Free up capital and reduce carrying costs with SKU rationalization

Constant, repeated SKU rationalization is a best practice of inventory management. This process aims to streamline the product catalog, making it simpler and easier to manage while reducing costs.

Stop wasting money on products that aren’t selling!

Here’s how SKU rationalization can help.

What is SKU rationalization and why is it important?

SKU rationalization (product rationalization or SKU optimization) is defined as reducing the number of SKUs (stock keeping units) in a company’s inventory.

The main goal of this process is to reduce complexity and costs while also making the product catalog simpler and easier to manage. Companies can sometimes get caught up in the “If we build it, they will buy” mindset. They add new products to their catalog without pausing to consider if there is any real demand.

This can lead to a bloated catalog with too many SKUs, many of which may not sell.

SKU rationalization benefits

There are many benefits to stock keeping unit rationalization. Here are some of the most important:

- Reduced costs — Carrying excess inventory is costly, and companies can save money by reducing the number of SKUs. Eliminating slow-moving or non-selling products can free up storage space and reduce warehousing costs

- Improved inventory management — A streamlined product catalog is simpler and easier to manage. This can lead to improved inventory management, including more accurate forecasting, better space utilization, and reduced stock-outs

- Increased sales — By eliminating slow-moving or non-selling products, companies can focus their efforts on promoting the products that are most likely to sell

- Improved efficiency — An optimized inventory is much easier to manage and organize. Eliminating SKUs that don’t sell clears up your warehouse of obscure items just gathering dust. Additionally, having fewer items can significantly simplify your manufacturing processes as you won’t have to produce as many different types of products

- Stronger brand identity — With a smaller product portfolio, you will be able to focus on fewer SKUs which can help to solidify your manufacturing brand’s identity. When customers can more easily associate your brand with a limited number of products, they are more likely to remember your brand and convert into loyal customers

With all the data you need to collect when rationalizing your SKUs. You have everything you need to generate better ads for your target market.

4 product rationalization challenges

While the long-term benefits are clear, every change comes with its own challenges that need to be considered:

- Complexity and time-consumption — SKU rationalization can be a complex and time-consuming process. It’s essential to clearly understand your inventory and business goals before you start. In addition, you will need to have access to accurate sales data in order to make informed decisions

- Changes in the supply chain — Another challenge is that stock keeping unit rationalization can sometimes lead to disruptions in the supply chain. For example, if you discontinue an SKU that is used in the production of another product, you may need to make changes to your manufacturing processes

- Impact on employees — It’s also important to consider the impact on employees. With changes in products and processes, some may need to be retrained on the new SKU lineup or be reassigned to different tasks

- Changes to packaging and visuals — In some cases, SKU rationalization may also require changes to your packaging or marketing materials. This is why it’s important to have a clear plan before making any changes

Now that we’ve covered the benefits and challenges, let’s see what steps you need to take to optimize your inventory.

The SKU rationalization process in 4 steps

There are four traditional steps in the rationalization process:

- Analysis — A SKU rationalization analysis of the current inventory includes looking at sales data, stock levels, and other factors to identify which products are selling and which ones aren’t

- Classification — Next, you’ll need to classify your products into different categories. This will help you determine which are essential and which can be eliminated

- Planning — Once you’ve analyzed your inventory and classified your products, you’ll need to create a plan for SKU rationalization. This plan should include which products will be eliminated and how the remaining products will be grouped together

- Implementation — This includes making changes to your product catalog – also known as an SKU reduction – updating your inventory management system, and training employees on the new process

This is all very well and good, but is there a tool for helping manufacturers calculate SKU rationalization?

SKU rationalization formula

There is no one-size-fits-all formula to determine SKU efficiency. The right approach will vary depending on the company, the products, and the market. However, there are a few factors that should be considered when developing a plan:

- Product demand — What are customers buying? Which products are selling well and which ones aren’t? Eliminate slow-moving or non-selling products

- Product profitability — What are each product’s margin %, contribution %, and other financial metrics? Eliminating products that aren’t profitable can help improve bottom-line results

- Product complexity — Products that are simple to manufacture and store are typically easier to manage than complex products

With this data in place, you can set thresholds that a product must meet or else it will be eliminated from the catalog. Let’s take a closer look at an example of how this works.

SKU rationalization example

Take a paint manufacturer, for instance. The company has grown over the years and now offers nearly 1,000 colors of paint, each with its own SKU. The company’s inventory management team is struggling to keep up.

After evaluating product demand, profitability, and complexity, the company decides to set the following thresholds:

- Demand — A color must sell at least 2 gallons per month to stay in the catalog

- Profitability — A color must have a gross margin of at least 30% to stay in the catalog

- Complexity — A color must be simple to manufacture (i.e. it can’t be a custom color) and store (i.e. it can’t be an aerosol) to stay in the catalog

With these thresholds in place, the company can reduce the number of SKUs to a few hundred. While some customers may be disappointed that a specific product is eliminated, the company will make more money by dropping carrying costs and consolidating marketing efforts into its most profitable colors.

Katana’s cloud inventory software

Take complete control of your business, from ordering raw materials to shipping finished products — Katana has you covered every step of the way.

How ERP software can help

Optimizing your inventory may seem daunting, but luckily there are tools to do the heavy lifting.

You can benefit from this SKU generator if you don’t yet have SKUs assigned to your items. Besides generating SKU codes, you can use this spreadsheet template to track your product inventory, including subassemblies and raw materials.

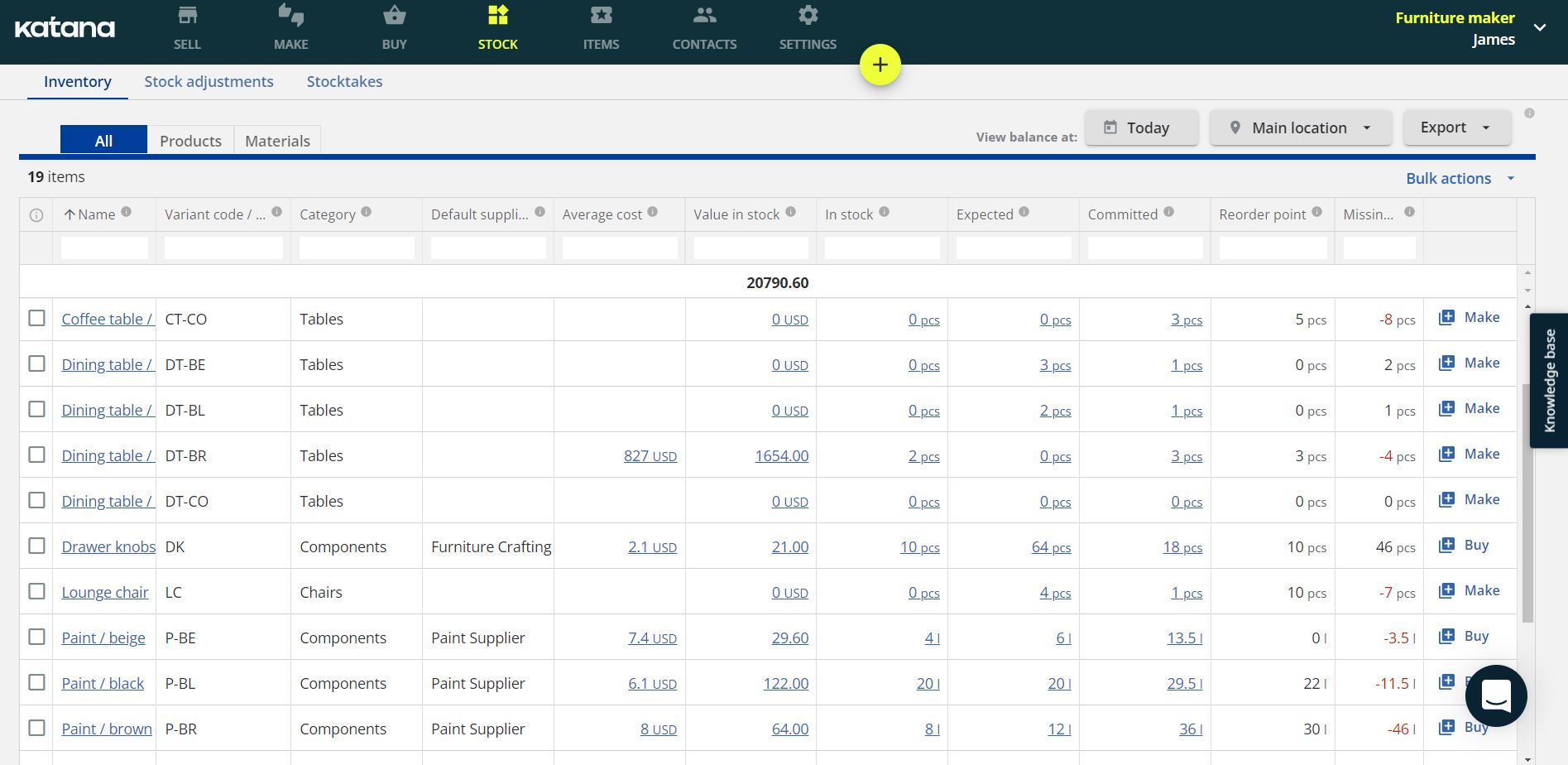

Another tool that every growing manufacturer should consider for inventory control is a manufacturing ERP.

With Katana’s manufacturing ERP software, you can keep track of your SKUs in one place. You can also seamlessly connect with the most popular reporting tools to get all the vital data you need regarding your inventory and SKU performance.

Get started by booking a demo with Katana today to improve your SKU rationalization!

Table of contents

Inventory management guide

More guides from Katana

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control