Everything you need to know about the safety stock

Safety stock is a mechanism which manufacturers of any size can benefit from. Your business can be prepared whether stock management is going bad or if demand spikes unexpectedly. Better be safe than sorry.

What is safety stock?

Safety stock is the process of storing a surplus of inventory to avoid a stockout during an unexpected surge of sales.

It’s always reassuring to have a safety net. Whether it’s bungee jumping, skydiving, or even a bottle of just-in-case sunscreen when you go on vacation — there’s nothing worse than picking up a nasty streak of sunburn because you ran out of sunscreen. And manufacturing is no different.

From a manufacturer’s perspective, safety stock principles can and should be applied to both raw materials and final products.

This ensures the availability of materials for production and products for sale. The point is that your customers get their deliveries on time, and safety stock is there behind the scenes making it happen. Otherwise, you might end up with a dreaded stockout and many a-waiting, unhappy customers.

It’s not as bad as trying to sleep with a sunburnt back, but it certainly comes close.

Want to see Katana in action?

Keeping track of inventory can be easy. Get a demo and see why thousands of manufacturers made the switch.

Why is safety stock important?

Most manufacturers employ minimum inventory management principles or MRP tool.

In a perfect world, your suppliers always deliver on time, and your sales do not fluctuate unexpectedly. So, your company will always have enough stock. Sadly, we do not live in a perfect world. Your suppliers can face delivery problems due to one-off events or mistakes.

It’s not always in their control either, so there is no point in bearing a grudge and getting sulky.

The manufacturing world is slippery, and anything can come up at any time.

You can find that sometimes you may fail to meet your weekly manufacturing targets. Sometimes your sales are also affected by seasonal effects and unexpected marketing successes or failures. Don’t panic — all of this is normal.

Manufacturers carry safety stock for these very reasons.

The causes of stock issues can be broken down into the following:

- Fluctuating manufacturing lead times

- Customer demand changes

- Flawed forecasting

Unexpected spikes in any of the above are difficult to predict.

The supply chain is full of surprises – some fun, others not. Due to this uncertainty, having some safety stock in reserve helps you deliver on time and satisfy your customers.

Pro tip: Many manufacturers are cutting out the middleman and selling their products directly to customers. Calculating your safety stock is just the tip of the iceberg. Get ahead of the competition by understanding how Shopify inventory management works.

How to calculate safety stock?

Despite the importance of safety stock, it does come at a cost.

Lean manufacturing principles guide you to eliminate waste, and excessive stock is a waste as there are many costs to holding excess inventory.

Examples include renting additional warehouse space, paying salaries to people handling the stock, the risk of stock expiring or becoming outdated, and much more.

Also, excess inventory means your cash is tied up, and it can be greatly beneficial to cut carrying costs.

Thus, every manufacturer needs to find a good balance between having enough safety stock to weather the storms but not so much that it would break the bank.

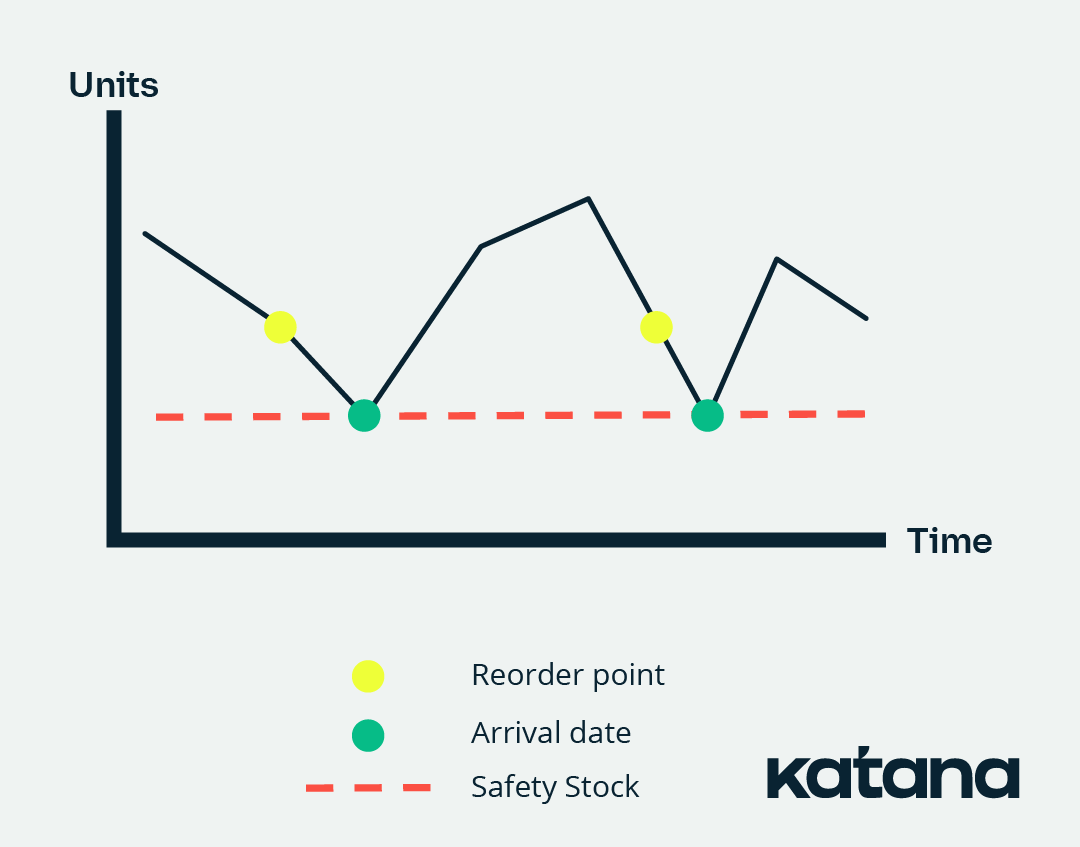

Below is an example of a monthly sales cycle of a company where the safety stock helps to mitigate spikes in sales.

Far too many manufacturers try to do guesswork and estimations with their stock levels. But as far as their instinct might take them, the chances are that they are either in excess or risking stockouts. The point of safety stock is mitigating these risks and margins of human error.

That’s why calculating safety stock has a method and formula to follow.

It considers both the amount of time it takes for your purchases to come through and the average amount of sales you have in a specified period.

The calculation is easy, provided reliable purchase and sales order histories are available.

Here is the safety stock formula:

Safety stock = (Maximum daily usage x Maximum lead time days) – (Average daily usage x Average lead time days)

Ultimately, the safety stock will be produced for you in the units in which you keep the materials. You know then the amount of safety stock and can set the reorder point appropriately.

First, let’s take an example to put a face to the formula.

Let’s say there is a hidden workshop on a distant asteroid.

They produce and sell hand-crafted Jedi Lightsabers to customers across the galaxy. As you well know, forging a lightsaber is a complex process that requires a number of rare components. One key component of a lightsaber is a Kyber crystal.

Every lightsaber needs one.

So, let’s assume the workshop operates with the following characteristics:

- Production, on average, consumes 10 packs of Kyber crystals per day to produce 10 lightsabers

- Maximum production capacity allows the consumption of 14 Kyber crystals

- It takes on average 14 days for Kyber crystals to arrive from a Kyber crystal mine on a faraway planet once the purchase order is placed

- Historical data reveals that delays in supply because of Sith supply raiding parties push the lead time up to 21 days

- It takes on average 5 days to produce one lightsaber. However, blockages in production because of Jedi swordmasters called on a mission sometimes result in a 10-day production cycle

On average, 10 lightsabers are sold per day. However, demand peaks (read: school starts in Jedi Academy) occasionally push the daily sales volume to 30 lightsabers per day

The table below sums it up nicely:

| Kyber crystal | Lightsaber | |

| Maximum daily usage | 14 | 30 |

| Maximum lead time days | 21 | 10 |

| Average daily usage | 10 | 10 |

| Average lead time days | 14 | 5 |

| Total | 154 | 250 |

The safety stock level for Kyber crystals would be:

(14 x 21) – (10 x 14) = 154 units

And the safety stock level and for Lightsabers would be:

(30 x 10) – (10 x 5) = 250 units

As the manufacturing process consumes, on average, 10 crystals per day, then the artisans have a bit more than two weeks of raw material inventory available to guard against the unexpected.

As the workshop sells, on average, 10 lightsabers per day, the business has a bit less than one month of ready-made product inventory available to weather unexpected occurrences.

That was simple enough, right?

Just note that with the safety stock calculation, you should always pay attention to changes in underlying metrics. Maximum daily usage and average daily usage are not figures carved in stone. They increase as your business grows and fluctuate depending on whether you are approaching high season or low season.

Thus, you should recalculate your safety stock levels from time to time.

A good tip to follow would be to revisit these calculations every quarter.

That way, you can always be confident that your customers will be able to handle pesky stockouts.

Want to see Katana in action?

Keeping track of inventory can be easy. Try Katana for free and see why thousands of manufacturers made the switch.

What’s next on your journey to safety stock inventory

Now you know the safety stock definition.

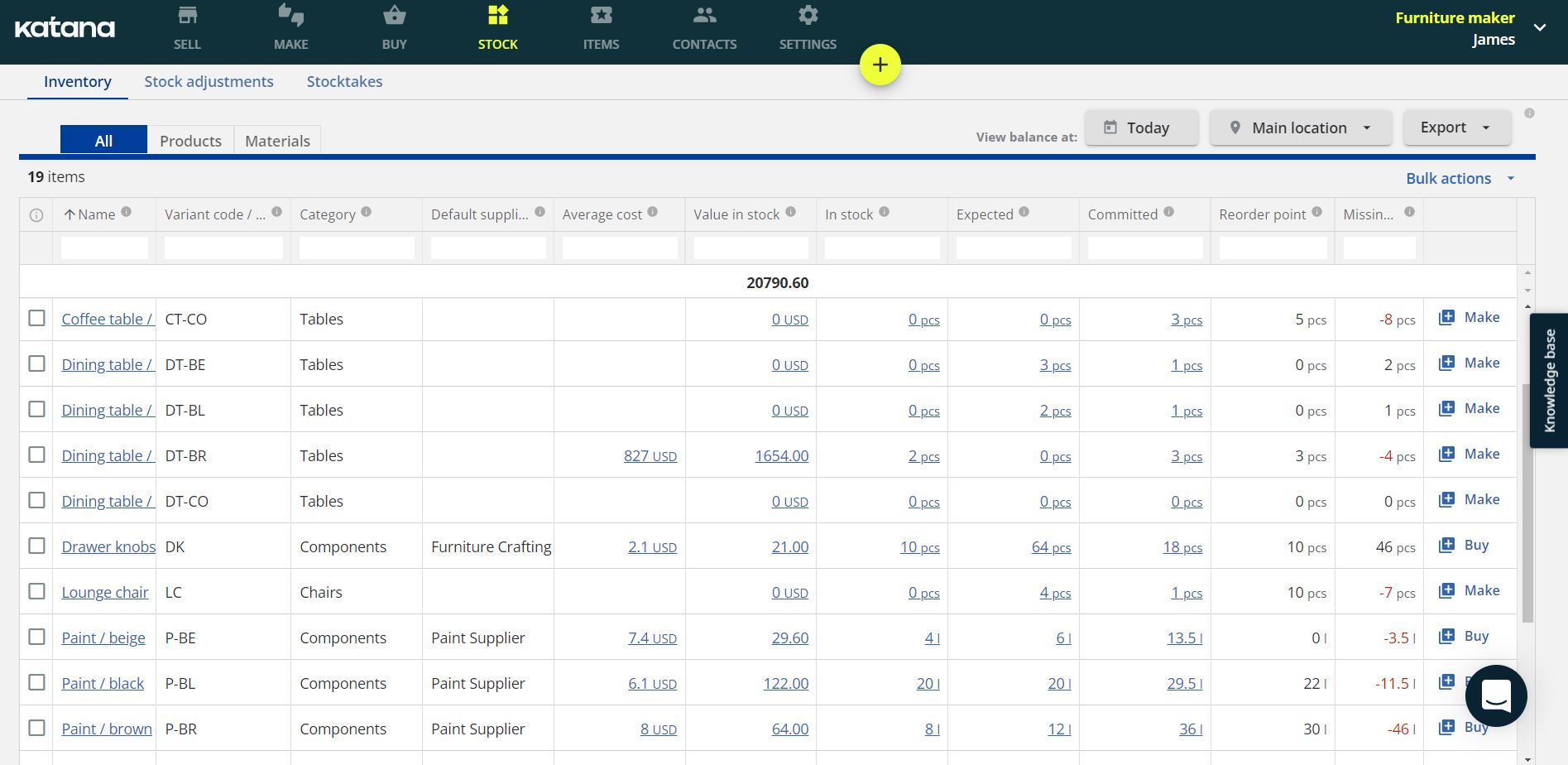

More importantly, you know how much safety stock you need to keep readily available in your warehouse — and so do the Jedi sword masters working on that distant asteroid. Now comes the easy bit of incorporating it into your manufacturing ERP system. Using Katana, you can set reorder points and manage your stock levels seamlessly within your entire workflow.

No more tedious back and forth between spreadsheets is required.

Katana gives you all the data and tools you need to set the optimal stock levels for lightsabers and anything else you happen to produce. And, after all, having a safety stock of lightsabers is a life-and-death question for the Jedi. You must get it right.

You wouldn’t want disgruntled Jedi banging on your factory door inquiring about late delivery.

Safety stock FAQs

Is safety stock the same as reorder point?

Safety stock and reorder point are related concepts, but they are different. Safety stock is an extra inventory maintained to ensure you never run out of a product due to unexpected delays or other disruptions. Reorder point, on the other hand, is when a predetermined quantity of inventory has been sold, and it’s time to replenish the stock levels by placing a new order.

Is safety stock the same as EOQ?

Safety stock is different from Economic Order Quantity (EOQ). Safety stock acts as a buffer to protect against unexpected fluctuations in demand, supply shortages, or other unforeseen events. Economic Order Quantity (EOQ) is a model used to calculate the optimal order size for inventory management. When determining the safety stock, it is important to consider the EOQ.

Table of contents

Inventory management guide

More guides from Katana

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control