Discrete vs process manufacturing: What’s the difference?

Discrete and process manufacturing are among the most commonly used manufacturing processes. But how to tell whether a product is made via discrete vs process manufacturing?

Erik Väli

There’s a chance you might be reading this article while having a little snack on the side (and if you aren’t, hopefully reading that didn’t just make you hungry). And, more than likely, you will be reading it from either a smart device or desktop.

In either of those cases, you’re already enjoying and benefiting from products made via process and discrete manufacturing.

But how to know which type of manufacturing is used in the creation of which products? In this article, we’ll look at how to distinguish between discrete manufacturing vs process manufacturing and figure out which one is more relevant to your needs.

Discrete vs process manufacturing

Discrete manufacturing produces individual items or products and is distinct from process manufacturing, which involves transforming raw materials into finished goods through a series of chemical, physical, or biological processes.

Process manufacturing and discrete manufacturing are types of manufacturing that cover the production of a very diverse range of products. If you’re a manufacturer, chances are high that you use one or the other for your manufacturing process.

Let’s go over each type of manufacturing, along with some examples of the goods they can produce.

Discrete manufacturing

The key feature of discrete manufacturing is that products are created as separate units.

This means products made through discrete manufacturing are countable and made from individual components. The final product can often be reverted back into these components. For example, if you want to replace a component in order to fix a broken product.

Or, to put it simply, they’re the kind of things you have to put together from various bits and pieces rather than mix together in a lab. So, discrete manufacturing can actually apply to a very wide range of products.

Discrete manufacturing can be applied to anything from massive automotive factories to cellphone manufacturers to artisan goods.

So, goods made through discrete manufacturing would include:

- Cars

- Electronics

- Toys

- Tools

- Furniture

Process manufacturing

Goods made through process manufacturing use a recipe or formula to combine raw materials, supplies, or ingredients into the final product. Essentially, whatever raw materials are used in creating a product through process manufacturing cannot be retrieved from the final product once it’s been created.

If that sounds a little confusing, perhaps an easy way to think about whether a product has been made through process manufacturing is to ask whether it has been made through a formula or recipe rather than assembled from components.

Generally, goods created through process manufacturing are not created as single units (but they can be packaged and sold as individual units).

For example, toothpaste is measured by its volume rather than as “one toothpaste”. However, after packaging the toothpaste into a tube, it can still be quantified and sold as a single unit.

The range of products made via process manufacturing is just as extensive as discrete. Process manufacturing can include both complex chemical products made in a lab to the sauce on the pizza you order from your favorite restaurant.

Here are just some examples of goods made through process manufacturing:

- Pharmaceuticals

- Soft drinks

- Laundry detergents

- Ketchup and other condiments

- Rubber and plastics

Discrete vs process manufacturing — how to easily tell them apart

One of the simplest ways to understand the difference between discrete manufacturing vs process manufacturing is to look at the final product and work your way back.

For example, you can’t “unbake” a loaf of bread into flour, water, and whatever other ingredients were used to make it.

And while a loaf of bread is considered a single unit, you can cut a slice, and the rest of the loaf would still remain, well… bread — there’d just be less of it. You wouldn’t call the loaf “broken” just because you’ve already eaten some of it.

On the other side of the spectrum, a car is a single “thing” that’s made up of several smaller components. Components that can be removed, replaced, and repaired, all of which make up the car. Therefore, it’s created through discrete manufacturing.

Cars are made through discrete manufacturing — and repetitive

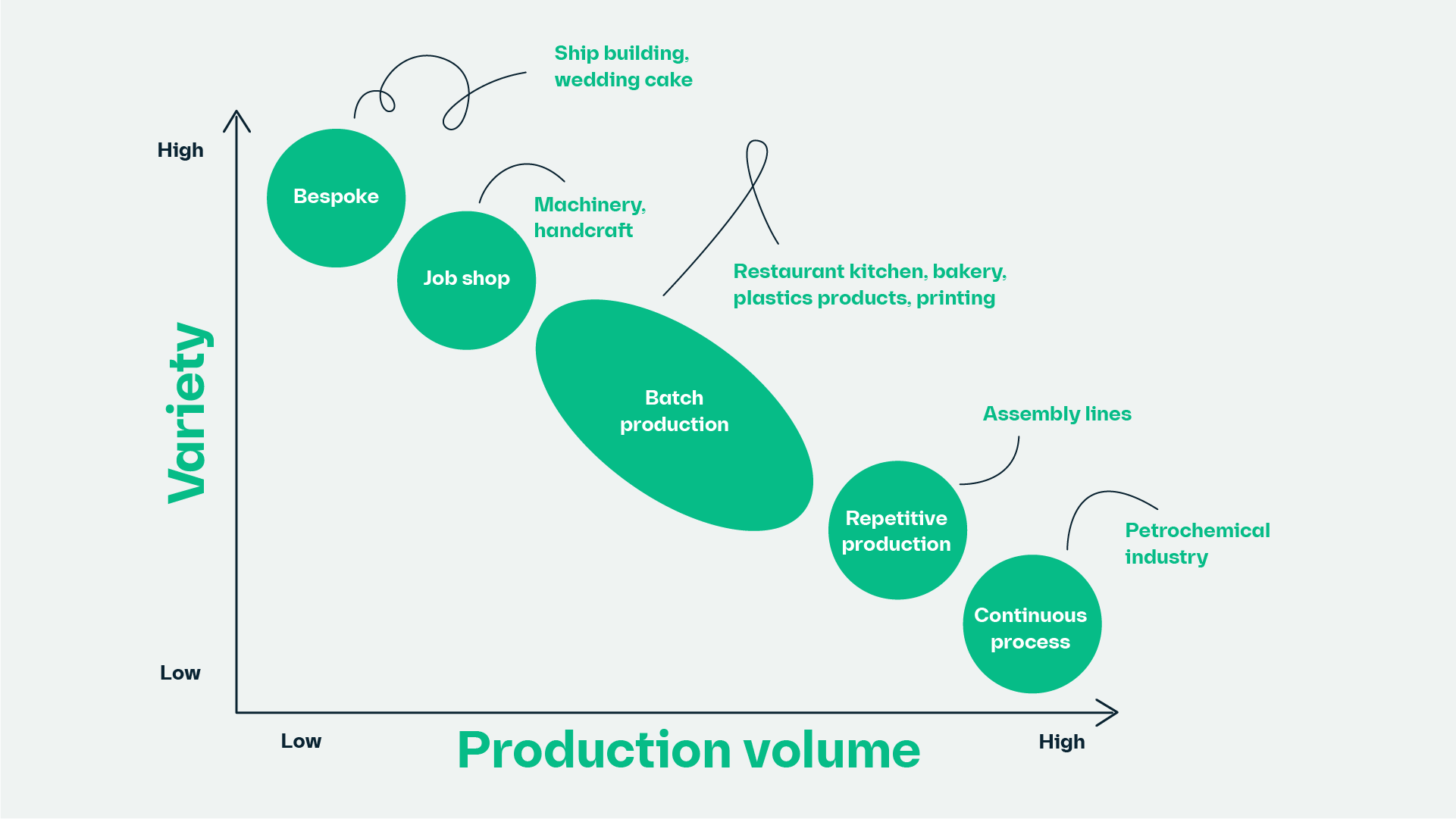

Consider also reading up on repetitive manufacturing if you’re interested in the production of goods such as cars, computers, and cell phones. Repetitive manufacturing is similar to discrete manufacturing in many ways but is focused more on the rapid production of goods using assembly and production lines.

What about products that are in between?

Process vs discrete manufacturing can still leave a bit of a gray area with certain products. But they aren’t necessarily opposed to one another. A product can indeed be created through both process and discrete manufacturing.

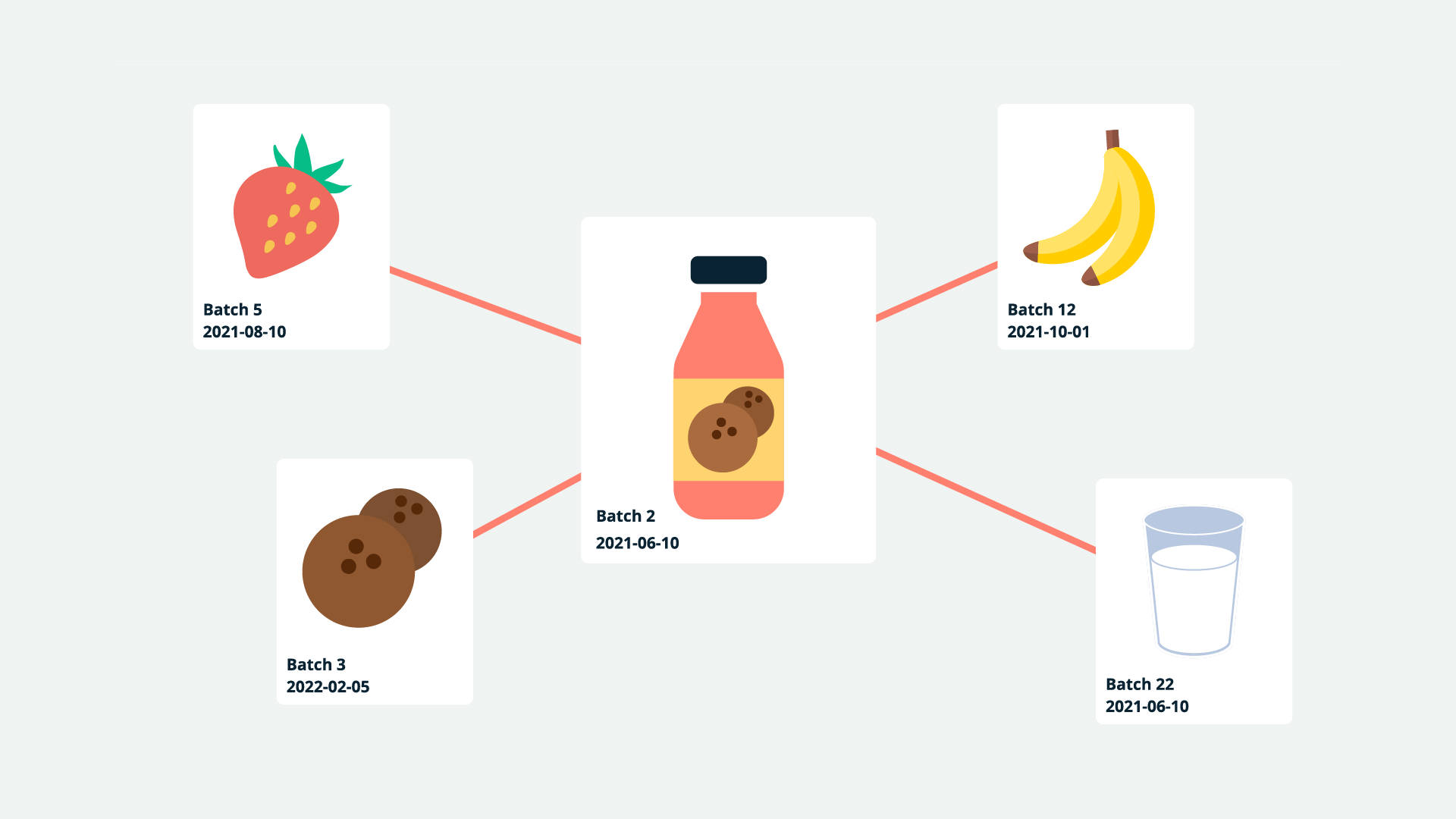

Let’s take a bottle of your favorite drink. As we’ve hopefully established, the drink itself is created through process manufacturing (unless your favorite drink is natural spring water or something, but let’s not make this too complicated).

But think about the final product — the drink you see on supermarket shelves, complete with:

- A label

- A lid

- The bottle itself

- The liquid inside of it

- And everything else needed to sell your drink

To get the final product ready, you’ll also need to employ a bit of discrete manufacturing.

This is because you’d put it together either by hand or in a bottling plant, and you could “take apart” the individual parts the bottle is made up of (for example, by pouring the liquid into a glass or removing the label).

In fact, the bottle itself will have been made through both process and discrete manufacturing. The glass itself would be made through process manufacturing using sand and a lot of heat, but the crafting and molding of the actual bottle from those raw materials would be considered discrete manufacturing. So manufacturing isn’t always discrete vs process — they can work hand in hand.

But you can’t really take apart a glass bottle

Well, you could potentially recycle the glass after you no longer need the bottle and use it to make something else (in a discrete manufacturing process). So, you can still “disassemble” a glass bottle to show it’s been made through discrete manufacturing. But you can’t turn the glass back into sand.

So almost every product you use in your day-to-day life will have had some form of process or discrete manufacturing used in its construction. Hopefully, this article has been helpful in understanding the difference between discrete vs process manufacturing. But the reality is usually a bit more complicated than theory. You might consider using manufacturing ERP software, such as Katana, to help you with that.

Take your business to the next level

Katana tracks your sales and inventory data in real-time to ensure all your teams are up-to-date and have the live insights they need to spot shortages before they cause trouble.

Katana can help you with both discrete and process manufacturing with ERP software

Regardless of whether you use process manufacturing vs discrete manufacturing, you’ll want all the tools at your disposal to keep track of your manufacturing process. Thankfully, Katana’s manufacturing ERP software is flexible and can accommodate all your manufacturing needs.

Katana is specifically built for manufacturers and comes equipped with all the essential tools needed for tracking a smooth production run. Regardless of how you manufacture your finished products, you can take advantage of features such as:

- Barcode and RFID tracking

- Batch and lot tracking

- Historical data tracking of batch-produced items

- And so much more

Get started by booking a demo with Katana and keep track of your manufacturing process, whether your manufacturing process is discrete, process-based, or you use a combination of both.

Download the definitive guide to batch production

Download our free ebook guide on batch production to learn more about the benefits, workflows, and software you need to get started.

Erik Väli

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control