Ecommerce fulfillment: Streamline your logistics operations

Henry Kivimaa

We’ve all heard quotes about journeys and destinations.

While embarking on an unknown journey, blind to the dangers and challenges that await, holds a certain thrill, there’s wisdom in introducing oneself to the specifics beforehand. Whether it’s a rocky and dangerous road to Mordor, a yellow-brick road to Oz, or a routine cargo voyage across the Pacific from your warehouse to the client’s doorstep — being prepared, transforms the journey from potential chaos to an exciting adventure.

Unless you have a wizard named Gandalf who does the logistics for your operations, it’s best to plan ahead and ensure you optimize your ecommerce fulfillment to your best capabilities. Gandalf may leave you to go on a side quest, but a streamlined ecommerce fulfillment system will support your adventure without taking any unexpected detours.

This is precisely why we want you to understand what ecommerce fulfillment entails and how it can become the cornerstone of your successful online business operations.

What is ecommerce fulfillment?

Ecommerce order fulfillment is the process of fulfilling ecommerce orders. This includes everything from receiving items to the ecommerce fulfillment center, order picking and packing, delivering it to the customer, as well as dealing with returns.

Often also referred to as simply order fulfillment, ecommerce fulfillment is specific to orders placed via ecommerce channels such as online stores and marketplaces. At the same time, order fulfillment can also be applied to purchases made directly from the manufacturer, via phone or email, or in a brick-and-mortar store.

Ecommerce order fulfillment depends strongly on technological solutions, such as ecommerce fulfillment systems and online logistics solutions. In contrast, regular order fulfillment can, theoretically, still be done with a pen and paper. But as an inventory software solution, we don’t recommend that.

Ecommerce fulfillment emphasizes the importance of streamlined operations and real-time updates to both the seller and buyer regarding order status, inventory levels, and shipping details. Given the competitive nature of ecommerce, fulfillment in this context also heavily focuses on customer experience, including fast shipping, accurate order tracking, and efficient returns processing to encourage repeat business and customer loyalty.

What’s the difference between fulfillment and shipping?

When hearing the term e-commerce fulfillment, many assume it means the stage of the process when the order is fulfilled aka. when it’s shipped. While it’s a solid logic, in the world of supply chain, that’s not quite accurate. So, let’s briefly go over the definition of both terms and how they’re used in this context:

- Fulfillment encompasses the entire process of handling an order from the moment it is placed by the customer until it is delivered to them. In the case of returns — these are also under fulfillment.

- Shipping is the specific stage of the e-commerce logistics process that deals with the physical transportation of the order from the warehouse or fulfillment center to the customer’s address.

So, fulfillment covers multiple steps within the warehouse or fulfillment center, from order receipt to packing and labeling for shipment, while shipping is specifically about transporting the order to the customer.

What’s the ecommerce fulfillment logistics process?

Fulfilling an e-commerce order involves a series of steps designed to efficiently process the order from the moment it is placed by the customer until it is delivered to their door. Here is a step-by-step overview of how to fulfill an e-commerce order.

1. Receiving and storing inventory

The ecommerce fulfillment process way before an order is placed online. The first part of ecommerce fulfillment is receiving products from suppliers and manufacturers. The items get delivered to an e-commerce fulfillment warehouse, where they are checked and added to your warehouse inventory management system. The products need to be stored in the designated locations to ensure they are easily retrievable when orders are placed.

2. Order placement

Order processing begins when a customer places an order online. This involves confirming the order, verifying payment details, and preparing the order for picking and packing. The order details, including customer information and product specifications, are recorded for accounting and operations purposes.

3. Order processing

The order is then taken into handling, which typically involves confirming the payment has been authorized and updating the inventory levels to reflect the sale. The order details are forwarded to the warehouse or fulfillment team.

This step prepares the order for picking and packing by ensuring all necessary information is accurate and complete.

4. Picking

Now, the warehouse staff retrieves the ordered items from their storage locations. This step may involve using a picking list or a mobile device that guides the picker through the warehouse to collect the correct items in the right quantities.

This step focuses on accurately and efficiently collecting all items that make up the order.

5. Packing

Once picked, the purchased items are packed for shipment. This usually involves selecting the appropriate packaging materials to ensure items are protected during transit while also considering the weight and dimensions to manage shipping costs. Packing slips, invoices, and any promotional materials may also be included.

Secure packaging helps minimize damage that may occur during transportation and ensures all order components are included.

6. Shipping

The packed order is labeled with a shipping address and a tracking number. The package is then handed over to a shipping carrier for delivery. Shipping options can vary, offering different speeds and costs to meet customer preferences.

In this step, the order is dispatched to the customer promptly, using the most appropriate shipping method. In many cases, buyers are given the option to choose between free standard shipping or more expensive express shipping.

7. Delivery

The shipping carrier transports the package to the customer’s delivery address. The customer is often able to track their package using a provided tracking number. Delivery tracking allows both the seller and buyer to ensure the order is delivered to the correct address within the expected delivery time.

8. Returns processing

In cases where a customer wants to return an item, the fulfillment process includes receiving the returned product, inspecting it for damage, processing a refund or exchange as per the return policy, and restocking the item if it’s in sellable condition.

Effective returns handling helps maintain customer satisfaction and manage inventory accurately.

Order fulfillment strategies

Order fulfillment strategies are critical for businesses to meet customer expectations efficiently and cost-effectively. The choice of strategy depends on various factors, including business size, product type, order volume, and customer base. Below are some of the most popular order fulfillment strategies used by businesses today.

1. In-house fulfillment

The business manages all aspects of the fulfillment process internally, from storing inventory to picking, packing, and shipping orders.

This strategy is suitable for small businesses with manageable order volumes or businesses with unique product handling requirements. It gives them total control over the fulfillment process, direct inventory handling, and potentially lower shipping costs for local deliveries.

However, it requires significant investment in warehouse space, technology, and staff. This can be difficult for businesses with limited budgets and may become inefficient as the organization scales.

2. Third-party logistics (3PL)

Outsourcing means utilizing a third-party provider that stores inventory, processes orders, and handles shipping on behalf of the business.

This strategy suits best businesses looking to scale without the overhead of managing their own warehouse or those needing expertise in logistics and fulfillment. It grants them access to logistics expertise, scalability, and potentially lower shipping costs due to the 3PL’s volume discounts. It also frees up time and resources to focus on core business activities.

As a downside, it provides less control over the fulfillment process, and there’s the risk of communication issues with the 3PL provider.

3. Dropshipping

The seller takes orders, but the product is shipped directly from the manufacturer or wholesaler to the customer, with the seller avoiding any physical handling of the product.

The most suitable business models for dropshipping are startups and businesses that want to offer a wide range of products without holding inventory. It requires a low upfront investment, as there’s no need for inventory or warehouse space. It also allows for a broad product offering without significant risk.

On the other hand, businesses lose control over shipping times and product quality. Also, there are lower profit margins due to reliance on third-party suppliers.

4. Fulfillment by Amazon (FBA)

Businesses send their products to Amazon’s fulfillment centers, where Amazon stores the inventory, processes orders, and handles shipping and customer service.

This strategy is best for e-commerce businesses looking to take advantage of Amazon’s unlimited customer base and top-tier logistics network. It gives them access to Prime customers, a streamlined fulfillment process, and reduced shipping times. Amazon handles customer service and returns.

On the downside, Amazon fees can be high, and businesses must adhere to Amazon’s strict packaging and preparation guidelines.

5. Hybrid fulfillment

As the name hints, hybrid fulfillment is a combination of fulfillment strategies to meet different needs. For example, a business might use in-house fulfillment for local orders and a 3PL for international orders.

This approach suits businesses with diverse product lines, varying order volumes, or those selling through multiple channels. It provides flexibility to choose the most efficient and cost-effective method for different situations. It also helps optimize speed, cost, or control as needed.

As a negative, it can be complex to manage multiple fulfillment processes and systems.

Choosing the right fulfillment strategy involves weighing the pros and cons of each option in the context of your business needs, goals, and resources. Many businesses start with one method and evolve their strategy as they grow and customer expectations change.

How to choose the best ecommerce fulfillment system for your business?

Now that you know which fulfillment strategies there are, it’s time to select the best one for your specific business needs.

Choosing an ecommerce order fulfillment system or strategy is a decision that can significantly impact your operational efficiency, customer relationships, and the overall bottom line. The secret to making the right choice is understanding your business needs, customer expectations, product characteristics, and long-term business goals.

Here’s how to approach this process.

Understand your business needs

First, think of the size of your business. Small companies with limited order volumes may find in-house fulfillment manageable and cost-effective, but larger sellers or those experiencing rapid growth might benefit from the scalability of 3PL providers.

Keep in mind the type of products you handle. Unique, fragile, or high-value items might require the control that comes with in-house fulfillment, whereas standardized products can easily be handled by 3PLs or even dropshipping methods.

Don’t overlook demand trends, holidays, and seasonality. Fluctuating order volumes might benefit from the flexibility of hybrid fulfillment solutions, allowing your business to adapt to changing demand without overcommitting resources.

Evaluate customer expectations

Anyone who has ever ordered anything online knows the feeling of refreshing the tracking info three times a day. The perfect delivery date will always be yesterday. If your market competitive advantage relies on fast delivery times, leveraging fulfillment networks like Fulfillment by Amazon or a well-connected 3PL could be crucial.

Something that both sellers and customers can agree on — shipping should be as cheap yet reliable as possible. For businesses focusing on minimizing shipping costs, in-house fulfillment might be more appealing, especially if your customer base is localized.

How much should you charge for shipping?

The short answer — nothing!

People have really come to expect free shipping, even if that means the product costs that much more. For some reason, we truly appreciate free stuff. So, if we have an option to purchase a packet of wontons for $4 plus $2 for shipping or $6 and free shipping, most of us will jump at the second option.

- 80% of American consumers anticipate free shipping when their orders surpass a specific amount¹

- 66% believe free shipping should apply to all orders¹

- 50% of consumers have abandoned their online shopping carts due to unsatisfactory shipping or delivery options¹

If you consider that the shopping cart abandonment rate is about 70%², offering free shipping has the potential to cut that number drastically.

Consider product characteristics

Take into consideration the size and weight of the packages you send out. Bulky or heavy items might require specialized fulfillment solutions that minimize shipping costs or handle storage peculiarities.

Products with limited shelf life or special storage requirements, like refrigeration for perishables, need more control and faster turnover.

Analyze long-term business goals

If rapid expansion is in your business plan, partnering with a 3PL can provide the necessary infrastructure to scale up without the need for significant capital investment in warehouses and logistics.

For businesses looking to expand into new geographical markets, utilizing a fulfillment strategy that includes local 3PL services or hybrid models can reduce shipping times and costs, making your products more competitive.

Balance pros and cons

Each fulfillment strategy comes with its set of advantages and challenges.

For instance, while in-house fulfillment offers control, it may not be as scalable as using a 3PL. Dropshipping minimizes inventory costs but can lead to lower profit margins and less control over the customer experience. FBA provides access to a vast customer base but at the expense of higher fees and strict compliance requirements. Hybrid models offer flexibility but require more complex management and oversight.

Ask yourself which is more important to you — control or convenience. Balance the desire for control over the fulfillment process with the convenience and expertise offered by external providers. Perform a thorough cost-benefit analysis of each option, considering both direct costs like shipping and storage and indirect costs such as customer satisfaction and brand control.

Many businesses find that their needs change over time, requiring a reevaluation of their fulfillment strategy as they grow.

Ecommerce fulfillment challenges

Ecommerce fulfillment faces several challenges that can impact operational efficiency, customer satisfaction, and profitability. These challenges stem from the complexities of managing inventory, orders, and logistics across diverse and often global supply chains. Here are some of the key challenges.

Inventory management

Keeping accurate track of inventory across multiple sales channels and fulfillment centers can be difficult and lead to overstocking or stockouts. Poor ecommerce inventory management can cause lost sales, excess carrying costs, or dissatisfied customers due to unavailable items.

Shipping costs and delivery times

As we’ve established — consumers expect fast and free shipping, but managing shipping costs while meeting these expectations can be challenging, especially with rising fuel prices and shipping rates. High shipping costs can decrease your profit margins but also make many customers abandon their carts. Additionally, long delivery times can lead to poor customer satisfaction and undermine your brand reputation.

Returns management

Handling returns efficiently and cost-effectively while maintaining a positive customer experience is complex, especially with high return rates in specific ecommerce categories like apparel and electronics. Inefficient returns processes can increase costs, tie up inventory, and negatively impact the customer’s experience.

Scalability

Ecommerce businesses often experience fluctuating demand, with seasonal peaks that can put a strain on your operations. Failing to scale operations effectively during peak times can lead to delayed shipments, errors, and a backlog of orders, which damages your customer relationships.

Globalization

Selling and shipping internationally creates new complexities, including customs, duties, and varying shipping regulations and standards. Navigating these hurdles can slow down international expansion and complicate logistics even more.

Technology integration

Integrating various systems, such as ecommerce platforms, warehouse management systems, and shipping carriers, is essential for seamless operations but can be technically challenging. On the other hand, a lack of integration can lead to inefficiencies, errors in order processing, and a lack of visibility into overall order and inventory data.

Customer expectations

Consumers have high expectations for fast delivery, order accuracy, easy returns, and responsive customer service. Not meeting these expectations can quickly lead to negative reviews, customer churn, and a damaged brand reputation.

Sustainable practices

There is growing pressure on businesses to adopt environmentally friendly practices in packaging, shipping, and overall operations. Implementing sustainable practices can increase costs and operational complexities but is increasingly vital for brand image and customer loyalty.

Top ecommerce fulfillment success stories

Mastering ecommerce fulfillment is a competitive edge that separates market leaders from other businesses. Through innovative approaches, optimized processes, and customer-focused practices, these companies have turned logistical nightmares into strategic advantages.

Let’s look at some success stories that brilliantly showcase how effective fulfillment strategies can drive growth, enhance customer satisfaction, and set new industry standards.

Amazon

As an ecommerce leader, Amazon faces the continuous challenge of delivering a vast array of products to customers as quickly as possible, often aiming for same-day or next-day delivery.

To deal with this, the company developed a highly sophisticated fulfillment network, including fulfillment centers strategically located near major urban areas, advanced robotics technology to improve warehouse operations, and its own delivery network, Amazon Logistics. It also introduced Amazon Prime, a subscription service offering fast, free shipping, to enhance customer loyalty and increase sales.

These strategies have enabled Amazon to set and constantly meet high customer expectations for delivery speed and efficiency, contributing to its position as a leading e-commerce retailer globally.

Amazon in numbers

- Amazon had a global net sales revenue of $575 billion in 2023³

- 37.6% of US ecommerce sales are made on Amazon⁴

- On average, Amazon sells $4,722 worth of products every second⁴

Walmart

Walmart is in constant competition with Amazon’s rapid delivery service while also managing its extensive network of physical stores.

To do that, Walmart has implemented an omnichannel fulfillment strategy, utilizing stores as local fulfillment centers in addition to traditional warehouses. This approach allows the retail titan to leverage its physical retail footprint for online order fulfillment, offering services like in-store pickup and same-day delivery directly from nearby stores.

With this strategy, Walmart has significantly improved its ecommerce delivery times and customer satisfaction, making it an impressive competitor in online retail.

- In 2022, Amazon boasted $50.9 billion in sales revenue in the US, while Walmart had a “measly” $19.2 billion⁵

However, Walmart is putting a lot of effort into increasing its online sales and is creeping closer to Amazon while taking pieces of its pie.

Nike

Nike’s biggest challenge is enhancing direct-to-consumer (DTC) sales and improving fulfillment efficiency with a growing demand for online shopping.

The sportswear titan focused on digital transformation by investing in its online platforms and apps, along with streamlining its supply chain and fulfillment operations. It also introduced innovative services like customizing products online, which require a more flexible and responsive fulfillment process.

Nike’s efforts have resulted in increased DTC sales, improved customer engagement, and a more agile fulfillment operation that can quickly adapt to changing consumer preferences.

Ikea

Ikea has been trying to adapt a traditional in-store shopping experience for bulky furniture items to an efficient online fulfillment model.

The home decor and furniture giant has invested in building more distribution centers and explored different delivery models, including smaller-format stores and collection points to act as local distribution hubs. This approach has helped reduce delivery times and costs for online orders.

As a result, Ikea has been able to offer more competitive online shopping options, including lower-cost shipping options and faster delivery times, enhancing its e-commerce presence.

Apple

When thinking about how Apple sells their products, we usually picture an elegant glass building with a minimalistic, clean look and incredibly helpful employees answering all questions that may arise. However, the consumer electronics behemoth makes a large part of their sales online.

- In 2022, Apple had a revenue of $394.3 billion⁶, and $59.3 billion⁷ of that was generated through its website

Clearly, this number is nothing to be scoffed at.

Apple has the difficult task of maintaining a high level of customer service and product experience in the online order fulfillment process. As a solution, they provide a seamless online shopping experience with efficient logistics that include fast and reliable shipping options. It also offers services like in-store pickup and easy returns to ensure customer satisfaction. Apple’s fulfillment strategy is tightly integrated with its retail operations, ensuring products are delivered in a timely and secure manner.

This approach has helped Apple maintain its brand reputation for quality and customer service, encouraging customer loyalty and repeat purchases.

How to use technology in ecommerce fulfillment?

As we know, tech is one of the fastest-moving things in the world. Only losing to the speed of light and Peregrine falcons. This means that in the fast-paced world of ecommerce, using technology is not just an advantage — it’s essential for survival and success.

Technology plays a vital role in optimizing ecommerce fulfillment, enabling businesses to meet customer expectations for swift, accurate, and transparent order processing and delivery. Here are some tips on how to use technology effectively in your ecommerce fulfillment strategy.

Implement an order management system

An ecommerce order management system (OMS) centralizes orders from various sales channels and provides real-time visibility into inventory levels, order statuses, and customer information. This integration ensures that your ecommerce orders are accurately fulfilled and inventory is consistently updated, reducing errors and improving customer satisfaction.

Utilize warehouse management software

Warehouse management software (WMS) optimizes warehouse operations by automating tasks such as picking, packing, and shipping. A WMS can significantly reduce fulfillment times, increase accuracy, and manage inventory more efficiently, allowing for better space utilization and streamlined workflows.

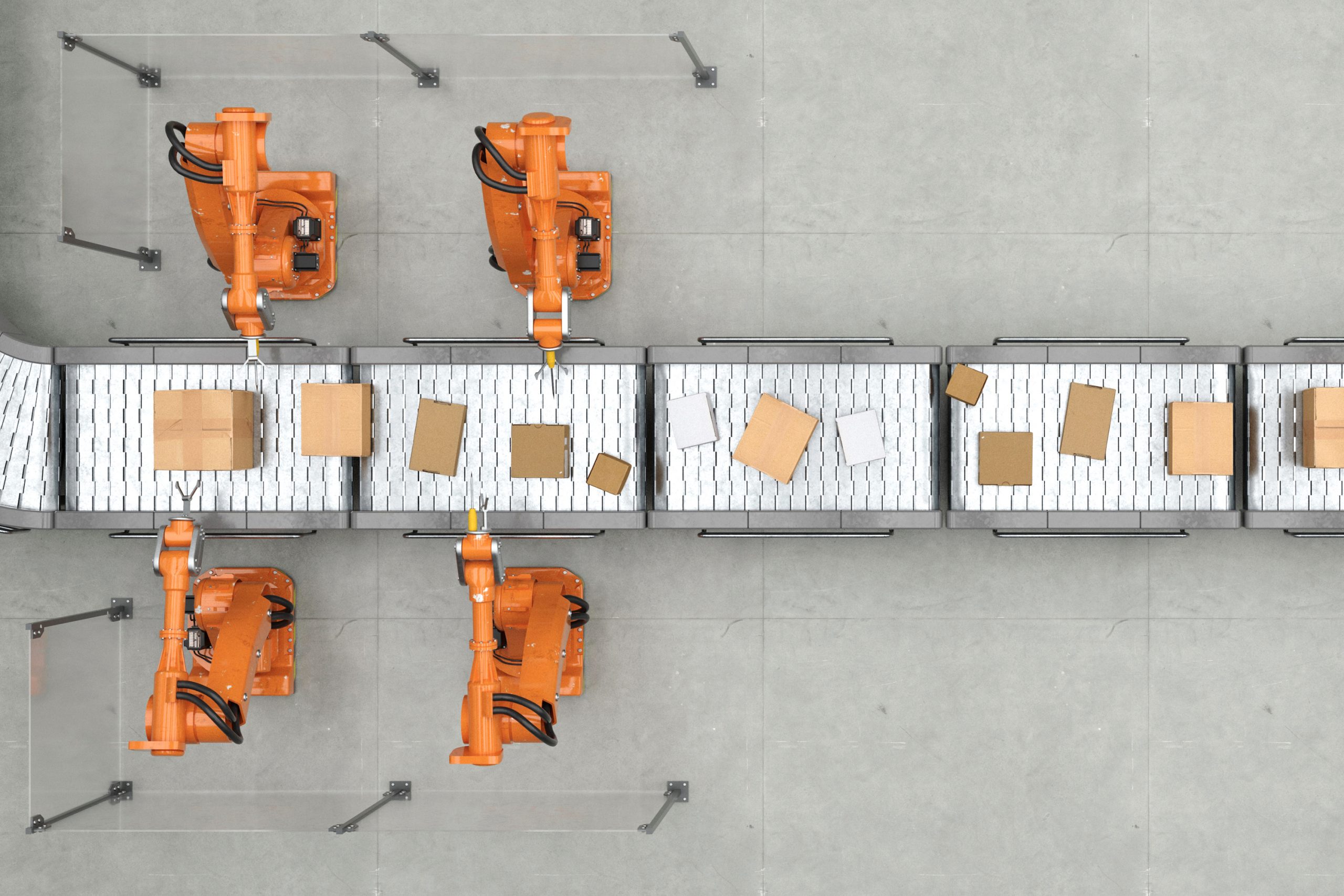

Adopt automated picking and packing solutions

Automation technologies, including robots and conveyor systems, can speed up picking and packing, minimize human error, and reduce labor costs. Automated solutions are able to work around the clock, ensuring fast order processing even during peak seasons.

Leverage data analytics for forecasting

Data analytics tools can evaluate historical sales data, customer preferences, and buying trends to forecast future demand accurately. This insight allows sellers to optimize inventory levels and reduce carrying costs, prevent stockouts or overstock, and plan for seasonal fluctuations.

Implement shipping and logistics software

Shipping and logistics software streamline the delivery process by offering the best shipping options and routes, real-time tracking, and automated communication with customers about their order status. This technology enhances the customer experience by providing transparency and reducing delivery times.

Enhance customer experience with technology

Technologies such as chatbots for customer service, augmented reality (AR) for product visualization, and personalized shopping experiences through AI and machine learning can make the customer experience a lot better, encouraging loyalty and repeat business.

Ensure mobile access

With more and more consumers shopping on mobile devices, ensuring your ecommerce platform is optimized for mobile is crucial. A mobile-friendly platform enhances the shopping experience, potentially increasing sales and customer satisfaction.

How to use Katana in ecommerce fulfillment?

Katana Cloud Inventory is a modern ecommerce inventory management software that’s particularly well-suited for businesses involved in direct-to-customer (DTC) sales, as well as those balancing both ecommerce and wholesale channels. It has many essential features to streamline your order fulfillment process, making it more efficient and less prone to errors. Here’s how you can leverage Katana’s features for e-fulfillment.

Centralized order management

Katana provides a live view of all your orders across different ecommerce platforms and sales channels. This system helps you prioritize orders based on their deadlines and stock availability, ensuring prompt fulfillment.

There are also numerous integrations with popular ecommerce platforms to choose from. Shopify and WooCommerce are just two that can automate the flow of sales orders into the system and reduce errors that can happen with manual data entry.

Inventory management

With Katana, you can track your inventory levels in real time across multiple locations and warehouses. This includes raw materials and finished goods, helping you prevent stockouts or overstocking.

Katana also allows detailed tracking of products and their variants, including size, color, and other attributes, making it easier to manage inventory for a diverse product range.

Production planning

For businesses that not only sell but also manufacture their products, Katana offers smart production planning tools. It automatically adjusts production schedules based on sales orders and available inventory, ensuring that you’re always ready to fulfill orders. You can also set reorder points to receive reminders to restock so you never run out of inventory.

Katana also makes it easy to manage your BOMs, which is crucial for accurately calculating the cost of goods sold (COGS) and ensuring all necessary components are available for production.

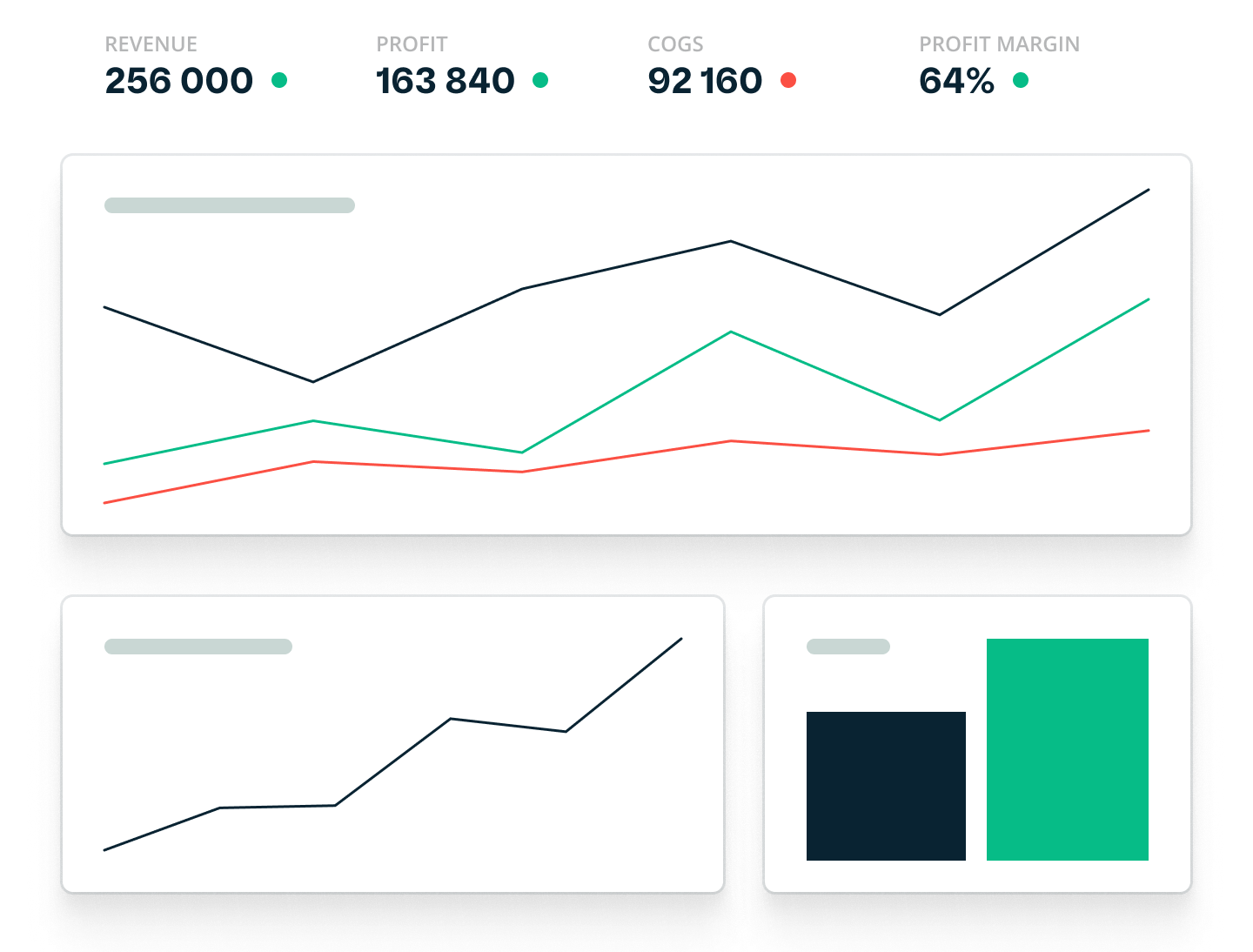

Analytics and reporting

Gain insights into your most profitable products, order fulfillment efficiency, and inventory turnover rates. Katana’s analytics can help you make informed decisions to optimize your operations and increase profitability.

Tailor reports to meet your specific needs, focusing on the key performance indicators (KPIs) that matter the most to your business.

Scalability

Katana is designed to scale with your business, supporting increased order volumes and more complex manufacturing requirements without the need for significant changes to your fulfillment processes.

Besides ecommerce platforms, Katana integrates with accounting software like QuickBooks and Xero, shipping and fulfillment services, and other tools essential for ecommerce businesses. This ecosystem of integrations streamlines your entire operation from your order placement to delivery, allowing it to grow organically.

By effectively utilizing these features, ecommerce businesses can significantly improve their order fulfillment processes, making them more efficient, reducing lead times, and enhancing customer satisfaction.

Katana provides the tools needed to manage inventory, production, and orders in a unified platform, offering a comprehensive solution for ecommerce fulfillment challenges.

Want to see it for yourself? Request a demo with our team of experts and see why thousands of businesses have already made the switch.

Sources

¹Free Shipping Statistics, Capital One (2023)

²49 Cart Abandonment Rate Statistics 2024, Baymard (2024)

³Amazon – statistics & facts, Statista (2023)

⁴20 Amazon Statistics You Need to Know in 2024, RepricerExpress (2024)

⁵Amazon vs. Walmart Head-to-Head in this Infographic, Multichannel Merchant (2022)

⁶Apple Reports Fourth Quarter Results, Apple Inc. (2022)

⁷E-commerce net sales of apple.com worldwide from 2014 to 2022, Statista (2023)

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control