What is electronics contract manufacturing?

Are you a manufacturer looking to outsource your electronic components? Keep reading to find out all there is to know about electronics contract manufacturing and ‘watt’ it could mean for your business.

Henry Kivimaa

Many kids grow up wanting to become inventors, building gadgets for secret agents and machines for supervillains. Once reality hits in the form of a failed physics test, the dream slowly starts to evaporate. But wouldn’t it be nice to outsource all the difficult work and enjoy the creative process?

There actually is a solution, and it’s ‘shockingly’ simple — electronic contract manufacturing.

What is a CEM manufacturer?

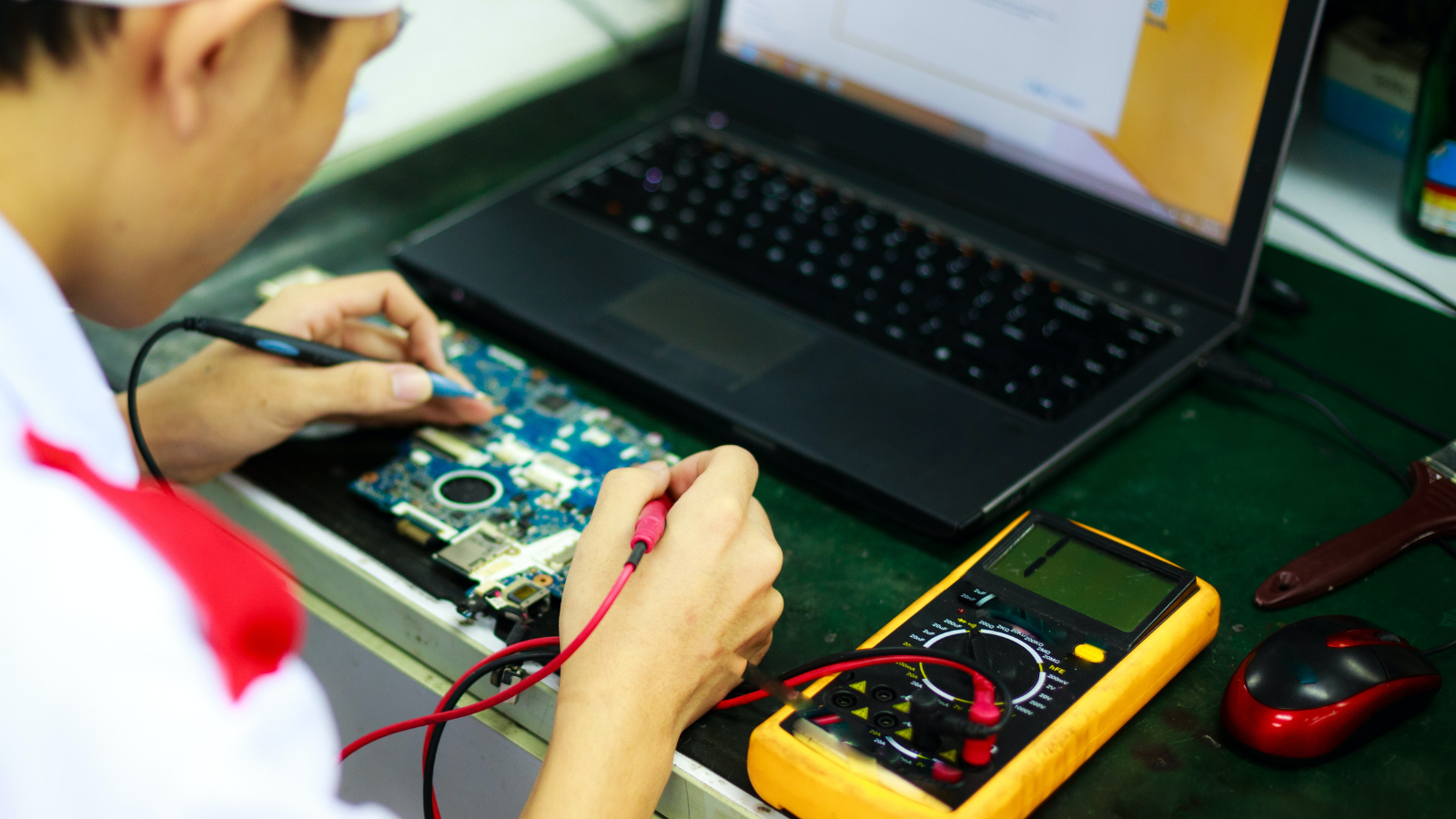

A CEM (Contract Electronics Manufacturer) is a business that specializes in providing custom design, engineering, and manufacturing services for electronic products. Many CEMs offer a wide range of services, from component design to assembly, testing to packaging.

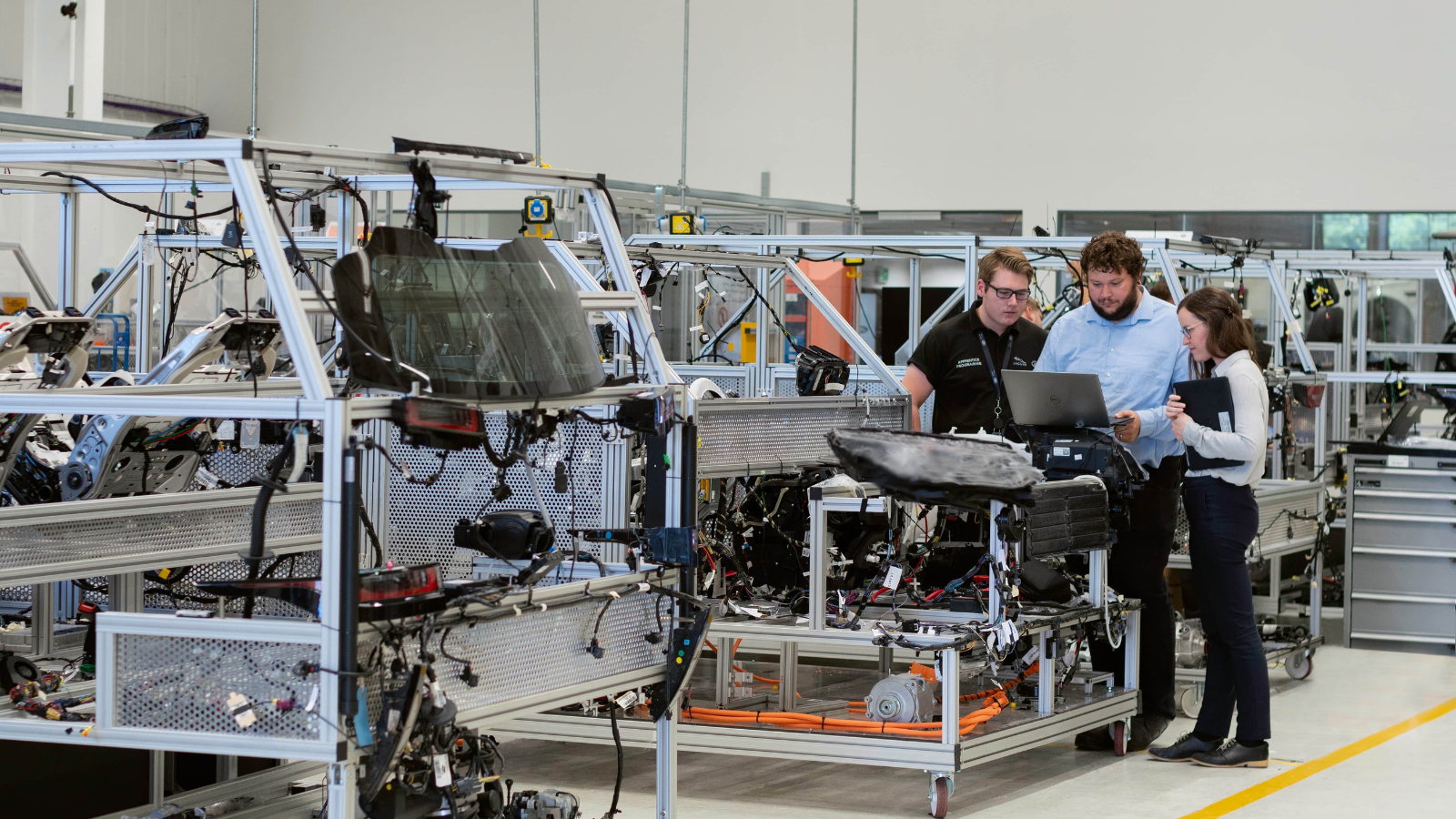

By utilizing outsourced electronics contract manufacturing for product development, businesses can focus their resources on more essential matters while leaving electronics manufacturing in the capable hands of their partners.

What does EMS mean in manufacturing?

EMS, or Electronic Manufacturing Services, is the collective name for all processes and services used to create electronic assemblies. This includes operations like:

- Surface Mount Technology (SMT) assembly

- Printed Circuit Board (PCB) assembly

- Electronic enclosure design and build

- System integration of multiple sub-assemblies

- Testing and verification of the product

EMS allows manufacturers to outsource the production of their products so they can focus on more essential business operations such as research and development, marketing, and sales.

What are the benefits of electronic contract manufacturing?

There are several benefits of outsourcing your EMS. This includes:

- Cost efficiency — Electronics contract manufacturers have the required knowledge, tools, and facilities to manufacture large quantities of electronic components. This results in lower material costs, reduced waste, and improved efficiency.

- Faster time-to-market — CEMs have the capacity to amp up production and deliver finished products on time. This is particularly important in the fast-paced electronics industry, where it’s essential to get new products to market quickly.

- Quality control — CEMs have extensive quality control checks in place to ensure that electronic components meet industry standards and customer specifications. This helps to ensure the production of high-quality electronic products.

- Reduced risk — Electronics contract manufacturers can help reduce the risk of manufacturing failures, supply chain disruptions, and logistical issues. By outsourcing your electronic manufacturing needs to a CEM, you can focus on your core competencies while leaving the manufacturing to the experts.

What is the difference between OEM and CEM?

OEM stands for Original Equipment Manufacturer and means a company that produces parts and equipment sold to another company to be used as part of their own product.

CEM is an organization that specializes in providing full-service custom design, engineering, and manufacturing services for electronic products.

OEMs typically will only manufacture the parts that make up the final product, while CEMs often provide more comprehensive services such as assembly, testing, sourcing, and packaging. Both OEM and CEM companies are involved in the manufacturing process, but their most significant differences lie in their customer base and the type of services they offer.

Amp up your manufacturing with Katana

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Manage your CEM needs with Katana

Even after outsourcing some of your manufacturing, it’s important to have an accurate overview of your entire production flow. Many businesses turn to software solutions due to them being more reliable and relatively effortless compared to spreadsheets and tedious paperwork.

One of the ways to amp up your electronics business is Katana. It is a cloud-based, all-in-one solution to manage your manufacturing business. Take a look at some of the features that Katana offers.

Inventory tracking

Get a live overview of your stock levels, whether it’s raw materials, parts, or finished goods. This helps you keep an eye on your own products as well as the incoming electronic components.

Track your product lifecycle from manufacturing to sales and, in case of a recall, trace back to the batch to remove any items from retail shelves.

Production scheduling

Prioritize your manufacturing based on customer demand, sales trends, and inventory levels. Just because part of your manufacturing is outsourced doesn’t mean you shouldn’t stick to deadlines. Katana helps you create tasks and schedules for your entire team to follow.

Having a schedule in place will help you plan your own processes as well as keep an eye on manufacturing partners.

Shop floor control

After creating tasks and schedules for the entire team, you can give your shop-level workers access to the Shop Floor App. There they can see all their assignments — those to be done as well as those already completed.

The Shop Floor App gives the operators an overview of the materials they will be working with and the exact operations that need to be completed. Once the task is marked done in the app, it automatically triggers a status and inventory change in Katana, if applicable.

This streamlines your manufacturing processes without you having to be present for each step. At the same time, you still have a clear overview of the manufacturing status and have a chance to reprioritize and reassign tasks if necessary.

Barcode systems

Katana supports barcodes in manufacturing and inventory management. This means you can attach barcodes to almost every step of your production, thereby improving your workflows.

Implementing a barcode system with your electronics contract manufacturing partners will speed up the processes of accepting incoming shipments and integrating them into your manufacturing.

Integrations

Katana has numerous integrations, all carefully hand-picked to optimize different areas of your business — from automation to accounting, e-commerce to shipping.

If you’re already using tools that support your cooperation with external partners, Katana’s open API allows you to build a custom workspace to fulfill the specific needs of your business.

Get Katana and be ohm-azed!

Katana will help your business reach its full potential. Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control