What is a lot number and why manufacturers need them

Learn all about what is a lot number, how and where to use them, and the benefits of implementing them in your workflow.

James Humphreys

Up to 400 products are recalled each year by the Consumer Product Safety Commission in the US alone.

We know what a product recall means for the public. But, what does it mean for the manufacturer? Product recalls, regardless of how they’re handled, have the chance to:

- Raise costs for retrieving, replacing, fixing, or reimbursing customers for affected goods

- Tarnish your business’ reputation

- Ruin a business that doesn’t have adequate cashflow

- Can send your company’s stock prices plummeting

That’s why in this article, we’re going to help you and your warehouse managers avoid these worst-case scenarios by telling you all about what is a lot number.

Katana lot number tracking inventory software

Katana gives users the ability to track lots, serial numbers, and expiration dates, ensuring industry compliance and empowering them with total business visibility.

What is a lot number?

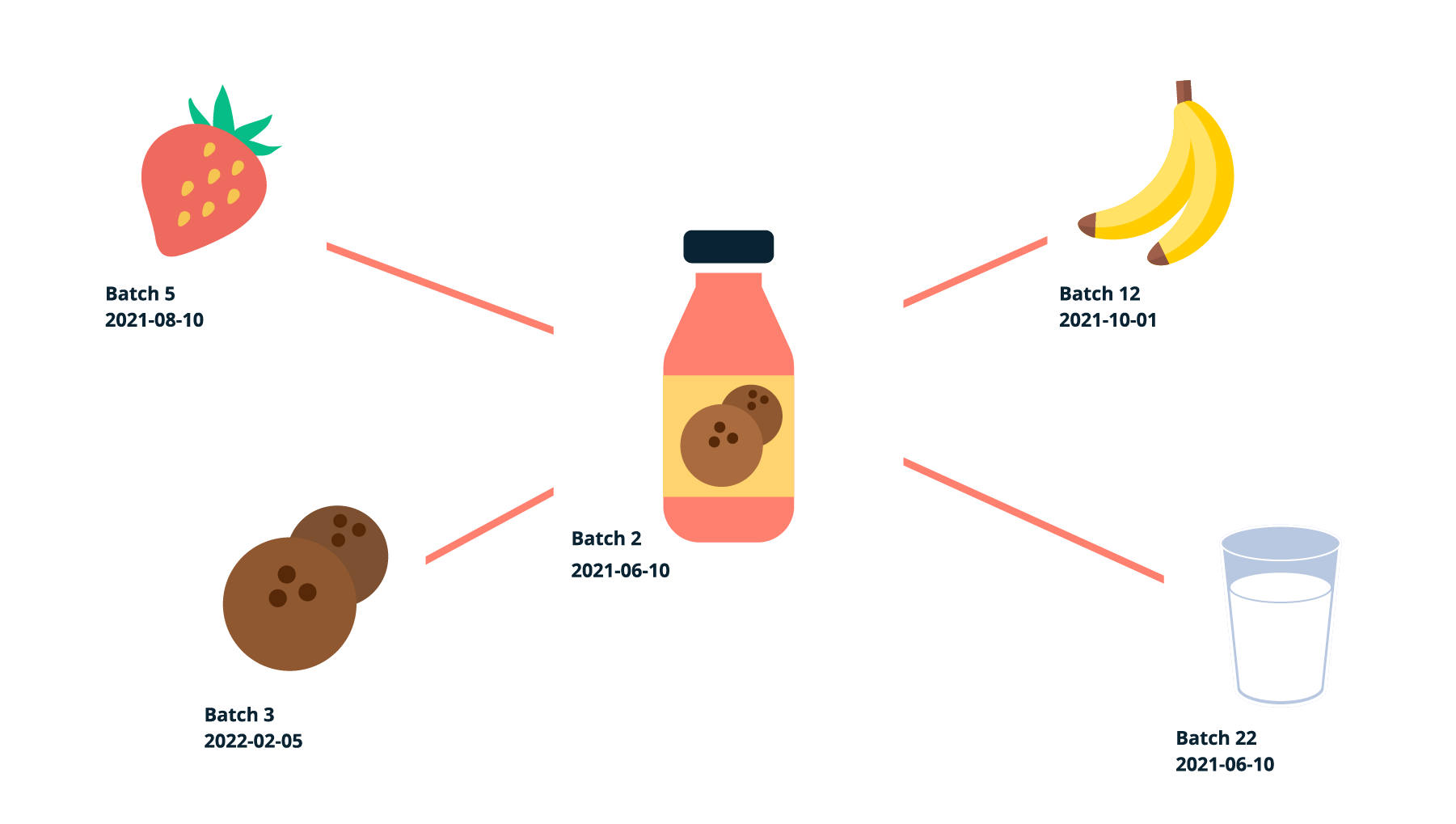

A lot number is a unique identifier assigned to a batch of items.

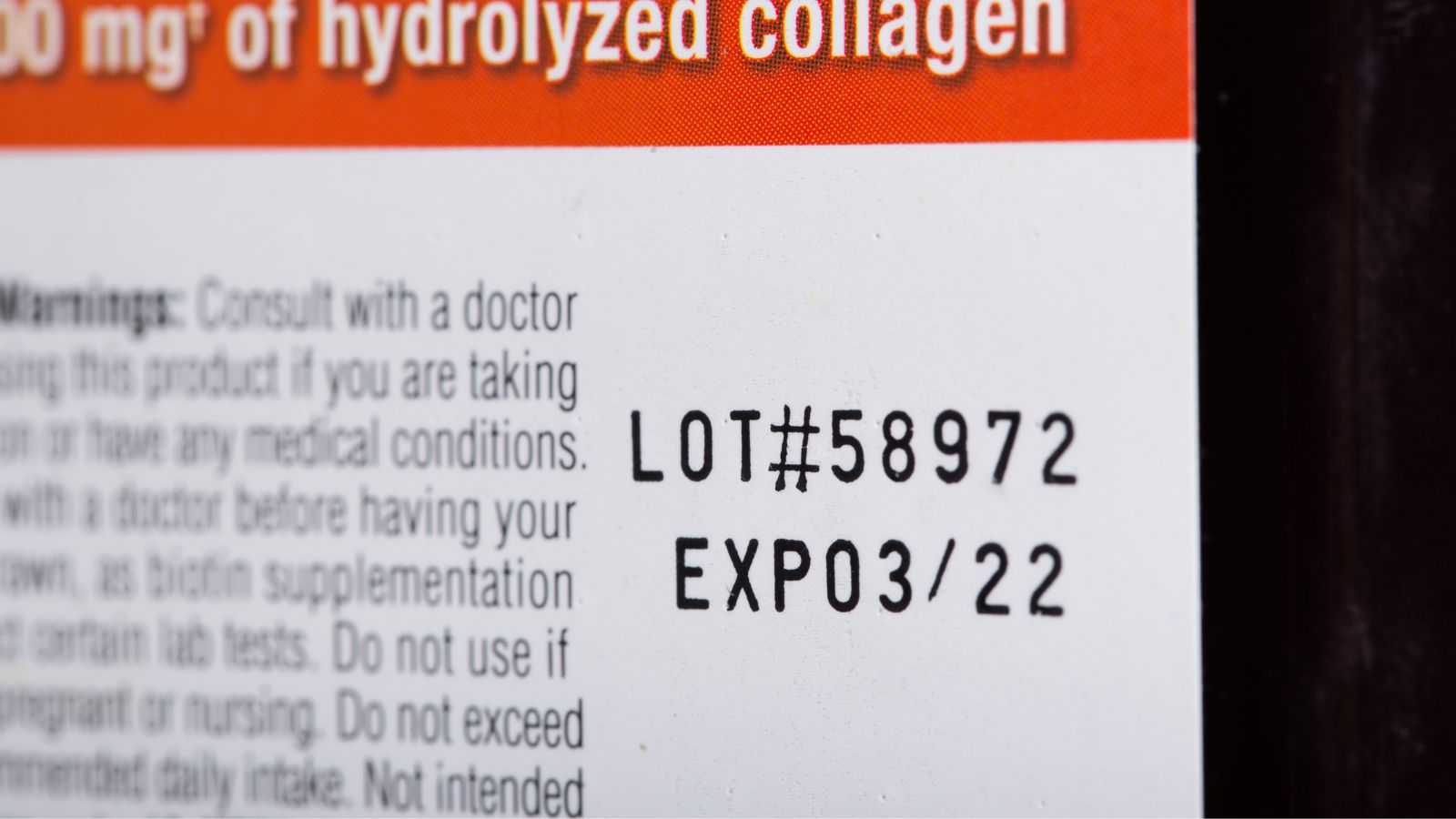

Lot numbers are used to track items throughout the manufacturing process and can be used to identify recalled items or products with defects. You can find lot numbers on the packaging of many products, which may be printed as a series of letters and numbers or as a barcode. To find the lot number on a product, look for a label or stamp that says lot number or batch number.

you may also see the FDA registration number.

This unique identifier is assigned to all food and drug manufacturers by the US Food and Drug Administration. You can use an FDA registration number to look up information about a company, but it will not provide any information about a specific product.

As you can already guess, what is a lot number usage in manufacturing? It’s great for those who work with items that need lot numbers and expiration dates, like in the food and beverage industry.

Download the definitive guide to batch production

Download our free ebook guide on batch production to learn more about the benefits, workflows, and warehouse and inventory management software you need to get started.

Where should I place the lot number on products?

The lot number on products is often printed on the label, near the barcode or SKU.

Alternatively, manufacturers might print the lot number on the same label as the barcode or SKU. Wherever you decide to place it, the lot number will help you track a product’s manufacturing information, such as where and when it was made. If you send components or subassemblies to a contract manufacturer, they can even use the lot number to track the same information.

As a rule of thumb, try and implement a standard practice when placing lot number labels underneath all your products, as this will speed up the time to locate them.

Then, should an issue arise in the future, you can quickly and easily find the lot number and determine if an issue affected other products from the same batch.

Now you know what is lot number on products and where they go — how do you use them?

When searching for lot tracking software, be sure to find integration with popular e-commerce and accounting software such as:

- QuickBooks Online

- Amazon FBA

- Shopify POS

When should you use a lot number?

In business, inventory management techniques are all about tracking the correct information to make informed decisions.

Too much data can be just as problematic as too little data, so it’s important only to track what’s necessary. So, when should you use a lot numbers?

Generally speaking, lot numbers should only be used when required by law or when it’s essential for quality control purposes. For example, if you’re manufacturing pharmaceuticals or other regulated products, lot numbers are typically required to track and trace materials throughout the production process.

In other cases, using lot numbers can help you ensure that products meet certain quality standards. For example, if you’re selling perishable goods like food inventory or cosmetics inventory, you want to use lot numbers to keep track of expiration dates. Luckily, most food distribution software has that feature built in.

Of course, there are exceptions to every rule.

Ultimately, it’s up to you to determine whether or not using lot numbers makes sense for your business. If you’re unsure, err on caution and start tracking lot numbers for your inventory. Removing unnecessary data is always easier than adding missing data later.

What is a lot number application good for when it comes to handling goods? E-commerce inventory management software features for lot or batch tracking are great for:

- Monitoring food products in your business

- Items such as consumer electronics depreciate overtime

- The food and beverage industry in general

How to track lot inventory

If you’re looking to keep track of your lot inventory, there are a few key steps you’ll need to follow.

First, you’ll need to set up a reliable infrastructure for tracking and storing your data. This may include setting up a system for tagging and identification and creating a process for regularly recording data. Tracking your inventory should be fairly straightforward once you have these things in place.

Here are a few tips to get you started:

- Set up a system for tagging and identification — this will make it easier to keep track of your inventory and ensure that all data is accurate

- Create a process for regularly recording data — this will help you stay on top of your inventory levels and ensure that you’re always aware of what’s in stock

- Use a tool like a barcode scanner or RFID tags to automate your data collection — this can save you time and energy, and it will also help to ensure accuracy

- Implement regular checks and audits — this will help you catch any errors or discrepancies in your data, and it will also give you peace of mind knowing that your inventory is being tracked correctly

- Stay organized and concise in your data recording — this will make it easier to track your inventory over time, and it will also help you spot trends or issues more efficiently

By following these tips, you’ll be well on your way to tracking your lot warehouse and inventory effectively. With a little effort, you can ensure that you always know what’s in stock and that your data is accurate.

Lot number vs SKU

Here is the difference between lots and SKU — Lot numbers refer to the specific batch or production run of a product. This information is important for quality control, as it can help businesses track down issues with a particular batch of products. On the other hand, SKUs are unique identifiers assigned to each product. This information is important for inventory tracking as it allows businesses to quickly and easily identify individual items.

What are the benefits of lot tracking?

There are several benefits of lot tracking for businesses, including:

- Helping businesses keep track of when raw materials were received, so they can more easily identify when items need to be restocked.

- Helping businesses keep track of where inventory came from, so they can more easily identify which suppliers might be experiencing quality issues.

- Helping businesses with quality control by allowing them to identify which batches of products might be defective.

Though, understanding the benefits of what is a lot number doesn’t stop there — here are seven more benefits to using lot numbers in manufacturing:

1. Lot number tracking can help ensure product quality

Quality is important for many reasons:

- It’s a large determinant of customer satisfaction

- It affects a company’s bottom line through increased costs or decreased revenue

- Reduces risks for public safety

To avoid something going wrong in any of these three areas, businesses need to ensure that their products meet certain quality standards. There are many ways to measure product quality. Some companies use objective measures like inspections or testing, while others rely on subjective measures like customer feedback.

No matter how a company measures it, quality is an important metric for any business to track lot.

Customer satisfaction is perhaps the most obvious reason why quality is important. If customers are unhappy with the products they receive, they are unlikely to continue doing business with that company. In addition, unhappy customers are likely to tell others about their bad experiences, damaging a company’s reputation.

Quality also has a direct impact on a company’s bottom line.

When products are defective or do not meet customer expectations, businesses have to spend money to fix the problem. Sometimes, they may even have to issue refunds or perform product recalls. This can all lead to decreased revenue and higher costs for a business.

Poor quality can create safety risks for consumers.

If products are not made correctly, they can break or malfunction in ways that could hurt people. In extreme cases, faulty products can even cause fatalities. By ensuring that their products meet high-quality standards, businesses can help protect the public from harm.

As you can see, there are many good reasons why quality is important for businesses.

By batch tracking and improving product quality, companies can avoid various problems and improve their bottom line.

2. Lot tracking can help identify potential issues with products or production processes

There are several reasons why it is important to identify potential issues with products or production processes.

First, doing so can help prevent or mitigate potential problems that could occur down the line. Second, it can help ensure that products or processes are up to standard and meet customer expectations. Finally, identifying issues early on can save time and money in the long run by avoiding costly repairs or replacements.

3. Lot tracking can help you meet regulatory requirements

There are several key reasons why it is important to meet regulatory requirements in batch manufacturing:

- To ensure product quality and safety — Meeting regulatory requirements helps ensure that products are manufactured to the highest quality standards and safe for consumers

- To avoid costly recalls and legal penalties — Failure to comply with regulatory requirements can lead to costly product recalls and legal penalties

- To maintain market access — Many markets require compliance with certain regulatory requirements to sell products there

- To protect the environment — Some regulatory requirements exist to protect the environment from harmful manufacturing processes.

- To support sustainable development — Compliance with relevant regulations can help manufacturers operate more sustainably.

Overall, meeting regulatory requirements is essential for manufacturers to maintain high standards, avoid costly penalties, and protect the environment.

4. Lot tracking can improve customer satisfaction

It is important to improve customer satisfaction for several reasons.

As mentioned earlier, happy customers are more likely to return and do business with a company again. They are also more likely to tell their friends and family about their positive experiences, leading to even more business. Satisfied customers tend to be more loyal and less likely to switch to another company or service provider.

In other words, they are less price-sensitive and more likely to stick with a brand they trust.

So, what is a lot number going to do to improve customer satisfaction?

Lot numbers help identify which batch an item comes from, so if there’s a defect, you can quickly act and remove other defective items from your inventory. Lot control can help companies plan for customer demand more effectively. By knowing how much inventory is available for each product and when it was made, companies can create clearer forecasts of customer demand and ensure that they have enough stock on hand to meet it.

5. Lot tracking can reduce waste and improve inventory management techniques

The amount of waste produced by businesses and households has a major impact on the environment.

In addition to the obvious problems of pollution and landfill, waste also uses up valuable resources that could be used to create new products or support other important environmental initiatives. Inventory management is key to reducing waste and making the most efficient use of resources. By keeping track of inventory levels and ensuring that items are only produced when needed, businesses can minimize surplus stock and avoid having to dispose of unused materials.

Efficient inventory management techniques can also help businesses save money — By reducing the amount of time spent searching for products and managing stock levels, businesses can free up staff resources to focus on other business areas.

6. Lot tracking can help you make better decisions about your products and production processes

There are a number of reasons why it’s important to make good decisions about your products and production processes:

- Poor decisions can lead to inferior products — If your product is not up to par, it could reflect badly on your company and damage your reputation.

- Bad decisions can also lead to inefficiencies in your production process — ultimately increasing your costs and decreasing your profits.

- Making bad decisions about your products or production process can also put your employees at risk — they may be exposed to dangerous materials or working conditions.

Ultimately, it’s simply in everyone’s best interest to ensure those good decisions are made about your business’s products and processes.

7. Lot tracking can improve communication between different departments within your company

Communication is key to success in any organization, and businesses are no different.

Good communication helps different departments within a company work together more efficiently and effectively. It can also help resolve disagreements and prevent misunderstandings. There are many reasons why it’s important to improve communication between different departments within your company.

For one, it can help increase productivity.

When employees have clear lines of communication, they can more easily collaborate on projects and get tasks done more quickly. Good communication can also help reduce errors and improve customer satisfaction. Additionally, strong communication between departments can help build morale and create a more positive work environment.

Employees who feel like they can openly communicate with one another, and their supervisors are more likely to be engaged and satisfied with their jobs.

Finally, good communication can help improve decision-making at all company levels. Different departments can share information and ideas openly, leading to better decision-making overall.

There are several ways to improve communication between different departments within your company.

But to do so, you must ensure that clear communication channels exist, such as designated meeting times or regular updates from department heads. Additionally, it’s important to encourage employees to communicate openly and frequently. Creating an environment where open communication is valued will go a long way in improving communication throughout the company.

Manufacturers implement tools such as batch manufacturing software to set up this communication channel management and get access to features for improving lot number tracking management.

Katana for lot tracking

Never lose track of an item again by treating yourself with automation tools that can do all the heavy lifting so you can focus on growing your business. End-to-end lot traceability at your fingertips.

Katana for implementing your lot numbers

Katana Cloud Manufacturing Software is an easy-to-use but intuitive tool for manufacturers and warehouse managers looking for real-time insights into their warehouse and inventory.

Easily implement end-to-end lot traceability in your business using Katana’s power inventory control features, such as using a barcode scanner and inventory tracking of raw materials, WIP items, and finished goods. From shop floor to customer door, easily monitor where ingredients originally came from, an operation status, or locate items anywhere along your supply chain. If you’re handling perishable, you can simply use Katana to add expiration dates to products to get total control over your shelf-life management.

Why not see for yourself? Get started by booking a demo with us, so you can take your newfound knowledge of what is a lot number, and using Katana implement a lot tracking workflow with automation that works with you, not against you.

And until next time, happy tracking!

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control