A guide to inventory days on hand (DOH)

There is nothing more critical to a business than inventory management.

Knowing how much product you have in stock, when you need to reorder raw materials, or how to adjust production based on customer demand are all critical factors in keeping your business running smoothly.

One key metric for any company measuring and managing its inventory is days on hand (DOH).

Inventory DOH tells you how long, on average, it would take to sell all the units of a product you have in stock. This allows you to manage your production levels and inventory effectively and anticipate customer demand. Here’s a closer look at DOH and how it can be used in manufacturing.

What is inventory days on hand?

Inventory days on hand is a metric used to measure the average number of days it would take to sell all the units of a product you have in stock. It is also known as days inventory outstanding (DIO) and days sales of inventory (DSI).

For a grocery store, DOH may be capped at just 2-3 days as products will go bad if they are not sold. For other businesses, such as those selling expensive jewelry or electronics, DOH could be much higher as customers may take longer to make a decision on a purchase, resulting in low inventory turnover.

Why do inventory days on hand matter?

There are a few reasons why inventory DOH is such an important metric.

First, it lets you track how quickly or slowly your product sells. This information can help you make decisions about production levels.

If you see that a product has a high DOH, it may mean that you need to adjust your production levels downwards. On the other hand, if a product has a low DOH, it may be time to ramp up production.

Second, inventory DOH can help you predict future customer demand. If you see that a product’s DOH is increasing, it may be an indication that customer demand is about to spike. This information can help you have fewer stockouts by ensuring that you have enough product on hand to meet customer needs.

Finally, inventory DOH is a key component of capital management. Working capital is a business’s money available to fund day-to-day operations and short-term expenses.

Money that is tied up in inventory that has not yet been sold is a major piece of that capital calculation.

By optimizing a company’s inventory carry costs, businesses can free up working capital that can be used to invest in other areas of the business, fund short-term expenses, or increase their liquidity ratio. This can be a critical tool for small businesses with limited funding access.

How to calculate days inventory on hand (DOH)?

For a days on hand calculation, you will need three things:

- Average inventory value — This is the average value of inventory over a given time period, such as monthly or quarterly. To calculate your average inventory, add your beginning inventory to your ending inventory and divide by 2

- Cost of goods sold — This is the total value of goods sold over a given length of time. You can find this number in your ERP system or accounting software

- Number of days in an accounting period — This could be the number of days in a month, quarter, or year. Calculating days of inventory on hand for various smaller sections of the year can give you a more detailed picture of your inventory management

Once you have these numbers, you can plug them into the days on hand inventory formula.

Inventory days on hand formula

The DOH formula is:

DOH = (Average inventory / Cost of goods sold) x Number of days

There is one other way, and that is through calculating your inventory turnover ratio. You can learn how to calculate this way by taking your cost of goods sold and dividing it by your average inventory value.

Once you have your turnover ratio, you can use this formula to calculate days on hand:

DOH = Number of days Inventory turnover ratio

Both of these methods will give you the same answer.

DOH Examples

Let’s look at an example to illustrate how this formula might be used to calculate inventory days on hand.

Say your company sells electronics, and your average inventory value is $100,000. Your cost of goods sold for the month is $80,000, and there are 30 days in the month.

First method

To calculate using the first method, we would take our average inventory ($100,000) and divide it by our cost of goods sold ($80,000). This gives us 1.25.

We then multiply that number by the number of days in the month (30), which gives us 37.5 as our final answer.

(100,000 / 80,000) x 30 = 37.5

Second method

To calculate using the second method, we would take our cost of goods sold ($80,000) and divide it by our average inventory value ($100,000). This gives us 0.8.

We then take the number of days in the month (30) and divide it by that number, which also gives us 37.5.

30 / (80,00 / 100,00) = 37.5

Really, these are the same formula with the factors moved around. It is up to you to decide which is easiest given the information you have available.

What is a good DOH?

When trying to determine whether your DOH is good or not, there are a few things you need to consider:

- Industry — Every industry is different, so it’s important to compare your DOH to businesses in the same sector. For example, if you are a retailer, you will likely have a lower DOH than a manufacturer as products move through your supply chain faster

- Business goals — What are you trying to achieve with your inventory management? If you are looking to increase turnover or reduce waste, you will want to lower your inventory DOH. If you are trying to increase customer satisfaction by always having products in stock, you will want a higher DOH

- Customer demand — This ties into your business goals but is worth mentioning separately. If customers are demanding products faster than you can produce them, it may be time to reevaluate your amount of inventory

There is no magic number for what makes a good DOH. The key is to understand your business goals and compare yourself to similar businesses in your industry to maintain a competitive edge.

Decreasing inventory DOH with Katana

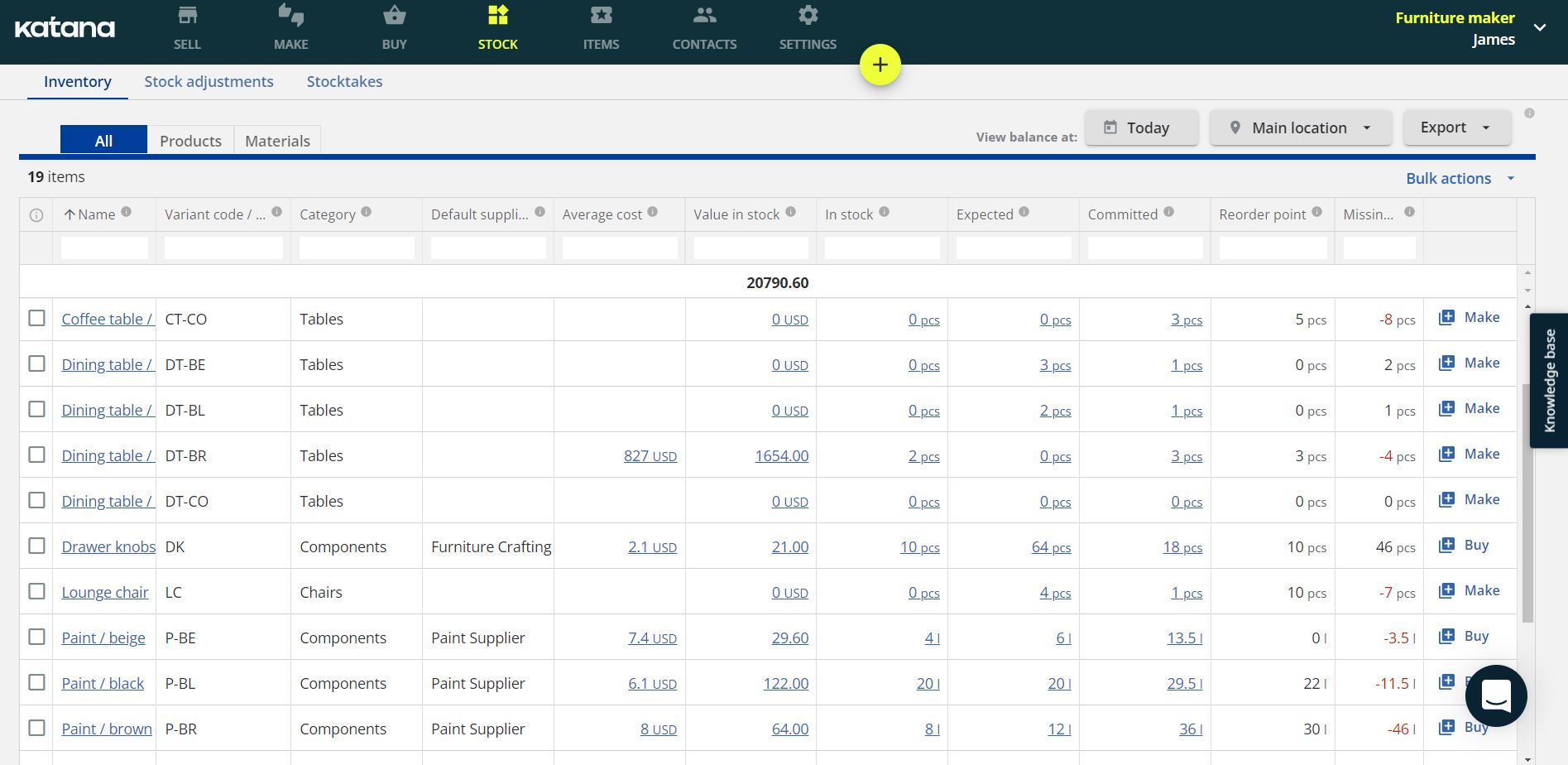

With Katana’s inventory management software, you can

- Get real-time updates on your inventory levels

- Forecast and plan your inventory

- Set up reorder points when inventory reaches a certain level

- Analyze historical data to predict customer demand and plan production accordingly

All of these features can help you decrease your DOH and keep reduced inventory levels without sacrificing customer service. Contact us today to learn more about how Katana can help your business streamline its inventory management with comprehensive ERP solutions.

Table of contents

Inventory management guide

More on inventory management

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control