Just-in-time inventory: Definition, example, pros and cons

In traditional inventory management, a business orders large quantities of raw materials, ensuring they have enough to start production immediately when an order comes in.

But what if you have just enough on-hand inventory to satisfy demand instead of storing all the inventory you might need to gather dust as you wait for an order? Would that approach come with issues rendering the process useless, or is it a methodology that every business owner should jump on without hesitation?

In this article, we’re going to look into the world of just-in-time inventory.

We’ll see where it originally started, explore the costs, the benefits, and discuss whether you should implement it in your business. If streamlining your inventory management is something you’re passionate about, you’re definitely in the right place, so make yourself comfortable and let’s get started!

What is just-in-time inventory?

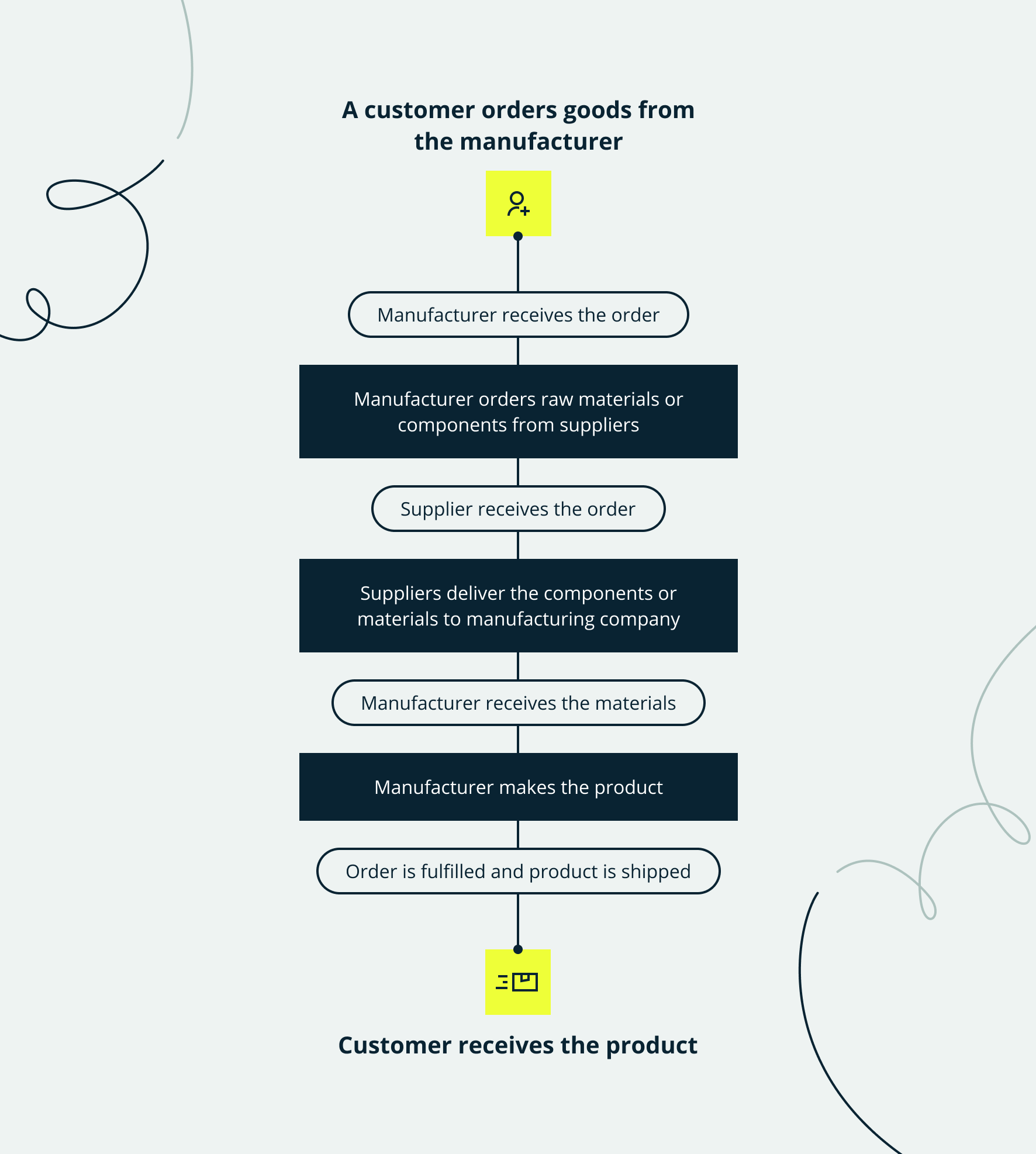

Just-in-time stock control is the philosophy of filling the market demand quickly and only using exactly what you need — you make goods when orders come in, not before.

The goal of just-in-time (JIT) inventory is to cut down costs from the production process. This is done with careful planning. All waste and inefficiencies are identified and reduced as much as possible. All resources (human, material, space, and time) are used to create the highest-quality product while cutting down costs.

Retailers use inventory management which is a form of JIT.

When you go into a supermarket, there is an unbelievable amount of choice, but only a few of each item. When an item’s SKU runs low, the supermarket’s JIT inventory system flags this up, so the manager can order more. This approach keeps stock at optimal levels, ensuring that stock-outs don’t happen or that an excess inventory would result in waste.

The history of the just-in-time inventory

In the wake of WWII, Japan was in a dire situation — most of its factories had been destroyed.

They had to deal with high levels of unemployment and an extreme lack of space and natural resources. Japan was facing post-war stagnation. It seemed impossible to build up any momentum to overcome this.

Meanwhile, in the USA, business was booming.

Everything was in abundance, as they were relatively untouched by the war. Not to mention demand was sky-high, so products were flying out of the door. The philosophy of the day was “more is better.”

There was no reason to hold back, so they favored large-scale mass production.

Isolated Japan needed to get its economy going ASAP.

Pioneers stepped up to develop ways to lean up their inventory management completely. They built smaller factories that only kept the raw material inventory needed for existing orders. Less capital tied up with carrying inventory allowed these businesses to be more flexible.

They also adopted the best practices from the US, including Ford’s moving assembly line.

The results spoke for themselves, and people paid attention when Japanese manufacturing started to become competitive in the 1970s.

Fast-forward to 2022 — Japan is in the top six countries for manufacturing competitiveness and is projected to stay there in 2023. Companies across the globe have adopted just-in-time inventory management to replicate this success. Investment in technology has allowed countries like the US, the UK, and Japan to remain relevant in worldwide manufacturing.

Advanced machinery and lean inventory software modernized JIT inventory management, so it kept its competitive edge.

In 2021, Toyota Motor Corporation reported over $23 billion in net profit. Toyota has been one of the top-performing automobile companies for years, and they attribute its meteoric success to its commitment to just-in-time manufacturing. Despite some hiccups, it is clear that using just-in-time inventory management has been a success.

What are the key features of just-in-time inventory systems?

Just-in-time inventory management is a philosophy rather than a strict set of rules. This means you can apply as much or as little of JIT as you want.

The key characteristics of just-in-time inventory management are:

- Elimination of waste — Waste of any kind, including raw materials, time, and human resources

- Continuous performance evaluation — Analyzing everyday tasks based on productivity

- Continuous improvement — Striving for quality finding ways to improve efficiency

- Customer-driven — Using a responsive pull supply-chain strategy

- Finely-tuned work environment — Clean, focused, with no bottlenecks

The just-in-time method uses all resources at your disposal to their maximum potential.

Your main resource is the people in your business, including yourself. That’s because it is up to the people to uphold a company’s philosophy. Your employees need to understand why you are moving to just-in-time inventory.

They shouldn’t see it as more hoops to jump through.

In fact, JIT should make your employees’ jobs easier and more enjoyable.

It’s up to you to provide the management and support to communicate the benefits for employees and customers. Inventory management is one of the most laborious and tedious business operations. Imagine what your business can achieve by cutting down on this zero-value task.

Instead of spending endless hours doing stocktakes, you can do more productive things like:

- Customer support

- Product photography

- Social media

- Hosting workshops

- Developing your product line

All these activities can help you boost your business’ brand. They add value to your business. The core tenet of just-in-time management is eliminating all waste, including time-wasting.

If some aspect of your process does not add value to the finished product, then eliminate it. If a chaotic work environment is causing delays, then what is the point of keeping it around?

Ask yourself: “Why does this happen? What benefit does it bring to customers?” for every part of your inventory management.

If you cannot think of a good enough answer for why something is there, then maybe you don’t really need it. This is true for physical objects, processes, and rules. Avoid unproductive money sinks. Too much inventory can suffocate your business.

Just-in-time inventory pros and cons

As with every system, there are advantages but also disadvantages when it comes to JIT. Below, we’ll list the main ones.

Advantages of just-in-time inventory

It requires minimal up-front expenditure, low inventory levels, and quick-moving inventory. All while keeping up with customer demand.

If you have a hobby business or side hustle, you most likely already use just-in-time. You will not make hundreds of your products in advance as you are unsure about future demand. You never want to be left with heaps of dead stock. Using a JIT inventory management system greatly reduces this risk.

JIT also protects against dead stock.

This affects products with relatively short shelf life or may go out of style quickly. Perishable goods are the most obvious in this category, but non-perishables, like clothing, can also fall into it. Styles can change quickly, rendering your inventory obsolete.

Having a lot of money tied up in inventory is also a huge risk.

JIT can help free up cash that would otherwise be spent on inventory. Besides, holding inventory is not without its costs. Every item in your stock incurs a carrying cost. There are warehousing and storage fees and the opportunity cost of not investing that money elsewhere.

Disadvantages of just-in-time inventory

The drawback of a just-in-time inventory system is that it can be risky under certain conditions:

- A disruption in the supply chain can take you out of action for a long time — if you haven’t planned for it

- Having too many SKUs also makes JIT difficult

- Your suppliers need to be close to your operations. If you are in the US and ordering materials from overseas, then this might make JIT unworkable

Now, it’s worth pointing out that most businesses do not manufacture hundreds of different items. The most successful companies thrive on only making a handful of specialized products. So, if you find yourself with an overabundance of SKUs, perhaps it’s worth looking into SKU rationalization or considering the 80/20 approach.

The verdict?

To reduce the risk, make just-in-time inventory and supply chain management work together. You can benefit from live inventory management software that tells you exactly what you have in stock and where it is. These systems also allow you to set up reorder points to ensure you always have enough on hand.

This means the best system to track inventory is a perpetual inventory method.

Developing good relationships with your suppliers helps a lot. You could even organize them to store inventory for you. Having alternative supply chains on standby in case one fails is another countermeasure.

Don’t be put off — the potential benefits of just-in-time inventory management outweigh the risks. It is hugely profitable in the long term. Your products can become more affordable, which allows you to increase your market share in your industry.

As long as you are proactive with management, disasters will never catch you off-guard.

Just-in-time production examples

Just-in-time inventory systems can be seen in some of the world’s biggest product-led businesses. Toyota, Apple, and McDonald’s are some of the biggest advocates for this inventory system.

Toyota

Toyota is often credited with the development of JIT and also remains one of the most successful practitioners. They do not bring raw materials to the production floor until an order is received, minimizing inventory levels and reducing carrying costs while also allowing them to quickly adapt to customer demand and special requests.

Toyota’s approach to inventory management even has its own name — the Toyota Production System (TPS). It’s a holistic approach to manufacturing, emphasizing inventory control, workforce empowerment, and continuous improvement.

A core component of Toyota’s JIT inventory management implementation is the Kanban system, a visual signaling system that helps regulate the manufacturing process, regulating the flow of materials and ensuring that only the optimal quantities of parts are supplied.

Apple

Since Apple outsources much of its production, its approach to JIT is less about manufacturing and more about supply chain optimization. Leveraging strong relationships with its suppliers helps maintain minimal inventory at its central warehouse in the US while using dropshipping for online purchases to reduce shipping and storage costs.

Apple also uses advanced forecasting and logistics technology to synchronize its supply chain, from parts suppliers to assembly workshops to retailers, minimizing time and inventory throughout the process.

This allows Apple to introduce new products rapidly and efficiently without having the burden of excessive inventory and dead stock.

McDonald’s

To ensure freshness and consistency in customer experience, McDonald’s prepares food items like hamburgers and sundaes only after the order is placed, except during peak times when a few finished items are kept ready. This JIT adaptation, often referred to as the “made for you” system, revolutionized fast-food operations.

Similarly to Apple, McDonald’s heavily relies on a meticulously coordinated supply chain. They work closely with suppliers to ensure the timely delivery of fresh and high-quality ingredients, which is critical for the JIT model to work in the fast-food context.

Through this approach, McDonald’s minimizes their inventory holding costs and reduces food waste significantly. This not only improves profitability but also enhances customer satisfaction, or in their case, customer loyalty.

Maintaining a balance between safety stock and preparing goods make-to-order is an art that these businesses have mastered to a T, making them industry leaders in their business field.

Just-in-time inventory method for scaling businesses

Let’s take a look at how JIT is applied in a business. We will go through a just-in-time inventory case study.

The leather design studio you see in this article uses just-in-time stock to full effect. They manufacture high-end leather goods like bags, purses, wallets, and accessories. These are artisan goods, and so their raw materials are expensive. The business would be unsustainable if they made loads of stock in advance.

Instead, they use a make-to-order workflow.

Their clients can customize their orders to their heart’s content which gives a great sense of exclusivity to their products. They value transparency — customers make orders with complete knowledge about the length of the production process. This allows them to develop great relationships with their customers while giving each order 100% care and attention.

Tips for adopting the best just-in-time practices

- Shop around — Don’t feel tied down to suppliers. Negotiate and let them know your expectations. Be prepared to look elsewhere to get a good deal. Maybe another supplier is more expensive on paper but is more supportive of just-in-time stock

- Limit SKUs — The more product variations you have, the higher the pool of different materials and components you need to access. This makes tracking and organizing your stock that much more difficult. A profitable business doesn’t have to have hundreds of different products. Look at your sales records and decide which products are worth continuing and which cost you more than they make

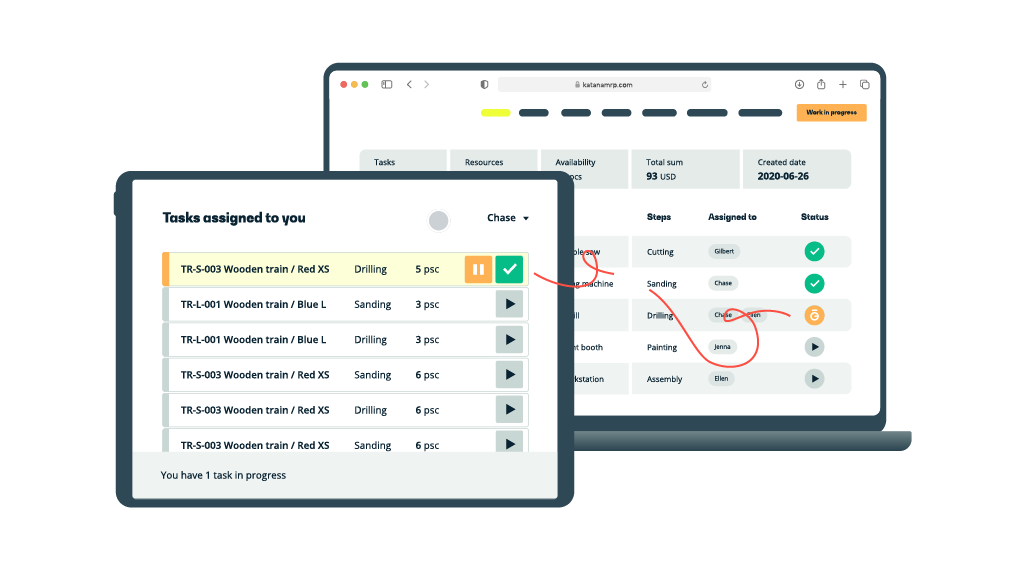

- Break down your operations — Setting up separate stages in your production process makes managing it easier. The process becomes more open, and staff becomes more skilled as they are not constrained to one place. Reduce lead time by assigning staff to the required stage

- Reduce on-hand stock — There’s no need to keep a mountain of backup stock. Don’t believe us? Apple cut down on warehouses and is now selling more than ever with a maximum of six days of on-hand stock at one time. Could your workshop use some de-cluttering? Try it and see if your business is more efficient

Apple, the most valuable company in the world, is known to keep very little inventory. The company’s CEO, Tim Cook, said, “Inventory is fundamentally evil. You kind of want to manage it like you’re in the dairy business. If it gets past its freshness date, you have a problem.”

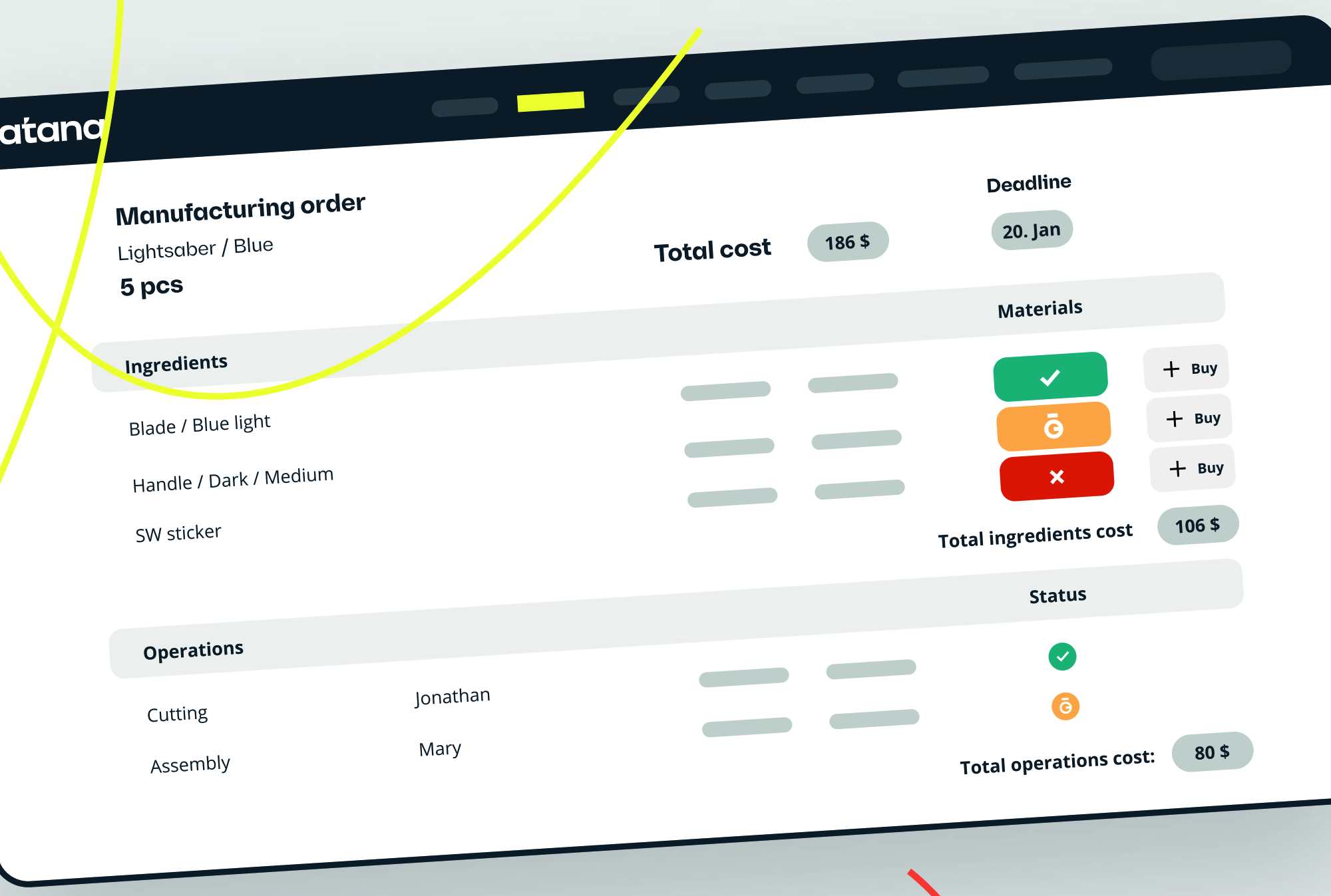

- Use perpetual inventory — Katana’s enterprise manufacturing software keeps track of all your inventory, including raw materials, work-in-progress items, and finished goods. This way, you have absolute knowledge of numbers and commitments down to the last product. This makes it easier to do just-in-time inventory, as you always know where you stand

- Repurpose empty space — Once you have cleared excess stock, you can find a way to get that space to make money rather than cost you

- Plan to minimize commitment — Retail giant Zara never plans inventory more than six months in advance and has 50% come in mid-season. They haven’t succeeded despite this, but because of it. Using a just-in-time system allows them to be so much more agile. They can be the most up-to-date with fashion trends. They always stay several steps ahead of their competitors, who must get rid of all their stock before reordering more

- Have a backup plan — All of the above depends on your ability to deal with a supply-chain breakdown. You don’t sign up for AAA after your car strands you in the middle of nowhere. Your business should be no different. Plan a course of action for all the things that could go wrong using just-in-time inventory

Make to order and never run out of stock

Using just-in-time inventory management is positively correlated with business success. Despite this, many business owners think it isn’t for them — the pitfalls and consequences seem like too much of a burden. This is why we have brought lean manufacturing to the scaling manufacturers. Your resources are limited, and it is important to use them in the most effective way possible.

When you understand the philosophy of JIT, the application to your business should become clear to you.

Katana makes your lean process even leaner and gives you complete just-in-time stock control. There is no need to do calculations by hand, figure out the best time to reorder stock, or micromanage staff. You can manage everything with intuitive cloud inventory software:

- Set reorder points, ensuring raw materials are ordered at the exact right time

- Allocate tasks to your staff based on your current inventory

- Improve the efficiency of the management by taking care of repetitive tasks

- Free up your time on more challenging tasks

Everything flows, and lead times are kept to a minimum. When a customer places an order, you can be sure it will get fulfilled in time. See Katana’s production management software in action by requesting a demo today.

Table of contents

Inventory management guide

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control