Manufacturing business processes to streamline your operations

Starting out, many small manufacturers just do what they do, day in and day out, without much thought to efficiency or effectiveness. As the business grows, inefficiencies begin to take their toll in the form of longer lead times, higher costs, and less customer satisfaction. At this point, it is usually time to take a step back and analyze the operations and see where improvements can be made.

That’s where manufacturing business processes come in.

Manufacturing business processes allow you to take a closer look at the individual steps that make up your operations and identify areas where improvements can be made. By streamlining your processes, you can improve efficiency, quality, and customer satisfaction while also reducing costs.

So, without further ado, let’s take a look at manufacturing business processes and see how you can leverage them to improve your operations.

What is a business process?

Business processes are the backbone of any organization, large or small. They provide a framework for activities and help ensure work is completed efficiently and effectively. While some business processes are relatively simple, others can be quite complex, involving multiple steps and countless interactions.

Regardless of their size or complexity, all business processes share one common goal — adding value to the organization.

This value can take many forms, including reducing costs, increasing revenues, or improving product quality. Companies can gain a significant competitive advantage by understanding and leveraging business processes.

Some common examples of business processes include order processing, accounts receivable, and accounts payable. Other business processes may be specific to a particular industry, such as claims processing in the insurance industry or loan origination in the banking industry.

Now that we have an understanding of what business processes entail, let’s look at the key business processes in manufacturing.

What are the business processes in the manufacturing industry?

There are many business processes for manufacturing companies needed to produce goods, and these can be broadly classified into the following categories:

- Product development

- Supply chain management

- Sales and marketing

- Customer support services

- Other support services

Product development

The product development process covers all activities from the initial concept to the final product launch. It includes market research, product planning, design, engineering, prototyping, and testing.

Product development is often referred to as new product development (NPD) in the manufacturing industry. The NPD process generally has the following seven steps:

- Idea generation — The first step in the NPD process involves generating new product ideas. Ideas can come from internal sources such as employees, the research and development department, management, or external sources such as customers, suppliers, or industry experts

- Idea screening — In this stage, ideas are evaluated, and those considered feasible are selected for further development

- Concept development and testing — The selected ideas are developed into concepts and tested with potential customers to gather feedback

- Business analysis — This stage involves conducting a detailed analysis of the concept to assess its feasibility from a business perspective

- Product development — The product is designed and engineered in this stage. Prototypes are created and undergo testing to ensure they meet all required specifications

- Market testing — The product is introduced to a select group of customers in order to gather feedback on its performance and any necessary improvements that need to be made

- Commercialization — This is the final stage of the NPD process and involves preparing the product for mass production and launch into the market

Supply chain management

Supply chain management (SCM) is a business process for manufacturing that encompasses all activities, from sourcing raw materials to delivering the finished product to the customer. It includes planning, procurement, manufacturing, logistics, and warehousing.

The goal of SCM is to ensure that products are delivered to customers promptly and efficiently while minimizing costs. To achieve this, businesses need to have visibility of their entire supply chain and be able to manage all the different components effectively.

The four main phases in the supply chain management process are:

- Planning — Businesses develop plans for procuring materials, manufacturing products and delivering them to customers. This planning is typically done using production management software that provides visibility of the entire supply chain and helps to identify potential issues

- Procurement — In this phase, businesses purchase the raw materials and components required for manufacturing their products. They also need to manage supplier relationships and contracts

- Manufacturing — This is the stage where products are actually manufactured. Businesses need to ensure that they have the necessary equipment and workforce to meet production demands

- Delivery — In the final stage, products are delivered to customers according to the plan developed in the first stage. This includes managing transportation, warehousing, and distribution logistics

Sales and marketing

The sales and marketing process covers everything from generating leads to closing deals and ensuring customer satisfaction. It includes market research, product development, pricing, promotion, and sales.

This process aims to generate revenue for the business. For that, companies need to have a clear understanding of their target market and what their needs are. They also need to develop effective marketing strategies and create a sales force to sell their products.

There are generally three main phases in the sales and marketing process:

- Lead generation — The first phase of the sales and marketing process involves generating leads through various channels such as advertising, direct mail, or trade shows

- Lead nurturing — In this stage, businesses work to build relationships with potential customers and turn them into qualified leads. That can be done, for example, by sending educational emails or providing free trials

- Sales — At the final step, businesses close deals with customers and generate revenue by negotiating contracts and pricing

Customer support services

Customer support services are responsible for assisting customers who have purchased a product or service. This assistance can be in the form of troubleshooting, repairs, or replacements. Businesses often make customer support available 24/7.

Customer support services aim to ensure that customers are satisfied with their purchase and resolve any issues they may have. The business achieves this by hiring customer support representatives who are knowledgeable about the products they offer. They also need to have systems in place to track customer inquiries and complaints.

The customer support process usually has four stages:

- Inquiry handling — Customer support representatives receive and respond to customer inquiries. This includes activities such as answering questions, providing information, and troubleshooting problems

- Complaint handling — In this stage, customer support representatives receive and resolve customer complaints. The team will need to investigate the complaint, determine a resolution, and take action to resolve the issue

- Escalation — In case the support representative is unable to come to a desirable conclusion, they can escalate customer inquiries or complaints to higher levels of management. This is done in order to ensure that the issue is resolved in a timely manner

- Resolution — In this final stage, customer support representatives follow up with customers to ensure that they are satisfied with the resolution of their inquiry or complaint. For example, the support team may send a thank-you note or issue a refund

Other support services

These services are required to run the business but are not directly related to the production, sales, or marketing process. Examples of other support services include accounting, human resources, and information technology.

Other support services aim to ensure that the business runs smoothly and efficiently. For that, companies need to have systems and procedures in place for managing these services. They also need to have a team of employees who are responsible for carrying out the tasks.

By understanding the individual steps involved in each business process manufacturing companies follow, they identify potential areas for improvement. Additionally, they can use process mapping to document processes for training purposes or to create standard operating procedures. Ultimately, well-designed business processes are essential for ensuring efficient and effective operations in the manufacturing industry.

What are the benefits of business process improvement?

Manufacturing business process improvement can bring a number of benefits to organizations, including improved efficiency, quality, and customer satisfaction. Additionally, companies can reduce costs and improve profitability by improving the existing manufacturing processes.

At times of low economic activity, process improvement can be a crucial manufacturing strategy as businesses aim to cut costs and improve efficiency to remain competitive.

Process improvement can help identify areas where manufacturing companies are wasting resources, such as time, money, or materials. Additionally, by improving processes, businesses can increase outputs without necessarily needing to increase inputs, leading to increased profits.

Improving existing processes can help to create a more agile organization that is better able to respond to change.

When done correctly, business process improvement can be a powerful tool that can transform the way an organization operates. By streamlining processes and removing bottlenecks, companies can see dramatic improvements in their overall performance.

How can you streamline manufacturing business processes?

One way to streamline manufacturing business processes is to use process mapping to identify potential bottlenecks and inefficiencies. Once these have been identified, you can work on streamlining the processes to improve overall efficiency. Additionally, automating certain manufacturing processes can also help to speed things up and reduce errors.

Many companies use process improvement tools such as lean manufacturing or Six Sigma to streamline their operations. These tools can be extremely effective in identifying waste and improving efficiency. If you’re not already using these methods, it may be worth investigating how they could benefit your business.

Finally, businesses can invest in technology solutions such as enterprise manufacturing software to automate and optimize their manufacturing processes.

Improve your manufacturing business processes with Katana

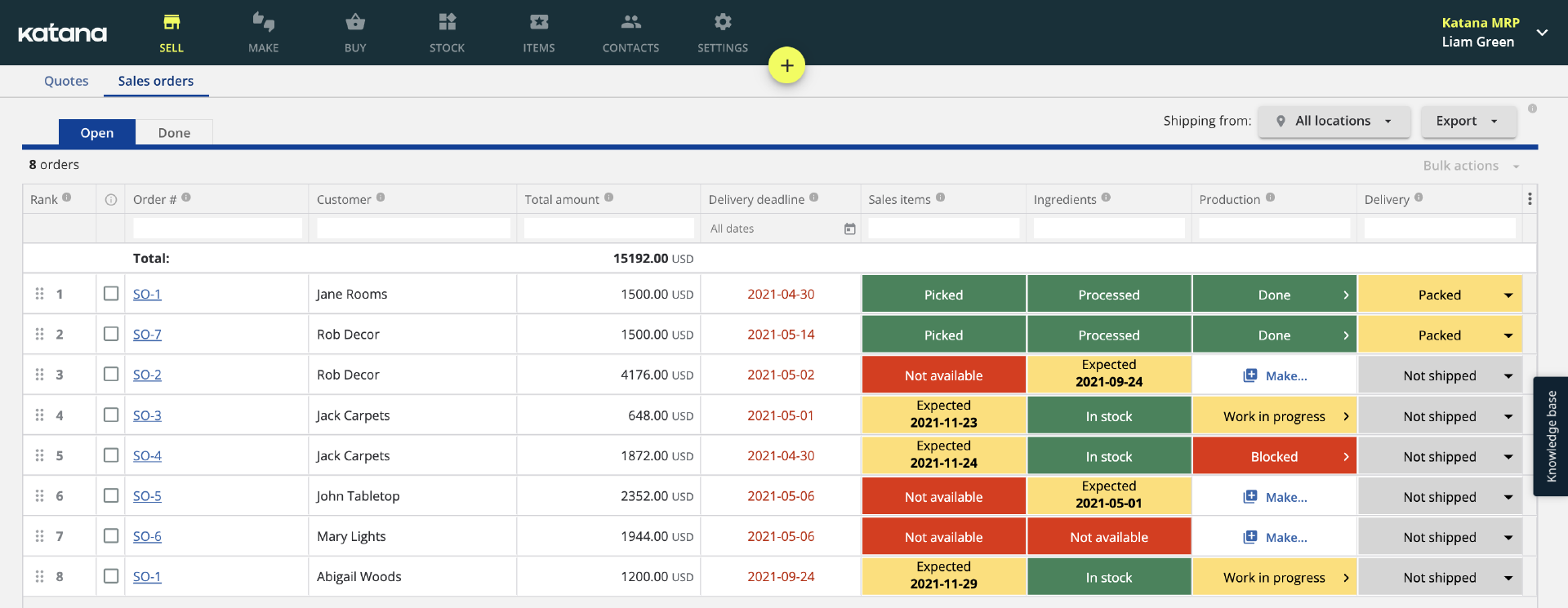

Katana’s cloud inventory software helps businesses manage inventory levels, production schedules, and other aspects of the manufacturing process. It comes with everything you need to eliminate waste and inefficiencies from your processes.

Besides the built-in tools, you can seamlessly integrate Katana with your existing business tools like CRM platforms, accounting software, and reporting tools. This allows you to manage your entire business from a centralized platform.

Let Katana manage your manufacturing processes so you can focus on growing your business. Request a demo today.

Table of contents

Manufacturing guide

More on manufacturing

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control