Lot tracking: How to boost traceability in manufacturing

Lot tracking helps manufacturers ensure that they don’t sell faulty items, expired food and beverage, and outdated goods. In this article, you’ll learn all about the world of lot traceability.

James Humphreys

Product recalls are considered by many to be a fact of life when it comes to doing business.

But, that doesn’t mean you should resign yourself to fate and blindly wander into a scenario where you have to recall items. According to a Food Marketing Institute and the Grocery Manufacturers Association study, a company can lose around $10 million per recall in direct costs alone. That’s a lot of cheddar.

So, what can you do to prevent being in a costly situation like this?

Many other manufacturers implement lot traceability to help them better track their item’s movements. In this article, we look (a lot) into lot traceability and discover the best tool for implementing end-to-end tracking in your business.

Download the Definitive Guide to Batch Production

Download our free ebook guide on batch production to learn more about the benefits, workflows, and manager software used to get you started.

What is lot tracking?

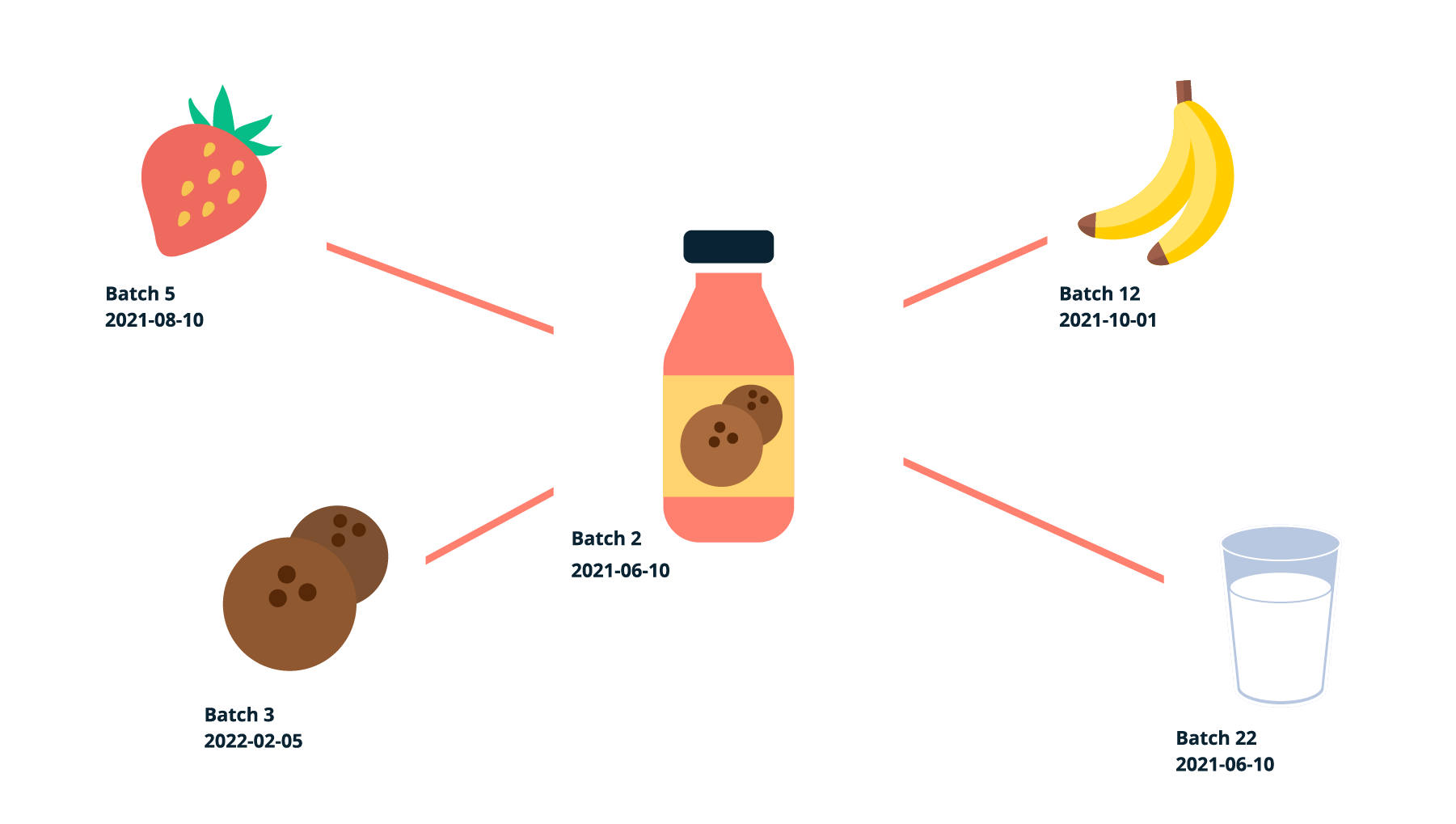

Lot tracking is an inventory management process that involves tracing specific batches or lots of products throughout their entire lifecycle, ensuring better inventory control, quality control, and recall management.

This can be done manually or with the help of specialized lot tracking features that come along with food manufacturing software, which makes it easier, faster, and more accurate to track lots in manufacturing. At its core, lot tracking ensures quality control and compliance standards. For manufacturers, in particular, lot control and traceability allows them to identify product issues and make necessary adjustments to prevent future problems.

It helps keep track of any recalls or defects to quickly address these issues when needed.

One key benefit of using digital lot tracking software for this process is that it automates many aspects of lot tracking, allowing you to easily manage and monitor your product data.

This can save you a significant amount of time and resources while also reducing the chance of human error. Overall, lot tracking is an essential process for manufacturers who want to ensure the quality and safety of their products. Using digital lot tracking like food inventory management software can streamline this process and make it more efficient and effective.

No more lost lots

Katana cloud inventory system can get you set up with lot traceability and batch tracking for end-to-end inventory management.

Why is lot traceability important?

Lot tracking and traceability ensure product quality and safety in the food supply chain and other manufacturing industries.

By tracking finished products from supplier to table, businesses can quickly identify any issues that may arise and take corrective action to prevent problems from occurring in the future.

Lot management involves maintaining records of where each batch of products came from and when they were produced. This information is valuable if there is a problem with a particular batch, as it can help businesses pinpoint the source of the issue. In addition, lot management can also help companies to keep track of inventory levels and ensure that they always have enough products on hand to meet customer demand.

Traceability is the ability to track a product back to its origin.

This is important in the food supply chain because it allows businesses to quickly identify and recall products that may be contaminated or otherwise unsafe. By tracing products back to their source, businesses can also discover any issues with the manufacturing process and take steps to correct them. Both lot management and traceability are important for ensuring the safety and quality of food products.

By tracking products from supplier to table, businesses can prevent problems before they occur and keep their customers safe.

With improved lot management and greater traceability, your business can ensure that its products are always of the highest quality.

Best practices of lot tracking

While each business is unique, there are some key points that every manufacturer should keep in mind when implementing lot tracking. Here are a few that will help you achieve a smooth traceability flow.

Clear identification

Assign unique and easily identifiable lot numbers or codes to each batch or group of items. These can be barcodes, serial numbers, or other easily implemented identifiers. This helps keep inventory tracking accurate and reduces the chances of confusion or error.

Detailed information

Maintain comprehensive records for each lot in manufacturing, including relevant details such as production date, expiration date, supplier information, and other essential data. This allows for effective monitoring, decision-making, and recall management.

Tracking system

Implement a reliable lot tracking system or software that enables real-time tracking of lots throughout the entire supply chain. Such a system should allow you to record and update lot information, track movement, and retrieve data quickly when needed.

Inventory system integration

Integrate your lot tracking software with your overall inventory management system. This ensures that lot information is synchronized with stock levels, order fulfillment, and production planning. It enables you to make informed decisions based on accurate lot and inventory data.

Inventory management methods

Follow the principles of “First-In, First-Out (FIFO)” or “First-to-Expire, First-Out (FEFO)” when it comes to using or selling products. Using the older or closest-to-expiration lots first minimizes waste, prevents obsolete inventory, and keeps your products fresh.

Regular audits

Conduct routine inspections to verify the accuracy of lot tracking records and the physical presence of the corresponding lots. This ensures that your lot tracking system is always reliable and up-to-date.

Employee training

Provide comprehensive training to your staff on lot tracking procedures, including properly handling, labeling, and recording lot information. Well-trained employees are vital to maintaining accurate lot tracking records and executing proper inventory management practices.

Regulations

Understand and adhere to any industry-specific regulations and standards related to lot tracking. This includes product labeling, serialization, recording, and quality control requirements. Compliance not only ensures legal and regulatory safety but also builds trust with customers and partners.

Data backups

Regularly back up lot tracking data and ensure robust data security measures are in place. This protects you against data loss, system failures, or unauthorized access, safeguarding critical lot information and maintaining business stability.

Continuous improvement

Regularly evaluate and refine your lot tracking processes based on data analysis, feedback, and changing business needs. Look for opportunities to optimize efficiency, reduce errors, and enhance overall traceability.

Benefits of lot tracking

With lot tracking manufacturers can:

- Improve product quality

- Help identify manufacturing defects

- Assist in root cause analysis

- Improve customer satisfaction

- Reduce the number of product recalls

Product quality is critical to the success of any manufacturing business. Lot tracking can help improve product quality by identifying manufacturing defects and analyzing the root cause. Manufacturers can reduce customer complaints by improving product quality and increasing customer satisfaction.

Lot tracking can also reduce the number of product recalls. In a recall, lot tracking can help identify and isolate the affected products from the rest of the inventory. This can minimize financial losses and damage the company’s reputation.

Overall, lot tracking provides many benefits to the manufacturing industry. It can improve product quality, assist in root cause analysis, and improve customer satisfaction. Implementing an effective batch tracking system can be a key part of success for any manufacturing business.

Lot tracking and accounting

Do you need to integrate lot tracking and traceability in manufacturing with your current accounting software? Some cloud inventory systems can integrate with your favorite accounting tools, for example:

Which manufacturing industries use lot tracking?

Tracking a batch of products is a vital component of the manufacturing industry, and it can be applied to businesses in many different fields.

Some of the main industries that benefit from lot tracking include:

Food and beverage manufacturers

One area where lot tracking is critical is food production. It’s vital to keep track of individual batches throughout the preparation, production, storage, and, finally, the distribution of food. This ensures quality control and compliance with regulations related to:

- Perishable inventory

- Ingredients

- Storage conditions

- And other factors

Pharmaceutical manufacturing

Similar rules and regulations apply when dealing with pharmaceuticals. These substances must be handled carefully, so having access to up-to-date product information helps ensure safety throughout the process. In addition, any human errors can be easily traced back to the original source.

Cosmetics manufacturing

In many cases, in cosmetics manufacturing, products are made from organic raw materials and other components that cannot withstand extreme temperatures or handling without being damaged. This makes lot tracking a crucial aspect of this industry as well — it ensures that batches stay fresh, safe for consumers, and traceable should something go wrong.

Manufacturing in general

Lot control and traceability can be beneficial for all types of manufacturing processes.

Businesses can better track their sources and improve quality control by clearly understanding where products come from. Whether you’re producing footwear, electronics, industrial machinery, or anything else, lot tracking offers many benefits that make it an important part of manufacturing.

Essential features of lot tracking software

Lot tracking capabilities are a critical component of any production management software. It provides complete traceability of product lots, which is essential for recalls and regulatory compliance. The following are some of the key features of lot tracking software:

Lot creation

This feature allows users to create new product lots. The software can store all relevant information about the lot, such as production date, expiration date, and batch number tracking.

Lot tracking

Track the movement of product lots throughout the supply chain. Information such as where the lot was shipped, when it was received, and who handled it can be easily monitored.

Lot traceability

Get better product traceability for lots and track them back to their origins. This is essential for product recalls and for meeting regulatory requirements.

Lot reporting

Lot reporting allows users to generate reports on product lots. This information can be used to track trends, assess risk, and make decisions about a product recall or other actions.

Katana lot tracking software

Katana cloud inventory software gives factory owners and managers real-time insights into all the moving parts that make their business — from sales to inventory and beyond. These are a few of the features Katana offers.

Inventory tracking

Katana is a one-size-fits-all solution that gives manufacturers live end-to-end traceability.

With an inventory system that supports barcode scanning and serial numbers, users can easily get started with batch tracking for products and raw materials using lot numbers. This means you can easily monitor where the ingredients of a finished product came from, the product’s manufacturing progress status, and track exactly where an item has gone once it leaves your warehouse.

You can even assign expiry or best before dates to items, giving you total control over your shelf life management — perfect for those who make food products or sell time-sensitive goods like computers.

Integrations

Katana has partnered with many platforms to offer an all-encompassing manufacturing experience.

There are integrations to take care of all aspects of your business — from automation to accounting to shipping. Build a custom workflow with our native integrations, or create your own workspace using Katana’s open API.

Insights

Gather, monitor, and analyze data using Katana’s Insights feature.

Conduct manufacturing and inventory analyses and audits using data about production, sales, orders, and customers. Identify bottlenecks, improve problem-solving, and make more data-driven decisions based on past trends.

Request a demo and see firsthand how to take your business to the next level.

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control