Job shop manufacturing: A manufacturer’s best friend

Every day is Christmas in Santa’s workshop. Well, surely that’s Father Christmas’ approach to management to get his workforce to meet those massive quotas. All ready for that one day of the year. He must operate his not-for-profit business this way since the items are so diverse it’d be impossible for him to incorporate assembly lines.

So, how the heck does Santa do it?

If you don’t know how he does it, don’t worry, you’re not a cotton-headed ninny muggins. Let us tell you all about the world of the job shop manufacturing process.

What is job shop manufacturing?

Job shop manufacturing characterizes itself as a shop with tools, machines, and facilities with similar functions or performances. The separated workstations perform different tasks during a product’s manufacturing process. The final products are produced in small batches (of varying quantities). Customers customize their orders to meet their specific needs.

This means a business will produce a small volume of products that are not standardized.

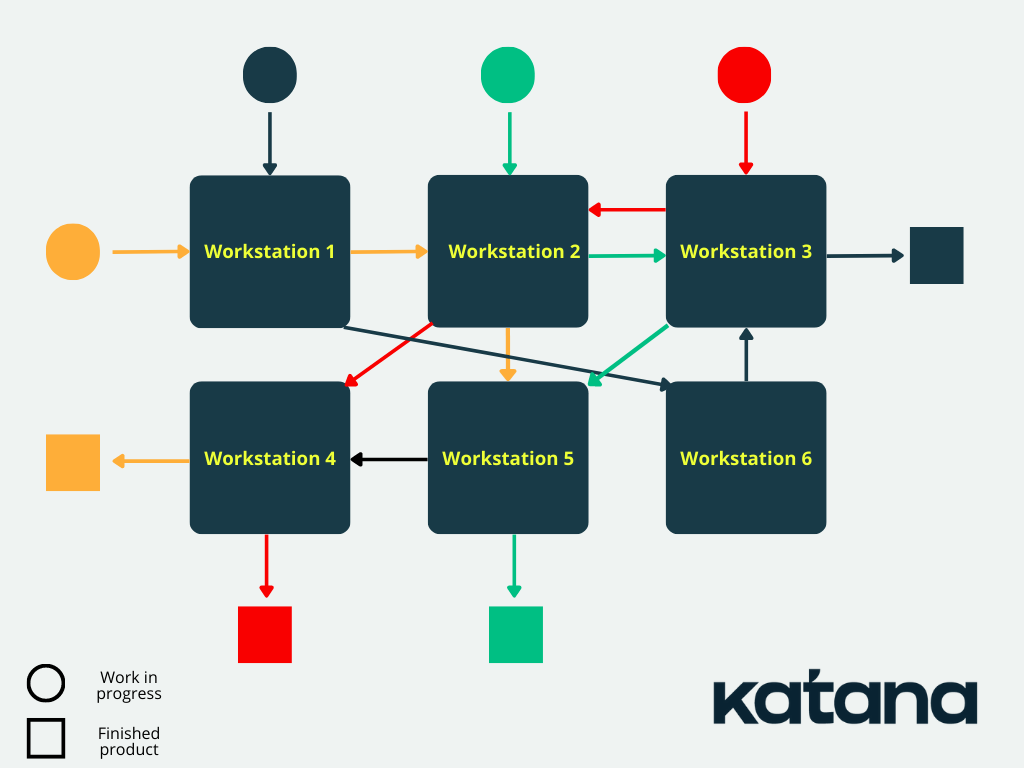

The level of personalization offered by the job shop process means shop floors have a unique setup and process steps. Products produced by a company may not go in the same direction. Meaning items will move differently to the next process and may even return to the same workstation several times.

All this depends on the product’s manufacturing requirements.

Job shop manufacturers can sell their wares directly to customers, via a wholesaler, or produce parts for other businesses. Businesses that use job shop production often employ just-in-time (JIT) workflow to fulfill customer orders.

Now that we know what is job shop production let’s look at an example.

Manufacturing vs. production

While these terms are often used interchangeably, there is a distinct difference between the two.

- Manufacturing — The process of turning raw materials into finished products

- Production — All the activities associated with the creation of goods

The manufacturing process begins with raw materials and ends with finished products. On the other hand, the production process encompasses all the activities necessary to create a product, from start to finish. This includes everything from sourcing and procuring raw materials to packaging and shipping the finished product.

To lear more about the differences, you can check out the following article — Production vs. manufacturing: what’s the difference?

A job shop production example

The fruits of a diverse selection of items were produced in a job shop manufacturing environment. There is a huge list of businesses that use this process. However, for our job shop manufacturing example, we’re going to look into the world of producing eyeglasses.

Framed by Karl is a business that makes and sells customizable eyeglasses made from wood. Let’s look at the exact steps involved.

Design

At Framed by Karl, glasses are customized by the customer. Job shop production allows manufacturers to personalize each individual item because of their unique setup.

The customer chooses from a range of stock frames to have their own personalized glasses. During this stage, they also have the option to select the particular type of wood they want to have. The company will collect the customer’s measurements for the item’s blueprint so production can begin.

Along with different variations for customers, they can decide if they would like hinges before placing the order.

Preparation of material and cutting

Once the order is made, the raw materials get prepared from the company’s inventory. Then begins the cutting of the material as per the requirements of the customer’s order.

An employee carefully cuts the material into the desired shape. This workstation will be specific to this step of the manufacturing process. In job shop manufacturing workstations are divided to avoid clutter and backlogs.

Shaping

Once the materials are cut and prepped, they enter the shaping process. The wood is bent and placed inside a tool, putting pressure on the frames to achieve the desired shape. After an ‘X’ amount of time, the frame holds its rough final form.

Varnishing

Once the frame is ready, the product goes through varnishing. One coat of varnish will be applied, then removed after 30 minutes to avoid warping the wood. This process takes place several times across multiple days. It is not unusual in job shop manufacturing for products to go through a process several times.

Final product

The frames will go through their final stages of polishing before completion. The final touches are applied, bringing the item to completion after going through the relevant processes of the job shop manufacturing.

This meticulous approach to work allows for complete customization of a customer’s order. Having the workstations separated this way enables the product to be easily transported to the following process. Although, having the options for personalized items means the items won’t go through the same order.

The complicated workflow of job shop manufacturing looks like this:

As you can imagine, or even experience yourself, this type of workflow can be very sporadic. Meaning that job shop manufacturing comes with its own unique advantages and disadvantages.

Pro tip: Are you a scaling business manufacturer who wants to overhaul their productivity? Check out our must-have guide to answering the question of what is manufacturing.

7 advantages of job shop production

The characteristics of job shop production system mean it has many advantages, let’s see what these are in a bit more detail.

1. Customize product design

Job shop production process allows customers to personalize their orders. This makes items unique and allows the customer to participate in the process.

2. Easily adaptable to change

The workstations and machines being divided means if the shop floor needs to be rearranged or the process changes, this can be quickly and easily done, unlike other manufacturing processes which require a reconfiguration of the entire company layout.

3. Better use of resources

All your resources can be efficiently utilized to fulfill orders by being able to focus on each product.

4. Flexibility

The erratic nature of the workflow means you have the option to prioritize certain operations.

5. Floor-level monitoring of products

The movement of the products going through their individual processes means you can easily track their development.

6. Highly skilled workers

For this type of manufacturing process to work correctly, you will need employees that are highly skilled in the specialized craft of your business. This means you can leave workers to continue their tasks, and their skill level will ensure that they deliver a quality product in a timely manner.

7. Lower Investment

You buy the relevant tools and machines, you store them in the most effective places for your products to pass through during manufacturing, and that’s it — you’re set up. If you need more things to meet customer demand and finish products, you just purchase more. The installation of any new workstations shouldn’t disrupt the current workflow.

Job shop manufacturing is the perfect process for any modern manufacturer. Most businesses even find their roots in it. However, that isn’t to say that this process isn’t without its flaws, so let’s review these to ensure you’re aware of them and can take the necessary steps in advance.

5 disadvantages of job shop production

As with everything, there rarely ever are silver bullets that fix all your ailments without any adverse side effects. The same goes for job shop production. While there are many clear advantages, there are also some disadvantages that you should consider before deciding if this type of manufacturing is right for your company.

1. Difficult to schedule

The randomness and inconsistency of orders can often lead to a backlog, which is accepted among many job shop manufacturers. You might have only a few orders come in one day and a whole load the next day, meaning that a schedule may need to change to meet orders constantly.

2. Difficult to organize

Because items pass through different processes, it can be challenging to organize your production flow. Some orders can be relatively straightforward, while others can have a massive bill of materials (BOM) which will be costly for your resources.

3. Material handling costs

Transporting, storing, and damage to goods are just a few costs that affect your business while using job shop manufacturing. In lean manufacturing, this is known as muda (waste), and it’s categorized as an action that doesn’t add value to the customer’s sale.

A very simple example would be ‘transport’. Moving the item around the shop floor costs resources but doesn’t add value.

4. High production lead time

Because items are customizable, you have to wait until you receive the customer’s order. Then you’ll have to generate a manufacturing order before beginning production.

5. High levels of work

The workload can be intensive if you receive a high amount of orders. Though, the opposite is also a disadvantage too. Low to no orders mean resources aren’t being fully utilized. Nevertheless, both can be stressful to experience.

The disadvantages of a job shop perhaps appear daunting. Even though you can run the risk of encountering these types of issues, there are steps you can take to avoid these.

How can scaling manufacturers use job shop manufacturing?

As previously mentioned, one of the most significant issues a business owner finds with this process is that it’s challenging to organize. Some managers get around this by tracking their key performance indicators (KPIs). These KPIs can be their lead time, machine utilization & capacity, worker assignment, and inventory.

How you decide to monitor your business’s progress is down to you. Though, you should be aware of the responsibilities that will fall on you as an owner or manager, which will help you ease any of the disadvantages mentioned.

Manufacturing lead time

One of the major disadvantages of running a job shop is the long lead time. However, if you take the time to calculate your manufacturing lead time, you can avoid keeping your customers waiting and keep them happy.

Production scheduling

Your production scheduling needs to be on point. Not only should it be pitch-perfect, but it should also be dynamic. Your schedule needs to fully utilize your resources in a workshop that has already been designed to maximize efficiency.

One way of achieving a smooth production schedule is by managing your job shop manufacturing layout. Your shop floor workstations and inventory should be positioned in places for convenience. You can do this by arranging your orders into runners, repeaters, and strangers:

- Runners — Items that have a low turnaround and make up for most of your orders

- Repeaters — Products that come through regularly as runners but not at a similar frequency

- Strangers — Products that aren’t ordered as much as runners or repeaters

Arranging your workshop with the complexity of your orders into consideration means you can prioritize orders as soon as they come in. Runners first, repeaters second, and strangers last.

This approach can help you avoid cluttering your shop floor and to minimize your backlog.

Another step you can take is to have the most used tools and materials near or on the shop floor to speed up production.

Supply chain management

This will also fall under production scheduling, and your manufacturing lead time will affect your supply chain management.

Avoid hiccups by mastering supply management to get all the necessary materials and your products shipped for on-time deliveries.

The high mix and low volume of products mean manufacturing times change with each order. An item with low direct labor hours but a big BOM will take up most of your time with supply management as you gather the materials for construction.

Having no forecast means the time available depends on your quote to the customer and the production time starts immediately once receiving the order.

Upgrade to Katana’s job shop manufacturing software

Learn more how Katana’s job shop manufacturing software can get you back in control over your manufacturing processes.

Simplify job shop manufacturing with a manufacturing ERP

“Most managers react to the confusion in their job shops in one of two ways. Either they turn to outside vendors for the latest in automation technologies and production control software — an expensive response that seldom delivers the promised benefits — or they throw up their hands.” — Article from Harvard Business Review, 1989.

This was obviously written a lifetime ago, but there’s still some truth in there. Most ERP systems are developed in mind for large corporations with thousand plus employees.

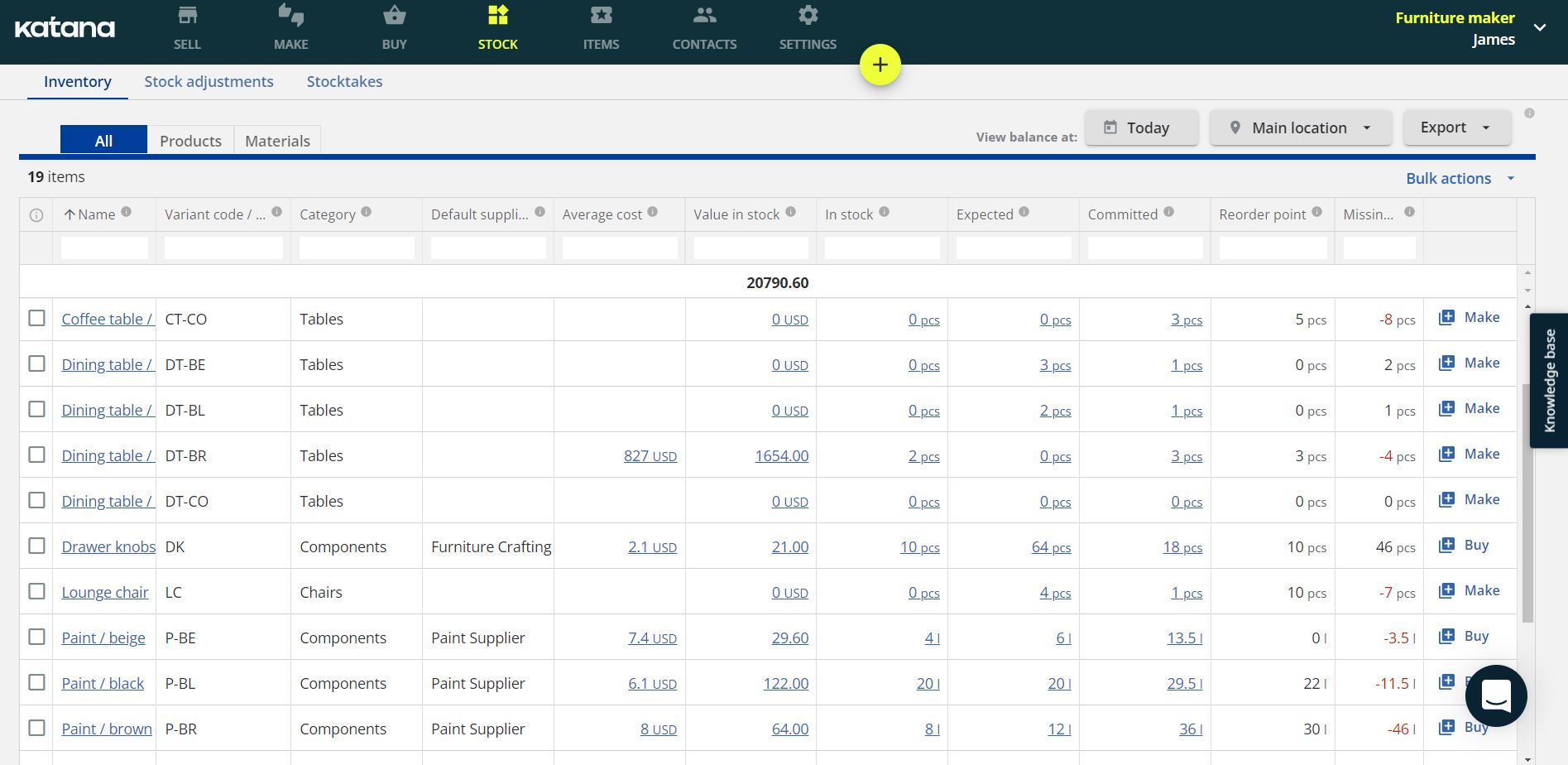

However, times have changed, and cloud inventory software like Katana is here to do much more than just handle your inventory. Katana offers you the chance to monitor your business from one easy-to-read platform. You can get an overview of the manufacturing order’s progress from the overhead view, all color-coded to make the information more accessible.

Let’s see what Katana’s manufacturing inventory software has to offer.

Autonomous inventory management

There’s nothing worse than having to input your recent inventory movements manually. No, wait, there is. To make those updates, realize there’s a mistake and then manually correct those errors. Katana eliminates that annoyance by automatically updating and saving inventory movement as soon as you commit material into production. The same goes if you want to allocate the material elsewhere or make new products.

Katana offers a ton of seamless integrations which means you can connect all your favorite business tools. Making your sales, inventory management, and accounting even more streamlined and accessible from a central place.

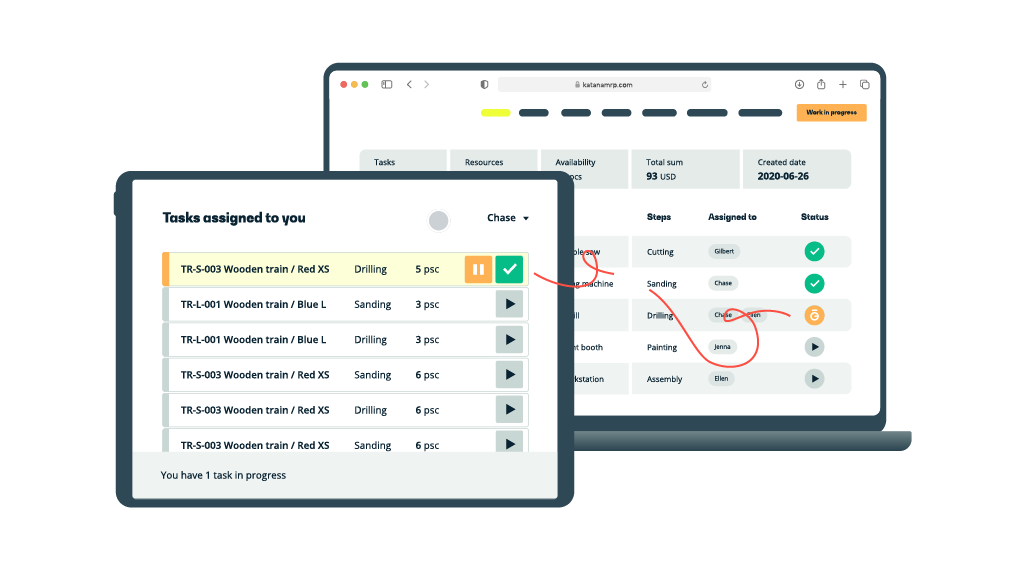

Floor-level management

You’re able to prioritize tasks, track employees’ progress and monitor production times. Checking on material availability will help you decide if you need to make orders, which means you’ll be able to calculate your product’s manufacturing lead time easily.

Scalability

Choosing a system that can scale with their business is crucial for small manufacturers. Many small manufacturers start with a bunch of Excel spreadsheets, but as the business grows, these sheets quickly become a chaotic mess. It’s time to ditch Excel and allow your business to grow.

Whether you’re just starting up or are already deep into the world of manufacturing your unique products, mastering job shop manufacturing is key to your business’s survival and growth.

With the information provided above, you should be able to identify other businesses that use this process and figure out the steps you need to take to make your business a success.

However, if you’d really like to excel, invest in enterprise manufacturing software and apply it to your job shop manufacturing process to take your business to the next level.

Until next time, happy manufacturing.

Table of contents

Manufacturing guide

More on manufacturing

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control