How to optimize your automotive manufacturing process

There’s no reason to reinvent the wheel, so why make yourself suffer when trying to optimize production lines. We look into the automotive manufacturing process, so you can implement best practices to make your manufacturing more efficient.

James Humphreys

Everyone’s car requires inspections and repairs to ensure that the vehicle is roadworthy.

Without these checkups, the car will eventually break down and become unusable. And the same can be said about the production lines from which the car was created. If a manufacturing company doesn’t have a system in place to perform inspections and maintenance on their production lines, the assembly plant will be doomed to fail eventually.

That’s why we’re going to look into the automotive manufacturing process, to learn about the history and how other car manufacturers stay relevant.

If you’re a manufacturing or an operations manager looking to improve your manufacturing, this article is for you.

The entire history of automotive manufacturing processes

The automotive manufacturing industry has come a long way since its early days in the late 19th century.

Today, the industry is a major global economic force, responsible for 2.8 million jobs and $130 billion in annual compensation in the US. Here’s a look at the key moments in the history of automotive manufacturing processes:

1886: The first gasoline-powered car is built by Karl Benz in Germany. Benz’s invention is widely considered to be the first true automobile.

1896: The first mass-produced car, the Daimler Stahlradwagen, rolls off the assembly line in Germany.

1908: Ford Motor Company launched the Model T, the first mass-produced car to be affordable for many middle-class Americans.

The 1920s: The automotive industry expanded rapidly in the United States, thanks in part to the growing popularity of cars as a status symbol. Major manufacturers such as General Motors and Chrysler emerge during this period.

The 1930s: The Great Depression takes a major toll on the automotive industry, with sales plunging and many companies going out of business.

The 1940s: The automotive industry turns its attention to wartime production during World War II, building vehicles for military use.

The 1950s: The postwar boom increased demand for automobiles, and the industry entered a new era of growth and prosperity.

The 1960s: A new generation of American consumers comes of age, and “muscle cars” like the Ford Mustang and Chevrolet Camaro become hugely popular.

The 1970s: The oil crisis and the resulting rise in gas prices shifted away from large, V8-powered cars toward smaller, more fuel-efficient models.

The 1980s: Thanks to new manufacturing technologies like fuel injection and computer-aided design, the automotive industry rebounded and experienced renewed growth.

The 1990s: A wave of globalization sweeps through the automotive industry, as Japanese automakers establish a major presence in the United States and other markets worldwide.

The 2000s: The industry was dealt a major blow by the global financial crisis of 2008 but began to recover in the following years.

Today: The automotive manufacturing industry is a major driver of economic growth around the globe.

With new vehicles technologies, manufacturing trends, and predictions constantly emerging, the industry’s future automotive manufacturing processes looks poised to be just as exciting as its past

Electric vehicles will take over the automotive market in the coming years. With advances in battery technology, automotive manufacturing processes, and a growing awareness of the environmental benefits of electric cars, more and more consumers are making the switch to electric vehicles. In fact, according to a report from Bloomberg New Energy Finance, electric cars are expected to make up 54% of new car sales by 2040.

This is a huge increase from just 1% of sales in 2015.

This shift to electric cars will have a major impact on automotive manufacturing. Here are three ways that electric cars will change the automotive sector:

- Electric cars will require less maintenance than traditional petrol or diesel cars. This means that service and repair shops will need to adapt their business models to cater to electric cars

- Electric cars will have a smaller environmental footprint than traditional petrol or diesel cars. This will put pressure on automotive manufacturers to adopt green manufacturing into their business

- Electric cars will need a different type of infrastructure than traditional petrol or diesel cars. This includes charging stations, which will need to be installed in cities and towns across the country

The shift to electric cars is inevitable, and it will have a major impact on automotive manufacturing, and along with 3D printed cars, and autonomous vehicles.

Companies that don’t adapt to this new reality will be left behind.

The automotive manufacturing process workflow

The automotive manufacturing process is a complex one that involves many different steps.

To ensure that cars are of the highest quality, manufacturers must follow strict guidelines and procedures. Carmakers start rapid prototyping of their vehicles. They then test these prototypes to see how they perform in various conditions.

Once the design, development, and product analysis phase is complete, tooling and equipment preparation is the next step.

Manufacturers create and source the tools and equipment needed for the mass production of their vehicles at this stage.

This includes everything from stamping machines to paint booths. Once the tooling and equipment are in place, the next step is production planning. Manufacturers decide how many vehicles they will produce and when in production planning.

They also develop schedules for the different steps in the automotive manufacturing process.

After assembly operations, the car undergoes a series of quality control tests.

What are the manufacturing steps of the automotive industry?

The automotive industry is one of the most lucrative industries globally, responsible for producing millions of dollars worth of products each year.

The manufacturing process of automotive products is complex, involving many different steps and factors. Let’s look at the manufacturing steps of the automotive manufacturing process.

First step:

The first step in the manufacturing process is the design phase.

In this phase, engineers and designers create the plans, specifications, and bill of materials for the vehicles that will be produced. This phase can take months or even years to complete, depending on the project’s complexity.

Second step:

Once the design phase is complete, it’s time to build the vehicles.

This is where assembly lines and industrial robots come into play. The assembly process is used to assemble the various parts of the cars, while robots are used for tasks such as the welding and painting process. This phase of the manufacturing process can take weeks or even months to complete.

Third step:

After the vehicles are built, they must undergo a series of safety tests and quality checks before being sold to consumers and dealerships.

These tests ensure that the vehicles meet all safety and performance standards. Only after passing these tests can the cars be sold to customers.

Final step:

The final step in the automotive manufacturing process is shipping the vehicles to dealerships.

This is where logistics and transportation come into play. The vehicles must be carefully loaded onto trucks or trains and transported to their destination. This phase of the process can take days or even weeks to complete.

As you can see, the automotive products’ manufacturing process is a complex one.

There are many different steps and factors involved in the process. However, by understanding how the process works, you can better understand how the industry works and what goes into making a vehicle.

What raw materials do automotive manufacturing use?

The automotive manufacturing process uses various raw materials, including iron for steel, aluminum, rubber, and petroleum products.

These raw materials are used to create the different parts and components that make up a car:

- Iron is one of the most important materials used in automotive manufacturing. It is used to create steel, a solid and durable sheet metal essential for constructing car body parts

- Aluminum is another important material used in automotive manufacturing. It is lighter than steel and can be used to create lightweight car parts

- The rubber is used to create tires and other car parts that require flexibility

- Petroleum is used to create plastics and other synthetic materials used in the production of cars

The automotive manufacturing process requires a variety of raw materials to create the various parts and components that make up a car. These raw materials are essential for the construction of safe and reliable vehicles.

Types of production lines found in production facilities

There are three main types of production lines in automotive manufacturing:

1. Conventional production line

This is the most common type of automotive production line.

Each vehicle passes through a series of stations in a conventional or repetitive manufacturing process, with each station dedicated to a specific task. For example, one station might be responsible for attaching the wheels, while another might install the engine. There are many benefits to using a conventional production line in the automotive manufacturing industry.

Perhaps the most obvious benefit is the increased efficiency that can be achieved. When all of the steps in the production process are carried out linearly, it is much easier to keep track of progress and ensure that each step is completed correctly. This efficiency can lead to reduced costs and improved quality control.

Another benefit of using a conventional production line is that it generally leads to more consistent results since it follows the same continuous process.

When all steps are carried out in the same order every time, it becomes easier to predict and control the outcome of the process. This consistency can ensure that car parts meet safety and quality standards.

Finally, using a conventional production line can help create a better working environment for employees.

When workers specialize in one particular task, they can become more skilled and efficient. This specialization can lead to higher morale and motivation among employees, further improving the quality of the final product.

2. Flexible production line

A flexible production line or discrete manufacturing is similar to a conventional production line but built with more production flexibility.

For example, a moving assembly line might have stations that can be reconfigured to accommodate different tasks depending on the vehicle being assembled. Flexible production lines are often used in automotive manufacturing because they offer several advantages over other production systems. One of the main advantages is that they can help to increase efficiency and productivity.

This is because flexible production lines allow for a greater degree of customization, which means that each vehicle can be produced more quickly and with fewer errors.

In addition, flexible production lines can also help to reduce production costs. This is because they often require less investment in terms of machinery and equipment, and they also tend to use less energy and water than other types of production systems.

Finally, a flexible production line can also help to improve communication and coordination within the company. This allows different departments to work more closely together, leading to a more efficient production process.

3. Modular production line

A modular, or job shop manufacturing, production line comprises a series of modules responsible for a specific task.

Once a module is complete, it is then moved to the next station on the line. Modular lines are typically used for assembling vehicles with complex designs. One of the main benefits of using a modular line is that it can help to improve efficiency and productivity in the manufacturing process.

Having a dedicated line for each type of product can help reduce waste and errors and improve the overall quality of the products being produced.

Additionally, modular production lines can be easily reconfigured to accommodate changes in demand or production volume, making them highly versatile and adaptable.

In today’s competitive marketplace, manufacturers need to be able to respond quickly to changing market conditions and customer demands, and modular production lines offer an ideal solution.

Henry Ford and the beginning of lean in the automotive manufacturing process

Henry Ford’s impact on the automotive industry is well-documented.

But what is often overlooked is his role in revolutionizing manufacturing methods. He was an early adopter of mass production techniques and a proponent of assembly lines to increase efficiency. His ideas have impacted automotive manufacturing processes, and lean manufacturing principles can be traced back to his work.

Ford Motor’s assembly line methods were first put into practice at Highland Park, Michigan, manufacturing plant in 1913.

The moving assembly line allowed for much higher production levels than previous methods. In addition, Ford Motor Company’s use of interchangeable parts meant that vehicles could be produced more quickly and with less waste. The success of Ford motor’s manufacturing methods soon led other companies to adopt similar methods.

Today, lean manufacturing is a widely used approach that helps businesses:

- Reduce waste

- Increase efficiency

- Improve quality

While the principles of lean manufacturing have evolved, they can all be traced back to the work of Henry Ford and his human workers.

Ford’s work in manufacturing revolutionized the automotive industry and had a lasting impact on manufacturing methods.

What is lean manufacturing?

Lean manufacturing is a methodology focused on enhancing the use of value-adding resources by eliminating wasteful activities.

Lean manufacturing has its roots in the automotive industry but has since been adopted by manufacturers in various industries worldwide. Lean manufacturing aims to create more value for the customer while using fewer resources overall.

Several key principles underpin lean manufacturing, including:

- Eliminating waste — Waste can take many forms in a manufacturing setting, including overproduction, defects, waiting time, and unnecessary motion or transportation. Lean manufacturing seeks to eliminate all forms of waste so that resources can be used more efficiently

- Continuous improvement — In lean manufacturing, there is always room for improvement. Even when a process is running smoothly, there is always the potential to make it even better. This continuous improvement mindset is key to achieving success with lean manufacturing

- Respect for people — Lean manufacturing relies on the expertise and input of every member of the team. Everyone has a role to play in improving the process and identifying waste

There are many benefits of lean manufacturing in the automotive manufacturing process.

One benefit is that it helps to reduce waste and improve efficiency. This can lead to increased profits for automotive companies. Additionally, lean manufacturing can help to improve quality control and reduce defects in products — leading to higher customer satisfaction levels and repeat business.

Finally, lean manufacturing can help to shorten manufacturing lead times and improve overall productivity levels.

This can help automotive companies to be more competitive in the marketplace and better able to meet customer demand.

Toyota’s world-famous TPS: a more efficient automotive manufacturing process

The Toyota Production System (TPS) is a world-renowned lean manufacturing system implemented across the globe and in various industries.

TPS aims to eliminate waste and achieve the best possible increased production efficiency. Toyota motor company has always been at the forefront of manufacturing innovation, and TPS is just one example of its commitment to continuous improvement. TPS has helped them become one of the most efficient and effective automakers globally.

TPS is based on two key principles:

- Jidoka

- Just-in-time

Jidoka refers to the principle of automating processes to prevent defects and ensure quality.

Just-in-time refers to the principle of producing only what is needed, when it is needed, to minimize the waste produced during production.

Together, these principles have helped create a lean and efficient rapid manufacturing process that is the envy of the automotive industry. Toyota is constantly improving its production methods and processes to remain the leader in efficiency and quality.

What is jidoka?

Jidoka is a lean manufacturing technique that helps to ensure built-in quality in a production process.

It involves stopping the production line to immediately fix an issue, preventing defects from being passed on to the next production stage or from reaching the customer. Jidoka can also be used to identify issues in the production process to be addressed and prevented in the future.

Jidoka is an important part of lean manufacturing techniques, which aims to eliminate waste and optimize efficiency in all stages of production.

Jidoka helps to achieve this by ensuring that defects are caught early and corrected quickly before they cause further problems downstream.

There are many benefits to using jidoka in manufacturing. By catching and correcting defects early, jidoka can help to reduce rework and waste, improve quality, and increase customer satisfaction. Additionally, because it helps to identify issues in the production process, jidoka can also help to improve efficiency and productivity over time.

Interested in implementing jidoka in your own manufacturing process? Keep a few things in mind.

First, it is important to have a clear understanding of what constitutes a defect or problem. This will vary from process to process, so it is important to tailor your jidoka implementation accordingly.

Second, you need to have a system to stop the car’s production line when a defect is detected. This could involve physical stop buttons, sensors, or other methods of identifying and communicating problems.

Finally, it would help if you had a plan to address and fix the defects found. This should involve all stakeholders in the vehicle production process, from operators to managers.

Jidoka is a powerful lean manufacturing tool that can help to improve quality and efficiency in your production process. By understanding how it works and implement it properly, you can start reaping its benefits in your own business. Use jidoka to improve quality and efficiency in your automotive manufacturing process.

What is just-in-time?

Just-in-time (JIT) is a type of inventory management where goods are received from suppliers “just in time” to fulfill an order.

JIT inventory management aims to help businesses avoid the cost and wasted space associated with storing excess inventory. JIT inventory management requires close coordination between a company and its suppliers. The supplier has to deliver goods exactly when needed, and the company must have a automotive manufacturing system in place to track incoming orders and ensure that they are fulfilled promptly.

The goal of JIT inventory management is to produce only what is needed, when it is required, and in the quantities needed.

Helping businesses save money on storage costs, reduce the risk of stockouts, and improve overall efficiency across the business.

This approach eliminates inventory storage, saving businesses money on warehouse costs. JIT production can also help improve quality control by reducing the chances of errors associated with carrying inventory. In addition, the JIT manufacturing techniques can lead to faster production times and shorter manufacturing lead times for customers.

There are some drawbacks to JIT manufacturing, however.

Because JIT production relies on a just-in-time delivery system, any disruptions in the supply chain can cause production delays. In addition, JIT manufacturing can require a significant up-front investment in equipment and training for workers.

But overall, JIT manufacturing can be a beneficial production strategy for businesses looking to improve efficiency and reduce waste.

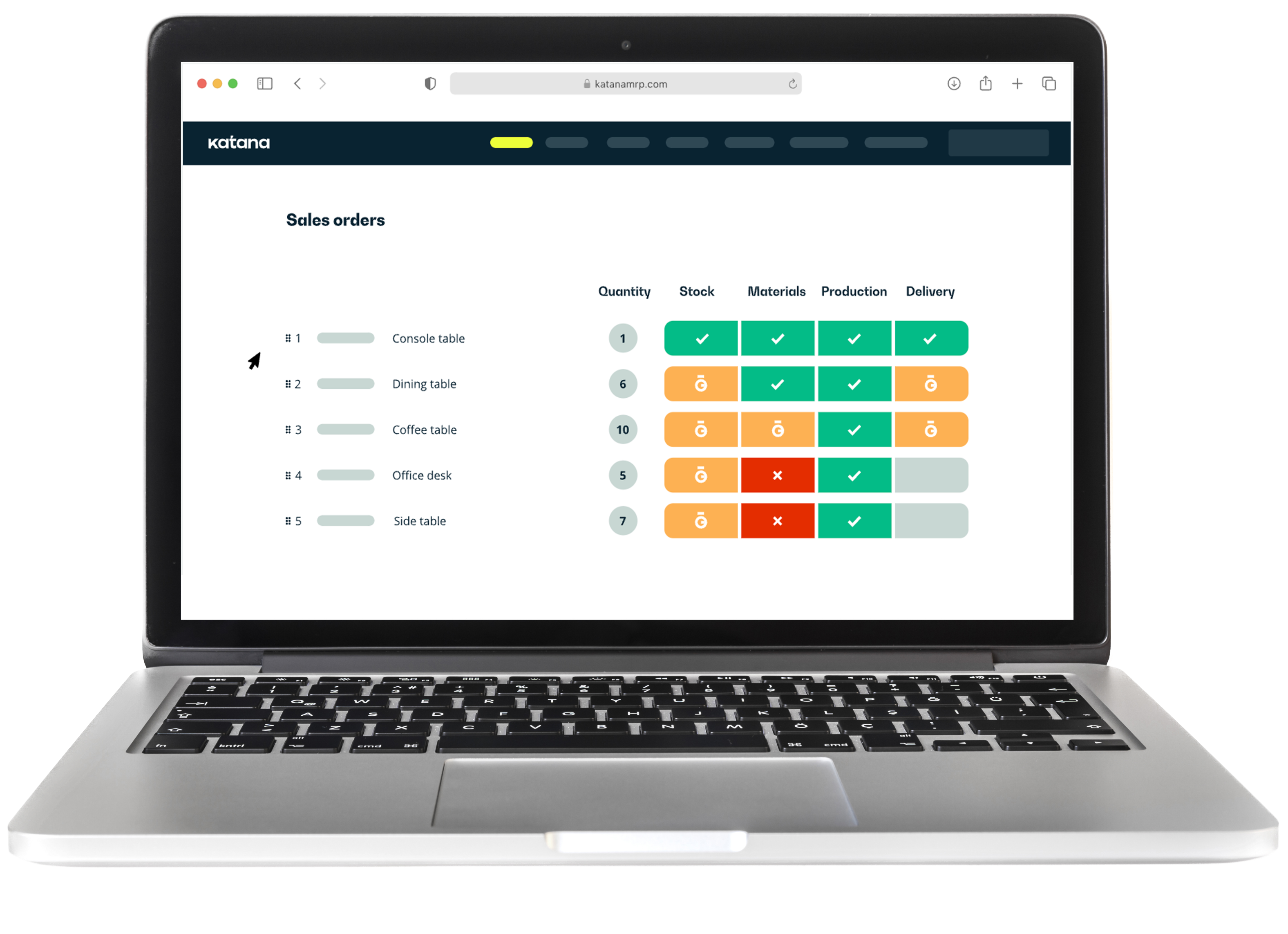

Katana Cloud Inventory Platform for managing your automotive manufacturing processes

When it comes to automotive manufacturing, there is a lot to manage.

The automotive manufacturing software needs to be up to the task, from production planning and scheduling to stock control and multilevel BOMs.

Introducing Katana automotive manufacturing software — a system designed to help you automate processes and efficiently manage every aspect of the automotive manufacturing process.

With Katana Cloud Inventory Platform, you’ll be able to:

- Plan and schedule production more effectively

- Keep track of inventory and stock levels

- Manage multilevel BOMs with ease

- Integrate other essential third-party software

- Improve purchase management

- And much more

CASE STUDY

Automotive company GJ Motorsports has already fully implemented Katana cloud software into their business and now enjoys benefits such as:

- The ability to monitor shop floor operations with the Katana Shop Floor App

- Automating their day-to-day repetitive tasks and shipping workflows with Zapier and Katana API

- Regular and real-time stock reports

You can check them out by reading our case study on GJ Motorsports.

If you’re looking for a way to streamline and improve your automotive manufacturing operation, look no further than Katana. Reach out to our sales team today to request a demo.

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control