Manufacturing assembly line: Understanding it from start to finish

Manufacturing assembly lines are the poster child of production set-ups. But why do manufacturers still use them and what are the different types?

James Humphreys

Fads and ways of working come and go.

A way of doing something can become outdated because of societal changes, inefficiencies, and a billion other different reasons. However, that isn’t the case for some things. Some things manage to stand the test of time, and this is an example of one of them:

The assembly line in manufacturing was originally created in 1913 and is still going strong to this day — albeit with modifications and different variations on the original concept.

So, in this article, we’re going to look into the manufacturing assembly line, from what it is, the different types, and the benefits.

What is an assembly line in manufacturing?

An assembly line manufacturing process is a series of individual workers assembling a product, each performing a specific task in a particular sequence.

The product moves along a conveyor belt or line, with each worker adding a new component or performing a specific action until the product is complete. This system was pioneered by the Ford Motor Company in the early 20th century, allowing for the efficient and standardized production of automobiles on a mass scale.

The assembly line definition in a nutshell

A manufacturing process known as an assembly line involves the sequential assembling of a product at a number of workstations, each of which carries out a particular task or operation. The assembled product moves along a conveyor belt or production line until completion.

The manufacturing assembly line concept has since been adopted by many industries, from electronics to food production, to increase efficiency, reduce costs, and improve quality control.

Download the ultimate manufacturing e-book for manufacturers

Learn how to organize and scale your manufacturing.

What is the difference between manufacturing and assembly line?

Manufacturing is a broader term that refers to the entire process of creating a product, from the initial design phase to the final assembly of the finished product.

It encompasses all the activities involved in producing a product, including:

- Research and development

- Design

- Production planning

- Sourcing of raw materials

- Fabrication

- Assembly in manufacturing

- Testing

- Quality control

An assembly line is a specific manufacturing process used to mass-produce standardized products.

It is a highly organized and efficient system sequentially assembles products using workers, machines, and tools. The workers along the assembly line perform specific tasks as the product moves along the line, such as:

- Attaching components

- Welding

- Painting

Pro tip: The interchangeable terms don’t stop there. There’s also often confusion between production and manufacturing. Be sure to check out this article on Production vs manufacturing: what’s the difference?

What’s the benefit of using manufacturing assembly lines?

The use of a manufacturing assembly line can provide several benefits for a business, including:

1. Increased productivity

Assembly lines allow for the efficient production of goods at a faster rate than traditional manufacturing methods. This is due to the linear arrangement of workstations and the division of labor among workers, which helps to streamline the production process and increase efficiency.

2. Reduced labor costs

Using assembly lines can reduce labor costs by minimizing the number of workers needed to manufacture a product. This is because each worker or workstation performs a specific task or operation, reducing the training and skill required for each worker.

3. Consistent product quality

Assembly lines help to ensure consistent product quality by standardizing the production process. This is because each workstation is responsible for a specific task or operation, which helps to ensure that the same process is followed for each product.

4. Reduced waste

Assembly lines can help to minimize waste by optimizing the production process and reducing the number of errors or defects in the production process. This helps reduce the time and resources needed to manufacture a product.

5. Increased production volume

Assembly lines enable businesses to produce goods at a larger scale than traditional manufacturing methods. This is because assembly lines are designed to be highly efficient and can produce goods much faster.

What are the different manufacturing assembly line examples?

There are several types of manufacturing assembly line systems used in manufacturing, including:

1. Continuous flow assembly line

The continuous flow assembly line is used to mass produce a single product. The materials and components move along the assembly line continuously, and the finished product is created as it moves down the line.

2. Cellular assembly line

A family of products or product variations on a cellular assembly line are produced in small batches. Each cell or workstation is responsible for a particular task or operation, and the finished product is assembled by combining the work of multiple cells.

3. Balanced assembly line

Balanced assembly line workstations are arranged in a specific sequence in this manufacturing assembly line. The time required for each workstation is balanced to ensure that no workstation is overburdened while others remain idle. This helps to optimize production and minimize waste.

4. Flexible assembly line

The flexible assembly line is designed to produce various products with different configurations and features. The flexible assembly line can be easily reconfigured to accommodate product design or demand changes.

5. Automated assembly line

An automated assembly line uses robotics and other advanced technologies to automate the manufacturing process, reducing the need for human labor and increasing efficiency.

A manufacturer’s choice of assembly line depends on factors such as product type, production volume, and desired automation level.

What is a production line and an assembly line?

Although “production line” and “assembly line” are frequently used synonymously, there is a little distinction between the two.

A production line is a manufacturing process that is designed to produce a particular product or a range of similar products. It typically involves a series of workstations or operations, each performing a specific task in the production process. The materials or components move along the production line, and each workstation adds value to the product until the final product is complete.

On the other hand, an assembly line is a specific type of production line characterized by a linear arrangement of workstations, each of which is responsible for a particular task or operation in the production process. The materials or components move along the assembly line, and each workstation performs a specific operation on the product until the final product is assembled.

So, long story short, a production line is a broader term that can refer to any manufacturing process that produces a particular product or a range of similar products. In contrast, an assembly line is a specific production line that uses a linear arrangement of workstations to assemble a final product.

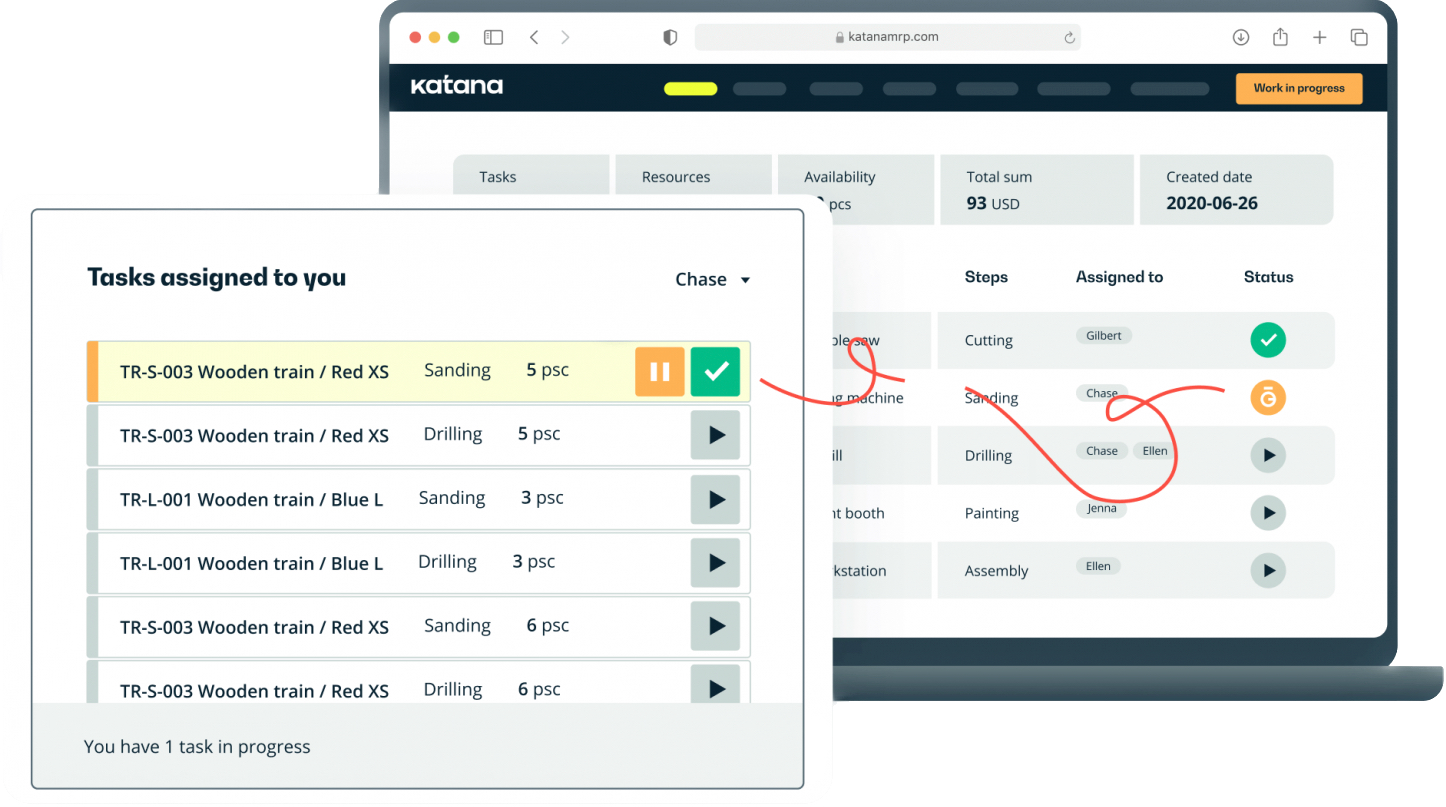

Using software within your manufacturing assembly line

Katana cloud manufacturing software is designed to help small and medium-sized manufacturers manage their production, inventory, sales, and other manufacturing business processes in a centralized system.

The software provides real-time inventory control, automatic production scheduling, and a visual interface to track orders, materials, and product availability. It also features integrations with popular e-commerce platforms and accounting software like QuickBooks Online, enabling manufacturers to streamline operations and reduce manual data entry.

Katana’s main features include:

- Bill of materials management

- Inventory control

- Order tracking

- Production scheduling

- Sales management

The software is versatile and accessible for manufacturers because it is made to be user-friendly and accessible from anywhere with an internet connection.

And there you have it! Everything you need to know about manufacturing assembly lines. Contact us at any time if you have any questions. And until then, happy assembling.

Save time and money by automating your processes

Get automatic manufacturing cost calculations with Katana, including live inventory management, real-time production planning, and more essential manufacturing features.

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control