Effectively manage your shop floor with WIP tracking software for manufacturing

Increase workstation flexibility without losing control of manufacturing operations. Work-in-progress tracking software like Katana helps you monitor time spent on tasks and materials used, giving you real-time insights into your business.

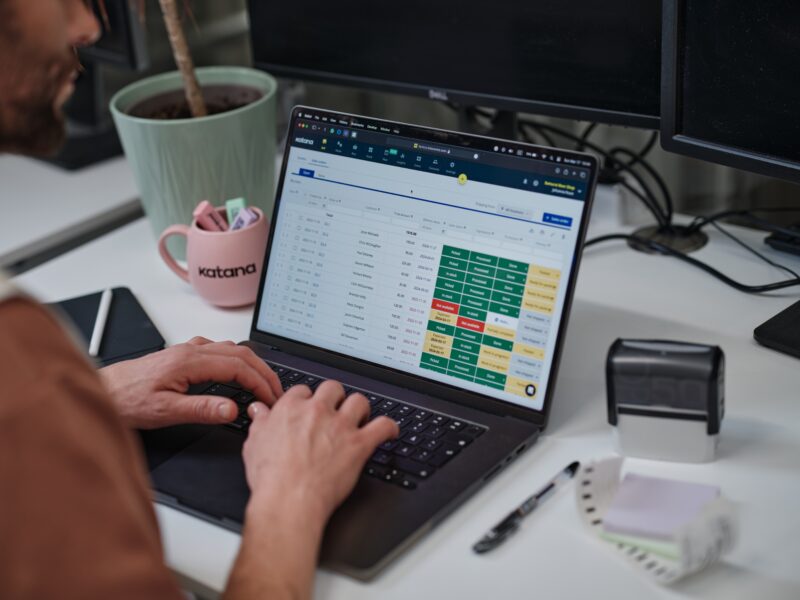

Check order progress with real-time WIP tracking software

Get live manufacturing status updates from anywhere with WIP tracking software like Katana. Set tasks for team members and track time and materials spent for total shop floor control.

Never lose control over your production operations

To make the right decisions at the right time, you need a live overview of your production. WIP software allows you to track progress with sales and production orders in real-time, giving you a virtual window into your shop floor operations. By spotting delays before they happen, manufacturers can keep up with deadlines no matter how high demand is.

- Get a live floor-level production status overview

- View manufacturing orders and ingredient lists in Katana’s Shop Floor App to keep your teams aligned

Assign tasks and track time and resources spent

Improve your floor-level operations with direct access to production tasks and ingredient lists for each task with a WIP tracking system like Katana’s Shop Floor App. Easily create, set up, and remove shop floor operators, track time spent on jobs, and measure real versus actual materials used to cut costs and time.

- Easily re-assign tasks to operators to maximize efficiency

- Generate shop floor tasks according to product operations for incoming manufacturing orders

Keep your teams and data in sync at all times

Managers, sales teams, and shop floor employees need access to the same information to keep their operations in sync. WIP software gives everyone in your organization the knowledge they need to make the right decisions. No more miscommunication or mistakes when it comes to deadlines, scheduling, or stock counting.

- Add notes to manufacturing orders to be displayed for related tasks in the Shop Floor App

- Shop Floor App task status updates are automatically sent to your cloud manufacturing software

Features

Getting your products to customers faster

Katana supports your workflows no matter your industry with the features and seamless integrations you need to manage your business how you want.

Inventory management

Get real-time inventory insights of all your items and optimize your inventory levels based on demand.

Purchase management

Issue purchase orders for supplies and materials in Katana that are delivered directly to your warehouse or contract manufacturer.

Sales order management

Consolidate all your online and offline sales channels and data into a single view for total omnichannel support.

Planning and forecasting

Make better data-driven decisions as Katana automates your inventory planning — using historical data to predict future demand.

Production management

Optimize your production and decrease lead times based on your bill of materials and operations data.

Cloud accounting

Get your inventory and accounting data in sync to better understand your business’s finances.

Warehouse management

Our Warehouse add-on provides all the tools and real-time insights to improve picking routes and manage receiving, mobile scanning, and printing — all from a mobile device.

Integrate with the best e-commerce,

accounting, reporting, and CRM

software out there

Create custom API integrations

Use Katana’s open API to create custom workflows and connect to apps beyond our list of integrations. Automate data transfers between the services you use to level up efficiency. Take a look at our API documentation to learn more.

Katana integrates everything, making for effective company-wide resource planning and control.”

Danielle Louw

Production Manager at CT LAB

We needed help with Shopify inventory management for raw materials, and Katana exceeded our expectations.”

Pablo Baque

Walk With Me CEO

Having the shop floor know what they can or can’t make on a given day is amazing, and replaces our previous “system” of spreadsheets.”

Sara Varela

Founder and Designer at Sara Gabriel

As an organic food processor, traceability is critical and our records must be meticulously kept. Katana fulfills all our needs in a simple, easy solution.”

Irah Vet

Founder and Production Manager at Hornby Organic

FAQs about WIP tracking software

WIP tracking refers to monitoring and managing work in progress (WIP) in a project or production environment. WIP refers to any items, tasks, or processes that have been started but are not yet completed.

Tracking WIP is important because it provides visibility into the status of ongoing work and helps identify potential bottlenecks or areas where improvements can be made to optimize efficiency and throughput. In order to guarantee that projects are finished on schedule and under budget, this can help project managers and team leaders make educated decisions about resource allocation, personnel, and scheduling.

WIP tracking can be done manually using spreadsheets or other tools. Still, it is often more efficient to use specialized software or project management systems that automate the process and provide real-time updates on the status of WIP.

Tracking production in manufacturing involves monitoring the status of the production process and the movement of materials and products through the manufacturing facility. Here are some key steps for tracking production in manufacturing:

1. Define production metrics: The first step is to establish metrics that will be used to track production. Examples of metrics include production volume, cycle time, defect rates, and inventory levels.

2. Implement a production tracking system: Various software tools are available to help track production in manufacturing. These systems can provide real-time visibility into production metrics and help identify bottlenecks or areas for improvement.

3. Use barcoding or RFID technology: Barcoding and radio frequency identification (RFID) technology can be used to track the movement of materials and products through manufacturing. This can provide real-time visibility into the location of materials and products and help optimize production workflows.

4. Implement visual management: Visual management tools such as kanban boards and production dashboards can help provide real-time visibility into production metrics and help identify areas for improvement.

5. Conduct regular reviews: Regular reviews of production metrics and processes can help identify areas for improvement and ensure that production goals are being met.

Overall, effective production tracking involves implementing a combination of software tools, technology, and visual management to monitor production metrics and identify opportunities for improvement.

To track the manufacturing process, there are several steps you can take:

1. Define the process: First, you need to define the manufacturing process for your product. This involves creating a detailed production process map, including all the steps and materials involved.

2. Identify key metrics: Next, identify the key metrics you want to track to measure the performance of the manufacturing process. These may include cycle time, scrap rate, first pass yield, and throughput.

3. Implement data collection: Collect data on the manufacturing process using manual and automated methods. This may involve using sensors, barcode scanning, or manual data entry.

4. Analyze the data: Once you have collected data, use statistical process control (SPC) methods to analyze it and identify trends and patterns. This will help you identify areas where the manufacturing process can be improved.

5. Use visual management: Implement visual management tools such as kanban boards, production dashboards, and process maps to help communicate the status of the manufacturing process to the team and identify areas for improvement.

6. Continuously improve: Use the data and insights you gain from tracking the manufacturing process to improve it continuously. This may involve implementing process changes, training team members, or investing in new equipment or technology.

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control