goals with ease.

Manufacturing planning software that does the heavy work for you

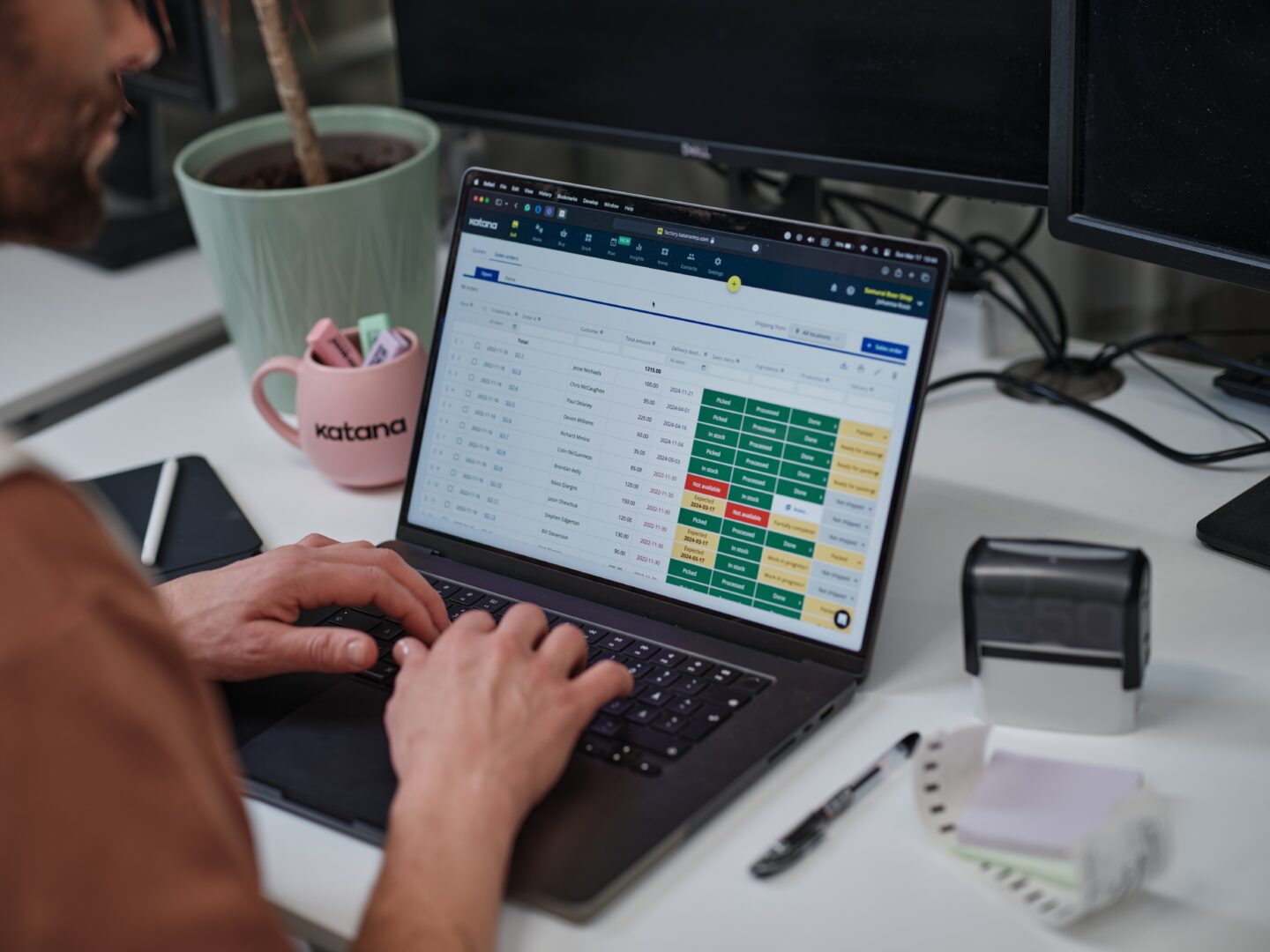

Katana automatically prioritizes your tasks based on when a manufacturing order (MO) is generated.

If there’s an order you need to work on sooner rather than later, though — no worries! In Katana, simply drag and drop an MO to the top of your production list. The production planning software will reprioritize the order and reallocate materials to fit the new workflow.

Katana’s manufacturing planning and scheduling software can automatically:

- Create a workflow and visually display the status of each MO

- Generate production deadlines based on your bill of materials (BOM)

- Calculate cost estimates and planned completion times

- Assign operators to resources if already specified beforehand

Production planning and scheduling software helps you manage all your resources

Manufacturers face constant change, both inside and outside their business. The more your business expands and grows, the more critical and challenging production planning becomes.

Katana comes with manufacturing analytics to anticipate future demand according to past sales performance. This can help you avoid production overload and HR issues without incurring overtime costs.

Manufacturing production scheduling software allows you to:

- Set up tasks according to product operations for incoming MOs

- Plan, schedule, and assign tasks to operators

- View the MO card and ingredient list for every task

- Track time spent on tasks to optimize shop floor activities

Unlock the potential of your business with production scheduling software

Gain access to a great deal of benefits that drive efficiency and enhance productivity. Seamlessly manage and allocate resources, optimize production timelines, and meet deadlines with precision.

Production schedule software helps you to establish manufacturing schedules, ensuring efficient collaboration across all teams and locations. Stay organized and enhance productivity by providing your team with a unified roadmap to follow.

Production scheduling software for manufacturing lets you:

- Maximize resource utilization

- Minimize downtime

- Improve workflow visibility

- Ensure on-time delivery

Features

Maximise productivity with Katana’s efficient production management tools

With a range of essential features and functionalities, Katana empowers businesses to optimize their manufacturing processes, efficiently allocate resources, and meet customer demands with ease.

Integrate Katana’s manufacturing planning software with your favorite business tools

Unite the services you love with integrated manufacturing planning software

Choose from various e-commerce, accounting, CRM, reporting, and automation integrations to streamline your key business operations beyond production planning. Katana is a system built to fit your essential business tools. Take a look at Katana’s growing list of integrations to learn more.

Katana integrates everything, making for effective company-wide resource planning and control. We now know what we have in store and where to look for it.”

Danielle Louw

Production Manager at CT LAB

We needed help with Shopify inventory management for raw materials, and Katana exceeded our expectations.”

Pablo Baque

Walk With Me CEO

We chose Katana because it presents our manufacturing business information in the easiest possible way.”

Miguel Salazar

Manager at IDC Componentes

I think that Katana had a much lower barrier to entry, and I was able to gradually build my processes into Katana’s system.”

Richie Duncan

Founder of KODAMA

Production planning and scheduling FAQ

Production planning is the process of creating and following a detailed roadmap for manufacturing operations to achieve desired goals efficiently. It encompasses activities such as production scheduling, resource planning, and coordinating various tasks to meet customer demand effectively.

To put together an effective production plan, you have to:

- Understand demand — Gather data on past sales and trends to understand potential customer behavior in the future

- Set production objectives — Establish specific goals and targets to follow along the process

- Determine production capacity — Understand the maximum efficiency your production can provide and take advantage of its full potential without draining all your resources

- Create a production schedule — Put together a schedule for all teams to meet deadlines and prevent downtime

- Plan material requirements — Determining the quantity and timing of materials needed for production

- Coordinate with suppliers — Communicate your expectations with partners and make sure you’re following the same guidelines

- Allocate resources effectively — Eliminate waste and optimize the use of resources as much as your production allows

- Monitor and control production — Conduct regular audits to detect deviations from the plan on time

- Seek continuous improvement — Find areas for improvement, and don’t stop looking for new ways to optimize your processes

- Adapt to changes — Adjust the plan according to shifts in objectives, customer demand, or business needs

Production scheduling involves creating and managing a detailed timeline and sequence of tasks within the manufacturing process. It includes determining the proper order of operations, providing resources, and establishing timelines to ensure efficient production.

To create a production schedule:

- Gather data — Find all the information available to you on orders, capacity, and resources

- Prioritize tasks — Determine the level of importance of tasks based on urgency and importance

- Map out production — Compose a list of processes and sequence of tasks

- Estimate time requirements — Put together a timeline for each task

- Allocate resources — Outline everything your team will need to perform production tasks, including materials, equipment, labor, and budget

- Create the schedule — Using software or other preferred tools, establish a schedule outlining the production process from start to finish

- Communicate the schedule — Review and share the schedule with your team and organize training if necessary

- Monitor the progress — Perform audits and controls regularly and make updates as needed

Production planning and scheduling software is a powerful tool that combines essential functionalities for effective manufacturing operations. It provides a centralized platform to streamline production planning, scheduling, and coordination, resulting in numerous benefits for businesses.

With manufacturing planning software like Katana, manufacturers can experience several key benefits.

- Enhanced efficiency — Optimize resource allocation, reduce downtime, and streamline workflows, thereby improving productivity and operational efficiency

- Accurate inventory management — Live inventory level updates enable optimal stock management, prevent stockouts, minimize excess inventory, and ensure smoother order fulfillment, ultimately enhancing customer satisfaction

- Improved order fulfillment — Effective order management and scheduling ensure timely deliveries, better customer satisfaction, and increased customer loyalty

- Seamless collaboration — Encourage smooth coordination among team members and departments involved in the production process by centralizing all operations and information into one platform

- Data-driven decisions — Access to real-time data on production, inventory, and orders empowers making better-informed decisions, identifying areas for improvement, and constant optimization of overall operations

There are multiple steps to follow for a smoother production flow, including:

- Forecasting demand — Following past trends and sales data, plan your manufacturing according to customer behavior to be prepared for spikes in demand and higher production volumes

- Determining production capacity — Taking into consideration your production capabilities and demand, determine how much manufacturing you will be able to take on without stretching out your resources and still meeting buyers’ expectations

- Developing a master production schedule — Plan your manufacturing processes and operations as optimally as possible to minimize waste, downtime, and excess costs

- Establishing inventory procedures — Establish policies and protocols for your team to follow to stay on the same page and focus on the same goals

- Planning and scheduling resources — Optimize your processes and operations to stop wasting resources like money, time, materials, and labor

- Monitoring and controlling production processes — Ensure you are on schedule and within budget and take corrective measures if you start noticing deviations

- Making adjustments as necessary — If customer demand and production goals change, adapt promptly and modify your production plan and schedule accordingly

- Continuous evaluations and improvements — Conduct regular audits and controls to ensure everyone is following the guidelines and still on the same page throughout the manufacturing process

These steps can be adapted to specific business needs or industry requirements. The main goal should remain to minimize waste, maximize productivity, and monitor progress along the way.

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control