The ultimate inventory management guide

Get the ultimate guide to inventory management

A comprehensive ebook that covers everything you need to know about inventory management.

Inventory management is the process of keeping track of all the goods your company has in stock. And the benefits of good stock management are clear because the costs of doing it poorly are high. If you have too much inventory, you are tying up cash and wasting money on resources like stock room space.

On the other hand, understocking can lead to delayed deliveries and mobs of unhappy customers wielding pitchforks at your door.

Inventory management is a central part of your business when dealing with physical products. How well you do it will determine your success.

This article contains everything you need to know about inventory management to help you take your inventory game to the next level. If you can master and implement the advice below, you’ll put yourself ahead of the competition in no time.

What is inventory management?

Inventory management is the science and art of ordering, storing, and using a company’s inventory — the materials and components a business sells or uses to make its products. It includes the systems and processes companies use to track their inventory and determine when to order more.

Before diving into the details, it’s always best to get to grips with the fundamentals. Otherwise, you’ll end up following others blindly.

At best, you’ll always be one step behind the leaders, at worst, they might take you over a cliff. In this case, we must understand what inventory really is and the aims and objectives of solid inventory management.

Once we unpack these a bit, the inventory management definition should come into focus.

Defining inventory — it’s much more than just your finished products

There are many definitions of inventory out there. Some offer an interpretation that refers to inventory as the sum of all items used in your business. This includes anything related to the operations of your business, such as safety or office equipment.

We believe it’s more helpful to think of inventory as the sum of all items used in your business intended for sale.

That means looking at all the bits that go into getting your products made. Regarding materials directly related to your production process, it includes items ready to be sold and items you intend to sell in the future. You could break down the types of inventory into the following:

- Raw materials — Components that can be used to create products

- Work-in-process — Items in the process of becoming finished products

- Finished goods — Products that are completed and ready to be sold

- MRO inventory — Maintenance, repair, and operations supplies needed to keep production running

Let’s look at the example of making candles. Raw materials would be wax, wicks, and colors. Work-in-progress would be colored or shaped wax. And, of course, the finished good would be a fully formed candle with a wick on top, ready to burn for a cheesy romantic dinner. Unfortunately, these progressions aren’t always so simple and linear.

You could have all kinds of different waxes being used to make a variety of candle shapes.

That’s one of the main issues businesses often have — dealing with the constantly moving pieces of raw materials and the finished products themselves. Inventory can be like a sneaky shapeshifter that always finds a way to slip out of your grasp before you get a full hold of it.

Understanding that inventory is dynamic and fluid is the first step to attaining good inventory management. Then, it becomes clear that keeping track of your stock is not something you can force. You need to look for the right tools to help you tame it.

It’s the whole reason that recording and tracking inventory digitally became a staple as soon as it was possible. Live inventory management software helps you keep your inventory information up-to-date and free from human errors.

State of Inventory Management Report

A massive migration to e-commerce and predictions for an economic slowdown — take advantage of the trends and insights in this report to prepare your business for uncertainty in 2024.

The difference between inventory and stock

Whether there is any difference between inventory and stock has been the root of much unnecessary confusion. Many business owners and retailers use both terms interchangeably — some note that inventory is used more in US English and stock in UK English.

Honestly, this is mainly a matter of personal preference and shouldn’t lead to trouble.

But minor distinctions can be made, so you should be aware of those too. It could come in handy if you have to explain or describe your inventory management practices accurately. One area you can be more specific with is how you distinguish the types of inventory in your business.

Some dictionaries define stock as the finished goods you have ready for sale. This is why the term in stock is commonly used in retail. In comparison, inventory can refer to finished goods, raw materials, and works-in-progress.

So, it’s a good idea to mention the type of inventory you are talking about if there is room to cause uncertainty. Here are the main forms of inventory:

Remember, the word inventory can be replaced with the word stock in these terms and still be perfectly valid. It just makes life easier to be a bit more specific sometimes.

Inventory management vs. inventory control

We found that inventory and stock are mostly the same, now let’s see the difference between inventory management and inventory control. Like inventory and stock, these two terms are often used interchangeably. But unlike with inventory and stock, equating inventory management and control is inaccurate.

- Inventory control — One part of the broader discipline of inventory management that’s focused on knowing where your inventory is and ensuring it travels to the right place.

- Inventory management — Encompasses the above, and in addition, it’s also the ongoing process of reducing the cost of inventory while maximizing the company’s profits. This includes expenses like purchasing raw materials, carrying costs of inventory, and inventory processing overheads.

Inventory control is the organization and logistics of your inventory. In contrast, inventory management is about how inventory fits into your overall business plan and success metrics. It makes sure production is efficient enough to be profitable.

Both are essential and should be understood as best as possible.

Why is inventory management important?

There are four common goals of inventory management to keep in mind when coming up with your strategy:

- Improving the accuracy of your production and order fulfillment cycle

- Keeping your inventory organized, using space to its full effect

- Cutting down on waste like inventory carrying costs and transport time

- Saving time and money by improving organization and lowering lead time

You get more out of what you focus on, so place your crosshairs on the positives — read the best resources and look to emulate the companies you admire. With these objectives in mind, we can sum up a useful inventory management definition:

Inventory management aligns all inventory types to the efficient creation of finished products and delivery to customers’ satisfaction.

The overall aims of inventory management are universal, but your business will be aligned toward different goals than your neighbor. That definition spells out the end goal that every business owner should have when it comes to inventory management.

Can you hazard a guess as to what it is?

The effects of good inventory management are saving time, money, and resources (including human energy), thus lowering stress levels all-round. However, these are positive side-effects of good practice, not the end goal. The end goal is 100% complete customer satisfaction.

Don’t underestimate the effect customer satisfaction has on your business. Reviews and word of mouth contribute to a reputation, and it’s hard to shake a bad one. Constantly having this goal in mind will make it a lot easier to focus on optimizing your inventory to achieve your business potential.

The difference between small and large-scale inventory management

Remember that stereotype of businesses with their giant warehouses?

From afar, it looks like they have enough stock to last them through an apocalypse. It’s a grand painting for sure, but realistically this method of stockpiling inventory should remain something for large enterprises. They have bigger budgets and orders and are less flexible with what they can do.

Historically, enterprise resource planning (ERP) software has been specifically designed for these huge companies to deal with this. The crazy thing is that the solutions are often tailored for each business separately. They are integrated with the entirety of their business, including areas such as human resources and marketing automation. So, these systems serve as the spine of the entire organization.

You can imagine how much of an expensive endeavor that is. And most companies cannot afford these systems where implementation alone can cost $75,000 to $750,000.

Luckily, there are now ERP solutions available that cater to small and medium-sized businesses (SMBs).

Many organizations in the SMB sector already have certain platforms they prefer to use, for example, for accounting or customer relationship management. These new ERP systems dedicated to SMBs can offer a central platform to integrate with your favorite business tools, allowing you to manage your whole business from one place without swapping over well-established systems.

Types of inventory management

It’s time to get to grips with the most popular inventory management techniques — the following are widely practiced and are here to stay, so the sooner you get to know them, the better.

Some are so successful that other industries, like software development, have adopted them.

The following principles work regardless of whether you have a small family-run business or aspire to head a multinational company. But one keynote before we start — these methods aren’t in competition or conflict with each other. You don’t have to choose one and ignore the rest.

The optimal approach is to find the most useful aspects of each theory that fits into your business as it stands.

In other words, you find what works for you because the real purpose here isn’t to make life more difficult for you. It’s to free you up and give you the space to focus on growing rather than dealing with boring stuff. So, let’s get down to the real nitty-gritty of inventory management systems.

Periodic inventory management

Periodic inventory management has been the traditional way of managing inventory. With this system, businesses take physical counts of their inventory at set intervals. The interval can be daily, weekly, bi-weekly, monthly, or even yearly. What happened in between was not tracked, so business owners hoped the books added up at each stocktake.

Hope has never been the most sustainable business strategy, so periodic inventory management is no longer the gold standard.

This system can be useful for businesses with straightforward inventory. For example, if you only have one type of product, and it doesn’t move very quickly, you might be able to get away with doing a physical inventory count once a year. However, as your product range grows, this system becomes too resource-heavy and error-prone.

The main advantage of periodic inventory management is that it is simple and easy to do. The disadvantage is that it can be inaccurate. If you don’t take physical counts often enough, your records might not reflect what you actually have on hand. This can lead to overstocking or stockouts.

Perpetual inventory management

Due to the shortcomings of periodic counts, perpetual inventory came along. It was known as the more accurate method but far more time-consuming. It works by constantly updating your inventory whenever an order is placed or stock is moved around.

Businesses that have used periodic inventory for years would shake their heads and say: “who’s got time for that?”. And back in the day, they would have been right. But now, with the help of warehouse inventory management software, accurately keeping track of stock 24/7 has become a breeze. When you receive a new order from your e-commerce platform, the system automatically deducts the necessary inventory from your total and lets you know if the materials are available.

The system tracks all types of inventory by itself and reassigns everything depending on its stage in the production schedule.

Another positive effect of constantly keeping track of everything is that inventory won’t go missing, be wasted, or be assigned to two things at once. Perpetual inventory is an inventory management technique that should always be going on in the background and makes the following methods that much easier to follow.

Just-in-time inventory management

The just-in-time inventory (JIT) system is an inventory management philosophy that aims to fill demand exactly. You make goods when orders come in, not before. The goal of JIT inventory is to cut down costs from the production process. This is done by careful planning.

All resources (human, material, space, and time) are used to create the highest-quality product while cutting down costs. For example, retailers use a form of JIT. When you go into a supermarket, there is an unbelievable amount of choice, but only a few of each item. When an item runs low, the supermarket system flags this up, so the manager can order more.

All waste and inefficiencies are identified and reduced as much as possible. These are the five elements to focus on if you want to get into the game:

- Eliminating waste — Look at all your resources and identify inefficiencies

- Constant performance evaluation — What could you be doing better?

- Improving continuously — Aim higher with all your processes

- Become customer-focused — Use supply-chain strategies that account for customer demand

- Balance your work setting — Create a clear and focused atmosphere

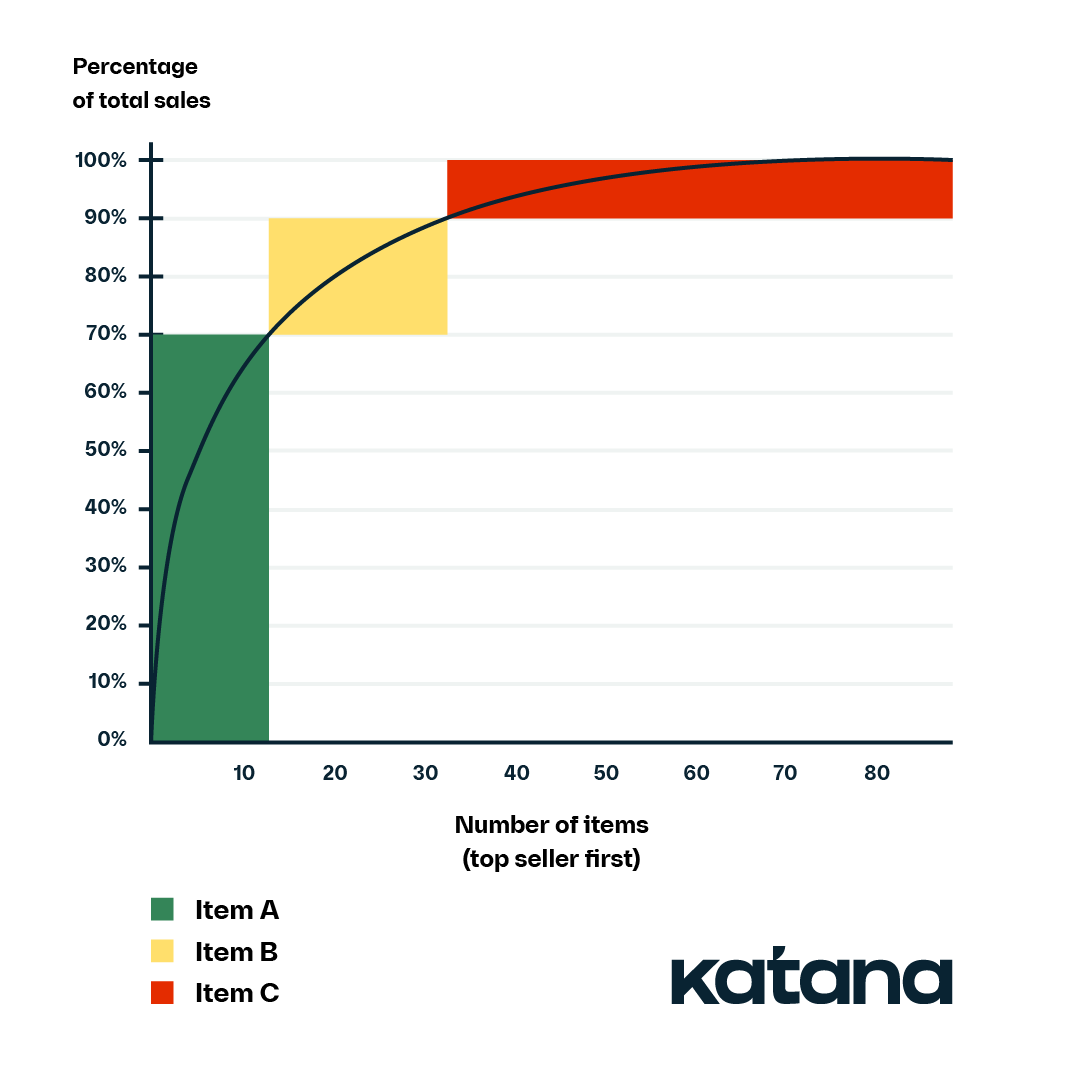

ABC inventory management

Another widely used method of categorizing your product inventory into what sells best and what doesn’t is ABC inventory. This model is based on the Pareto principle and supposes that most of your sales are from a minority of the products you sell. In other words, 15% of your product variations may account for 70% of your sales (Item A). Conversely, certain products that take up around 50% of your inventory only account for around 10% of your total sales (Item C).

The rest lie in the middle ground, neither very fast nor slow-moving inventory.

These aren’t exact numbers, but they give you a good idea. ABC inventory is designed to help you identify that different parts of your inventory have different inventory turnover rates. Knowing the average lifespan for each inventory item tells you where your inventory flows most effectively, what the average is, and what the dead weight is.

Pro tip: If you have inventory that sticks around for months, it may be a good time for some SKU rationalization so you can free up that warehouse space for better-selling products.

Once you know your average inventory counts over a set time and your cost of goods sold (COGS), you can work out the inventory turnover ratio for that item. Your inventory turnover ratio tells you if you have:

- Too much inventory at one time

- Enough sales

- Too high costs

- Kept up with customer orders

Some experience and sound judgment are needed, but you can unlock so much information about how well your inventory works for you if you do this right. Though you can do the calculations yourself, inventory management software can help you find average lifespans and the cost of goods sold to save you time.

Consignment inventory management

When using consignment inventory, the ownership of goods only changes hands when the goods are sold to the end customer. This means that the supplier still owns the inventory until it is sold. This is a good idea for trying out a product without market research. It could even be used for that purpose because vendors are likely to agree to take stock if they don’t have any risk with whether they get sold.

On top of that, you save a lot of money by reducing the number of deliveries you make.

Rather than selling products one by one, you just send off a big batch to a customer, and then they return what they didn’t sell months later. It’s a specific way of doing things, and you need to find a supplier willing to play ball. But if it’s right for your business or products, your stock room is going to be very tidy indeed. Because you’re not the one holding onto inventory, it’ll be your customers themselves.

Essentials of inventory management

The theory is one thing, but what about doing all this in practice?

Of course, the best inventory management software can do a lot of everything mentioned in this guide for you. But there are some steps you can take to aid your optimization efforts. Don’t worry, the methods aren’t too complex. You won’t be staying up all night, tearing your hair out after your sixth cup of coffee, trying to understand what’s going on.

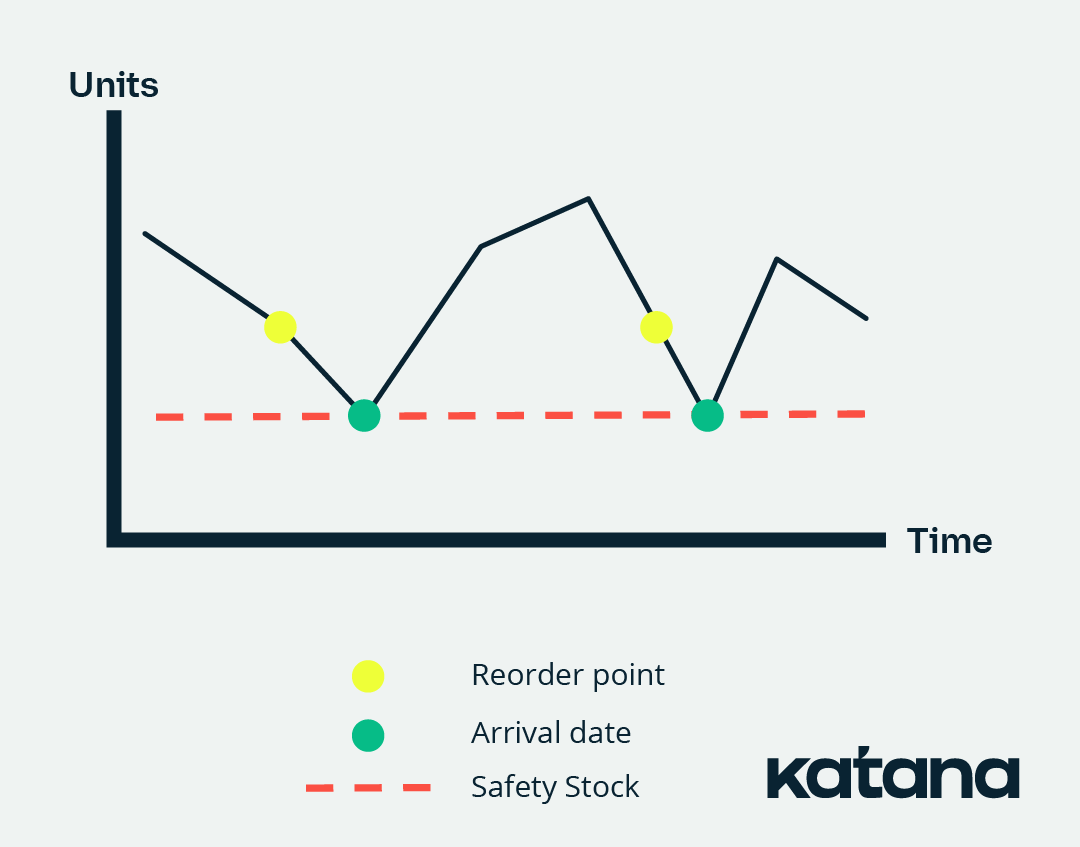

Reorder points

Reorder points are stock thresholds that let you know it’s time to order more inventory.

It’s a fail-safe that keeps your stockroom from falling into chaos. The ideal inventory reorder point allows for adequate time to make a new order before your stock reaches zero. You set a reorder point to let you know two vital things:

- The right time to order more materials from your suppliers

- The right time to make more sub-assemblies and products

When the stock level for materials or finished products reaches the reorder point, you want to place a purchase order immediately. Your inventory reorder point levels should cover every item in your inventory. This takes away any doubts or second-guessing.

Your reorder point is there, clear as day. You just need to react when it is reached.

Your stock will be better regulated, with fewer interruptions like supply-chain breakdowns or bottlenecks. Gone are the days when you start a new order only to realize that you don’t have enough supplies. Reorder points are essential to ensure your schedule is not delayed or interrupted.

Want to know how to calculate your reorder point? Check out this blog post on reorder point formula to find out.

Safety stock

Safety stock describes the amount of inventory a business keeps in the warehouse to protect against spikes in demand or shortages in supply. It’s a helpful buffer that’s part of careful demand planning. It helps you out in emergencies, like when a supply order does not get to you in time or you have a hectic holiday season.

As a manufacturer, safety stock principles can and should be applied to both final products and raw materials inventory. That means you should have a buffer of raw materials to create orders, as well as finished goods, in case you need to fulfill a wind whirl of customer orders. This ensures the availability of materials for production and products for delivery.

The point is that your customers get their deliveries on time, and safety stock is there behind the scenes making it happen.

However, the trick (like with every other inventory management principle here) is balance. You don’t want to swamp your factory with safety stock. That is why you apply a safety stock formula to make sure you don’t go overboard. It probably won’t be as much as you expect. But this is one of those methods that will make a noticeable difference.

The bonus is that it’s measurable too, which every manager loves.

SKU rationalization

The act of reducing the number of unique products in your inventory is called SKU rationalization. It’s also known as product rationalization or SKU simplification. The idea behind it is that by having fewer items, you can focus on the items that matter and generate more revenue.

There are several ways to go about this, but here are a few key methods:

- Stop selling low-margin products

- Remove slow-moving products

- Consolidate similar products

Let’s say you have two types of a particular product, A and B. Product A is selling quite well, while product B isn’t doing so hot. In this case, you would remove product B from your inventory to focus on product A. Or, you might have two products that are very similar, like a black shirt and a navy shirt. In this case, you would choose to keep one product and remove the other.

SKU rationalization is all about streamlining your inventory and getting rid of the items that are dragging you down. It’s a tough call to make, but it can really pay off in the long run.

Challenges in inventory management

While efficient inventory management seems to be the answer to all the problems a business may face, there are plenty of hardships on the journey to efficiency.

- Making sure all staff are working from and updating the master copy of the inventory

- Accounting for lost stock due to damage, theft, or loss

- Keeping up-to-date while not interfering with daily operations

- Estimating production time to meet customer demand

- Finding the best inventory management software that suits your business

- Training employees in the use of specialized software

Pro tip: To become a master in fighting issues and tackling hardships like a warehouse superhero, we suggest you read up on the most common inventory management challenges. We’ve gathered the biggest obstacles businesses face in daily stock management and share the best solutions to each issue.

Or, if you want to dive even deeper, then we’ve put together a comprehensive article on supply chain inventory management, including 7 best practices to set yourself apart from the competition.

Different approaches and requirements for inventory management

Retailers, manufacturers, and e-commerce sellers all need inventory management. A business’ exact methodology changes drastically depending on its inventory types and what inventory is used for.

Retail inventory management

In general, a retail business purchases products from suppliers and sells them to customers.

These items can be sold via a brick-and-mortar store or online, and the inventory is usually held in a warehouse. Regardless of how, a retail business needs to track inventory levels and sales data.

This information is then used to order new products and to forecast future sales.

Retailers need to have a good understanding of their customer base and what products are selling well to make accurate decisions about what inventory to carry. This information can be easily accessed using retail inventory management software.

E-commerce inventory management

An e-commerce business sells products online through a website or a marketplace such as Amazon or eBay.

Many e-commerce sellers use dropshipping, meaning they don’t hold any inventory. Instead, they purchase products from a supplier as needed and have them shipped directly to the customer.

Find out more about the intricacies and nuances of online sales from our article on e-commerce inventory management.

Multilocation inventory management

Lots of businesses have warehouses and locations scattered across the map.

Navigating stock across all sites, whether physical or online, requires a strategic approach in order to run smoothly. Businesses must centralize control while keeping in mind location-specific preferences, using preferred systems for real-time tracking, sales data analysis, and data-driven decision-making.

We’ve written a whole blog about handling multilocation inventory and invite you to check it out.

Warehouse inventory management

Whether a business creates its own products or purchases them from a supplier, it still needs a place to store all the goods.

The primary goal of warehouse inventory management is to streamline stock processes to optimize storage space, track all products quickly and effortlessly, and ensure accuracy in inventory levels at all times.

An efficient warehouse is essential for maintaining a well-organized sales flow and keeping customers happy. Learn more about warehouse inventory management.

Manufacturing inventory management

A manufacturing business produces items either to sell to customers or to use in the making of other products.

Manufacturers need to track inventory levels of raw materials and finished products. In addition, they have to keep track of production data, such as the number of products produced, the time it takes to make them, and any scrap or waste left over. This information is used to forecast future demand, as well as for production planning.

All businesses are unique, and as an owner, only you know what is best for your organization. What works for large manufacturers does not work for small ones.

Here are some tips to enhance inventory management for manufacturers:

- Use SKUs — Stock-keeping units (SKUs) are unique ID numbers for each product variation. They let your system process orders more accurately and integrate better with e-commerce channels.

- Anticipate changes — Notice and learn trends in customer activity. Then you can keep up with changes in demand without straining your operations.

- Be a good customer — Make sure you’re the ideal company for your supplier to work with. Pay invoices early, develop a good relationship, and they’ll become a dependable partner. If you’re ever in a pinch, you’ll be at the top of their list.

- Get to know the cloud — Use cloud-based inventory software so your inventory can be managed from multiple locations. This allows you to stay up-to-date at all times and stay connected to your team wherever you’re currently working.

- Listen to your customers — Find out about customer satisfaction. How many receive their orders on time, or early even? Research ways to improve management to create a better experience for your customers.

It can be useful to incorporate all the above, but obviously, it’s up to you to select the focus points. Take a bit of time to come up with a general strategy, and the whole thing will start making sense quicker than you can say safety stock formula.

Inventory management software for manufacturing

There are dozens of options when it comes to inventory management software, but only a handful are geared specifically toward manufacturing businesses. Manufacturers have unique needs when it comes to inventory management, so it’s important to choose software that fits the bill.

Some of the key features to look for in inventory management software for manufacturers:

- Enter product recipes and manufacturing processes so you can track your product flow more effectively

- Allocate materials to the priority orders in the list so that they get out the door first, minimize work-in-process, and fight over-ordering

- Manage your team by assigning duties and daily goals on your production schedule

How to choose the best inventory management software for manufacturers?

Good software has all the features listed above, but great software targets your specific requirements so that you can get the most out of your inventory.

A basic example is that if you sell your designs on an e-commerce platform like Shopify or BigCommerce, you should try looking for specific software. For example, you can search for software for BigCommerce inventory management to find exactly what you’re looking for.

You want to be able to trim all the fat off and keep only what is necessary to get products to your customers. As a growing manufacturing business, this means solutions that:

- Harmonize your raw materials and finished products inventory

- Help you move on from the burdened world of Excel or limited software solutions

- Seamlessly incorporate inventory management into your order fulfillment cycle

- Offer the option to integrate with e-commerce channels

- Are simple to navigate and easy to understand

This is an exciting time for manufacturers everywhere with all the options on offer, though it might seem daunting to find the right fit. But as mentioned before, there has been a recent development with the emergence of manufacturing ERP systems targeting modern business owners’ needs.

The difference with legacy ERP is that these are cloud-based and focus on integrations most vital to manufacturers. For example, Katana’s lean manufacturing software integrates with popular e-commerce platforms to allow sales to become directly part of the manufacturing flow.

Problems when inventory management is not done properly

Proper inventory management takes a lot of time, dedication, and resources. If not done correctly, it can lead to a number of problems. Let’s look at some of the issues you can avoid by having a good inventory management system in place.

Dead stock

Dead stock, sometimes incorrectly referred to as deadstock, is a product that hasn’t been sold but is still held in inventory. Deadstock, on the other hand, is inventory that isn’t stocked anymore and often comes with a premium price. There are multiple reasons why a business might accumulate dead stock, but the main ones are:

- Poor inventory management

- Not accepting reality

You might convince yourself that holding inventory that’s not performing isn’t much of an issue. However, this hiccup can quickly drain your business’ revenue without you even noticing.

Integrating inventory management software will help you monitor stock and combat this problem from affecting your business.

Stockouts

A stockout is when you don’t have the inventory on hand to meet customer demand. This can be a big problem for businesses, leading to lost sales and unhappy customers.

There are a few reasons why stockouts might occur:

- You didn’t order enough inventory

- Inventory was damaged or lost

- Inventory was stolen

- There was a problem with the supplier

- Customer demand increased unexpectedly

To avoid stockouts, you need robust MRP software with inventory management features that help you track your inventory levels and remind you when to reorder.

Overstocking

Overstocking is when you have too much inventory on hand. This can be just as big of a problem as stockouts, as it can tie up your capital in inventory you can’t sell.

There are a few reasons why overstocking might occur:

- You ordered too much inventory

- Customer demand decreased unexpectedly

- You’re holding on to slow-moving inventory

To avoid overstocking, you need a good inventory management system that helps you track inventory levels and anticipate customer demand.

A closer look at inventory management systems

When people think of inventory, they often imagine gargantuan warehouses packed to the rafters with cardboard boxes and hundreds of staff scurrying around. But that’s not always the case. In fact, most businesses need only a fraction of that space to store their products and materials.

What is an inventory management system?

Inventory management systems are processes and solutions to manage all goods, materials, products, and components owned by a business.

The first port of call, as always, is a pen-and-paper system. This includes written stocktakes and order invoices. Many hobby and micro businesses use this method to manage inventory, if only in part.

But the limitations will be reached very quickly here.

A step up the ladder is using Excel spreadsheets for inventory management. These work fine for a while as long as good practices are followed, like backing up data. Even Formula 1 cars have been built using only an Excel sheet for inventory management.

However, this functionality is restricted. You will have to constantly update a web of spreadsheets to keep your purchases, recipes, raw materials, final products, and sales all in check at the same time.

Sooner or later, problems will occur, regardless of your spreadsheet skills.

The more inventory data added, the more human errors will crop up, which leads us to the final option — real-time inventory management software. These are more robust than spreadsheets and come with functions specifically designed for the purpose of inventory management, so you don’t have to do any tinkering.

What should good inventory management software do?

There’s no doubt that inventory management software is the solution for small and medium-sized companies to optimize their inventory.

The real question here is: How do you pick the right software?

Let’s dig deeper into the features you should look out for when choosing a software system for inventory management.

How to choose an inventory management system?

The main things your inventory management software should be capable of include:

- Storing your entire product portfolio in one place with no need to enter something twice

- Integrating with the most popular business tools for a unified experience

- Using barcode scanners for stocktakes

- Attributing as many variations (size, color, embellishments, etc.) to each product

- Tracking orders from suppliers so you know when stock is expected

- Setting reorder points to avoid stockouts

- Being accessible to you anywhere while still being secure, also known as cloud inventory management

What are the 4 types of inventory management systems?

There are four primary types of stock management systems:

- Manual

- Barcode-based

- RFID (radio frequency identification)

- Automated

Manual inventory management

Manual is the most basic type of inventory management system. Here, businesses manually track their products using paper forms or spreadsheets. This type of system is suitable for small operations where tracking a few dozen items isn’t an issue. However, it quickly becomes cumbersome as the number of items grows and is not recommended for larger operations.

Barcode-based inventory management

Barcode-based systems are the next step up from manual inventory management and offer more accuracy than manual systems. Here, items are assigned a barcode which is then scanned whenever they’re moved into or out of inventory. This allows for quick and accurate tracking of products as well as real-time updates on stock levels.

RFID inventory management

RFID (radio frequency identification) takes things one step further by using radio waves to track products in real time without having to scan barcodes.

This allows businesses to quickly and accurately track their products without the need for manual intervention, making it ideal for large-scale stock management systems with potentially thousands of items in inventory.

It is also great for businesses that handle massive items or parts like shipbuilding operations or large containers of raw materials. The RFID tag can be placed anywhere on the item, which allows it to be accounted for as it passes through a loading bay or other scanning port.

Automated inventory management

At the highest level is automated inventory management. Here, businesses use robotic systems to quickly and accurately move products into and out of their warehouses — think conveyor belts, automated pickers, and robotic arms. This type of system is ideal for enterprise-level businesses with high-volume operations, saving them time and money in the long run. Understandably, these systems are extremely expensive and require a significant upfront investment.

Inventory management software for total inventory control

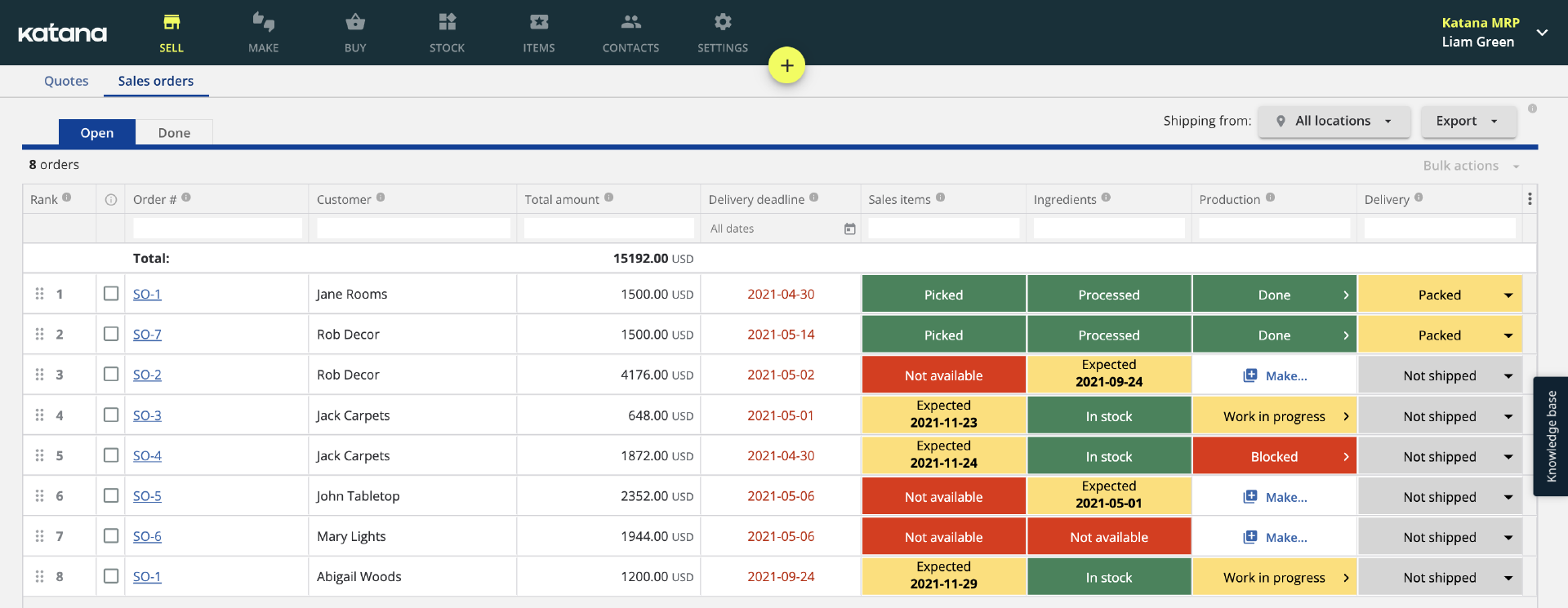

The theory is all well and good, but how does it all pan out when you get to the real thing? Let’s look at Katana’s inventory management software and see how we can implement some of the points we’ve covered.

1. Live inventory management

One of the main problems that businesses encounter when fulfilling their sales orders and scheduling their production is the constant need to check inventory — whether that means going into the stock room or trawling through spreadsheets to see what finished goods and raw materials are available.

Katana’s live inventory management software does all the hard work for you by keeping an up-to-date inventory, which shifts every time a sales order comes in. There’s no need to modify data every time an order comes in because the system does that for you. What’s more, Katana lets you forecast and plan inventory based on accurate sales data, so you’re always prepared to meet the demand.

2. Setting reorder points

Remember these? Katana allows you to set reorder points for each item, so you always know when to make additional products or purchase more materials. You can easily see under the column “Missing/Excess” how close you are to the optimal level of 0. You know you’re in the negative if it’s red and suggests filling up on that item.

Missing/excess = in stock – committed + expected – reorder point

3. Real-time master planning

The real magic with inventory management comes when you consider raw materials. One of the difficulties with production is that different products can share the same materials. This complicates keeping stock because you must track where your materials are used. Katana, however, will keep track of all these so-called “committed” materials so that you never run short.

On top of that, you can prioritize your orders with a simple drag and drop.

So if you have an order you want to get done faster (maybe the customer is a little bit of a VIP), you can just move the order up the line. The software will automatically book your available material stock to higher priority orders. This means that you can easily see what the effects are going to be on all other production orders in a color-coded visual chart. Katana will highlight any resulting delay risks of not getting the customer orders shipped on time.

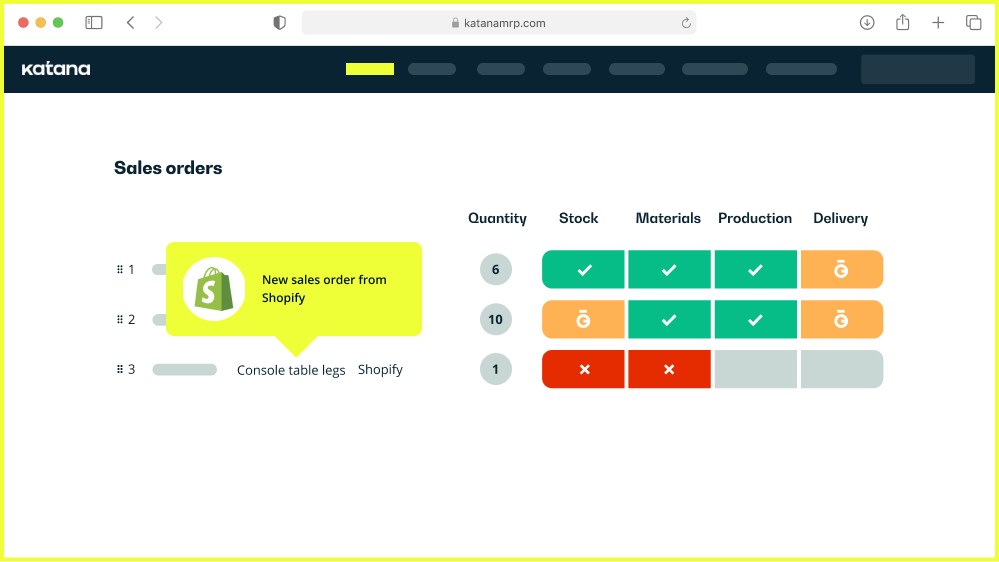

4. Sales order fulfillment

Having your entire flow from purchasing to sales in one place makes it easy to make decisions and changes. With seamless integrations to the most popular e-commerce platforms, all your sales are synced to Katana, so your inventory doesn’t need to be managed in more than one place.

Every time an order comes in, Katana adjusts your inventory and production line without any extra input needed from your side. You will immediately see whether you have the necessary items in stock or raw materials available to make the products ordered by the customer.

5. Integration with essential business tools

While inventory management is the pillar of any business handling products or materials, there are plenty of other aspects of a business that need tending to. From accounting and sales to reporting and shipping — the right software can speed up processes and take much of the work off your hands.

Katana has numerous integrations to choose from to keep your data and teams in sync. And if you’re using a tool that you can’t imagine parting ways with, there’s a solution for that too.

With our open API, you can build custom flows and create the perfect workspace fitting the specific needs of your business.

So, there you have it, the ultimate guide for inventory management.

No business wants to be spending all their days keeping up with inventory. The whole point of this guide is to show you how to make managing your inventory as streamlined as possible, giving you enough time to grow your business and focus on the things that really matter.

Managing your inventory properly takes a lot of planning, time, and effort, but it can be a breeze with the proper tools in place.

Katana brings together every aspect of your inventory management. Request a demo today to see it in action. Soon enough, managing your inventory will become second nature, and you’ll wonder what all the fuss was about.

Table of contents

Inventory management guide

More on inventory management

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control