Your complete guide to purchase and purchase order management

Every business needs to purchase materials, products, or services to keep business operations running. Every purchase comes with the need to create and track a purchase order. This process must be appropriately managed to ensure every purchase is necessary, cost-effective, and you get precisely what you paid for.

This article looks into purchase management as a whole and how you can optimize the process to increase efficiency. In addition, we’ll explore the purchase order management process, from how to manage, automate, and optimize your PO management.

What is purchase order management?

Organizations use purchase orders (POs) to streamline their internal procurement processes and ensure that each purchase is necessary, justified, and optimized for costs.

PO management is the set of policies and procedures used to generate, track, and approve POs. An effective PO management system can help an organization save money by preventing duplicate or unnecessary purchases, reducing supplier prices through negotiations, and improving inventory management. Additionally, an automated purchase order system can improve communication between buyers and suppliers, leading to better relationships and improved customer service.

Several purchasing management systems can automate various aspects of the PO management process, from creating and issuing POs to tracking deliveries and payments.

What are the 3 types of purchase orders?

There are 3 main types of purchase orders:

- Standard purchase orders (SPOs)

- Blanket purchase orders (BPOs)

- Contract purchase orders (CPOs)

Let’s go over these in more detail to understand the different types of purchase orders and how they are used.

1. Standard purchase orders (SPOs)

SPOs are issued for routine, small-dollar purchases that have been pre-approved by the organization. SPOs typically do not require competitive bidding or extensive negotiations with suppliers.

2. Blanket purchase orders (BPOs)

BPOs are issued for recurring purchases of goods or services from a specific supplier. BPOs can be open-ended, meaning they do not have a set expiration date, or they can be valid for a particular period.

3. Contract purchase orders (CPOs)

CPOs are issued for large or complex purchases that require competitive bidding and extensive supplier collaboration. CPOs typically have strict terms and conditions that the supplier must meet, and they may include provisions for liquidated damages if the supplier fails to meet its obligations.

Each type of PO has its advantages and disadvantages, so choosing the right type for each purchase is important for your business.

For example, SPOs are generally the easiest and fastest way to procure goods or services, but they may not be the best price for the organization. On the other hand, CPOs can take longer to process but often result in better prices due to the competitive bidding process. When choosing a PO management system, selecting one that will meet your organization’s specific needs is important.

There is no one-size-fits-all solution, so you’ll need to consider:

- The types of purchases your organization makes

- The frequency of purchases

- The number of suppliers you work with

You’ll also want to ensure that the system you choose is compatible with your existing accounting and inventory management software.

Purchase management vs. purchase order management

Purchase management and purchase order management are related but distinct concepts in procurement and supply chain management.

Purchase management is a broader concept that encompasses the entire procurement process, while purchase order management specifically deals with the creation and management of purchase orders.

What is purchase management?

Purchase management, or procurement management, is the process of acquiring goods and services from external sources. It involves identifying the need for the purchase, selecting suppliers, negotiating contracts, and managing the entire procurement process from requisition to payment.

Purchase management encompasses the entire purchasing process, including creating and approving purchase orders. It also involves various other activities, such as supplier evaluation, contract management, and inventory management.

Purchase management is crucial for improving inventory management. It involves the decision to commit large quantities of business spending. What does this mean for you? Without proper purchase control, you risk losing capital by getting involved with a supplier who isn’t fit for the purpose.

Another thing that needs to be considered is that your purchase department will negotiate with suppliers and represent your company. They will need to finalize deals between your business and supplier as well as maintain your business’s reputation.

If your purchase management workflow is established correctly, you can use it as leverage to save you time, money, and resources. Most of the cost reduction will come from avoiding long lead times and maximizing your resources. All of which will significantly improve your bottom line.

The benefits of implementing purchase management

The most significant benefit of establishing sound purchasing management is creating a set of rules that will allow you or your purchase managers to hasten approvals and place orders for supplies in a timely fashion — improving inventory control and lowering costs.

Here are 6 other benefits of introducing proper purchasing management:

1. Lower costs

Organizing your procurement management process will help you get the best prices and terms with suppliers. Also, having the process more controlled means purchasing managers can take advantage of possible warranties and discounts that would otherwise go unnoticed.

2. Reduced risks

When negotiating for items, you can share or move risks onto vendors. Your purchase managers can dedicate their time to identifying key supplies and focus on keeping the supply chain stable.

3. Supply chain management

Purchase management is an essential aspect of your supply chain. By improving your purchasing management, you can streamline your supply chain to provide the most value to your customers — this could be by reducing associated costs or simply finding better materials.

4. Inventory management

Improving purchase management will have a spillover effect on your inventory management. You can avoid:

- Overstocking

- Low stock

- Stockouts

- Dead stock

Basically, all the supplies you need will be where you want them exactly when you want them, reducing carrying costs and increasing the value of your products.

5. Supplier relationship management (SRM)

Ideally, you want to find a supplier who will provide you with maximum value and one willing to stay in this partnership for the long haul. Your purchasing managers must cultivate this relationship, preferably with a tool or purchase management system that both businesses can use to adjust real-time inventory data.

6. Quality management

By improving purchase control and following your quality control checklist, you can set performance targets for quality and easily monitor deliveries, such as checking the durability of items or the timeliness of delivery.

Objectives of your purchase management

Using this article, perhaps you’re already aware of what’s coming up in this section — which of the following is the objective of purchasing?

Here are some objectives you should focus on improving your purchase control capabilities.

Perfecting your stock control

You or your purchase manager will need to keep a close eye on materials to identify essential items for your sales and business.

This will help with improving your stock control, purchasing, and identifying safety stock levels and reorder points. Analyzing your purchasing will allow your business to order the correct stock quantity to ensure there is no shortage or excess inventory.

Focusing on supplier management

Firstly, going into business with the supplier offering the cheapest deal doesn’t necessarily mean larger profit margins for you.

Your primary goal with finding a supplier is to find the most responsible seller and not the one selling products cheaply. Once you find the perfect match, you need to maintain a good relationship with them. Both of you should be performing to a certain standard — for example, fulfilling regular purchases and sales.

However, don’t be afraid to collect several suppliers’ contact details. That way, you can purchase from elsewhere or get better deals during negotiations.

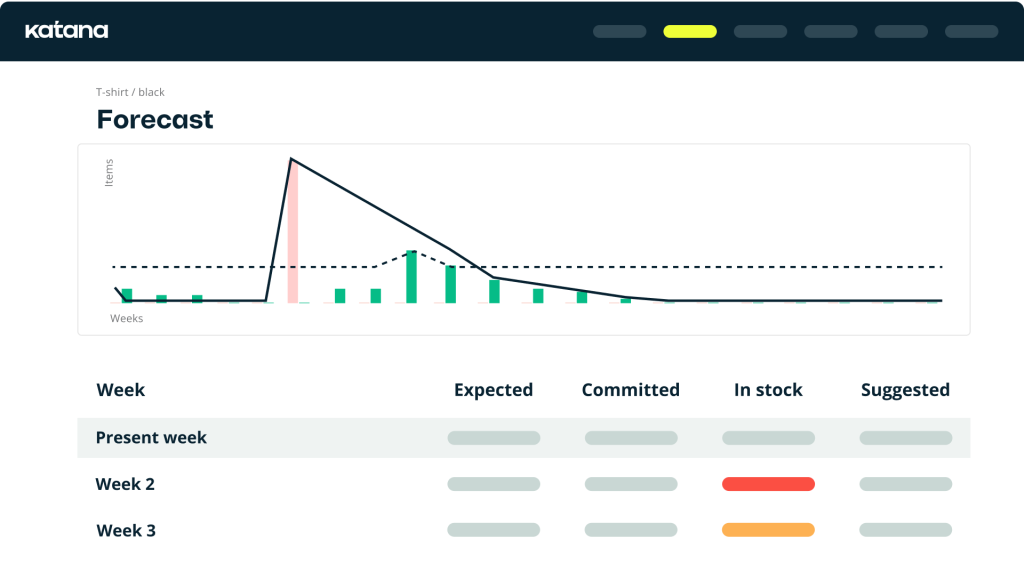

Forecast requirements

Using demand planning, look into historical business insights (purchases and sales) and current trends and predictions to try and estimate your future material requirements.

Doing this will not only help you better understand how much or little you need to buy, but it will also give you an insight into the monthly costs of purchases and identify the best supplier for each item. All of this data will give you ideas on how to provide even more value for your customers and make better business decisions.

Research your budget

This is closely related to choosing the right supplier, but don’t only use price as your criteria for finding a supplier since that might not be the best deal.

You’ll need to consider other aspects, such as quality of materials and delivery terms, because, without due diligence, the wrong supplier drives up costs. Can they guarantee on-time delivery? Because a shortage or a delay will only cause inconvenience and downtime on your behalf.

Don’t rough it out with spreadsheets

Managing your purchase order request with spreadsheets on a small scale and with one purchase manager might be achievable.

Once your business starts to scale, spreadsheet inefficiencies will rear their ugly heads. That’s why many companies turn to automated purchase order management solutions to help them keep track of their purchases. Another benefit of using software for purchase order management is that it allows you, your employees, and even suppliers access, so purchase statuses can be updated in real time from anywhere.

How to make a strategy for your purchase management objectives

Now that you’re fully educated on all matters involving purchase management, it’s time to put together a plan and execute flawless purchasing control.

But here’s the issue. Your strategy will all depend on your business. The strategy has to be so unique that many companies hire outside consultants to help them with this task.

It’s not essential, but you can use your strategy to understand your purchase cycle.

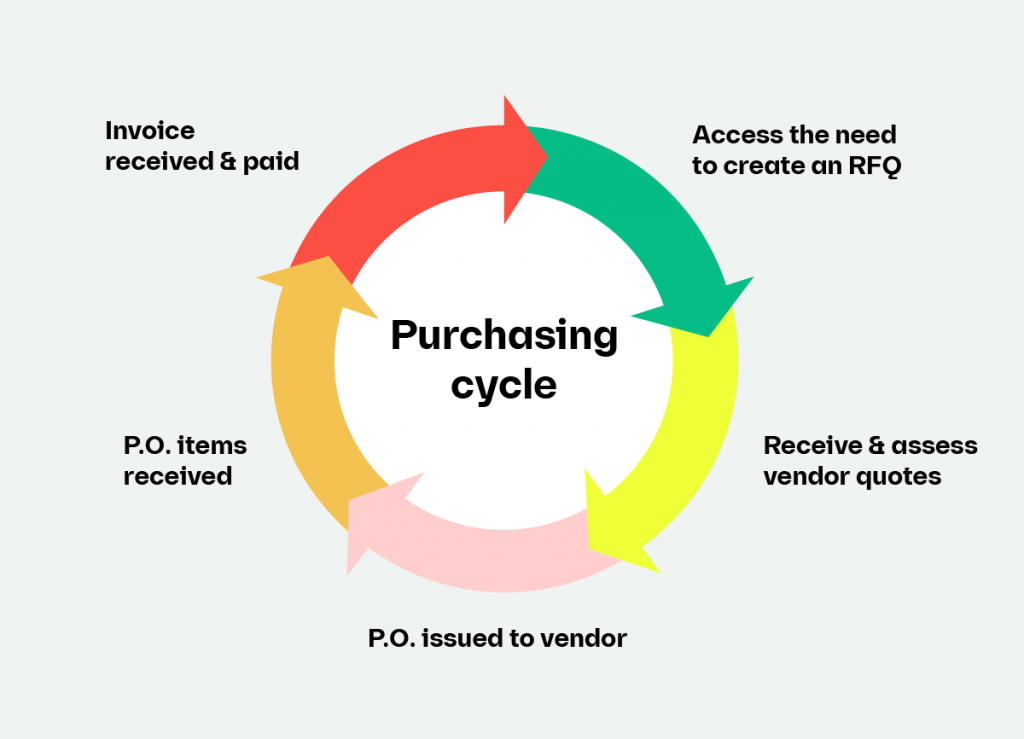

Understanding the purchase cycle

The purchasing cycle is the process or workflow for ordering, securing, and paying for goods and services for your business.

The first thing that needs to be established is the purchase requisition process. Is there a price threshold that will need to be approved by multiple purchasing managers? Will you need to inspect the quality of supplies and delivery?

These questions will help you start to develop procedures and policies for purchasing items.

Getting this established allows a certain level of autonomy in your company because they can follow your purchase order template.

Your purchasing managers will handle long-term contract approvals once you have a supplier in mind, assuming it’s not a one-off purchase. If the items pass your product management quality inspections, record them for inventory and future reference. Then, repeat the purchasing cycle with a group of core suppliers, and outsource larger ad-hoc purchases during emergencies.

Purchasing management is a repetitive endeavor, and this is why many businesses implement process automation to help them stay on top of this important task.

What are accounts payable (AP)?

Accounts payable (AP) are debts that a company owes to its creditors or suppliers. The money owed is typically for goods or services that have been received but not yet paid for. Accounts payable are considered short-term debt since they are typically due within 30 days.

Companies keep track of their accounts payable using an account in their general ledger. When a payment is made, the amount is debited from the accounts payable account and credited to cash.

If you’re running a business, keeping your accounts payable is important. You need to ensure that you’re paying your creditors on time and not more than you need to. Negotiating favorable payment terms with your creditors can help you save money and improve your cash flow.

How does the purchase order process work?

The purchase order management process is a business’s system to track inventory and orders.

It begins when a customer places an order with a business. The business then creates a purchase order sent to the supplier. The supplier then fills the order and sends it back to the business.

Once the business receives the shipment, they update the purchase order accordingly and send it back to the customer — thus completing the purchase order management process.

Businesses use purchase orders to keep track of their inventory and ensure that orders are filled promptly. This system helps businesses run smoothly and efficiently.

If you’re a business owner, it’s essential to understand the purchase order process to keep track of your inventory and fulfill orders promptly — understanding how the purchase order process works allows you to keep your business running smoothly and efficiently.

How to manage your purchase orders

As your business grows, you’ll need to get a handle on PO processing. Here are four ways to do it.

1. Use an automated system

Many purchasing management systems are available that can help you automate the purchase order process, saving you time and effort in tracking down information and keeping everything organized. Automations add an extra layer of efficiency and accuracy to your work, streamlining many daily tasks and giving you the freedom to focus on more important tasks requiring more brain-power.

2. Delegate responsibility

If you have employees, delegate responsibility for managing purchase orders to one or more of them. This will take some of the burdens off your shoulders and help ensure that things are handled efficiently. Delegating also helps facilitate an environment of shared accountability, ensuring the team that their opinion and work matters.

3. Stay organized

Keep all of your purchase orders in one place, whether it’s in a physical file or an electronic database. This will help you track what’s been ordered and what still needs to be processed. Keeping an archive of all past purchase orders gives you the safety of always having a centralized system to find critical data.

4. Follow up

When it comes to supplier management, make sure to follow up with suppliers promptly to ensure that your orders are filled correctly and on time. This will help avoid any delays or issues down the road. Regular conversations and contact also empower strong supplier relations, creating a trusting environment and potentially paving the way for good discounts or deals in the future.

Following these tips, you can master the art of PO processing.

Best practices for purchase order management

If you’re looking to optimize your purchase order management workflow, here are six best practices others are using.

1. Define your PO process and workflows

The first step to streamlining your purchase order management process is to define the various steps involved and who is responsible for each task. This will help ensure that everyone knows their role and promptly completes tasks. Establishing this clarity also facilitates smoother communication between departments, further streamlining the procurement process.

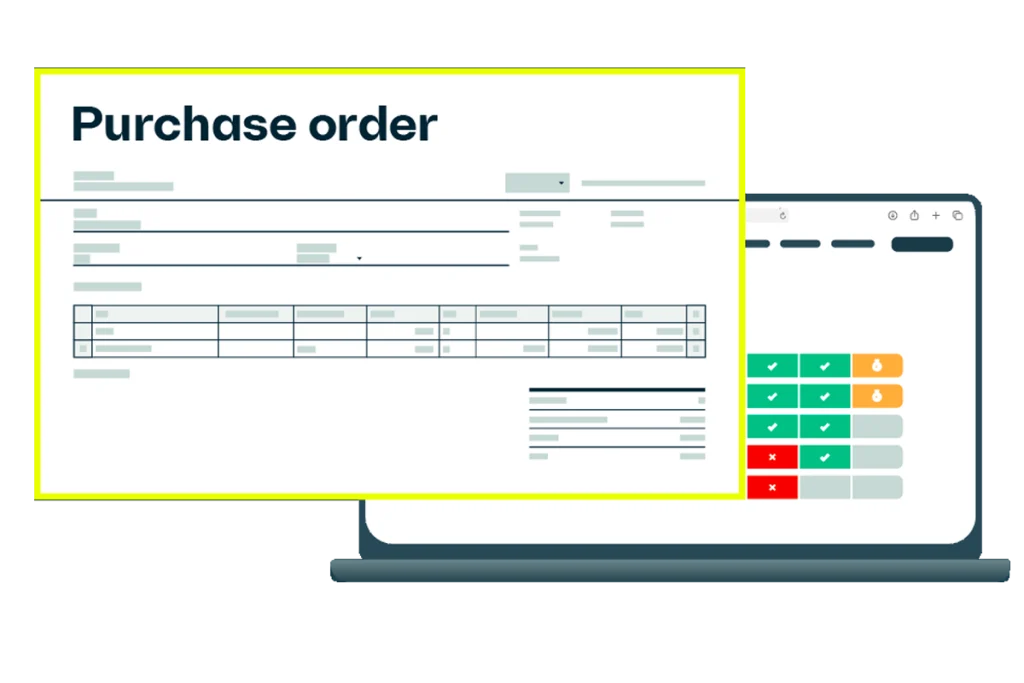

2. Set up an electronic PO system

An automated purchase order system can save time and hassle by automating many tasks involved in managing purchase orders. This includes creating and sending POs, tracking approvals, and monitoring delivery status. Additionally, it enhances data accuracy and accessibility, allowing businesses to come up with better strategies and plans for their operations.

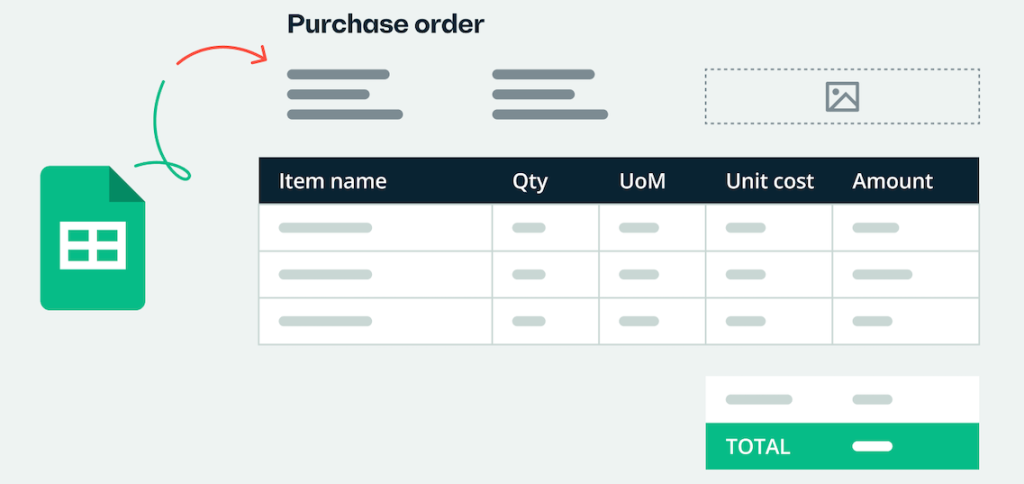

3. Use purchase order templates

Creating purchase order management templates for commonly ordered items can save time and ensure accuracy when creating new POs. This is especially helpful if you have many SKUs to manage. Templates standardize purchasing, making it easier to compare orders over time and streamline the reordering of supplies, reducing errors and improving operational efficiency.

4. Implement PO approval workflow

A PO approval workflow will help ensure that all POs are reviewed and approved by the appropriate parties before being sent to the supplier. This can help avoid errors and delays in the ordering process. This structured approach also adds a layer of accountability and control, making it easier to manage budgets and expenditures effectively.

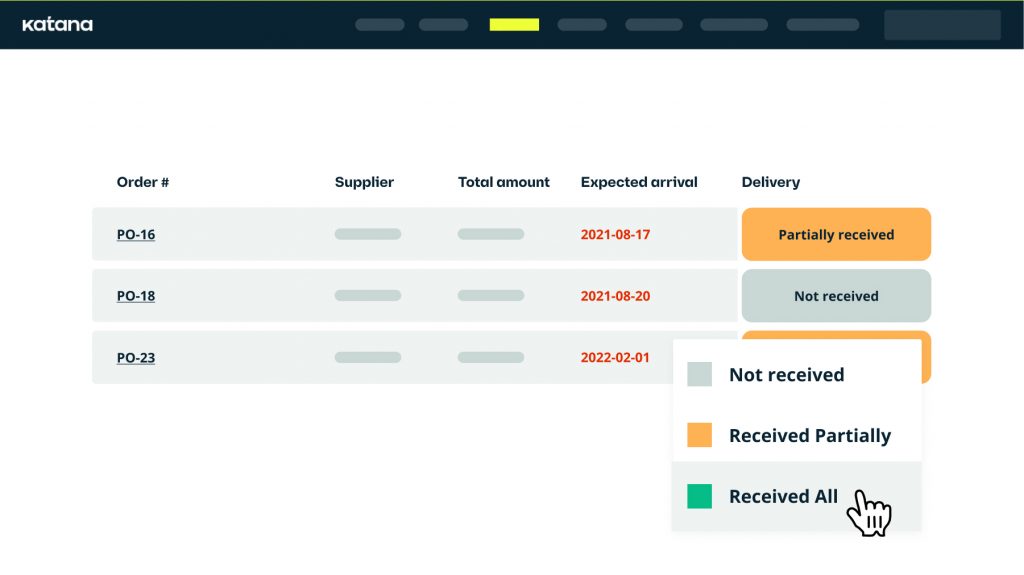

5. Monitor delivery status

Once a PO is placed, it’s important to monitor the delivery status to ensure that goods are received on time. This information can be used to follow up with suppliers if there are any delivery issues. Following deliveries gives you a real-time shipping status, allowing you to react to any changes or delays as soon as possible.

6. Manage supplier performance

Monitoring supplier performance is an important part of purchase order management. This includes:

- Tracking on-time delivery

- Quality of products

- Responsiveness to requests

This information can be used to identify issues early and improve supplier relationships.

Following these best practices can help streamline and automate the purchase order management process, saving time and ensuring accuracy.

How to automate your purchase order process in your business

If you’re like most businesses, your purchase order management is probably a manual process.

That means it’s subject to errors, duplicate orders, and other inefficiencies that can cost your company time and money. Fortunately, there’s a better way of managing this task. By automating your purchase order management, you can streamline procurement, cut out errors, and reduce costs.

Here’s how:

1. Implement an electronic purchase order system

Instead of using paper POs, switch to an electronic purchase order (ePO) system or e-procurement software, as inefficient spreadsheets are prone to cause mistakes and issues.

Managing purchase orders in one place ensures that orders are placed correctly and easily trackable. An electronic purchase order system streamlines the procure-to-pay process by automating your manual process and integrating it with other business systems.

This provides a single source of truth for:

- Purchase orders

- Invoices

- Payments

- Eliminating errors

- Duplications

In addition, an automated system can provide visibility into spending, helping procurement teams negotiate better deals with suppliers.

And because it’s all digital, businesses can take advantage of early payment discounts and save on paper and postage costs. It’s no secret that the purchasing process can be time-consuming and costly. However, businesses can improve efficiency and accuracy by automating purchase orders while reducing expenses.

2. Set up vendor portals

Vendor portals give your vendors a secure online space to view their POs and submit invoices — helping to streamline communication and reduce the chance of errors.

It’s important to set up vendor portals for a number of reasons.

- Streamlining the procurement process by automating tasks helps cut down on errors and saves time and money

- Vendor portals can provide a central repository for all your supplier information, making it easier to keep track of contracts, invoices, and other important documents

- Vendor portals help build better relationships with your vendors by providing a space for communication and collaboration

3. Automate PO approvals

Approving POs can be time-consuming, but it doesn’t have to be.

You can save yourself valuable time and ensure that orders are approved quickly and efficiently by automating purchase order management. One of the most important aspects of any business is procurement, which means acquiring goods or services. An essential part of procurement is creating and approving purchase orders (POs).

POs are legal documents that define the terms of a transaction between a buyer and a seller.

While manually creating and approving POs can be done, it is often error-prone and time-consuming.

This is why many businesses choose to automate their purchase order management process. Automating PO approvals can streamline procurement, cut out errors, and reduce costs. This is done by using tools such as barcode inventory management software or manufacturing ERP software.

There are several benefits to automating PO approvals, such as:

- Streamlined procurement

- Cut out errors

- Reduced costs

- Increased efficiency

- Better decision making

- Improved communications

- Greater visibility

- Increased control

- Improved compliance

- Reduced risk

Automating PO approvals streamlines procurement, cuts out errors, and reduces costs when it’s implemented correctly.

4. Use a purchase management system

A purchase management system can help you manage all your POs in one place, automate repetitive tasks, and find and fix errors more easily.

Look for a purchasing management system that integrates with your existing accounting and business tools for maximum efficiency.

Using purchase order software can help streamline the process, cut out errors, and reduce costs. By automating the purchase order process, businesses can avoid many common mistakes that can lead to overspending or delays in receiving goods. In addition, a purchasing management system can provide valuable insights into spending patterns and allow businesses to negotiate better prices with suppliers.

When used correctly, purchase order software can be a powerful tool for professionals.

When it comes to streamlining procurement, purchase order automation is key.

By automating the creation, sending, and tracking of purchase orders, businesses can avoid many errors. In addition, automation can help to speed up the procurement process, allowing businesses to get goods and services faster. Automation can also help businesses track spending patterns and supplier prices, valuable information when negotiating contracts.

While there are many benefits to using purchase order software, it is important to use the purchasing software correctly to maximize its potential.

When creating purchase orders, businesses should include all relevant information, such as:

- Delivery dates

- Quantities

- Item descriptions

- Prices

In addition, businesses should carefully track their purchase orders and monitor for changes in supplier prices or delivery schedules.

By following these best practices, businesses can ensure they get the most out of their purchase order software.

5. Train your employees

Make sure your employees are trained in using your new purchase order system.

The more comfortable they are with the system, the more likely they will use it correctly and avoid errors.

By following these tips, you can automate your purchase order process and improve the bottom line of your business. Purchasing automation is a smart investment for any business that wants to save time and money. It is important to train your employees in purchase order management because it can help streamline procurement, cut out errors, and reduce costs.

By automating the purchase order process, you can ensure that all orders are accurate and that no items are mistakenly ordered.

This can save your company time and money by reducing the need for returns or replacements.

In addition, automated systems can also provide real-time tracking of inventory levels so that you can keep tabs on what is available and where it is located.

This information can be beneficial when planning future purchases. Overall, automating the purchase order process can help make your business more efficient and save you money.

What are purchase order management systems?

Purchase order management systems (POMS) are tools that automate the process of creating and approving purchase orders.

They streamline the approval process, reduce paper waste, and ensure that all POs are compliant with company guidelines.

Organizations of all sizes can use purchasing management systems to manage their purchasing processes. Large organizations may have complex purchasing management systems that integrate with other enterprise manufacturing software. Smaller organizations may use simpler, stand-alone POMS solutions.

POMS typically includes the following features.

PO creation

Users can create POs using an online form or interface, eliminating the need for paper-based processes and simplifying the initial steps. The PO is then routed to the appropriate approvers for approval. This streamlines the transition to the following steps without any manual intervention, reducing the risk of delays and errors.

Approval workflow

POMS systems include built-in approval workflows that route POs to the correct supervisors based on predefined rules and hierarchies. This ensures that all POs are reviewed and approved on time, facilitating a smoother, more organized process that keeps operations moving efficiently and helps maintain compliance with internal policies.

Electronic signatures

POMS systems support electronic signatures, allowing users to approve POs digitally. This reduces paper waste and speeds up the approval process. Digital access enables approvers to sign off on purchases from anywhere, at any time, making procurement activities more flexible and responsive to the needs of the business.

Audit trail

POMS systems keep track of all changes made to a PO, providing a comprehensive audit trail that enhances transparency and accountability. This trail can be used to review purchase history, ensure that spending aligns with budgetary and business guidelines, or investigate potential fraud, thereby protecting the integrity of the process and the whole company.

POMS systems can help organizations save time and money by streamlining the PO creation and approval process. They can also improve compliance with company guidelines and reduce paper waste.

Finding a purchase order management system

Taking advantage of purchase order management software allows you to perform purchase control efficiently and automate all the mundane, repetitive tasks — helping you save time and money and free up resources.

Purchase control could come in the form of ERP software or a purpose-built tool. Regardless of the selected tool and how it is accessed, they all work to digitalize records, allowing production companies to achieve paperless manufacturing and ensuring that everyone is on the same page.

Ultimately, having your inventory management automated means that you can keep ideal levels of inventory moving through your business at all times.

Not only will a purchase order inventory management system give you centralized real-time inventory tracking to help you with purchase management, but other benefits include:

- Improved supplier control through supply chain management

- Long-term cost savings

- Greater efficiency and productivity

- Improved Inventory and warehouse management

- Real-time data to make better purchasing decisions

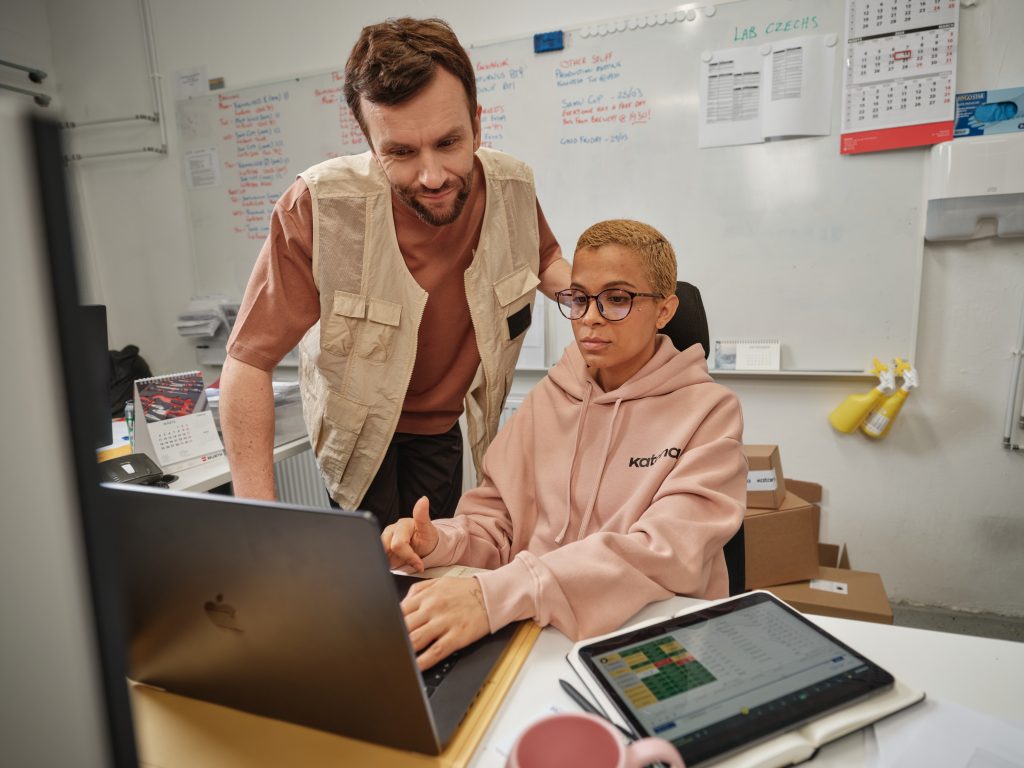

Katana’s purchase order and inventory management software allows users to manage their purchase orders, sales, manufacturing operations, and many other aspects of their business — all from one easy-to-use and intuitive platform.

Get started with Katana by booking a demo to learn to automate your purchase management and easily monitor your purchase cycle.

Until then, check out this short product tour of Katana to get acquainted with its features right now.