Monitor and improve processes using a discrete manufacturing software

While micromanaging gives you a sense of security and control over your business, it also takes a lot of time out of your day. Katana’s discrete manufacturing software streamlines repetitive tasks and gives you the time to scale your business.

Nothing’s discreet with discrete manufacturing software

The business world is competitive, and making a name for your company is challenging. While marketing goes a long way, your products speak for themselves. That is why it’s crucial to perfect your processes as much as possible and consistently deliver the best quality. Using discrete manufacturing software, streamlining manufacturing has never been easier.

Stay up-to-date on your inventory and supplies

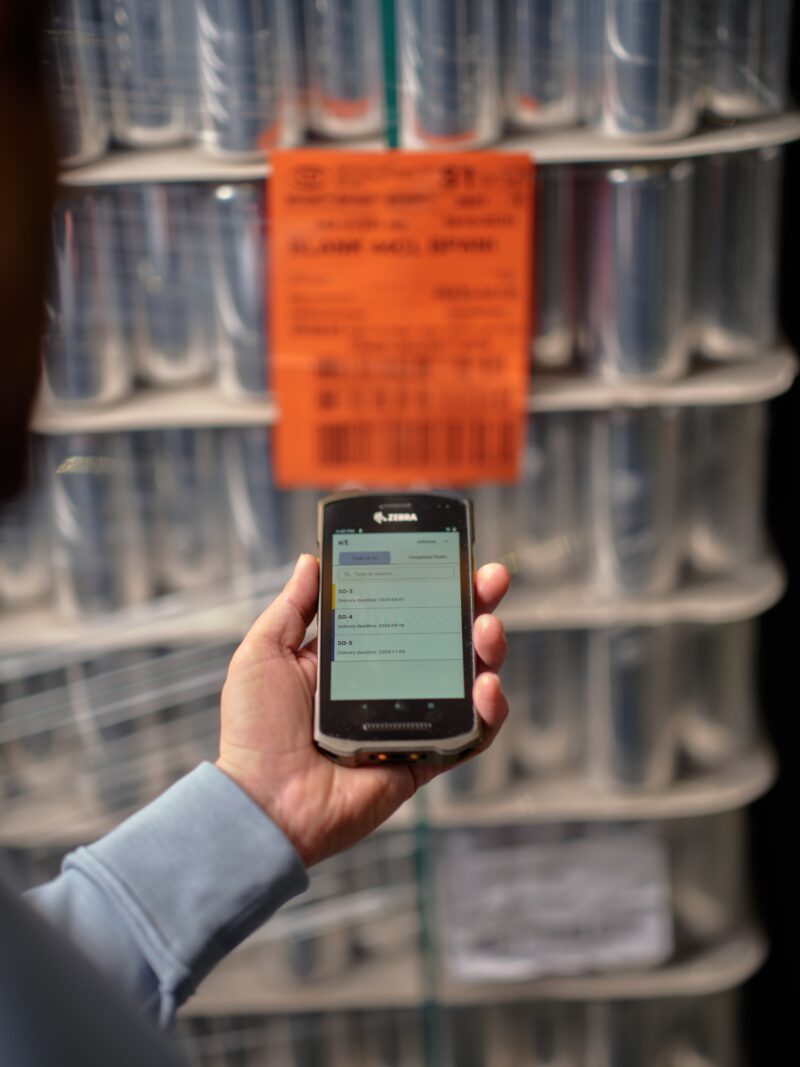

With real-time inventory tracking and reorder points, stockouts are a thing of the past. Katana’s discrete manufacturing ERP software allows supply chain visibility and task management. That means you’ll no longer have to maintain extensive spreadsheets and manually update them.

Here’s how Katana’s discrete manufacturing ERP software can help you keep an eye on your inventory:

- Real-time stock tracking for all your locations

- Reorder points to avoid low supplies

- Barcode scanning for receiving and shipping deliveries

Monitor and improve your manufacturing processes

Take full advantage of the Shop Floor App to distribute and observe all production tasks. That way, you’ll be able to track costs and time spent per assignment, reducing waste while increasing profits.

Here’s how the Shop Floor App will help you eliminate inefficiencies:

- Receive production updates in real time

- Assign and monitor tasks across different teams

- Keep important data discreet using user permissions

Create a custom workspace to adapt to your needs

Katana’s discrete manufacturing ERP software offers a variety of native integrations that will help take your business to the next level. From accounting to e-commerce, shipping to customer relations — there’s helpful software for all areas of your business.

Here’s how Katana helps you synergize your workflows with:

- Accounting integrations such as QuickBooks Online and Xero

- E-commerce platform integrations like Shopify, WooCommerce, and BigCommerce

- Access to Katana’s open API to create your own personalized integrations

Katana allows us to have a complete, real-time overview of our manufacturing processes and keeps our operations under control.”

Pablo Baque

Walk With Me CEO

It’s great to be able to see where inventory faults happen and being able to fulfill orders and where the turnaround happens.”

Alaina Oehrlein

Production Lead at Essence One

With Katana, we are able to track products, build recipes for materials, and set reorder points for our materials as well. That was the main reason why we selected Katana.”

Lisa Diep

Chief Operating Officer (COO) at Peace Collective

Since implementing Katana, it has freed up my time so I can focus on designing and creating more products. It also means that I am not working until 11 pm every night.”

Thomas Judge

Owner at GJ Motorsports

Want to see Katana in action?

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Customize your workflow with the essential tools for your business model

Custom API integrations

Katana’s open API lets you create a workspace that meets the specific needs of your business. Automatic data sync between the services improves efficiency and frees up much of your time. Read more about how to take full advantage of integrations.

Discrete manufacturing software FAQ

Discrete manufacturing is a manufacturing model where items are assembled from separate parts and the final product can be divided into bolts, screws, wires, and specific components. Learn more about discrete manufacturing in our blog.

While discrete manufacturing assembles products from separate components and parts, process manufacturing creates the final products using formulas and various processes combined into a final result.

Another difference is quantity — discrete manufacturing puts together one product at a time, even in mass production. Process manufacturing makes a batch of the final product and then separates it into smaller units that are fit for sale.

For a more thorough analysis, check out this article on discrete vs process manufacturing.

Every business has different requirements for manufacturing software, but there are definitely some features to look into regardless of your particular manufacturing process:

- Inventory management to stay on top of your product and supply stock

- Live data sync to optimize your daily processes to save time

- Prioritization of supplies to ensure the manufacturing of popular products

- Reorder points to ensure you always have enough materials to keep production moving

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control