Production planning KPIs: Your roadmap to success

Production planning KPI is vital for evaluating performance, identifying areas for improvement, and making data-driven decisions to optimize production processes and drive overall business success. Read on to learn all about production planning KPIs.

Henry Kivimaa

Effective production planning is essential for businesses to streamline their operations, meet customer demands, optimize resources, and maintain a competitive edge in the market. Key performance indicators (KPIs) play a crucial role in evaluating the performance and success of production planning strategies.

This blog post delves into the world of production planning KPIs, exploring their significance and some production planning KPI examples used to measure performance in this domain.

Whether you are a production manager, business owner, or simply interested in understanding how production planning works, this guide will provide valuable insights into the key metrics used to assess and improve production planning processes.

What is production planning KPI?

Production planning KPI is a measurable metric used to evaluate and assess the performance and effectiveness of production planning processes within a business or manufacturing environment. This metric provides insights into various aspects of production planning, enabling businesses to measure their performance, identify areas for improvement, and make data-driven decisions to optimize operations.

Production planning KPIs can encompass a wide range of metrics, which can be categorized into different areas based on their focus and purpose.

Why are production planning KPIs important?

Production planning KPIs serve as valuable tools to gauge the effectiveness of production processes, identify areas for improvement, and make informed decisions to optimize operations. By measuring and tracking specific performance indicators, businesses can:

- Evaluate efficiency — KPIs enable organizations to assess the efficiency of their production planning processes. By measuring metrics such as production yield, cycle time, and throughput, companies can identify bottlenecks, optimize workflows, and enhance overall productivity.

- Monitor quality — Quality metrics, such as defect rate, first pass yield (FPY), and customer reject rate, provide insights into product quality. Monitoring these KPIs helps businesses identify quality issues, implement corrective actions, and ensure customer expectations are met or exceeded.

- Manage inventory — Effective inventory management is crucial for minimizing costs and maintaining sufficient stock levels. KPIs like inventory turnover ratio, stockout rate, and days of inventory on hand (DOH) provide visibility into inventory performance, enabling businesses to optimize stock levels, reduce waste, and improve cash flow.

Key performance indicators in production planning

Production planning KPIs encompass a wide range of metrics that capture different aspects of the production process. These KPIs can be categorized into several key areas. Let’s go over some of these categories.

Efficiency metrics

Efficiency KPIs measure the utilization of resources, time, and equipment to assess the productivity and effectiveness of production planning. Examples include:

- Production yield

- Overall equipment effectiveness (OEE)

- Cycle time

- Throughput

Quality metrics

Quality KPIs focus on the accuracy and reliability of production processes and outputs. These help organizations monitor and improve product quality. Some quality metrics are:

- Defect rate

- First pass yield (FPY)

- Customer reject rate

By diligently following quality metrics and your production quality control checklist, you can be sure you’re only sending out products with high quality standards

On-time delivery metrics

On-time delivery KPIs measure the ability of production planning processes to meet customer delivery expectations. Key metrics in this category are:

- On-time delivery performance

- Order fill rate

- Perfect order index (POI)

These provide insights into order fulfillment efficiency and customer satisfaction.

Download a free production schedule template

Download this free production scheduling template to ensure you reach your KPI for production planning department.

Inventory management metrics

Inventory management KPIs measure the performance of inventory control and stock management processes. These provide insights into inventory efficiency, availability, and cost optimization. Inventory management KPIs include:

- Inventory turnover ratio

- Stockout rate

- Days of inventory on hand (DOH)

Resource utilization metrics

Resource utilization KPIs focus on assessing the utilization and efficiency of labor and equipment in production planning. Metrics such as:

- Labor utilization

- Machine utilization

- Capacity utilization

These help businesses optimize resource allocation, identify potential bottlenecks, and maximize productivity

Cost metrics

And the final category groups cost metrics. These production planning KPIs evaluate the financial performance and cost efficiency of production processes. These metrics help businesses track production costs, identify cost-saving opportunities, and ensure profitability. Examples of cost KPIs are:

- Cost per unit

- Production cost variance

- Return on investment (ROI)

By categorizing production planning KPIs into these key areas, businesses can comprehensively assess and analyze different aspects of their production processes.

Monitoring these metrics provides valuable insights into performance trends, highlights areas for improvement, and enables data-driven decision-making to enhance production planning strategies.

Looking for specific KPIs?

If you want to dig deeper into specific KPIs, be sure to check out this article about the 24 manufacturing KPIs.

Monitoring and reporting production planning KPIs

Establishing a robust monitoring and reporting system is crucial to utilize production planning KPIs effectively. Here are some key considerations for monitoring and reporting production planning KPIs.

Data collection

Ensure that accurate and reliable data is collected for each KPI. Utilize data collection tools and systems that capture real-time information from various stages of the production process.

Data analysis

Regularly analyze the collected data to identify performance trends, patterns, and areas for improvement. Use data visualization techniques such as charts, graphs, and dashboards to present the production planning KPI results in a clear and understandable format.

Frequency of reporting

Determine the appropriate reporting frequency based on the nature of your production operations. Some KPIs may require daily or weekly reporting, while others can be monitored monthly or quarterly.

Stakeholder engagement

Involve relevant stakeholders, including production managers, supervisors, and executives, in the monitoring and reporting process.

Ensure that the KPI results are shared with the appropriate individuals or teams, fostering accountability and encouraging collaboration in driving improvement initiatives.

Performance reviews

Conduct regular performance reviews where the production planning KPIs are discussed in detail. Use these reviews as an opportunity to analyze the results, identify root causes of performance gaps, and develop action plans for improvement.

Continuous improvement

Embrace a culture of continuous improvement by using the KPI results to drive targeted initiatives and implement corrective actions. Regularly evaluate the effectiveness of improvement efforts and adjust strategies as needed.

Reach your KPI targets with the help of Katana

Katana’s cloud inventory software sets your business up for success with features to manage your inventory, track your orders and manufacturing processes, and control your shop floor.

Best practices for improving production planning KPIs

Improving production planning KPIs requires a systematic approach and a focus on continuous optimization. Here are some best practices to enhance production planning performance:

- Set clear and measurable objectives — Establish specific, measurable, achievable, relevant, and time-bound (SMART) objectives for each KPI. Clearly define success and align the objectives with your overall production and business goals.

- Identify critical KPIs — Prioritize the KPIs that have the most significant impact on production planning performance. Focus on the KPIs that directly contribute to operational efficiency, product quality, customer satisfaction, and cost optimization.

- Establish baseline and targets — Determine baseline values for each KPI to understand the current performance level. Set realistic and challenging targets that drive improvement and motivate the production team to strive for excellence.

- Regularly track and monitor KPIs — Continuously track and monitor the selected KPIs to stay informed about performance trends. Regularly compare actual results against targets and take prompt action to address any deviations.

- Implement continuous training and development — Invest in training programs to enhance the skills and knowledge of production planning personnel. Ensure employees have the necessary tools, resources, and expertise to optimize production processes and achieve KPI targets.

- Foster collaboration and communication — Encourage open communication and cooperation between different departments involved in production planning. Foster a cross-functional approach to problem-solving and decision-making to address challenges and improve KPI performance.

- Embrace technology solutions — Leverage technology solutions such as production planning software, data analytics tools, and automation systems to streamline processes, improve accuracy, and gain real-time insights into KPI performance.

- Regularly review and refine KPIs — Periodically evaluate the relevance and effectiveness of the selected KPIs. Modify or refine the KPIs as needed to align with evolving business objectives and changing production dynamics.

Implementing these best practices allows businesses continuously improve production planning KPIs, optimize operations, and achieve better overall performance in meeting customer demands and maximizing efficiency.

Leveraging Katana for enhanced production planning

Katana is a cloud-based production planning and inventory management software that can greatly contribute to achieving and improving production planning KPIs. Here are some ways in which Katana can help businesses optimize their production processes and reach their KPI targets.

Real-time data visibility

Katana provides real-time visibility into critical production data, including inventory levels, order status, and production schedules. This visibility enables businesses to make informed decisions and take proactive actions to optimize production processes and meet KPI targets.

Inventory optimization

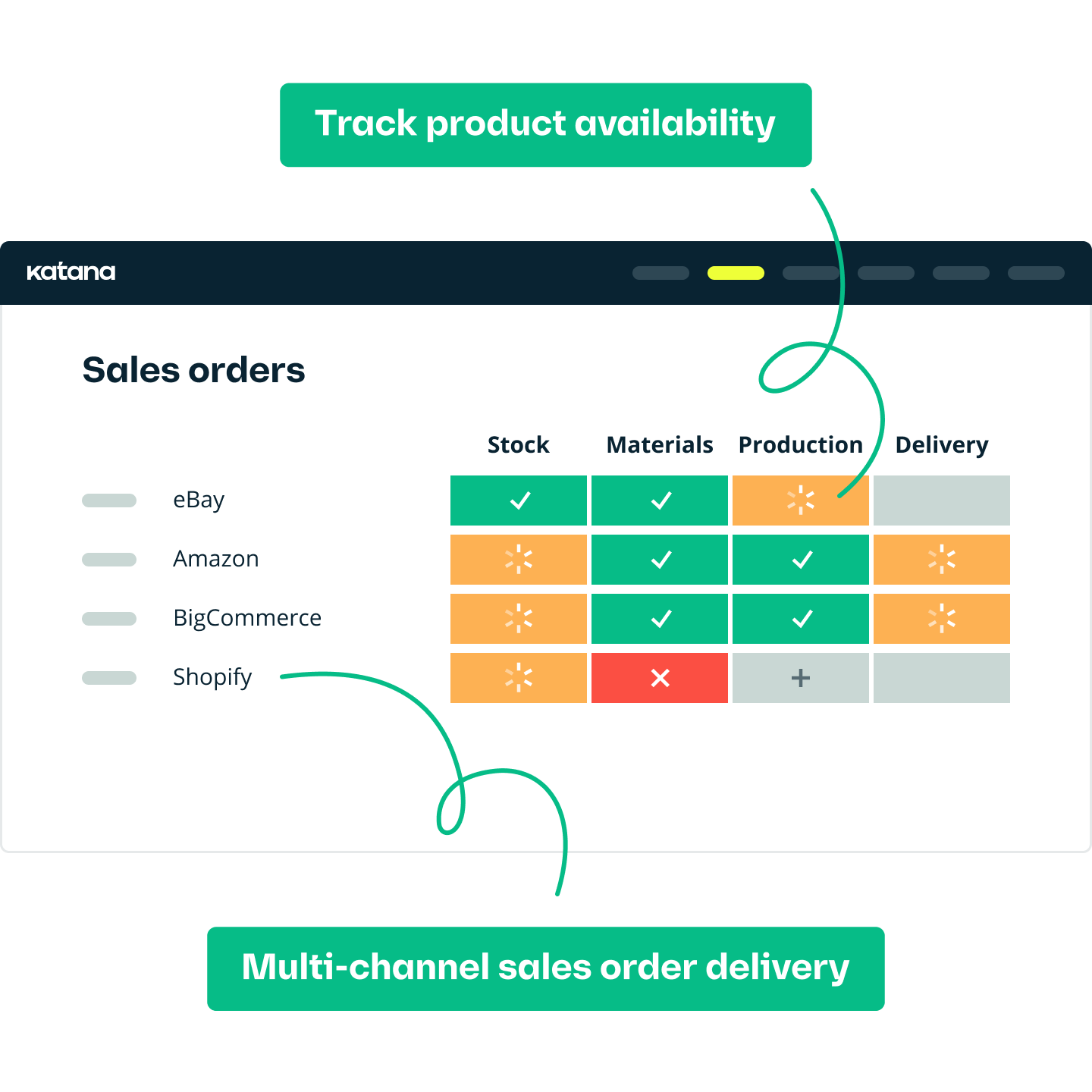

Effective inventory management is vital for production planning KPIs. Katana offers powerful inventory optimization features, such as multichannel inventory management, demand forecasting, and reorder point alerts. By optimizing inventory levels, businesses can improve inventory turnover ratios, reduce stockouts, and lower carrying costs.

Efficient order management

Katana’s order management features streamline the entire order fulfillment process, from order creation to delivery. By efficiently managing orders and reducing lead times, businesses can improve on-time delivery performance and enhance customer satisfaction, a crucial KPI for production planning.

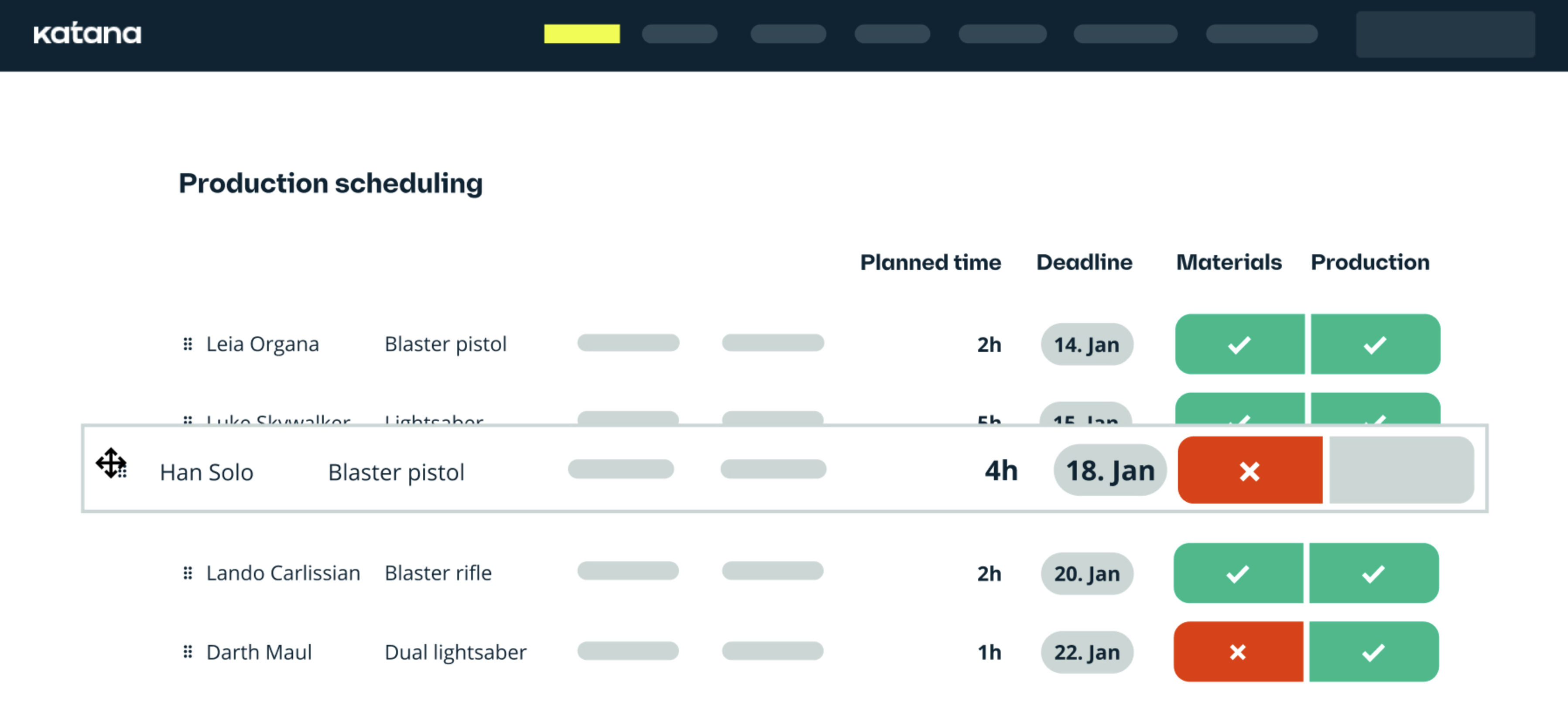

Resource planning and scheduling

Katana enables businesses to optimize resource allocation and production scheduling. By aligning production capacity with demand and ensuring efficient utilization of labor and machinery, Katana helps improve resource utilization KPIs and minimize idle time or bottlenecks.

Integrations

With its numerous seamless integrations to other business tools, Katana offers an ideal unified experience to businesses. Seamlessly connect your e-commerce platforms (Shopify, WooCommerce), your accounting software (QuickBooks Online, Xero), and many other tools ranging from shipping to reporting.

Get a demo and see how Katana can help you reach your production planning KPI targets.

Henry Kivimaa

Table of contents

Get inventory trends, news, and tips every month

Get visibility over your sales and stock

Wave goodbye to uncertainty with Katana Cloud Inventory — AI-powered for total inventory control