Cosmetics manufacturing: How to build your foundation

From conception to shipping your products. This is the ultimate guide to building up your cosmetics manufacturing business.

James Humphreys

If you’re looking to build a global cosmetics manufacturing empire from scratch or optimize your current business, look no further.

This article explores how those passionate about making cosmetic goods can build their business — or make their current business more efficient — from conception to packaging and shipping global cosmetics inventory to their eagerly awaiting customers.

What is cosmetics manufacturing?

Understanding the regulations that apply to your set of cosmetic products is vital to making sure the business runs smoothly. Cosmetics manufacturers often use cosmetics manufacturing software to track their materials and ensure they are always compliant.

Cosmetic products are those that we use on a daily basis to help cleanse and beautify our bodies. Whether that be lipstick, moisturizers, facial masks, concealer, foundation, and so on.

Technically, it also includes shampoos, conditioners, and hair products too.

As long as it applies externally to our bodies, then it fits.

Generally, they are made from a mix of organic and inorganic compounds, which could include oils, dyes, spices, synthetic colors, and even crushed insects.

And the processes which go into the final products can be incredibly vast too. From emulsifying mascara solution to melting and molding lipstick.

It can often be a complex process with intricate product recipes and precise use of raw materials.

So, as you can imagine, any manufactured products which are intended to be smeared onto our bodies have to be dissected quite carefully. It’s any cosmetics manufacturer’s worst nightmare to be uncovered for lack of quality control and potential contaminations.

That’s why there is a huge emphasis on cosmetics manufacturers to follow regulations and make sure they are testing their products properly.

Alongside the precious modern need for manufacturing branding and marketing efforts, this makes it quite a challenge for cosmetics manufacturers to stay on top of their businesses.

Because not only do consumers want innovative products which are tailored to their needs, but also a brand with which they can connect and rely on.

Next up then, we’ll dive into some of our tips on how you can make sure to spend time on your brand without losing sight of the gritty details which make cosmetics manufacturing so tricky.

The main pillars of cosmetics manufacturing

Before we delve deep into the cosmetics production process, we should highlight the basic production steps a hobbyist or an ambitious start-up will follow if they want to know how to get into cosmetics manufacturing.

The journey towards selling your cleaning and beautifying products will follow these five production process steps from beginning to end:

Developing a business plan

By taking the time to develop a plan, you’ll be in a better position to achieve your goals and grow your business even further.

They typically start with an overview of the cosmetic manufacturing company and its products or services, with market research analyzing the cosmetic markets and the competition. The plan then describes its strategy for growing its business and achieving profitability. Finally, a section on financials usually includes projected income and expenses.

Research and development

Most people think of research and development (R&D) as simply developing new products or improving old ones.

But in reality, R&D is a much broader term that encompasses everything from basic research to applied research to development.

Basic research is the kind of research done with pure curiosity, with no specific application. Applied research is when researchers apply basic research findings to practical problems. And cosmetic development is the actual work of bringing a product or process from idea to reality.

Formulation and ingredients

In cosmetics formulation, it is crucial to consider the ingredients used. Some ingredients may be more harmful than others, and some may not suit certain skin types. Doing your research before selecting ingredients and carefully reading the labels is essential.

Packaging

Packaging for cosmetics is important because it can impact how consumers buy and use beauty products.

For example, if the packaging is attractive and eye-catching, customers might be more likely to purchase the product. In addition, good packaging can help keep cosmetics safe and fresh, which is especially important for perishable items like lipstick or foundation. Finally, well-designed packaging can also communicate the brand’s identity and values, helping to create a connection between the customer and the product.

These factors mean that cosmetic packaging is essential for customers’ positive buying experience.

Delivery

When it comes to shipping makeup and cosmetics, there are a few things you need to take into account.

The first is that different products have different requirements in terms of packaging and handling. Additionally, you’ll need to be aware of any restrictions on what can be sent overseas or locally.

How to get a manufacturing license for cosmetics?

In the US, the FDA regulates the manufacturing process of cosmetics but does not issue FDA registered licenses. It might not even be a requirement for you to have a license. However, if you need a license for cosmetics in your state, you must contact your state or local authorities directly.

The ultimate checklist for your cosmetics manufacturing process

Regardless of if you’re an artisan looking to work from home or a seasoned manufacturer, using the following checklist will help you optimize your cosmetics manufacturing process:

1. Your Budget for the manufacturing process of cosmetics products

A budget is a critical financial tool that helps individuals and families track their income and expenses. It also enables them to make informed decisions about using their resources best.

Here’s how you can calculate your budget:

Calculating product fees

These costs will change from business to business, product to product, and ingredient to ingredient.

You can calculate these fees by looking into your manufacturing costs, allowing you to determine if:

- Your product fees are too high

- Your supplier is overcharging

- You can improve your profit margins by making a change to your cosmetics manufacturing process

Calculating manufacturing overheads

You’ll need to calculate manufacturing overheads to help you set a fairer price for yourself while giving your customers the best deal.

But the cosmetics industry is highly regulated, and those regulations differ from place to place. This is something that you’ll need to factor into calculating your manufacturing overheads. Such as what are the associated costs of:

- Regulations

- Licensing

- Permits

- Insurance coverage

Marketing and advertising

No business is complete without a website.

A website will help you with e-commerce D2C selling and give you visibility on search engines. But what other channels are you going to utilize, and what are the costs of advertising in these spaces? From social media to writing blogs, your approach and how many marketing strategies you use are down to you – and your budget, of course.

But as a rule of thumb, here is a list of essential marketing practices:

- Developing a press kit

- Email marketing

- Social media

A bonus marketing strategy: influencer marketing is extremely popular in cosmetics manufacturing.

Sales channels

We’ve already touched on the importance of having a website – for example, in 2018, digital sales in the US reached a whopping $258.9 million.

Physical stores just aren’t as influential as they used to be. Nowadays, it’s essential to leverage multi or omnichannel sales strategies by selling via:

- E-commerce

- In-person

- Retailers

- Social media

- Online and offline marketplaces

2. Formulation and ingredients in the cosmetics manufacturing process

Formulating is when you smash, mesh, blend, mix, synthesize, and do whatever else you need to do to achieve custom cosmetics manufacturing.

Here are the basics to getting started with formulating and managing ingredients when following a manufacturing process of cosmetics products:

Finding a starting formula

You can think of a formula as your bill of materials in manufacturing terms.

Your formula will be the recipe you need to follow to make your cosmetic products. However, first things first, you need to find a starting point. This could be from online formularies, from your raw materials suppliers, or even create your own.

Regardless of the source, your starting formula isn’t meant to be a finished document but a foundation to build upon.

Define your products

Once you have produced something you like, it’s time to start outlining the product.

For example, what is its purpose? Is it a cleaning product? A moisturizer? A sanitizer? A coloring product or a combination of different factors. Then you can note its aesthetic characteristics like:

- Color

- Thickness

- Clarity

If you have a specific vision of your product, and the final product doesn’t match, then it’s back to redefining your cosmetics manufacturing process and formula.

PRO TIP: cosmetics manufacturing goods can come in the form of lip balms, lip gloss, massage oils, creams makeup, hand sanitizer, makeup remover, body wash, and much more.

3. Cosmetics manufacturing by outsourcing or in-house production

Do you want to be hands-on with your cosmetics manufacturing, or would you prefer to send your formula off to a contract manufacturer and let them do the heavy lifting?

There’s no wrong answer – in fact, combining the manufacturing process of cosmetics products in-house and outsourcing some might be best for you.

The manufacturing process of cosmetics by outsourcing

Contract manufacturing is a business arrangement in which one company hires another to produce goods or services according to the first company’s specifications. Using contract manufacturing software makes it easy to manage inventory and production in supplier locations as well as your own.

This can be done on a short-term or long-term basis and often involves transferring proprietary technology from the hiring cosmetics company to the contractor. Contract manufacturer companies are often used to produce low-volume or customized products. If this is something that you think your business needs, then here are some quick tips for finding contract manufacturers:

- Attend cosmetic conventions

- Explore reputable cosmetics databases

- Look abroad for companies offering white label and private label manufacturing

The manufacturing process of cosmetics in-house

If you have the manufacturing facility to produce your goods from home or your own space, that’s great.

But now you need to take on all the associated responsibilities of manufacturing your own goods. So, where to begin?

Preparing your batch

Determine how many cosmetic products you’ll want to make and how many raw materials you’ll need. Depending on your production lines and business scale, you can do this in inefficient spreadsheets or use cosmetics manufacturing software.

Making your batch

When making your first batch, you should be treating it like a scientific experiment – well, it is a science.

Follow your formula carefully and take notes while going through the cosmetics manufacturing process. Recording your observations will be crucial when you refine the same formula or create new ones for future products.

4. Managing quality control when following the manufacturing process of cosmetics products

Given the fact that your customers are going to be smearing your goods all over their bodies — skin care, body care, or hair care products, for example — you can imagine how important it is to test the quality of your goods during the manufacturing process of cosmetics to avoid them experiencing discomfort.

Testing your batch

Once your batch is ready, let it sit at room temperature and begin taking measurements such as pH and viscosity to make sure everything is in order. Remember to weigh the batch since water can be lost during the heat and cooling process. If you’ve lost too much water during the process, you can top it up.

If you’re wondering how much water does cosmetics manufacturing require? On average, cosmetics goods contain around 60% to 85% water.

Know your regulations

Regulations for cosmetics manufacturing are constantly evolving and changing — with new requirements and restrictions created on a regular basis. Concerns for shelf life and safety of ingredients are only going to rise in the future.

So, the first thing you need to do is to become familiar with your country’s regulatory bodies. For US businesses, your port of call is going to be the FDA, which has more than a few rules regarding ingredients, labeling, and quality control.

You should also become acquainted with regulations abroad, in countries which you are planning to sell. It might initially seem like a tough ladder to climb, but there’s a good reason many have turned to the D2C business model and sold their products abroad.

The second point is that you take the time to implement practices that put these regulations at the forefront of your business’s consciousness at every turn.

Make sure quality control is being practiced in every stage of production and that you are using manufacturing software to track the appropriate use of materials.

Ultimately, it’s essential to your business to ensure your products comply with local and international regulations and that your product’s labels are compliant too.

5. Packaging your cosmetics products

Finally, once every manufacturing process for cosmetics products is followed and compliant, it’s time to ship them off for your customers to enjoy.

Storage

When a batch is finalized, there’s a high likelihood that you’ll need to keep products at your own storage facility before they’re shipped off.

That’s why it’s important to keep your warehouse and storage space organized to keep your carrying costs low. Also, your cosmetic goods will need certain requirements to stay fresh. Make sure the conditions of your warehouse won’t affect the quality of your products.

Shipping

Once you have some sales orders to fulfill, now is the time to ship your products.

Many cosmetic goods are prone to damage during transit. To keep it protected, you should consider packing makeup in dunnage, bubble wrap, or other leaks proof-packaging material. Just don’t forget to take out shipping insurance – it might cost extra, but if your items become damaged, at least the costs aren’t coming out of your pocket.

And with that, this concludes all the necessary things you’ll need to do to join other success stories as businesses involved with cosmetics manufacturing.

The next and very final step is finding a tool that can help you optimize your cosmetics manufacturing process and centralize your entire business.

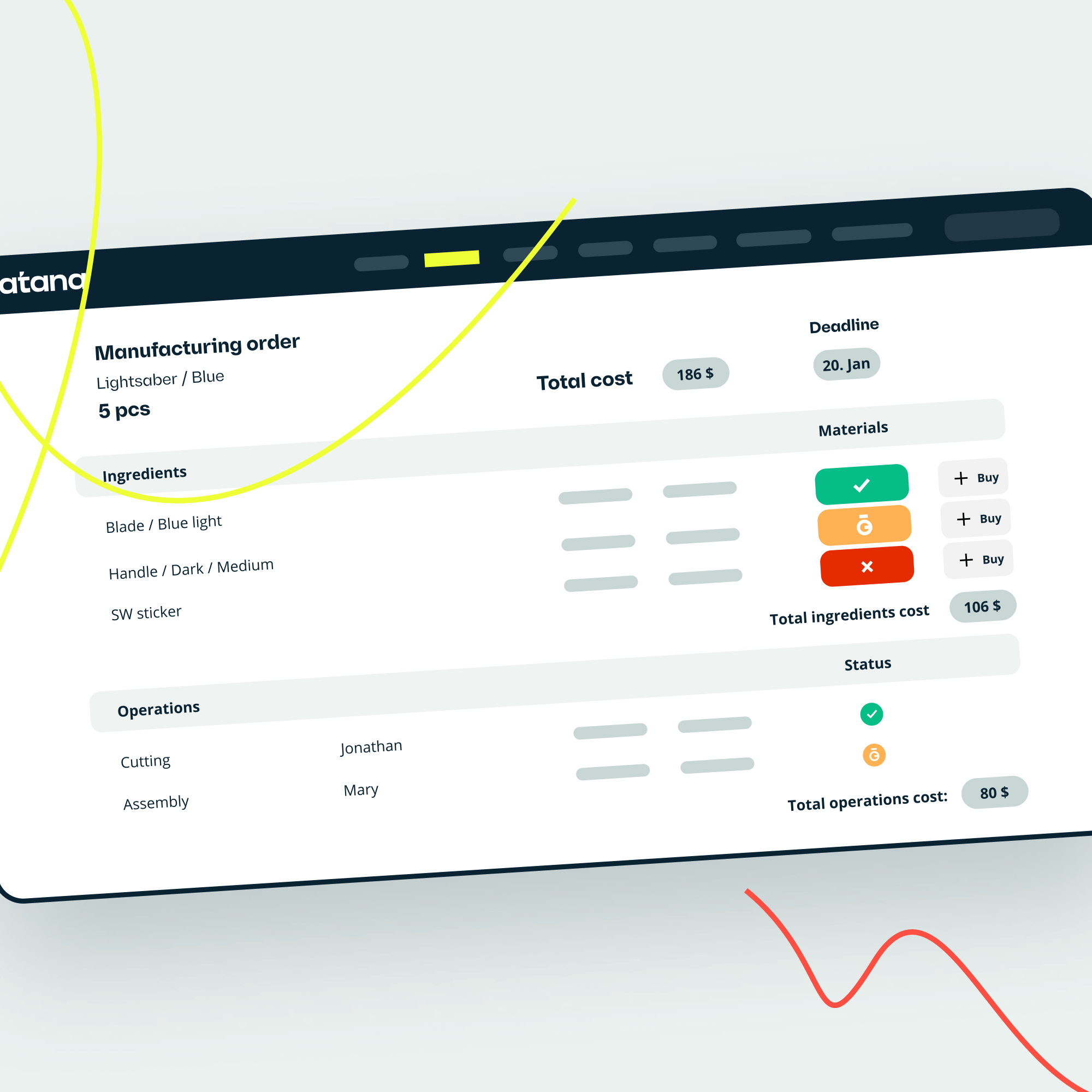

Katana cloud inventory software

Book a demo to get all your questions answered regarding Katana’s features, integrations, pricing, and more.

Katana cloud manufacturing software for cosmetics manufacturing

With fierce competition, it’s important to examine cosmetics industry trends to get ahead of competitors – and without the proper support systems in place, this will be an uphill battle.

Introducing Katana cosmetics manufacturing software, an inexpensive but high-quality solution for managing your entire business. From inventory to shop floor operations management, order fulfillment, and more. Katana enables manufacturers to scale their cosmetics business with:

- Priority-based batch production planning

- Raw material handling, WIP, and finished products inventory tracking

- Features for tracking individual items and batches

- Tools for tracking expiry dates of items

To name just a few.

Katana support 1000’s of businesses working in different areas of the manufacturing industry. Book a demo and see how Katana can work for you.

James Humphreys

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control