Xero bill of materials (BOM): tips and tricks

Bill of materials (BOM) is like a recipe for manufacturers. But can Xero, known for accounting, handle your BOMs?

In this blog, we’ll see if Xero can help you manage BOMs effectively, making your business smoother and smarter. Read on to explore how Xero’s numbers expertise meets the world of production details.

Table of contents

What is a bill of material?

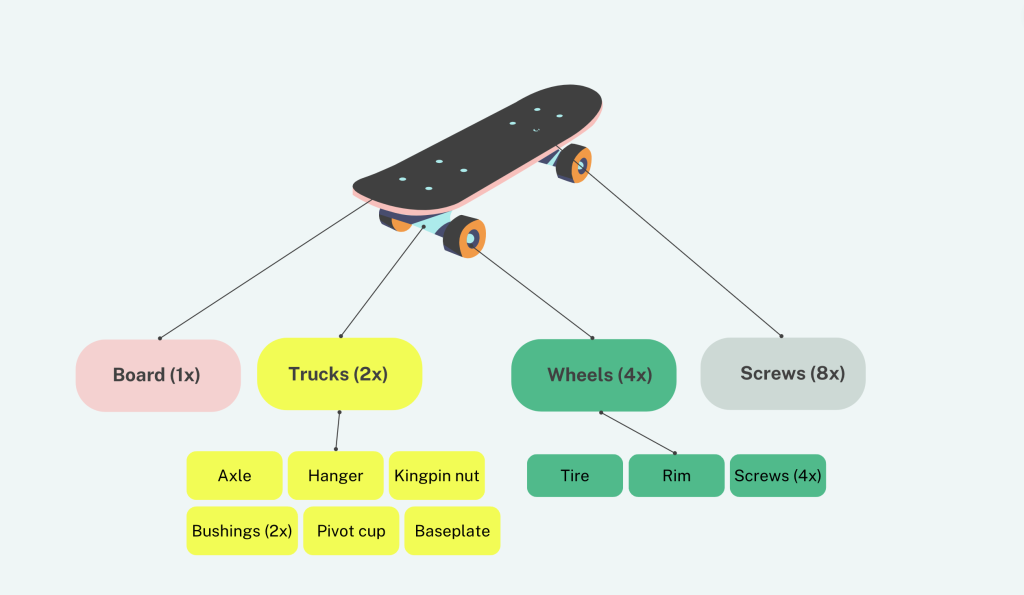

A bill of materials, often called just BOM or a product recipe, lists the raw materials, sub-assemblies, parts, components, and quantities each product will need during production. It serves as a detailed reference document that outlines the structure and composition of the final product.

BOMs are commonly used in various industries, such as manufacturing, engineering, construction, electronics, and more, to facilitate the planning, procurement, and production processes.

However, a BOM doesn’t stop there — it also details the operations (and the number of times) a product will need to go through routing manufacturing until it becomes a finished product. Getting your BOMs sorted is an essential element to running an efficient factory floor.

This is why it’s important to know about them before you start looking into your bill of materials on Xero.

When it comes to designing your Xero bill of materials, how in-depth you want to go is extremely limited (we’ll look into this in the next chapter), as the complexity of building some products consumes more resources than others.

Take assemble to order products like a bicycle and a computer. A bicycle could be realistically built with only a few subassemblies and in a few steps.

But a computer? You have the electronic bits, cases, and sensitive hardware. You’ll need to smolder, assemble, and follow many more steps and consume more materials before you’re finished.

Not the most elegant example, but the point is a BOM for one product could be simple, while another BOM could be complex. Your product’s BOM will fall under one of three types:

- Modular BOMs

- Configurable BOMs

- Multi-Level BOMs

Does Xero have a bill of materials?

There is no bill of materials on Xero, meaning there isn’t a module to save your bill of materials or BOMs onto Xero. But don’t go unsubscribing from Xero just yet, as there is hope.

Even though it is true that you’re unable to save your Xero BOMs, it does have an impressive App Store allowing you to search for third-party Xero inventory add-ons that support Xero bill of materials.

Alternatively, if you don’t wish to integrate a third-party solution for your BOMs, some workarounds can (technically) allow you to save and even track a basic Xero inventory bill of materials structure within the software.

So, let’s see what options there are.

Bill of materials on Xero

So, we’ve established that Xero doesn’t have a BOM but that there are workarounds to saving your Xero bill of materials. For explanation, let’s look at a Xero bill of materials solution for bike manufacturers.

Xero inventory management boils down to two categories:

- Tracked inventory

- Untracked inventory

Your tracked inventory will consist of your finished goods, and Xero will track those stock levels.

Your untracked inventory is your fiddly bits, the raw materials. You can track the costs of your materials, but this isn’t done automatically. And you can never see your actual stock levels for untracked inventory in Xero.

However, the workaround we’re about to show you not only helps you track your materials but also gives you a basic bill of materials on Xero.

Xero bill of materials workarounds

We’re going to look at two different options that would allow you to have a bill of materials on Xero.

Workaround #1

First things first, this method works better for those who follow a make-to-order workflow. It doesn’t mean you can’t use it with make-to-stock, but it means you’ll need to take regular stocktakes of your inventory.

For this example, we’ll assume the role of a bicycle manufacturer.

So, how to get a simple Xero bill of materials:

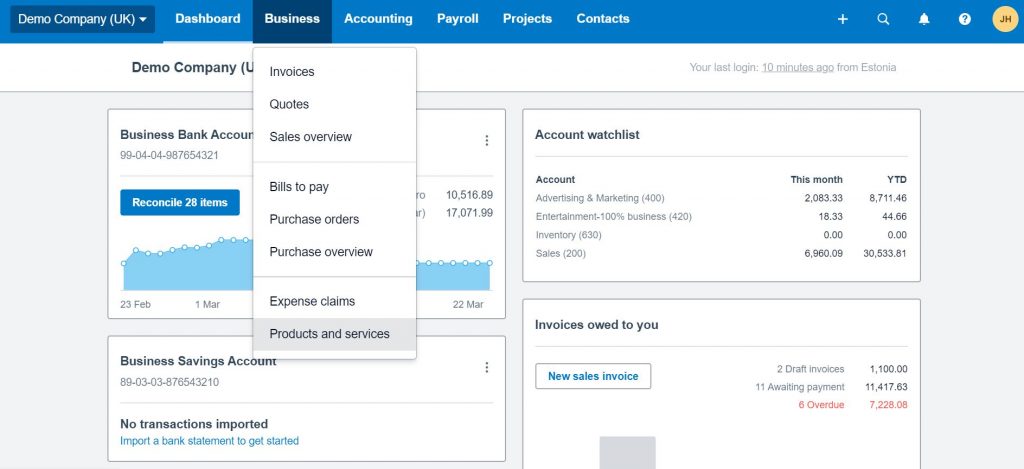

1. Log into Xero, and at the dashboard, select Business and Products and Services.

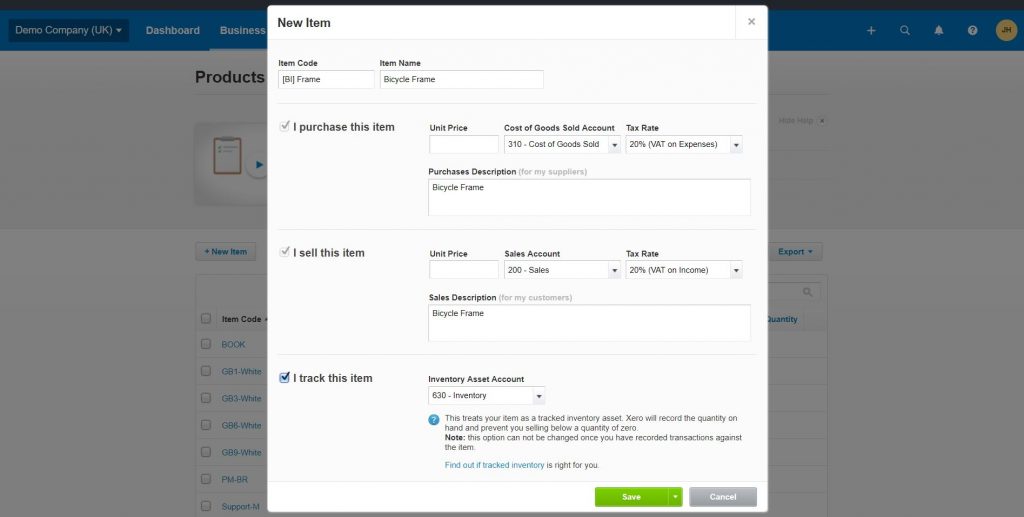

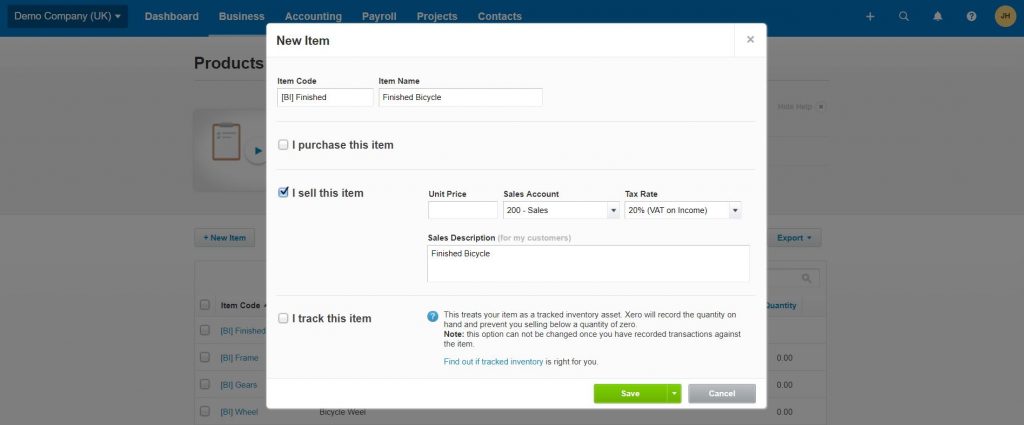

2. Select + New Item and, one by one, add the materials needed for building your product. In this case, it will be:

- Bicycle frame

- Bicycle gear

- Bicycle wheel

Make sure to check that you track this inventory.

3. Once you’ve input all your raw materials and components, you can add the actual finished product.

You’ll go through the same process, but instead, you’ll list this as an untracked version.

The idea is that you’ll sell the finished good to customers (which will have no stock levels), and you’ll track your raw materials in Xero instead. Once you make a sale, simply generate an invoice using your materials to track the manufacturing costs.

But either way, you will now (technically) have a simple bill of materials on Xero.

For the more visual learners among us, you can check out the video below on how to set up your bill of materials on Xero.

Workaround #2

It might be disingenuous to refer to this as a workaround, but if the first option doesn’t work, you could simply manage your BOMs and raw material elsewhere.

For this, you can download a free bill of materials template to manage your Xero BOMs from there.

Otherwise, your best solution for the Xero bill of materials issues, which Xero itself recommends, is to look for a third-party app.

Opting for a third-party app

Maybe you can use a workaround or find a way to cope with inefficient Excel spreadsheets. Still, you will be dedicating resources to manually updating stock levels when these resources could be focused on your manufacturing or growing your business instead.

Ultimately, the purpose of Xero is to optimize your bookkeeping, and the software does a fantastic job at that.

But why Xero recommends integrating third-party software is because it’s a far easier solution to bridging the gap between missing features on Xero, such as:

- Efficient raw materials and finished goods inventory management

- Production planning

- Monitoring your floor-level progress

You can even integrate your sales channels to create synergy between your different platforms, which is quickly becoming the winning D2C formula for manufacturers.

The best bill of materials plugin for Xero

Katana is a cloud inventory platform that seamlessly integrates with your Xero account and gives you a powerful Xero bill of materials features for managing your product recipes.

Once you set up the Xero ERP integration, you can start making specific BOMs for all of your products and their product variants (Katana will automatically generate each possible variation to save you time).

Within these BOMs, you can add your materials and subassemblies, based on which Katana will automatically:

- Make inventory adjustments

- Calculate manufacturing costs

- Check material availability for manufacturing orders

Not only will cloud inventory software provide a solution to the missing features for a bill of materials on Xero, but you’ll also have access to many other features designed to elevate your business processes.

Real-time master planner

You open up your spreadsheet or go to your inventory, always wondering if you have enough stock to satisfy your orders. Katana’s unique master planner removes that dread by automatically allocating available materials and finished goods to open orders in real time, so you know immediately when you can finish your orders.

Priority based planning

Scheduling can be a real pain, especially when you know that anything could happen that’ll need you to reschedule production again. Katana has an intuitive drag-and-drop feature, so you can easily rearrange your workflow. Best of all, the master planner will reallocate your resources to fit with the new schedule.

An overview of your floor-level progress

By only handling your manufacturing via Xero, you’re still going to need to figure out a way to monitor your production. Katana gives you and your team members a way to track the progress of:

- Manufacturing orders

- Individual jobs

All from one easy-to-read, visual platform.

How to implement Xero + Katana

Setting up your Xero bill of materials in Katana is pretty straightforward:

- Log in to Katana

- Once logged in, you can head to the Settings screen and select Integrations to connect Katana to your Xero account

- Once you’ve selected which account you would like to integrate, you can start editing how invoices and bills from Katana will appear in Xero

At this stage, you’ll be able to import your customer and supplier information from Xero to Katana.

And that’s it! You’re now ready to set up your Xero bill of materials and take full advantage of the powerful features Katana offers.

For a more visual demonstration of implementing live inventory software with Xero, be sure to check out the video below.

Alternatively, if the status of your invoices and quotes is what triggers your manufacturing orders in your current workflow, then we’d recommend checking out Zapier, which allows you to manage your Xero orders in Katana.

If you don’t yet have an account but want to see it in action, request a demo today.