Supply chain sustainability: The why’s and how’s

As the world progresses, businesses are placing more emphasis on reducing their environmental impact and embracing ethical responsibility. Supply chain sustainability is a critical component of this effort. In this article, we’ll explore the importance of sustainability and examine how companies are integrating it into their supply chains.

Henry Kivimaa

We know that supply chains and sustainability may not be the sexiest topics out there, but neither is the end of the world.

With the planet facing more frequent and intense natural disasters, it’s becoming increasingly clear that our current manufacturing supply chain practices are not sustainable. The effects of climate change, such as droughts, floods, and storms, interrupt supply chains across the globe, while manufacturing itself is largely to blame for these catastrophes. According to EPA, the industrial sector (including manufacturing) made up 23% of total greenhouse gas emissions in the United States in 2021.

If we don’t take action now, we may face a dystopian future where goods and services are scarce, buildings are collapsing, and a lone survivor like Mad Max wanders the barren wasteland.

But it’s not all doom and gloom.

There are steps that companies and individuals can take to improve supply chain sustainability and mitigate the risks of a catastrophic future. This means taking a hard look at how things are being done and what we can do to minimize the negative effects on the planet. By working together to create more sustainable supply chains, we can not only avoid a post-apocalyptic future but also create a better world for us and our children.

What does sustainability mean?

Sustainability refers to the ability to meet the needs of the present without compromising the ability of future generations to meet their own needs.

It is based on the recognition that the Earth’s resources are finite and that human activities can have a significant impact on the environment and society. Practicing sustainability means guaranteeing that the needs of the current generation don’t overshadow the quality of life for future generations. It shouldn’t be about a green footprint but creating a whole green path for future generations to follow. (Amen!)

Sustainability involves balancing economic, social, and environmental considerations to create long-term value for the planet, people, and businesses.

Environmentally, sustainability involves using natural and renewable resources to preserve their availability and quality for future generations. Socially, sustainability means promoting justice, human rights, and equity. From an economic perspective, sustainability should create value for businesses and society through innovation, efficiency, and long-term planning.

You could say that with more wind generators and turbines popping up around the globe, sustainability is gathering more and more fans.

It is increasingly important as the global population grows and natural resources become more scarce. Businesses, governments, and individuals recognize the need to adopt sustainable practices to create a more resilient and equitable future. This involves taking a more holistic approach to decision-making and balancing human and business considerations in a way that creates long-term value.

What is supply chain sustainability?

The sustainability of a supply chain is crucial in promoting environmentally and socially responsible practices.

It involves ensuring that companies prioritize the welfare of the planet and people while producing the goods that we enjoy. It is a collaborative effort where companies choose suppliers who share their values and employ ethical methods. For instance, a clothing company may opt for a cotton supplier that uses organic farming methods, which avoids harmful chemicals and conserves water.

Another aspect of sustainability is reducing waste and pollution.

One example is implementing a closed-loop system where a company recycles and reuses its own materials to reduce manufacturing waste and minimize the need for new resources. A tech manufacturer can recycle old electronics to make new products instead of discarding them. Plastic bottles are often gathered after use and remelted into new containers.

Finally, it is crucial to ensure that every stakeholder is treated fairly, enjoys the experience, and stays safe.

A fair and safe supply chain operates with transparency, integrity, and respect for everyone’s rights. It ensures workers are treated fairly, get a living wage, and have safe working conditions. This also goes for animals related to the process, like getting down feathers used in jackets from farms that treat their birds humanely.

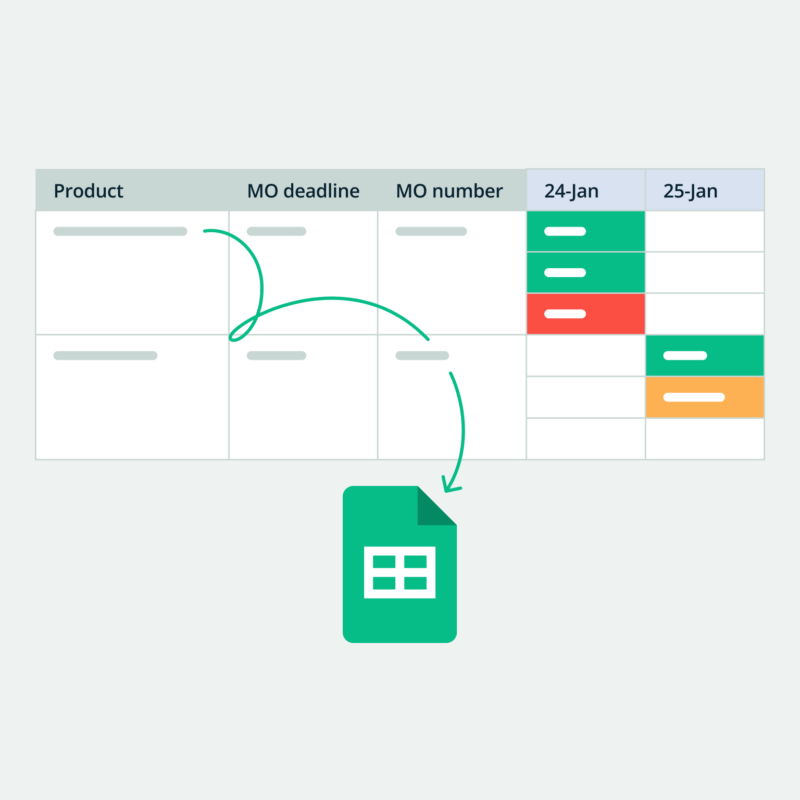

Optimize your manufacturing with a production schedule template

Download a free production schedule Excel template and start planning your manufacturing effortlessly. Eliminate inefficiencies and minimize waste while maximizing productivity.

How to make your supply chain more sustainable?

Making your supply chain more sustainable can involve a range of strategies and actions that aim to reduce the environmental and social impacts of your operations. Here are some steps you can take.

Assess your current supply chain

Start by mapping out your supply chain and analyzing the environmental and social impact of each stage. Identify areas of improvement and prioritize actions based on their potential impact and practicality.

Set sustainability goals

Establish measurable objectives and targets for reducing your environmental impact and improving social responsibility. Consider using established frameworks such as the UN Sustainable Development Goals or GRI Standards to guide your goal-setting process.

Engage with suppliers

Work closely with your suppliers to promote sustainable practices throughout the supply chain. Encourage them to adopt eco-friendly and socially responsible policies and practices. Consider establishing a supplier code of conduct that outlines your expectations and standards.

Reduce waste and emissions

Implement measures to reduce manufacturing waste and greenhouse gas emissions in your supply chain. This often means using more efficient transportation methods, minimizing packaging, or investing in renewable energy sources.

Adopt circular economy principles

Consider adopting circular economy principles that aim to keep resources in use for as long as possible and minimize waste. This could involve using renewable materials, designing products for disassembly, or implementing recycling programs.

Ensure compliance with regulations

Stay up to date with relevant environmental and labor regulations and ensure that your operations and suppliers stick to them. Conduct audits and adopt third-party certifications to verify compliance.

Monitor and report on progress

Regularly monitor your progress towards your sustainability goals and report on your performance to stakeholders. Use data and metrics to track your impact and identify areas for improvement.

What are the business benefits of a sustainable supply chain?

A sustainable supply chain can benefit your business, the environment, and society. Here are some key advantages.

Reduced costs

Adopting sustainable practices such as waste reduction, energy efficiency, and responsible sourcing can help reduce manufacturing costs in the long run. For example, reducing packaging and transportation can lower shipping costs, while energy-efficient manufacturing can save on electricity bills.

Improved brand reputation

A sustainable supply chain can enhance your brand reputation and help you differentiate yourself from competitors. Consumers are increasingly conscious of sustainability issues and are more prone to supporting brands that prioritize responsible practices.

Increased customer loyalty

You can build stronger relationships with customers who share your values by demonstrating your commitment to sustainability. This can lead to an increase in customer loyalty and repeat business.

Mitigated risks

A sustainable supply chain can help you reduce risks associated with environmental and social issues such as climate change, resource scarcity, and labor abuses. By proactively addressing these issues, you can avoid legal, financial, and reputational risks.

Enhanced innovation

Adopting sustainable practices can spur innovation and creativity within your organization. By challenging traditional business methods, you can identify new opportunities and develop innovative products and services.

What are the challenges of supply chain sustainability?

While there are many benefits to a sustainable supply chain, there are also several challenges that businesses may face when trying to implement sustainable practices. Here are some of the key challenges.

Complexity

Supply chains can be complex and involve many stakeholders, making it challenging to implement sustainable practices across the entire chain. Coordinating with suppliers and other partners often requires significant effort and resources.

Cost

Implementing sustainable practices can require upfront investment and may be more expensive than traditional practices in the short term. This can be a barrier for smaller and medium-sized businesses that don’t have the resources to invest in sustainable infrastructure yet.

Standards and certifications

A lack of universal standards and certifications for sustainability can make it difficult for businesses to measure and compare their sustainability performance. This can also make it challenging to communicate their sustainability efforts to customers and stakeholders.

Consumer awareness

While there is growing awareness around sustainability issues, many consumers may not be aware of the environmental and social impacts of supply chains. This makes it difficult for businesses to communicate the importance of sustainability to their customers.

Regulatory compliance

Compliance with environmental and labor regulations can be a challenge, especially for businesses operating in multiple jurisdictions with different regulations. Failure to comply with regulations can result in legal and financial consequences.

Supply chain transparency

Achieving transparency across the supply chain can be challenging, especially for businesses with complex global supply chains. This can make it difficult to identify and address sustainability issues at different stages of the supply chain.

What are the environmental impacts of a sustainable supply chain?

From raw materials extraction to product disposal — every stage of the supply chain can potentially harm the environment. However, with sustainable practices, businesses can reduce their ecological impact and protect the planet for future generations.

Carbon emissions

The production, transportation, and distribution of goods are responsible for significant greenhouse gas emissions. These emissions contribute to global climate change and have a negative impact on the environment. Sustainable practices such as using renewable energy, optimizing transportation, and reducing waste can help businesses to reduce their carbon footprint.

Waste

Throughout the supply chain, there is the potential for waste to be generated, from packaging materials to defective products. Sustainable practices such as reducing packaging, recycling, and using more sustainable materials can help to reduce waste and minimize the environmental impact of the supply chain.

Water use

Many products require significant amounts of water for production, and water shortages are becoming an increasing concern in many parts of the world. Sustainable practices such as water-efficient production methods and responsible water sourcing can help minimize wasting water resources.

Disposal

Companies committed to sustainability must consider the end-of-life of their products and packaging, as well as the disposal of any waste generated throughout their operations. Proper disposal methods, like recycling and composting, can help minimize the environmental impact of a supply chain.

Which companies have a sustainable supply chain?

Some companies are already implementing sustainability in their supply chains and paving the way for others to follow in their green footprints. Here are a few.

Patagonia

Patagonia is a well-known outdoor apparel brand that greatly emphasizes sustainability as a primary aspect of its business.

The company has taken numerous steps to reduce its carbon footprint, including implementing renewable energy sources in its facilities, reducing water consumption, and recycling waste. Patagonia also prioritizes transparency in its supply chain by providing customers with detailed information about the origin and manufacturing process of its products. As a result, they have seen increased customer loyalty and brand recognition and have even reported higher profits in recent years.

In addition to its own efforts, Patagonia has partnered with other organizations to promote sustainable supply chain practices across the industry.

For example, they are a member of the Sustainable Apparel Coalition and the Fair Labor Association. Both aim to improve social and environmental practices in the apparel industry. Patagonia has also launched a program called the Footprint Chronicles, allowing customers to trace the supply chain of their products and learn about the environmental and social impacts of each stage of production.

IKEA

IKEA has made significant efforts toward sustainable supply chain management.

The Swedish furniture retailer has based its approach to sustainability on a People and Planet Positive strategy, outlining ambitious goals to reduce its environmental impact and improve social conditions in its supply chain. Some of IKEA’s key initiatives are to use 100% renewable energy and recycled materials in its operations to become a climate-positive business by 2030. In order to achieve this, they have heavily invested in renewable energy sources, such as wind and solar power.

IKEA also strives to ensure that its products are made from eco-friendly materials and that they are manufactured under fair labor conditions.

Besides striving for sustainability goals, IKEA has adopted a transparent method in its supply chain management. The company publishes an annual sustainability report, providing detailed information on its environmental and social impacts, as well as progress toward its sustainability targets.

Unilever

Unilever, a global consumer goods company, has reached ambitious sustainability targets for its supply chain, including sustainably sourcing all its agricultural raw materials in 2023.

The company’s Sustainable Living Plan outlines ambitious goals to improve the environmental and social impact of its products, with a target of achieving net-zero emissions from its products by 2039. To achieve this, they have implemented various initiatives, including using renewable energy sources in operations, reducing waste and water consumption, and promoting sustainable agriculture. They are working closely with suppliers and investing in sustainable farming practices.

As a result, Unilever has seen improved supply chain flexibility, better access to raw materials, and increased brand loyalty.

They are committed to ensuring fair labor conditions and sustainability standards in product manufacturing and supply chain. The company has established the Unilever Sustainable Agriculture Code and partnerships with organizations such as Rainforest Alliance and Solidaridad to promote sustainable agricultural practices across its supply chain. Unilever, similarly to IKEA, is very transparent in its supply chain management, releasing a yearly report that offers in-depth insights into its sustainability goals.

Interface

Interface, the world’s leading modular flooring manufacturer, is a company committed to sustainable practices.

It has been a pioneer in promoting sustainability in its supply chain, introducing the Mission Zero sustainability program in 1994. The program aims to eliminate all negative environmental impacts of the company’s operations. Interface has adopted various innovative strategies to achieve this goal, including investing in renewable energy sources, implementing eco-friendly manufacturing processes, and developing sustainable product design.

Interface has also been a champion of sustainable sourcing practices.

The company is dedicated to procuring materials from sustainable sources and has established Environmental Product Declarations (EPD) to provide transparent data on the environmental impact of its products. Interface is also committed to engaging with suppliers to adhere to sustainability standards. Their actions demonstrate that sustainability and profitability can go hand in hand and that businesses can play a critical role in promoting sustainable practices across their supply chains.

Nestlé

Nestlé has taken significant steps to improve its supply chain sustainability recently.

The company has set impressive targets to reduce its environmental impact, promote sustainable sourcing, and improve working conditions throughout its supply chain. For example, Nestlé has committed to using 100% responsibly sourced cocoa by 2025 and has implemented programs to promote sustainable coffee and palm oil production. The company also aims to achieve zero waste across its operations by 2030.

However, Nestlé has faced criticisms and challenges in its sustainability efforts.

In 2018, the company was accused of not addressing child labor in its cocoa supply chain. In 2020, it faced a lawsuit alleging that it knowingly benefited from forced labor in its seafood supply chain. Although Nestlé has even been named one of the most hated companies in the world, their sustainability standards and plans, in theory, are an excellent benchmark for all businesses to follow.

Pro tip: Check out other supply chain disruption examples that have rocked the global supply chain from 2018 to 2023.

How can Katana help your business with supply chain sustainability?

Katana is a cloud inventory platform that can help your business move toward sustainable supply chain management and set up green manufacturing in several ways.

Efficient production planning

Katana production planning feature allows you to schedule manufacturing more efficiently by providing real-time insights into inventory levels, lead times, and production capacity. This helps reduce overproduction and waste of resources, contributing to a more sustainable supply chain.

Inventory management

Katana’s inventory management enables you to keep track of inventory levels and avoid stockouts or excess inventory. By following live stock updates, you can enhance the efficiency of your supply chain and minimize waste.

Shop-level control

Katana Shop Floor App gives managers shop-level control and operators access to their tasks, allowing teams to work and meet goals together. The Shop Floor App can be accessed via any smart device, allowing for more flexibility and increased efficiency. This can reduce waste and energy consumption, ultimately contributing to a more sustainable supply chain.

Reporting

Katana provides detailed insights on production efficiency, inventory levels, and material usage. These reports give you manufacturing analytics and help identify areas where sustainability and processes could be improved.

As exciting as apocalypse movies are, seeing it and living it are very different things. The traditional image of a smoking factory chimney will eventually cost us all, so let’s start breaking stereotypes instead of the ozone layer. Sorry, Will Smith, but you will have to wait.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control