In-depth study of modern manufacturers crushing it in 2024

We’ve investigated modern manufacturers who’re growing their business in 2024 and performed an in-depth analysis of the tools they use. Here is what we found.

Team Katana

No more second-guessing, it’s time to learn exactly how other manufacturers have found success in 2024. In our research of Katana users, we’ve looked into the set-ups that have helped manufacturers grow their business, so you can decide if you’re on the right path or if you should forge your own one.

It’s hard determining if your manufacturing business is on the right track or not, and it can even be a source of anxiety the longer you’re in the dark.

With a huge surge of customers turning to the internet to shop, and manufacturing businesses popping up across the globe, it’s nice to know how other entrepreneurs approach selling, production, and bookkeeping to find success.

That’s why we’ve investigated successful manufacturers who use cloud inventory software to manage their business and performed an in-depth analysis into:

— What type of businesses do manufacturers own;

— What workflows manufacturers follow;

— What’s the D2C manufacturer’s favorite e-commerce platform;

— Which accounting software D2C manufacturers use;

— What tools and platforms do D2C manufacturers love to integrate together;

— How many manufacturers own their own factories;

— How many manufacturers track their inventory at multiple locations; and

— How many have adopted lean and green manufacturing?

So, without further delay, let’s delve straight into it!

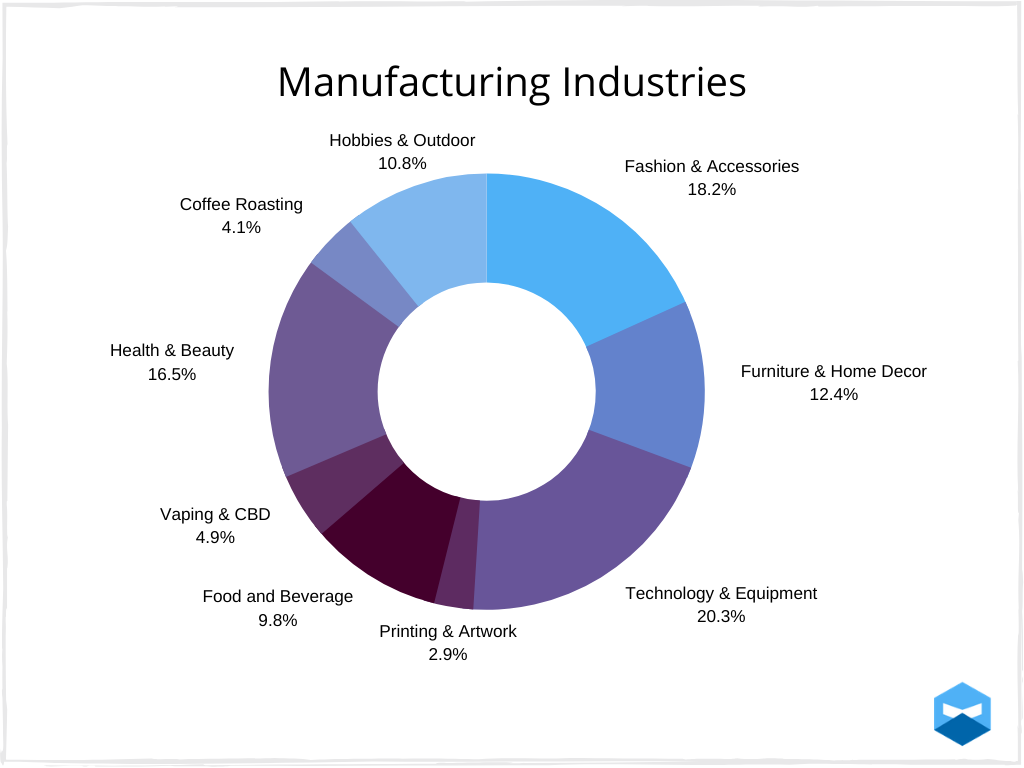

The Different Industries That Use Cloud Inventory Software

As we’ve looked into before in our ultimate guide to everything you need to know about what is manufacturing, the industry is massive, comprised of twenty different sub-sectors.

And those sub-sectors are broken down even further into other categories by the North American Industry Classification.

This means that manufacturers need different tools and support systems to help them with their manufacturing processes.

We looked into all our users and identified the industries in the graph above as the businesses in which Cloud Inventory software users operate.

So, for the rest of this article, we’ll be looking into these users and delving deeper into how they run and organize their businesses.

62% of Users Are Direct-to-Consumer (D2C) Manufacturers

D2C manufacturing is the hottest new approach to manufacturing and selling, and 62% of Katana users have already realized this.

Unlike traditional manufacturers, D2C manufacturers cut out the third-party retailers, wholesalers, or any other type of middleman by selling their products directly to their customers.

Current manufacturing trends and predictions show that D2C manufacturing is only going to increase in popularity as selling has become easier and more accessible with the rise of e-commerce platforms over the recent years.

But, ultimately with this tactic you get complete control over your business and products as you avoid any third-party fees, harsh requirements, or retailer space costs, and sell your products at fairer prices for your customers and yourself, while retaining more of the profits.

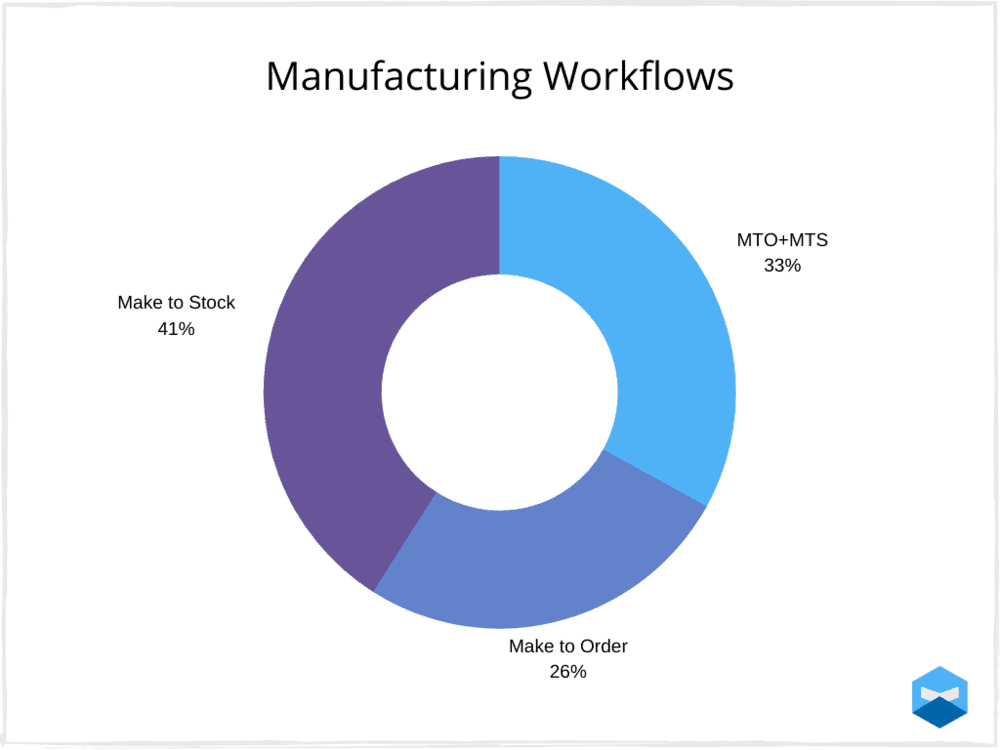

33% of Manufacturers Use a Combination of “Make to Stock” and “Make to Order” During Production

For a lot of manufacturers, it always boils down to two workflows:

Make to order Vs. Make to stock.

And manufacturers seem to favor one over the other, with 41% of users adopting a make to stock (MTS) workflow, and 26% adopting a make to order (MTO) approach.

Each workflow has its own distinctive benefits:

MTS – Manufacturers can reduce their carrying costs and adjust stock inventory in accordance to demand planning.

MTO – Will have longer manufacturing lead times but allows manufacturers to offer customization and to add bespoke manufacturing to their production processes.

However, 33% of manufacturers understand that flexibility is important when manufacturing their products.

Balancing the two workflows allows them to keep safety stock, offer personalized products, and adapt to any problems which might occur along the production line.

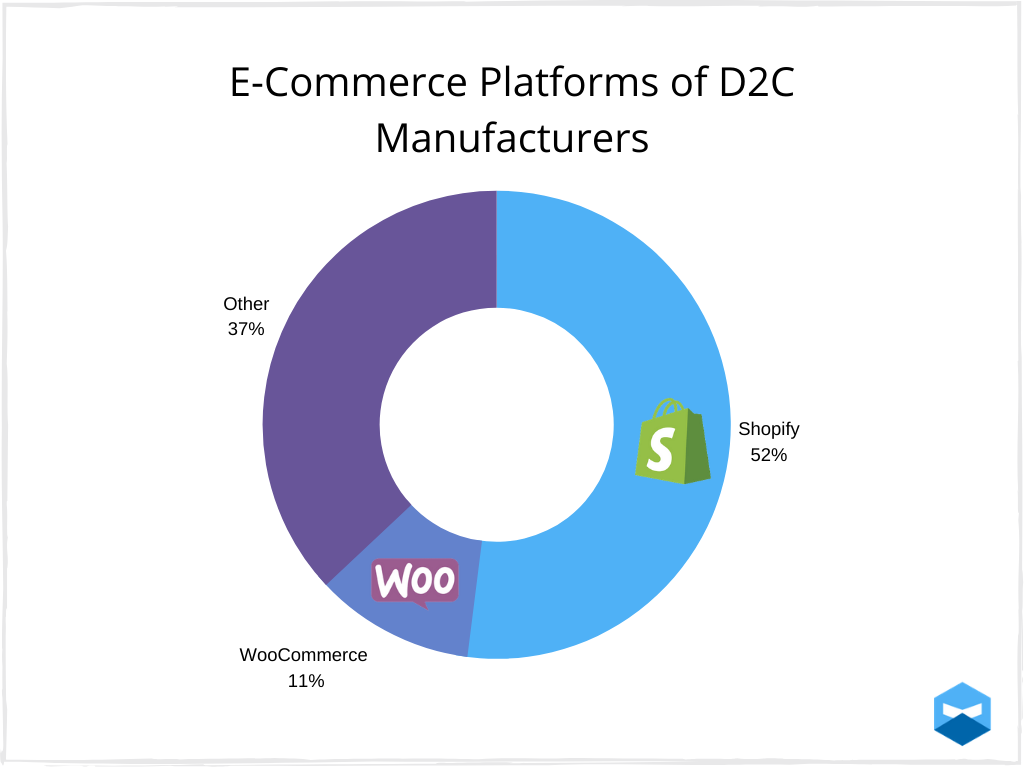

52% of D2C Manufacturers Sell via Shopify

E-commerce platforms have been an essential component for D2C manufacturers getting their products in front of customers.

And Shopify seems to reign supreme when it comes to which platform manufacturers decide to get set up on (not just manufacturers, as Shopify has over 1,000,000 businesses in 175 countries).

For a good reason too! Shopify gives you the tools to design your store’s website and to easily start accepting payments from customers, giving D2C manufacturing brands access to:

— Free and premium themes for your store

— The Shopify POS (point of sale) system

— The basic Shopify inventory management system

However, the biggest reason why D2C manufacturers use Shopify comes down to the Shopify Appstore, which allows you to integrate third-party tools to further customize your Shopify account and bridge any feature gaps (particularly when it comes to manufacturing) on the vanilla Shopify account.

PRO TIP: If you want to optimize your presence on Shopify, be sure to take advantage of the free and ultimate Shopify guide for manufacturers, giving you tips on how to make and sell your products on the platform.

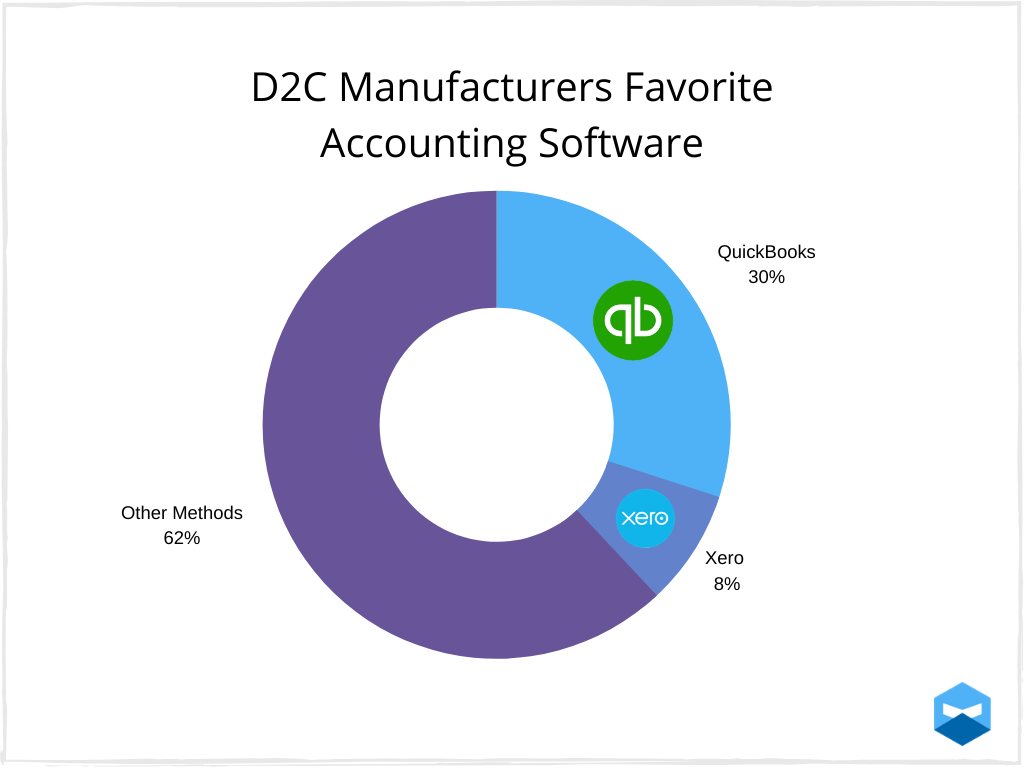

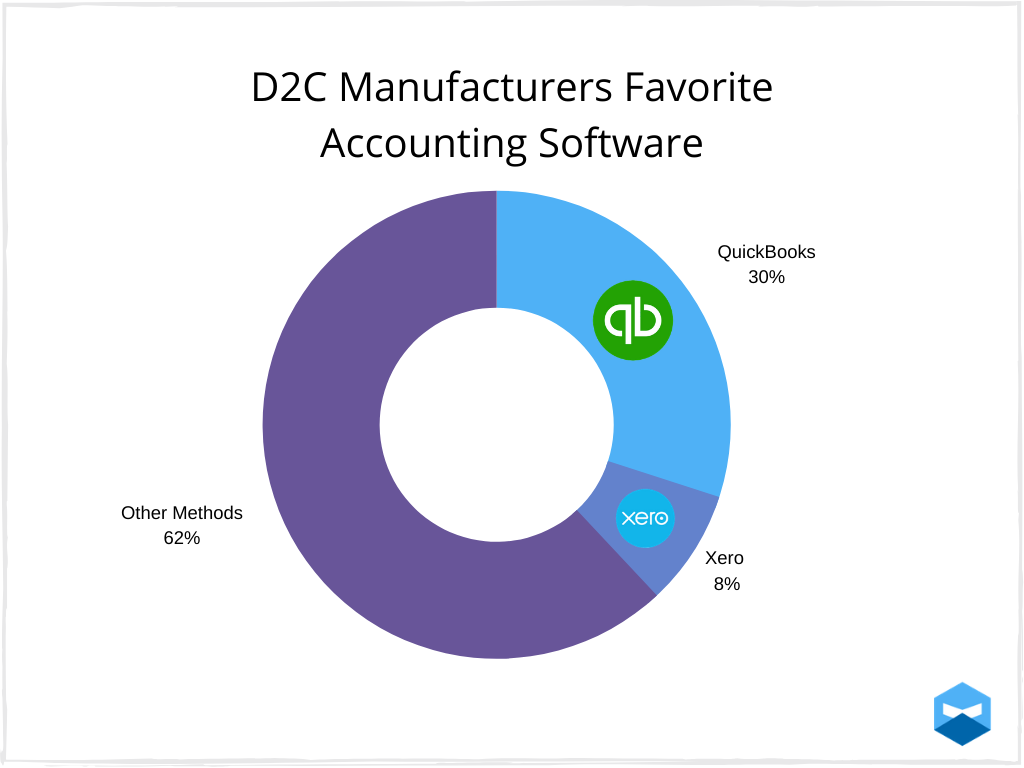

What Accounting Software Do Manufacturers Prefer?

Accounting software gives manufacturers the relief of knowing that they’re recording their finances properly and within regulation, allowing them to easily maintain their bookkeeping in real-time so they can stay focused on manufacturing.

When deciding which software to choose, manufacturers mostly use one of two apps:

— QuickBooks – 30%

— Xero – 8%

The reason is, that along with being able to track your finances, each has its own inventory tracking system: QuickBooks inventory management and Xero inventory management.

However, just like Shopify or the WooCommerce inventory management system, the inventory tracking features of accounting software are rather built for businesses who handle finished products and don’t need to track manufacturing costs or work on raw material inventory management.

Luckily, both QuickBooks and Xero have an impressive app store, so you can find solutions to any missing features that you may need.

The Winning Formula for D2C Manufacturers

The rise of e-commerce and the amount of accounting software available on the market has given D2C manufacturers the chance to integrate all their tools. This means that they can now have a smooth and uninterrupted workflow between their sales and finances.

The most common combination manufacturers use is integrating their Shopify and QuickBooks accounts.

However, regardless of which winning combo you decide to get set up with, the winning formula for D2C manufacturers is:

E-commerce platform + Smart Manufacturing Software + Accounting tool = Success

By D2C manufacturers integrating their tools, they’re able to get up-to-date and accurate information on sales, manufacturing, and accounting in real-time.

This synergy allows manufacturers to focus on manufacturing and scaling their business.

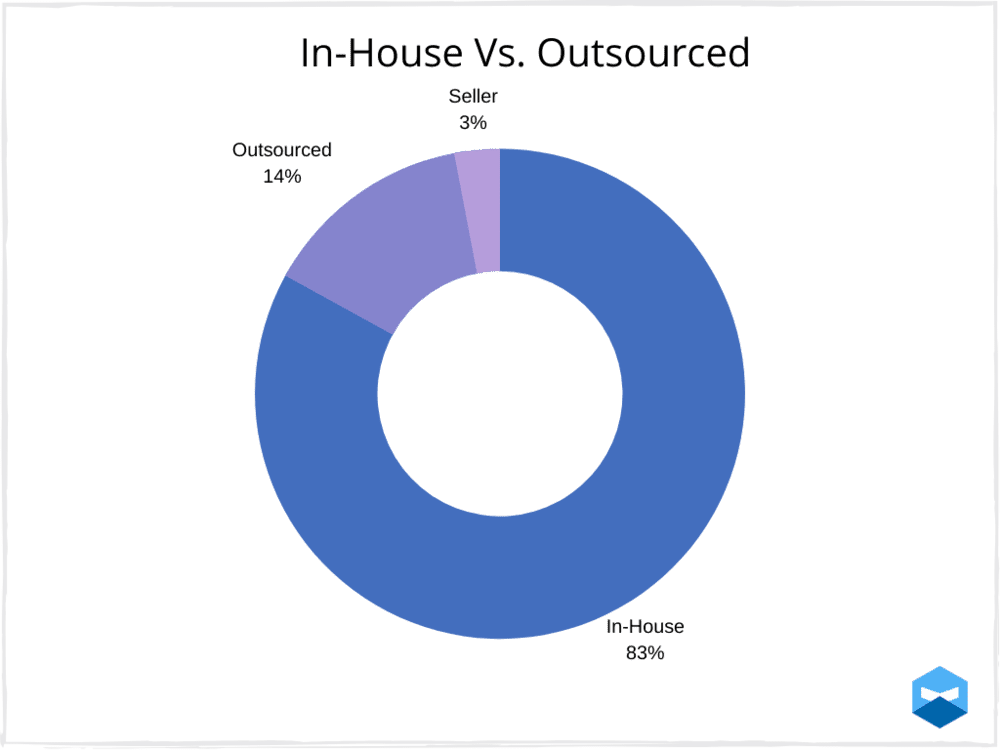

83%of Manufacturers Produce Goods In-House

The majority of manufacturers manage and make their products in their own workshop or factory, and the number of products they produce can range anywhere from 10 to 30,000 different products.

The complexity of the manufacturer’s bill of materials (BOMs) also varies, from 2 to 3 ingredients and manufacturing processes, to more complicated structures that require them to use multi-level BOMs.

However, 14% use outsource manufacturing, which can be a good tactic for negating start-up costs, spreading out production to avoid bottlenecks, and saving enough capital to set up your own production line, especially managed efficiently with the help of contract manufacturing software.

17% of Manufacturers Track Inventory at Multiple Locations

17% of manufacturers use the multi-location inventory management feature to track inventory at different locations.

There could be several reasons as to why manufacturers need to track inventory at more than one location. It could be:

— Outsource manufacturing;

— Multi-channel selling; or

— Storing inventory at different warehouses (either owned by the manufacturer or a third-party).

This means that manufacturers are growing their businesses and need tools that can help them monitor their inventory movements, at any location, along their expanding supply chain.

PRO TIP: If you want to get more control over your inventory management, you can find the free and ultimate inventory management guide for manufacturers that will help you better understand how to optimize how you handle your inventory.

80% of Manufacturers Are Lean and Green

The latest trends show that manufacturers are turning to green manufacturing, with 80% using lean manufacturing tools to eliminate paper from their manufacturing processes.

Adopting lean inventory techniques into your business can have a ton of benefits, such as:

— Cost reduction from minimizing waste;

— Getting your products to customers faster;

— Achieving a higher inventory turnover rate; or

— Becoming an eco-friendly business (which customers will love!)

At the end of the day, with shoppers looking for products that are ethically sourced and businesses becoming more conscious of their impact on the environment, not going lean and green is going to hurt your bottom-line and drive away potential customers.

Conclusion

And there you have it, with these figures you can get a better understanding of how other Katana users, especially D2C manufacturers, are finding success with their particular set-ups.

However, D2C manufacturing was once considered to be a risky move, with many businesses sticking to more traditional selling methods, such as selling via a third-party or going B2B.

Now, D2C is becoming the norm for a lot of manufacturers. However, following the footsteps of others to find success is one thing. The real trick is to forge your own path, as innovation doesn’t come from copying others (though, it certainly doesn’t hurt to know which directions others have gone).

As mentioned earlier, the manufacturers used in this case study are all users of Katana Cloud Inventory Software. To how it helps them get control over their sales, manufacturing, financing, and supply chain, request a demo today.

We hope you found this article inspiring, and if you have any questions, do not hesitate to get in touch.

And until next time, happy manufacturing.

Team Katana

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control