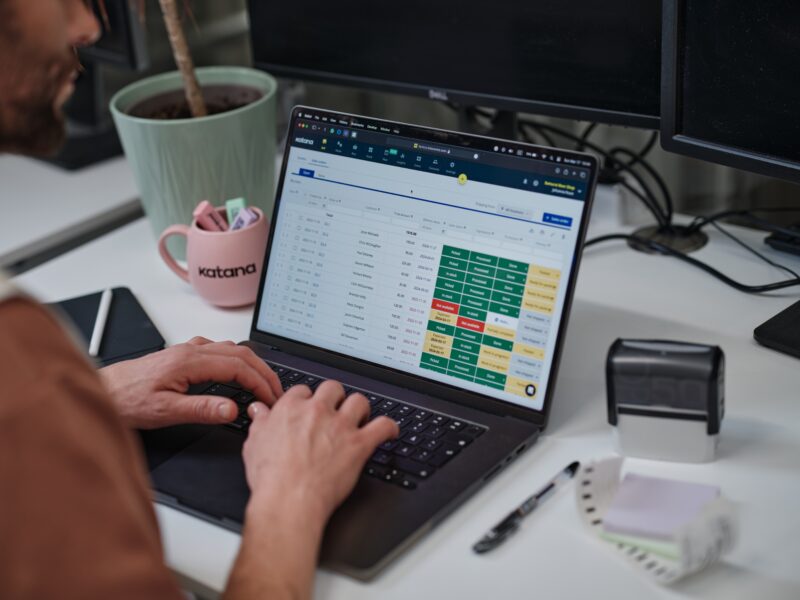

Manufacturing assembly software that’s easy to use

Get the features you need to manage everything related to production in one place with Katana’s manufacturing assembly process software. Katana supports small and medium businesses, so you can set it up to fit your manufacturing processes like a glove.

Improve operational efficiency with Katana’s manufacturing software

Whether you work in the food and beverage industry handling perishable goods or making nuts and bolts for the industrial machinery sector, Katana helps you optimize your supply chain. Implementing Katana in your company can improve inventory control and warehouse management while enabling you to integrate with a variety of tools.

End-to-end traceability of your supply chain and production

For assemble-to-order manufacturers, no matter the company size, taking every opportunity to control costs is vital to keep your profitability high. Katana’s automated tools and traceability provide price and quality control over your entire supply chain – helping you turn your challenges into competitive advantages.

Use Katana’s core features to monitor:

- The movements and expiration dates of your raw materials, components, and sub-assemblies

- Time allocation of your operators at the assembly lines to improve manufacturing management at all factories

- Task completion more accurately during your manufacturing operations at all times

Perfect your production management with Katana

Katana gives thousands of assembly manufacturers the tools for production planning, which they can use for automating inventory transactions to prevent stock-outs. Katana’s assembly software can track on-hand, committed, and expected stock amounts in real time, making it easy to stay in stock on top of inventory movements.

Use assembly manufacturing software to:

- Schedule production and calculate deadlines for optimal assembly operations

- Track your finished goods and raw materials in real-time for batch traceability

- Calculate manufacturing costs automatically to get more visibility into budget planning

Integrate with various tools for optimizing every aspect of your business

Katana’s assembly manufacturing ERP software integrates with several tools that can help you streamline and automate business processes. Katana can put the wind in your sails with a variety of integrations, whether you need more automation, advanced production scheduling, CRM solutions for monitoring changing customer demands, or platforms to sell products directly to consumers. Connect Katana with:

- Native integrations — Shopify, WooCommerce, QuickBooks Online and Xero integrations allow you to manage e-commerce sales and accounting all in one place

- Third-party platforms — powerful integration platforms CartRover and Zapier can connect Katana with thousands of apps for your every business-related need

- API — take a look at Katana’s open API and decide whether your company wants to invest resources to build your own app into Katana

Want to see Katana in action?

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Assembly manufacturing software that integrates with your favorite tools for a smooth workflow

Native integrations, codeless templates, and fully customizable API integrations

Katana gives users access to the API, allowing you to create custom workflows and connect your business apps to manage your sales, manufacturing, and accounting on one platform. Automate data transfers between the services you use to level up efficiency. Take a look at Katana’s API documentation to learn more.

Katana allows us to have a complete, real-time overview of our manufacturing processes and keeps our operations under control.”

Pablo Baque

Walk With Me CEO

Katana accurately keeps stock of assemblies and ingredients so that I can plan production and get instant feedback on whether we have enough resources in stock.”

Kelly Costello

Chief Executive Officer (CEO) at Puppy Cake

Having a system track inventory and what stage it is in has been incredibly helpful. It also has helped our team have a more clear delineation of the order of operations for each product in our catalog.”

Sarah Zinger

Director of Production Logistics at System76

I think that Katana had a much lower barrier to entry. It was still some work to get up and running, but I was able to gradually build my processes into Katana’s system over several months.”

Richie Duncan

Founder of KODAMA

Assembly manufacturing software FAQs

In simple terms, assembly manufacturing software is a computer application. It helps manufacturers manage and monitor the production process of their products. Assembly line operators use it for assembly planning and to make products correctly while keeping track of quality control.

A manufacturing ERP – acronym for Enterprise Resource Planning – is software that helps businesses manage and streamline their manufacturing processes. ERP system gives users a live visual look at all their business components — inventory management, order management, sales, and beyond.

Simply put, you can do significantly more with an enterprise resource planning system besides controlling your assembly lines and managing production. ERP software commonly has more features for inventory or warehouse management, and with the aid of intelligent integrations, you can significantly upgrade several processes, such as your manufacturing accounting.

Above all, ERP software helps businesses lose the siloed data as they can finally manage all departments from a single software solution, no matter the company size.

Assembly lines enable firms to mass produce products swiftly and more efficiently. Kitting involves bundling two or more similar items to create one ready-to-ship kit. Those bundles are usually sold as a single item. Also, unlike pre-assembled products, the end consumer usually assembles the items in kits by themselves.

Be prepared that even if those two words have slightly different meanings in manufacturing, some people still prefer using kitting and assembly interchangeably.

Bill of materials (BOM) software is designed for managing the bill of materials for every product. This can include tracking inventory levels, managing vendor relationships, and creating accurate production schedules.

ERP software goes beyond this to provide a complete view of your business operations and ERPs also come with BOM software features. Besides managing your bills, it tracks financial data, customer information, and monitors your supply chain data. ERP gives you a more complete picture of your business.

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control