Batch manufacturing software for end-to-end traceability

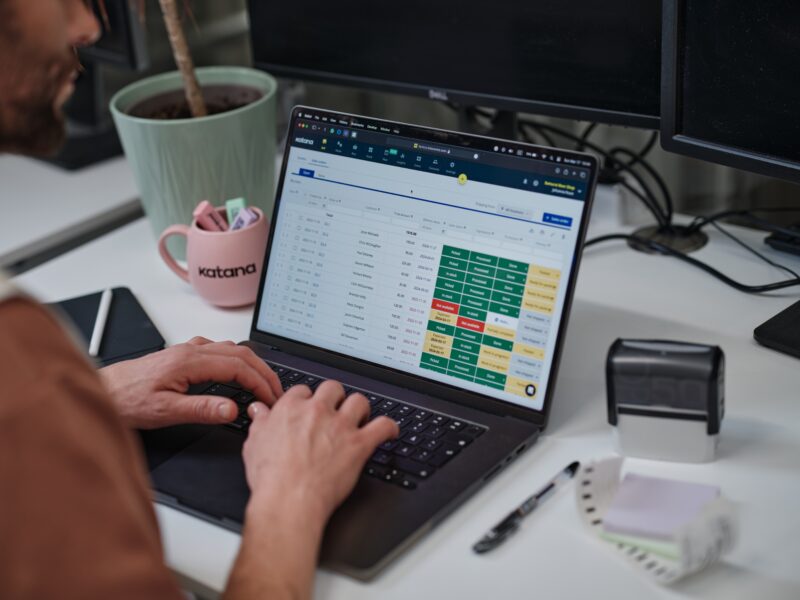

Being under-prepared for a product recall can stop your business operations dead in its tracks. Katana batch manufacturing software supports you in tracking items from supplier to customer — so you can simultaneously keep your eye on the ball while scaling your manufacturing operations.

One mistake in a spreadsheet can bring your batch processing to a screeching halt

Batch control software helps manufacturers manage B2B and D2C sales fulfillment strategies. It helps you identify where your products come from and where they have gone in seconds. The benefits don’t stop there. Using Katana Cloud Manufacturing software, you can perform accurate recalls, improve quality control and safety standards, and so much more.

Batch process manufacturing software with end-to-end inventory management

Farm to table or microchip to computer — whatever items you need to track, Katana’s full product traceability has your back. No more confusion when looking between your shop floors and storage units. Katana empowers you with real-time visibility over your entire manufacturing process, from purchase order management to delivering the finished product to the customer.

Batch process manufacturing software allows you to integrate your favorite e-commerce and accounting tools and automate data collection on raw material costs and finished products.

- Batch tracking for raw materials, expiry dates, components, and finished goods

- Monitor inventory levels with warehouse management features

- Implement end-to-end tracking and traceability for raw materials and products, perfect for those in food distribution

- Stay in control with batch scheduling and expiry tracking

- Autogenerate batch and internal barcodes for improved visibility

Omnichannel and manufacturing inventory management with batch manufacturing software

Centralize your sales and inventory management with Katana Cloud Manufacturing. The all-in-one cloud-hosted solution means you can access and monitor business activity, regardless of location. Suppose inventory runs low while you’re stuck at home with the flu or scaling Mount Everest. You can easily perform a stock transfer from one location to the other, provided you have a connection to the internet.

Batch production allows you to implement and manage omnichannel order management with features for cross-channel item tracking, stock movement updates, and automated inventory and warehouse management.

- Consolidate your e-commerce inventory and sales order management

- Synchronize your sales reports for efficient order fulfillment

- Monitor the availability of products and open sales orders will have products automatically assigned

- Simple yet intuitive drag-and-drop system to reprioritize sales and manufacturing orders

- Automatically convert sales order values to multiple currencies

Batch manufacturing software with real-time data tracking from anywhere in the world

Don’t let external factors derail your batch production runs. Katana helps eliminate human error by automating the repetitive day-to-day tasks of managing a manufacturing business. Using batch software in your process manufacturing workflow gives you insight into invaluable data such as sales, supplies, products, customers, and other essential departments in your business.

Katana achieves this by giving you access to features designed to make managing your business as easy as pie. This includes barcode scanning, data handling, and integrations with other important business management tools.

- Get complete control over all your different inventory types

- Improve inventory management with reorder points and safety stock levels, and automate your inventory transactions

- Total inventory control, including manufacturing and distribution, in real-time

- Manage product variants and materials all in one place

- Implement and use barcodes to receive and track stock

Want to see Katana in action?

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Batch manufacturing software that integrates with your favorite tools for a smooth workflow

From native integrations to code-less templates or fully customizable API integrations

Katana’s batch production features give users access to the API, allowing you to create custom workflows and connect your business apps to manage your sales, manufacturing, and accounting all on one platform. Automate data transfers between the services you use to level up efficiency. Take a look at our API documentation to learn more.

We also wanted an accurate inventory system for batch planning, warehousing, and sales. Katana fulfills all our needs in a simple, easy solution.”

Irah Vet

Founder and CEO at Hornby Organic

We struggled to know which items are in stock so that we could build a batch and therefore often found extra components lying around […] Katana, we can now know what we have in store and where to look for it.”

Danielle Louw

CT LAB

Katana provides us with all the necessary features for manufacturing order management. Furthermore, we can track inventory usage and incorporate our sales order tracking into Katana.”

Mikhail Moore

CEO at Vitacore Industries

Having a system track inventory and what stage it is in has been incredibly helpful. It also has helped our team have a more clear delineation of the order of operations for each product in our catalog.”

Sarah Zinger

Director of Production Logistics at System76

Batch manufacturing software FAQs

An ERP system is a software package that helps businesses manage their day-to-day activities, such as accounting, procurement, and production process. The acronym ERP stands for enterprise resource planning.

ERP software for process manufacturing is designed to give businesses a complete picture of their operations to make better decisions and improve efficiency. They typically include modules for monitoring production cost, inventory, warehousing, and customer relationship management (CRM).

ERP solutions can be complex and expensive to implement, but they offer many benefits. They can help businesses save time and money by streamlining processes, reducing errors, and improving decision-making.

If you’re considering a comprehensive ERP system for your business, it’s important to do your research and choose a package that fits your specific needs. There are many different ERP systems and materials requirements planning on the market, so it’s important to find one that’s right for you.

A bill of materials (BOM) is a comprehensive formula management list of all the components, materials, and parts needed to build or manufacture a product or service. It provides the key formulas and recipes about each component, including its name, quantity, function, and supplier.

BOMs play an important role in managing inventory and production costs. By having a complete and accurate recipe and formula BOM, businesses can avoid ordering too many or too few supplies, which can lead to wasted materials and costly delays. BOMs can also help businesses negotiate better prices with suppliers by ensuring that they are only ordering the exact amount of supplies needed.

Batch manufacturing software is commonly used in various industries to manage production processes. These industries include:

- Software chip manufacturing

- Pharmaceuticals and medical devices

- Food and beverage production

- Chemical manufacturing

- Discrete manufacturers

Batch manufacturing software helps companies in these industries to optimize their production processes and improve efficiency. The software can be customized to fit the specific needs of each industry, making it an essential tool for companies looking to improve their operations.

When investing in batch process manufacturing software, there are five essential features to ensure the process manufacturing application will provide must-have functionality and industry-specific functionality. These features are:

- Support for multiple processes: The process manufacturing solution should support multiple processes to adapt to changing needs and requirements.

- Flexible batch sizes: The software should allow for flexible batch sizes to accommodate different production requirements.

- Easy recipe management: The process manufacturing system should offer easy recipe management to streamline the production process.

- Comprehensive tracking and tracing: The software should provide total process control, tracking and tracing capabilities to ensure product quality and safety.

- Scalability: The software should be scalable to support future growth.

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control